Mtd Snowblower Repair Guide for Efficient Maintenance

When winter approaches, ensuring that your outdoor equipment is functioning optimally becomes essential. Proper maintenance can greatly enhance performance and extend the lifespan of these powerful machines. Understanding the common issues that may arise during their use can save time and effort in the long run.

In this guide, we delve into various aspects of upkeep and fixing, providing insights into typical problems and solutions. By familiarizing yourself with the inner workings of your device, you will be better equipped to handle any challenges that may arise, allowing for a smoother operation in even the harshest conditions.

Whether you are an experienced user or a newcomer, having access to comprehensive instructions can empower you to tackle maintenance tasks confidently. With the right knowledge and tools, you’ll find that keeping your equipment in peak condition is both manageable and rewarding.

Essential Tools for Snowblower Repair

When it comes to maintaining and fixing outdoor equipment, having the right instruments on hand is crucial. The proper tools can significantly simplify the process, ensuring efficient and effective troubleshooting and enhancement of performance. Here is a list of must-have items that every enthusiast should consider for their toolkit.

- Wrenches: Adjustable and socket wrenches are vital for loosening and tightening bolts and nuts.

- Screwdrivers: A variety of flathead and Phillips screwdrivers will help with different screws encountered during maintenance.

- Pliers: Needle-nose and slip-joint pliers are useful for gripping, twisting, and cutting wires or small parts.

- Spark Plug Socket: A specific socket designed for easy removal and installation of spark plugs.

- Oil Filter Wrench: Essential for changing oil and maintaining engine health.

- Multimeter: Useful for diagnosing electrical issues by measuring voltage, current, and resistance.

- Fuel Line Wrench: Designed to safely remove fuel lines without damaging components.

- Torque Wrench: Ensures that bolts are tightened to the correct specifications, preventing damage from over-tightening.

Investing in quality tools not only enhances efficiency but also prolongs the lifespan of your equipment. Keeping these essential items organized and readily available will facilitate quick and hassle-free maintenance sessions.

Understanding Common Snowblower Problems

During the colder months, mechanical devices designed for clearing snow may encounter various issues that hinder their performance. Identifying these problems early can save time and effort, ensuring efficient operation when needed most. This section delves into frequent challenges faced by users and provides insight into potential solutions.

Frequent Mechanical Failures

One of the most common issues involves the machine not starting at all. This can be attributed to several factors, including fuel issues, battery problems, or electrical faults. Ensuring the fuel is fresh and the battery is charged is crucial. Additionally, checking for loose connections and inspecting the ignition system may resolve the problem.

Operational Inefficiencies

Another prevalent challenge is the equipment failing to clear snow effectively. This may stem from dull blades or clogging caused by wet, heavy snow. Regular maintenance, such as sharpening the cutting edges and clearing any obstructions, can significantly enhance performance. Moreover, adjusting the chute direction can help in managing snow discharge more effectively.

Step-by-Step Maintenance Guide

Regular upkeep is essential to ensure optimal performance and longevity of your equipment. This guide provides a comprehensive approach to maintaining your machine, focusing on key areas that require attention. By following these steps, you can enhance efficiency and prevent potential issues.

1. Safety First

Before starting any maintenance tasks, ensure that the engine is off and the spark plug is disconnected. Wear protective gear, such as gloves and goggles, to safeguard against debris and sharp edges.

2. Clean the Exterior

Begin by removing dirt and debris from the exterior. Use a brush or compressed air to clear any buildup around the engine and components. This helps in preventing rust and other damage.

3. Check and Change Oil

Inspect the oil level using the dipstick. If the oil appears dark or gritty, it’s time for a change. Drain the old oil and replace it with fresh oil according to the manufacturer’s specifications.

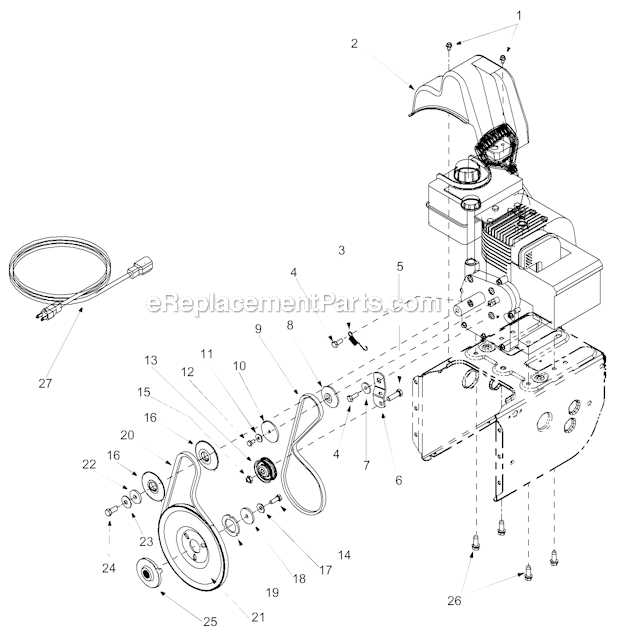

4. Inspect Belts and Cables

Examine belts for any signs of wear, such as fraying or cracking. Tighten loose cables and replace any damaged components to ensure smooth operation.

5. Clean or Replace Air Filter

A clean air filter is crucial for optimal performance. Remove the filter and clean it if it’s reusable. If it’s too dirty or damaged, replace it with a new one.

6. Sharpen or Replace Blades

Check the condition of the blades regularly. Dull blades can hinder performance. Sharpen them as needed or replace them if they are severely worn.

7. Test Battery and Electrical System

For machines with a battery, ensure it is charged and connections are secure. Test the electrical system to confirm that all components function correctly.

8. Final Checks

After completing all maintenance tasks, double-check that all parts are secured and fluids are at the appropriate levels. Reconnect the spark plug and start the engine to ensure everything is working smoothly.

By adhering to this maintenance routine, you can significantly improve the reliability and efficiency of your equipment, ensuring it remains in top condition for years to come.

Safety Tips for Snowblower Repairs

Ensuring safety during maintenance activities is paramount to prevent accidents and injuries. Proper precautions not only protect the individual performing the work but also extend the lifespan of the equipment. Understanding the essential guidelines is crucial for a successful and safe experience.

Essential Precautions

Before starting any service, it is important to follow these key steps:

| Tip | Description |

|---|---|

| Read the Manual | Familiarize yourself with the manufacturer’s instructions and safety warnings specific to your equipment. |

| Wear Protective Gear | Always use gloves, goggles, and sturdy footwear to protect yourself from potential hazards. |

| Disconnect Power | Ensure the power source is disconnected before beginning any work to prevent accidental starts. |

| Work in a Ventilated Area | Perform maintenance in a well-ventilated space to avoid inhaling harmful fumes. |

Handling Tools Safely

Using tools correctly is essential for avoiding injuries. Here are some guidelines to keep in mind:

| Tool Safety Tip | Description |

|---|---|

| Inspect Tools | Regularly check tools for any damage or wear before use to ensure they function properly. |

| Use Tools Appropriately | Always use the right tool for the job to minimize the risk of accidents. |

| Store Tools Safely | Keep tools organized and stored properly to avoid tripping hazards and misuse. |

Diagnosing Engine Issues in Snowblowers

Understanding engine malfunctions is crucial for effective maintenance and operation of outdoor equipment. Identifying the symptoms can help in pinpointing the root cause and ensuring smooth functionality during colder months. This section will guide you through common indicators of engine trouble and the steps to diagnose them.

Here are some common signs that may indicate engine issues:

- Difficulty starting or failure to start

- Unusual noises such as knocking or grinding

- Loss of power during operation

- Excessive vibration while in use

- Unusual smoke or exhaust colors

To systematically diagnose these problems, consider the following steps:

- Check Fuel Levels: Ensure that the fuel tank is full and that the fuel is fresh.

- Inspect the Spark Plug: Remove and examine the spark plug for wear or carbon buildup; replace if necessary.

- Examine the Air Filter: A clogged filter can restrict airflow, affecting performance. Clean or replace as needed.

- Look for Leaks: Inspect hoses and connections for any signs of leakage or wear.

- Test Battery Voltage: Ensure the battery is fully charged and connections are secure.

By following these steps, you can effectively identify and address issues related to engine performance, ensuring your equipment operates reliably when you need it most.

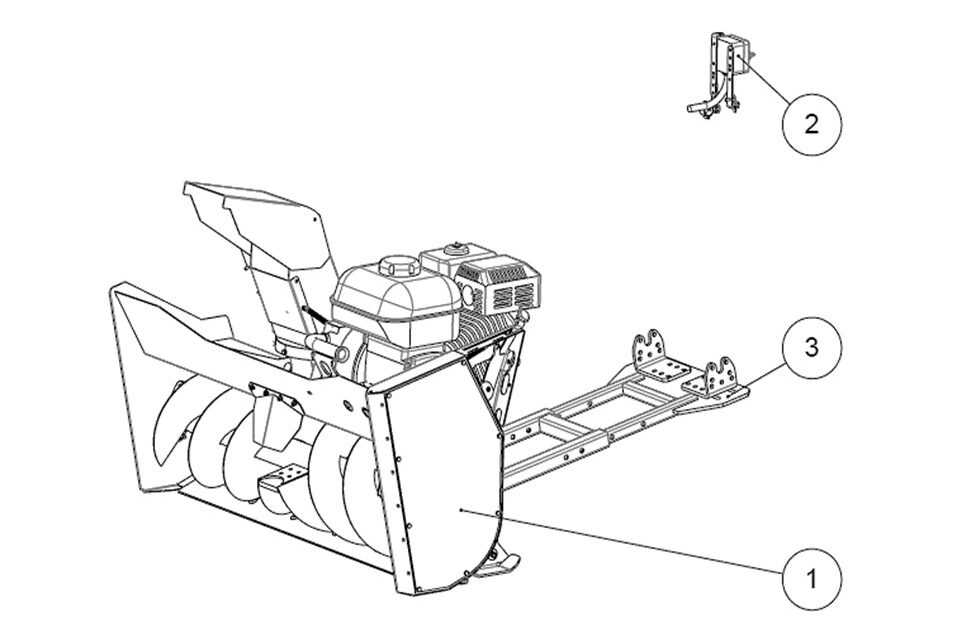

Replacing Blades and Augers

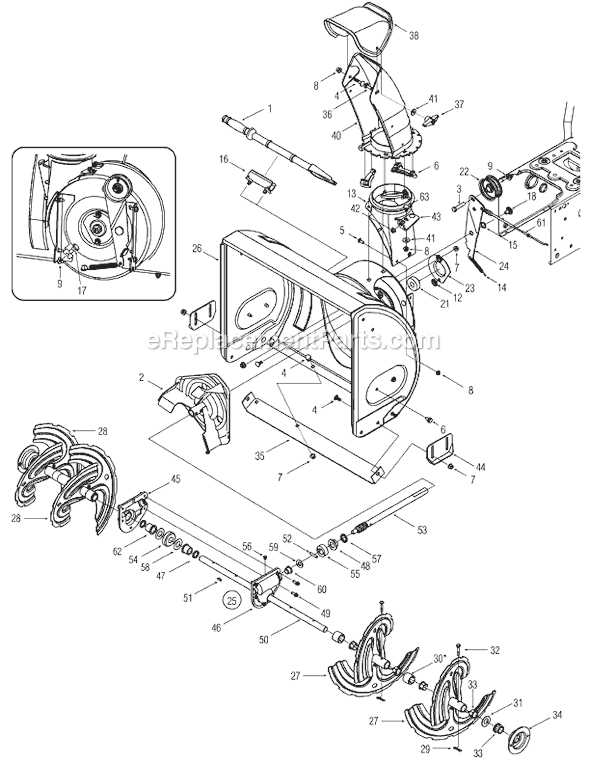

Maintaining optimal performance of your equipment often involves replacing critical components such as cutting edges and spiral devices. These parts play a vital role in ensuring efficient operation, especially when tackling heavy accumulation. Regular checks and timely replacements can prevent further damage and enhance overall functionality.

Preparation is key before starting the replacement process. Ensure you have the necessary tools and new components ready. Safety gear, including gloves and eye protection, should also be worn to avoid injuries during the procedure.

Begin by disconnecting the power source to eliminate any risk of accidental activation. Next, carefully remove any covers or panels to access the blades and augers. Take note of how components are positioned to facilitate reassembly.

Once you have access, remove the old blades by loosening the securing bolts. It’s essential to clean the mounting surfaces before installing the new parts. Position the new blades or augers accurately and tighten the bolts securely to ensure they are fixed in place.

Finally, reassemble any covers or panels that were removed. After everything is securely in place, reconnect the power source and conduct a test run to confirm that everything operates smoothly.

Winter Prep: Before First Use

Preparing your equipment for the chilly months ahead is essential for ensuring optimal performance and safety. A thorough check-up and maintenance routine can help prevent issues and guarantee smooth operation when the snow begins to fall.

Inspect and Maintain Components

Begin by examining all critical components, including the engine, belts, and augers. Look for any signs of wear or damage that could hinder functionality. Ensure that all moving parts are lubricated and free from debris. Regular maintenance not only extends the life of your machine but also enhances its efficiency.

Fuel and Oil Checks

Next, pay attention to the fuel and oil levels. Use high-quality fuel to avoid performance issues, and replace old oil with fresh lubricant to keep the engine running smoothly. Proper fluid maintenance is crucial for optimal operation during harsh winter conditions.

Troubleshooting Electrical Components

When dealing with mechanical devices that rely on electrical systems, understanding potential issues with electrical components is crucial. Identifying and resolving these problems can ensure optimal performance and prolong the lifespan of the equipment.

Common Electrical Issues

- Insufficient power supply

- Faulty wiring connections

- Defective switches

- Burnt-out fuses or circuit breakers

- Malfunctioning motors

Steps to Diagnose Problems

- Check the power source: Ensure that the device is plugged in and that the outlet is functioning.

- Inspect all visible wiring: Look for any signs of wear, fraying, or loose connections.

- Test the switches: Use a multimeter to verify that switches are operational.

- Examine fuses and circuit breakers: Replace any burnt fuses and reset tripped breakers.

- Assess the motor: Listen for unusual sounds and check for overheating or other abnormalities.

Following these guidelines can help in effectively diagnosing and addressing electrical component issues, leading to smoother operation of the machinery.

Seasonal Storage and Care Tips

Proper maintenance and careful storage during off-seasons can significantly extend the life of your outdoor equipment. Following specific guidelines ensures that these machines remain in optimal condition and are ready for use when needed. Implementing these practices can prevent unnecessary wear and facilitate a smooth start at the beginning of the next season.

Preparation Before Storing

Before putting your equipment away, it’s crucial to clean it thoroughly. Remove any dirt, debris, or leftover materials that may have accumulated. Inspect the machine for any signs of damage and address them promptly. Additionally, draining the fuel can prevent corrosion and keep the internal components in good shape. Be sure to check the oil levels, changing it if necessary, to avoid contamination during storage.

Storage Environment

Choose a dry, sheltered location for storage to protect against moisture and extreme temperatures. Covering the equipment with a protective tarp can help shield it from dust and dirt. If possible, store it off the ground to avoid exposure to dampness. Regularly check on the stored equipment to ensure that no pests have made it their home and that everything remains in good condition.