Comprehensive Guide to Garage Door Repair

The functionality of any entryway system plays a crucial role in ensuring safety and convenience in our daily lives. Understanding how these mechanisms operate and how to maintain them is essential for any homeowner. Proper guidance can help in troubleshooting common issues and ensuring longevity.

In this section, we will explore various aspects related to the maintenance and troubleshooting of these systems. It is vital to be aware of the typical challenges that may arise and the steps that can be taken to address them effectively. Through careful examination and understanding, one can enhance the performance and reliability of these essential components.

Having a well-informed approach can significantly minimize potential risks and unexpected inconveniences. Engaging in regular checks and adopting best practices for upkeep can lead to smoother operation and improved durability. By following this guide, you will be equipped with the knowledge to handle various situations that may occur.

Whether dealing with minor adjustments or more complex issues, a proactive mindset will serve you well. Empower yourself with the right information to navigate the intricacies of these entryway systems, ensuring they remain functional and secure.

This section will address frequent challenges encountered with automated entry systems. Understanding these issues is crucial for efficient troubleshooting and maintenance.

Here are some common problems that users may experience:

- Stuck Mechanism: Systems may fail to open or close smoothly due to debris or mechanical failure.

- No Response from Remote: The control device may not communicate effectively, often due to battery issues or signal interference.

- Unusual Noises: Grinding or squeaking sounds can indicate a need for lubrication or parts replacement.

- Misalignment: Tracks may become skewed, preventing proper operation.

- Sensor Issues: Sensors can malfunction or become obstructed, hindering the system’s ability to function safely.

- Electrical Problems: Wiring issues or circuit malfunctions can lead to operational failures.

- Remote Programming Errors: Users may encounter difficulties when trying to sync new devices with the system.

- Weather Damage: Extreme temperatures and moisture can affect functionality over time.

- Wear and Tear: Regular usage can lead to component degradation, necessitating periodic checks.

- Faulty Springs: Tension springs may weaken or break, impacting the opening and closing capabilities.

- Lubrication Needs: Inadequate lubrication can cause friction, leading to premature wear.

Addressing these common issues can greatly enhance the longevity and reliability of the system.

Tools Required for Repairs

For effective maintenance and troubleshooting, a selection of essential instruments is necessary. Having the right tools at hand can significantly ease the process and ensure efficient handling of common issues.

Basic Tools

The foundation of any successful fixing task begins with basic instruments. Screwdrivers, wrenches, and hammers are indispensable for various adjustments and minor alterations. A reliable measuring tape also proves useful for precise measurements during the process.

Specialized Equipment

In addition to standard tools, certain specialized equipment may be required for more complex tasks. Power drills can expedite the installation of components, while levels ensure proper alignment. For those tackling advanced issues, a multimeter might be essential for diagnosing electrical concerns.

Step-by-Step Repair Guide

This section provides a comprehensive approach to addressing issues related to entry barriers commonly found in residential settings. Following these instructions will help ensure proper functionality and extend the lifespan of your system.

Step 1: Begin by identifying the specific problem. Check for any visible obstructions that may be affecting movement.

Step 2: Ensure that all components are clean and lubricated. Dirt and grime can cause mechanical failure.

Step 3: Inspect the hardware for any signs of wear or damage. Replace any broken parts to restore optimal performance.

Step 4: Test the entire system after making adjustments. Ensure that everything operates smoothly and efficiently.

By following these steps, you can effectively resolve common issues and maintain the functionality of your entry barrier system.

Maintaining Your Garage Door

Regular upkeep is essential for ensuring the longevity and functionality of your entryway system. Proper care can prevent unexpected issues and enhance performance over time.

Routine Inspections

Conducting periodic checks can help identify potential problems early. Consider the following:

- Examine tracks for debris and obstructions.

- Inspect springs and cables for signs of wear.

- Ensure all fasteners are tightened and secure.

Lubrication and Cleaning

Keeping components well-lubricated and clean is vital for smooth operation. Follow these steps:

- Apply lubricant to moving parts such as rollers and hinges.

- Wipe down surfaces to remove dust and grime.

- Check seals for damage and replace if necessary.

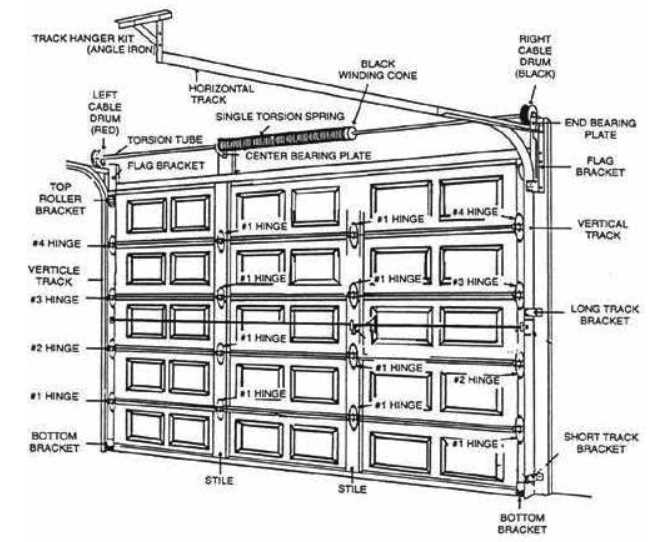

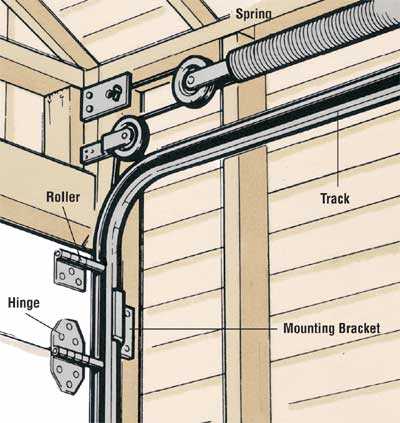

Identifying Garage Door Components

Understanding the various parts of a closure system is essential for effective maintenance and troubleshooting. Recognizing these elements allows for better management of functionality and safety.

Here are the key components commonly found in such systems:

- Track: Guides the movement of the panels.

- Panels: The large sections that make up the entire structure.

- Springs: Provide the necessary tension for smooth operation.

- Rollers: Facilitate the sliding motion along the tracks.

- Lift mechanism: Assists in raising and lowering the panels.

Familiarity with these parts can enhance the understanding of the overall system functionality and facilitate effective troubleshooting.

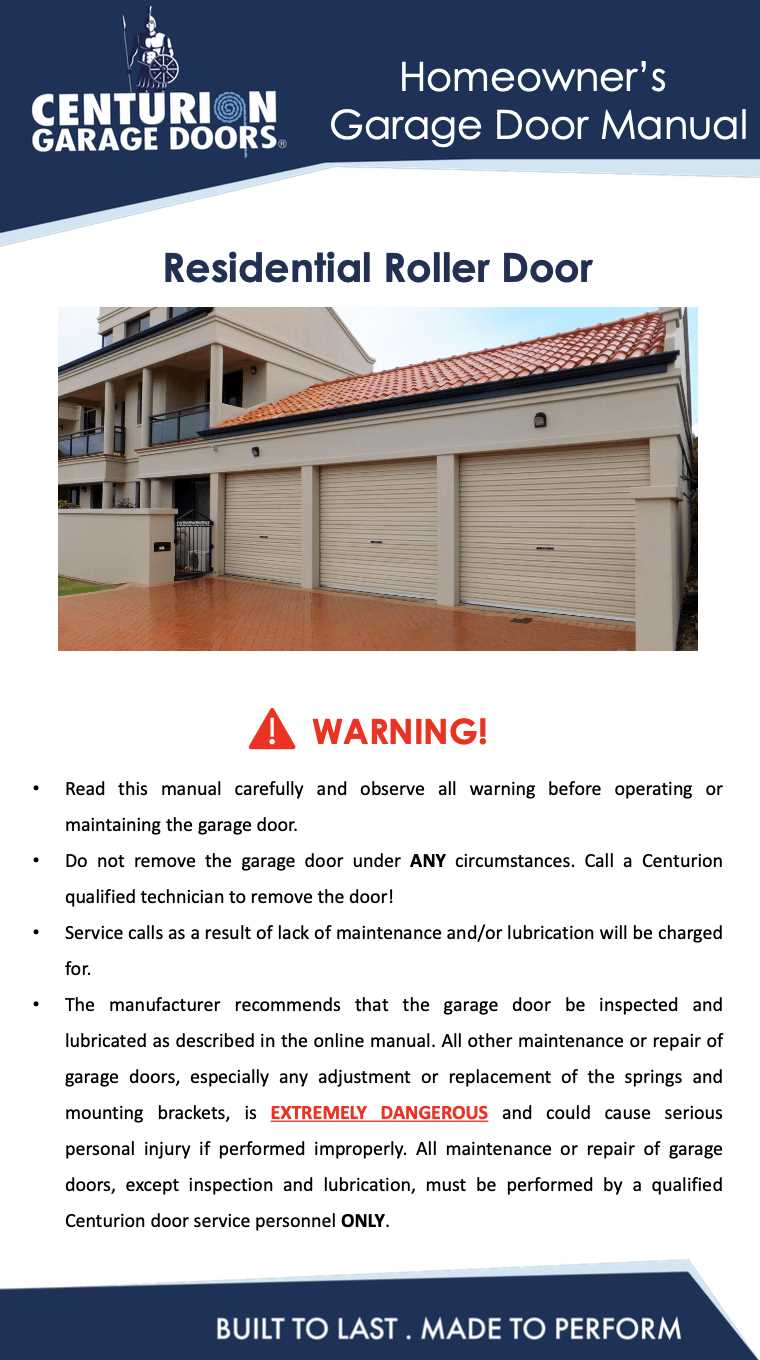

Safety Precautions During Repairs

When addressing maintenance tasks on mechanical structures, it is essential to prioritize safety to prevent accidents and injuries. Understanding the risks involved and taking appropriate measures can significantly enhance the safety of the working environment.

Essential Safety Measures

- Always wear protective gear, such as gloves and safety goggles.

- Ensure that the power source is disconnected before starting any work.

- Keep the work area clean and free from clutter to avoid tripping hazards.

- Utilize appropriate tools that are in good condition to avoid malfunctions.

Working with Others

- Inform someone about your repair plans before starting.

- Have a partner present to assist in case of emergencies.

- Communicate clearly about tasks to ensure everyone is aware of their responsibilities.

When to Call a Professional

Recognizing the right moments to seek expert assistance can save time and prevent further complications. While some issues can be addressed independently, certain situations necessitate the expertise of a skilled technician.

| Signs to Call | Description |

|---|---|

| Unusual Noises | Sounds like grinding or rattling may indicate serious underlying problems. |

| Frequent Breakdowns | Regular malfunctions suggest the need for a professional assessment. |

| Physical Damage | Visible damage requires specialized tools and knowledge to ensure safety. |

| Complex Mechanisms | Systems with intricate mechanisms should only be handled by trained individuals. |

Cost Estimates for Repairs

Understanding the potential expenses involved in fixing access barriers is crucial for budgeting and planning. Various factors can influence the overall cost, including the type of issues encountered, materials needed, and labor charges. This section provides a general overview of the expected financial outlay for common restoration tasks.

| Type of Service | Estimated Cost ($) |

|---|---|

| Spring Replacement | 150 – 300 |

| Track Realignment | 100 – 200 |

| Panel Replacement | 200 – 500 |

| Opener Repair | 100 – 250 |

| General Maintenance | 50 – 150 |

Upgrading Your Garage Door System

Enhancing the functionality and efficiency of your entryway system can significantly improve both convenience and security. By incorporating modern features and advanced technology, you can transform your existing setup into a more reliable and user-friendly solution.

Modern Features to Consider

When upgrading, consider adding automated controls, enhanced insulation, and improved locking mechanisms. These additions not only elevate security but also boost energy efficiency, ensuring a comfortable environment within your space.

Benefits of Advanced Technology

Implementing smart technology allows for remote access and monitoring, giving you peace of mind and control at your fingertips. With options like smartphone integration and real-time alerts, managing your entryway system becomes effortless and efficient.

Seasonal Maintenance Tips

Regular upkeep is essential for ensuring the longevity and functionality of your access points. Seasonal checks can prevent minor issues from developing into significant problems, providing peace of mind throughout the year.

During different times of the year, specific actions can enhance performance and reliability. Here are some essential tips to consider:

| Season | Maintenance Action | Description |

|---|---|---|

| Spring | Inspect Mechanisms | Check all components for wear and tear after winter usage. |

| Summer | Lubricate Parts | Apply lubricant to moving parts to ensure smooth operation in heat. |

| Fall | Weatherstripping Check | Examine seals for damage and replace as necessary to prevent drafts. |

| Winter | Clear Debris | Remove snow and ice buildup to avoid operational issues. |

Troubleshooting Automatic Openers

Automatic opening mechanisms can sometimes encounter issues that prevent proper functionality. Identifying and resolving these problems is essential for restoring convenience and efficiency. This section will outline common troubleshooting steps to help you diagnose and fix issues with these systems.

Common Issues

Several factors may lead to malfunctions in automatic openers. These can include power supply problems, remote control issues, or mechanical failures. Below are some of the typical symptoms and their possible causes:

| Symptom | Possible Cause |

|---|---|

| Opener does not respond | Power outage or disconnected power source |

| Remote control not functioning | Weak batteries or signal interference |

| Unusual noises during operation | Mechanical obstruction or worn components |

Diagnostic Steps

To effectively troubleshoot, follow these steps:

- Check the power supply to ensure it is connected and functional.

- Inspect the remote control batteries and replace if necessary.

- Examine the opener for any visible obstructions or damaged parts.