Comprehensive Guide to Repairing Your 1989 Toyota Pickup

When it comes to keeping vintage automobiles in peak condition, having access to detailed guidelines is essential. Enthusiasts and owners alike seek reliable resources that provide insights into the intricacies of their cherished vehicles. This section aims to equip readers with the knowledge necessary to tackle common challenges faced by owners of classic models, ensuring they remain roadworthy for years to come.

Maintaining a vehicle from a previous era requires a specific understanding of its components and systems. Whether you are troubleshooting issues or performing routine upkeep, having step-by-step instructions can make the process more manageable. This guide delves into various aspects of vehicle care, offering practical tips and techniques that simplify the maintenance journey.

In addition to enhancing performance, proper upkeep can significantly extend the lifespan of these iconic machines. Understanding how to navigate repairs and enhancements allows owners to preserve the integrity of their vehicles while enjoying the unique driving experience they offer. Dive into this resource to uncover invaluable information tailored for those who appreciate classic engineering.

Overview of the 1989 Toyota Pickup

This section provides a comprehensive look at a notable model from the late 20th century, known for its robust design and reliability. This vehicle has become a favorite among enthusiasts and everyday users alike, thanks to its practical features and performance capabilities.

Characterized by its durable construction and efficient engine options, this model caters to a diverse range of needs, from daily commuting to rugged outdoor activities. Its compact size makes it easy to maneuver, while still offering ample space for passengers and cargo.

| Feature | Description |

|---|---|

| Engine Options | Available with multiple engine choices, providing a balance of power and fuel efficiency. |

| Transmission | Offered with both manual and automatic transmission options for driver preference. |

| Interior Space | Designed to comfortably accommodate up to three passengers, with a functional dashboard layout. |

| Payload Capacity | Capable of handling significant loads, making it suitable for work-related tasks. |

| Off-Road Capability | Features a sturdy suspension system, enabling performance in various terrains. |

In summary, this vehicle stands out for its practicality and resilience, appealing to a broad audience that values functionality and performance. Its legacy continues to influence the design of contemporary models, solidifying its place in automotive history.

Common Issues in Older Models

As vehicles age, they often exhibit a range of issues that can impact performance and reliability. Understanding these common problems is crucial for owners seeking to maintain their vehicles effectively. Aging components, wear and tear, and outdated technologies can lead to various challenges that require attention and, in some cases, timely intervention.

Electrical System Failures

One prevalent concern in older vehicles is the electrical system. Wiring degradation, corroded connectors, and failing batteries can lead to inconsistent performance. These issues may manifest as difficulty starting, dimming lights, or malfunctioning accessories. Regular inspection of the electrical components can help mitigate these problems.

Engine Performance Degradation

Another frequent issue involves engine performance. Over time, components such as spark plugs, fuel injectors, and air filters can become clogged or worn out. This can result in reduced fuel efficiency, increased emissions, and overall sluggishness. Routine maintenance and replacement of these parts are essential to ensure optimal engine function.

Essential Tools for Repairs

Having the right equipment is crucial for any maintenance task. A well-stocked toolkit not only facilitates smoother operations but also ensures that each job can be completed efficiently and effectively. Below are some fundamental items that every enthusiast should consider for their workshop.

Basic Hand Tools

- Wrenches: A variety of sizes, including both metric and imperial, is essential for loosening and tightening bolts.

- Screwdrivers: Flathead and Phillips screwdrivers are necessary for a multitude of tasks.

- Pliers: Needle-nose and regular pliers can help in gripping and manipulating small components.

- Hammers: A ball-peen hammer is useful for shaping and fitting parts.

Power Tools

- Drill: An electric drill can speed up the process of creating holes and driving screws.

- Impact Wrench: This tool is invaluable for loosening stubborn bolts with minimal effort.

- Grinder: Useful for cutting or grinding down materials when needed.

Equipping yourself with these essential tools will prepare you for a variety of maintenance tasks, allowing you to tackle any challenges that may arise.

Engine Specifications and Maintenance Tips

This section provides essential details regarding the engine configuration and effective upkeep strategies to ensure optimal performance and longevity of your vehicle. Understanding the intricacies of the powertrain is crucial for achieving peak efficiency and reliability.

Engine Specifications

Below is a summary of key specifications that characterize the engine’s capabilities:

| Specification | Details |

|---|---|

| Cylinder Configuration | Inline-4 or V6 |

| Displacement | 2.4L or 3.0L |

| Compression Ratio | 8.5:1 or 9.0:1 |

| Max Horsepower | 116 hp or 150 hp |

| Max Torque | 140 lb-ft or 180 lb-ft |

Maintenance Recommendations

To maintain the engine in excellent condition, consider the following tips:

- Regularly check and change the oil to prevent sludge buildup.

- Inspect the air filter and replace it as necessary to ensure proper airflow.

- Monitor coolant levels and flush the system periodically to avoid overheating.

- Replace spark plugs at recommended intervals for optimal ignition performance.

- Keep an eye on belts and hoses for signs of wear or cracking.

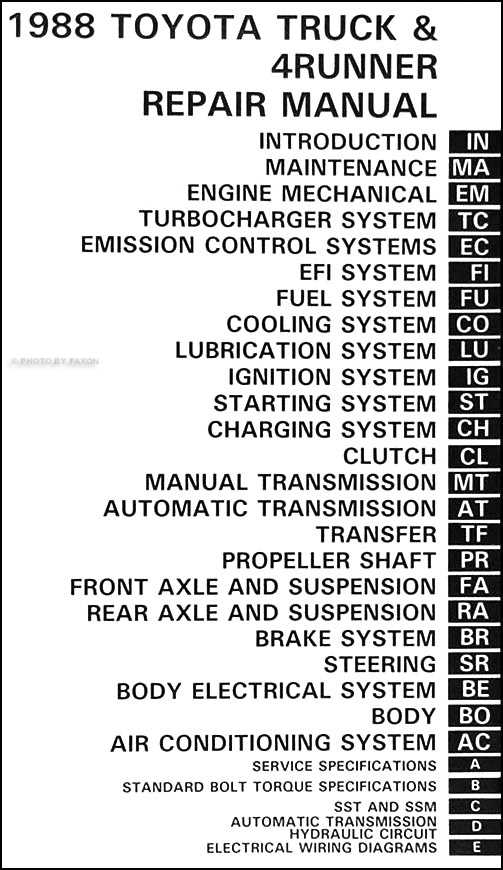

Electrical System Troubleshooting Guide

The electrical system of a vehicle is crucial for its overall performance and reliability. Understanding how to identify and resolve common issues can save both time and money. This guide provides a comprehensive approach to diagnosing electrical problems, ensuring that the vehicle operates efficiently.

1. Identify Symptoms: Begin by noting any specific issues that have arisen. Common symptoms may include dim lights, failure to start, or malfunctioning accessories. Documenting these signs can help narrow down potential causes.

2. Check the Battery: The first component to inspect is the battery. Ensure that it is fully charged and that the terminals are clean and secure. A weak or corroded connection can lead to various electrical failures.

3. Inspect Fuses: A blown fuse can interrupt the flow of electricity to specific systems. Locate the fuse box and examine each fuse for damage. Replace any that are blown and observe if functionality is restored.

4. Test Wiring and Connections: Frayed wires or loose connections can cause intermittent issues. Carefully inspect the wiring harness for any visible signs of wear or damage. Tighten any loose connectors and replace damaged wires as needed.

5. Use a Multimeter: For more advanced diagnostics, a multimeter can measure voltage and resistance. This tool helps determine if components are receiving the proper voltage and can pinpoint areas of concern.

6. Seek Professional Help: If troubleshooting efforts do not yield results, consider consulting a qualified technician. Complex electrical issues may require specialized knowledge and tools for accurate diagnosis.

By following these steps, you can systematically address electrical concerns and ensure optimal performance of your vehicle’s systems.

Bodywork and Interior Restoration Techniques

Restoring the exterior and interior of a classic vehicle requires a blend of creativity and technical skill. This process not only enhances the aesthetic appeal but also preserves the integrity and value of the automobile. Understanding the various techniques available is essential for achieving a quality finish and ensuring durability over time.

Exterior Restoration Approaches

When focusing on the outer shell, several key methods can be employed:

- Surface Preparation: Proper cleaning and sanding are crucial for removing rust, paint, and debris.

- Body Filler Application: Use high-quality filler to smooth out dents and imperfections before painting.

- Paint Techniques: Choosing the right type of paint and applying it in layers ensures a long-lasting finish.

- Clear Coat Sealing: A clear coat protects the paint and enhances gloss, adding to the overall visual appeal.

Interior Restoration Strategies

Revitalizing the inside of the vehicle involves several steps that can greatly enhance comfort and style:

- Upholstery Repair: Repairing or replacing worn-out fabrics and cushioning can transform the look and feel of the interior.

- Dashboard Restoration: Cleaning and refinishing the dashboard can restore its original luster and functionality.

- Flooring Solutions: Replacing or refurbishing floor mats and carpets not only improves aesthetics but also adds comfort.

- Accessory Upgrades: Modernizing features like sound systems and lighting can enhance the driving experience while retaining the classic charm.

Combining these techniques can lead to a comprehensive restoration, ensuring that both the exterior and interior reflect the vehicle’s heritage while meeting contemporary standards of comfort and style.

Transmission Repair and Adjustment

This section focuses on the essential processes involved in the maintenance and fine-tuning of the vehicle’s transmission system. Ensuring that the transmission operates smoothly is crucial for optimal performance and longevity. Various components must be regularly checked and adjusted to prevent common issues and enhance driving experience.

Common Issues and Symptoms

Identifying transmission problems early can save time and resources. Here are some typical symptoms that indicate potential issues:

| Symptom | Possible Cause |

|---|---|

| Slipping gears | Worn clutch or low fluid levels |

| Unusual noises | Faulty bearings or low lubrication |

| Delayed engagement | Contaminated fluid or malfunctioning solenoid |

| Fluid leaks | Worn seals or gaskets |

Adjustment Procedures

Proper adjustment of the transmission is vital for maintaining smooth operation. Follow these steps to ensure accuracy:

1. Begin by checking fluid levels and quality. Replace if necessary.

2. Adjust the linkage to ensure accurate gear selection.

3. Inspect the throttle valve and make necessary calibrations to optimize performance.

4. Test drive the vehicle to confirm that the adjustments have resolved any existing issues.

Suspension and Steering Components Explained

The suspension and steering systems are crucial for maintaining vehicle control, comfort, and overall performance. These components work together to ensure a smooth ride while allowing for precise handling, which is essential for safety on the road.

Understanding the different parts involved can help in recognizing their roles and the importance of regular maintenance. Below is a breakdown of key elements:

- Shock Absorbers: These components dampen the impact of bumps and irregularities in the road, enhancing ride quality.

- Struts: Serving as a structural component, struts support the vehicle’s weight and contribute to handling and ride comfort.

- Springs: These parts bear the vehicle’s weight, absorb shocks, and maintain the height of the body above the wheels.

- Control Arms: These connect the chassis to the wheels, allowing for vertical movement while maintaining stability.

- Steering Rack: This is a key element in translating the driver’s input into wheel movement, affecting maneuverability.

- Tie Rods: These connect the steering rack to the wheels, ensuring accurate steering response.

- Ball Joints: These allow for flexible movement in the suspension while providing a pivot point for the steering system.

Regular inspection of these components is vital. Worn or damaged parts can lead to decreased handling performance and increased tire wear, ultimately affecting vehicle safety. Understanding these systems aids in recognizing symptoms of issues and determining when maintenance or replacement is necessary.

Cooling System Functionality and Repair

The cooling system plays a critical role in maintaining optimal operating temperatures within the engine, preventing overheating and ensuring efficient performance. Understanding its components and functionality is essential for effective maintenance and troubleshooting.

Components of the Cooling System

- Radiator

- Water pump

- Thermostat

- Cooling fan

- Hoses and clamps

- Coolant reservoir

Common Issues and Solutions

- Overheating: Check coolant levels and inspect for leaks in hoses.

- Coolant leaks: Identify and replace damaged hoses or seals.

- Thermostat failure: Test and replace if it’s stuck closed.

- Radiator blockages: Flush the radiator to remove debris.

- Water pump malfunction: Listen for unusual noises and replace if needed.

Regular checks and timely interventions can significantly enhance the longevity of the cooling apparatus, ensuring the engine remains in peak condition.

Brake System Maintenance Best Practices

Proper upkeep of the braking system is essential for ensuring optimal performance and safety on the road. Regular checks and timely interventions can prevent costly repairs and enhance the lifespan of components. Understanding the critical elements involved in maintenance can empower vehicle owners to make informed decisions and prioritize their safety.

Key Components to Monitor

Regular inspection of various parts of the braking system is vital. Focusing on these components helps in identifying issues before they escalate:

| Component | Recommended Maintenance |

|---|---|

| Brake Pads | Inspect for wear and replace when thickness is below 3mm. |

| Brake Fluid | Check fluid level and quality; replace every two years. |

| Brake Rotors | Examine for warping and scoring; resurfacing may be needed. |

| Brake Lines | Inspect for leaks or corrosion; replace damaged sections promptly. |

Best Practices for Effective Maintenance

Implementing a few best practices can significantly enhance the reliability of the braking system:

- Regularly schedule professional inspections, ideally every six months.

- Ensure that brake components are installed correctly and are compatible.

- Pay attention to unusual noises or vibrations during braking; these may indicate issues.

- Keep the braking system clean by removing dirt and debris that may affect performance.

Upgrading Parts for Better Performance

Enhancing vehicle components can significantly boost overall functionality and driving experience. By focusing on specific areas, enthusiasts can achieve improvements in power, handling, and efficiency. This section explores key upgrades that can lead to noticeable enhancements.

Consider the following upgrades for optimal performance:

- Engine Tuning: Adjusting the engine’s parameters can yield increased horsepower and torque. Options include remapping the ECU and upgrading the intake and exhaust systems.

- Suspension Improvements: Upgrading shock absorbers, springs, and sway bars enhances handling and stability, providing a smoother ride on various terrains.

- Brake System Enhancements: High-performance brake pads, rotors, and calipers increase stopping power, improving safety during spirited driving.

- Tires: Investing in quality tires suited for specific conditions ensures better grip and responsiveness, essential for both off-road and on-road performance.

- Weight Reduction: Replacing heavy components with lightweight alternatives can improve acceleration and fuel efficiency, resulting in a more agile vehicle.

Each of these modifications contributes to a more engaging driving experience, allowing for a tailored approach to performance based on individual preferences and requirements.