Complete Guide to Repairing the 46RE Transmission

In the world of automotive systems, understanding the intricate components within power control units can seem overwhelming. These systems are composed of a variety of parts working in harmony, each vital to ensuring smooth and reliable operation. Over time, however, wear and tear can cause disruptions that require careful inspection and adjustments to restore functionality and maintain performance.

For those eager to gain a deeper knowledge of these intricate mechanisms, this guide provides essential insights. By exploring a variety of methods and techniques, enthusiasts and professionals alike can uncover solutions to common issues, extending the lifespan of these essential systems. With a strong focus on precision, reliability, and best practices, this guide offers valuable tips for diagnosing and addressing performance inconsistencies.

Whether you’re an experienced technician or someone interested in enhancing their skills, this resource serves as a thorough reference. Discover practical advice, troubleshooting steps, and maintenance strategies that make tackling mechanical issues both manageable and rewarding. Dive into an informative approach to hands-on repairs, ensuring that your machine operates with efficiency and longevity.

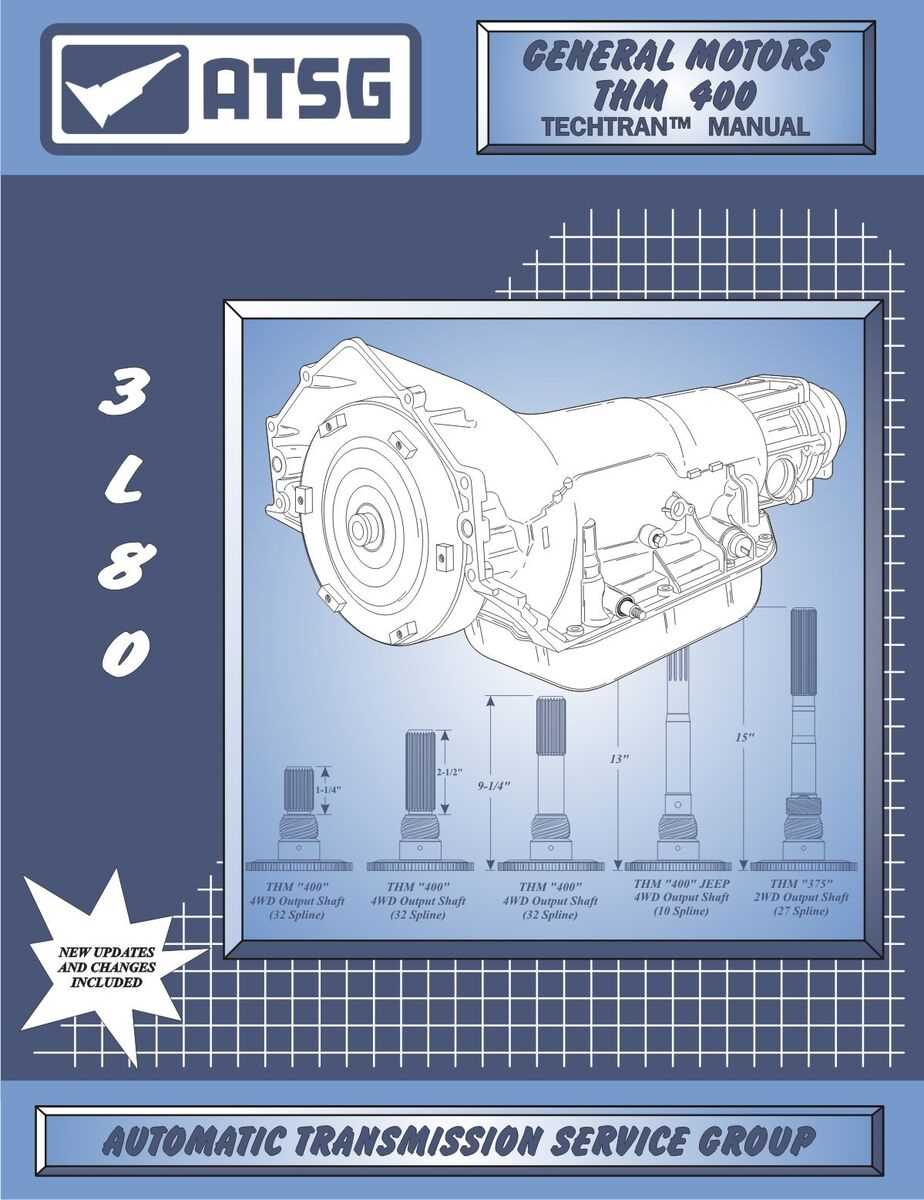

46RE Transmission Repair Manual

This section offers a comprehensive overview of essential procedures and guidance for rejuvenating and maintaining the specific automatic shifting mechanism commonly found in various models. Focusing on core components, it provides practical insights on enhancing performance, extending lifespan, and diagnosing common issues.

Key Components and Their Functions

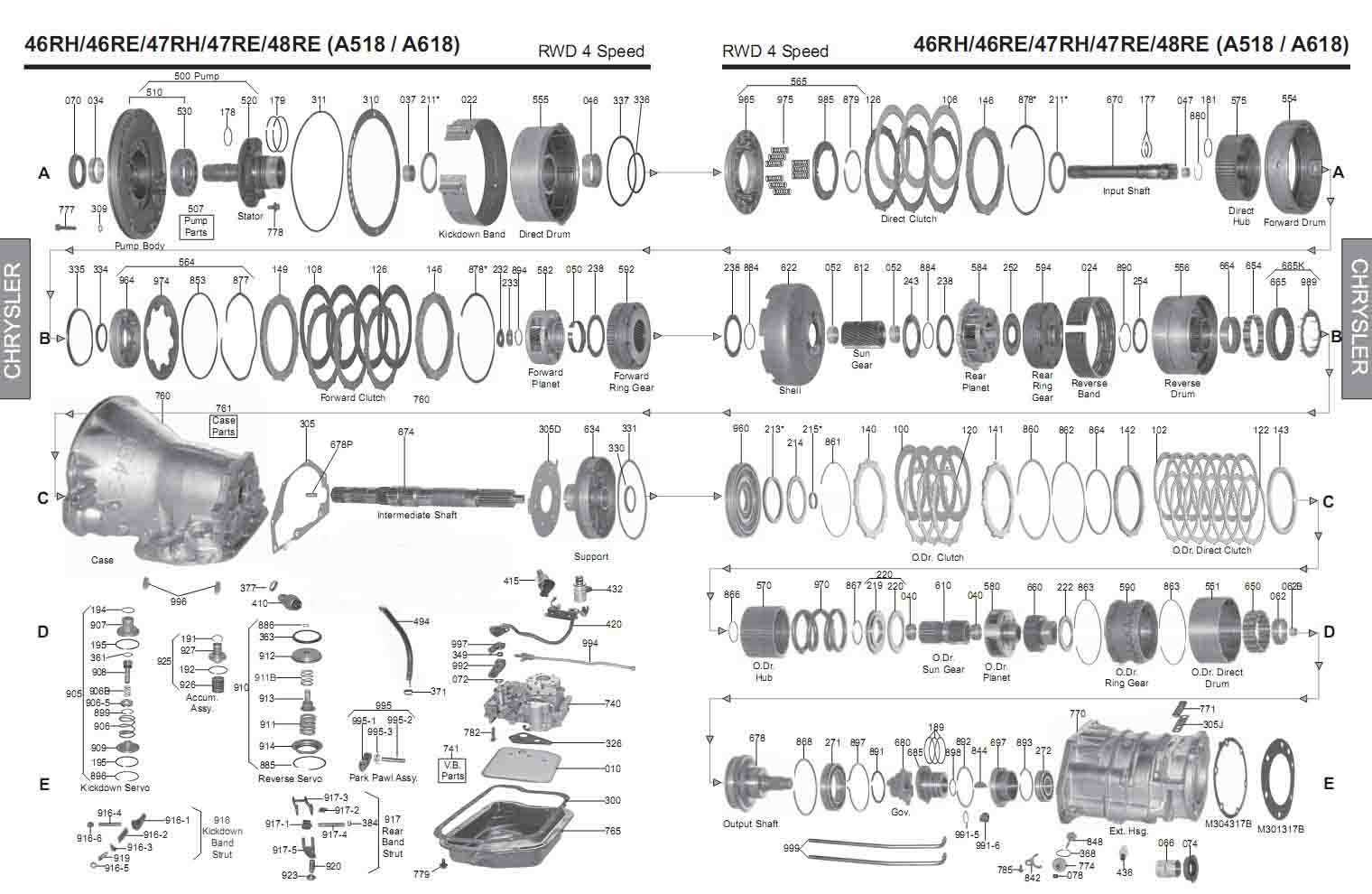

Understanding the main elements involved in the functioning of this automatic drive system can help streamline the restoration process. Below are the critical parts typically addressed:

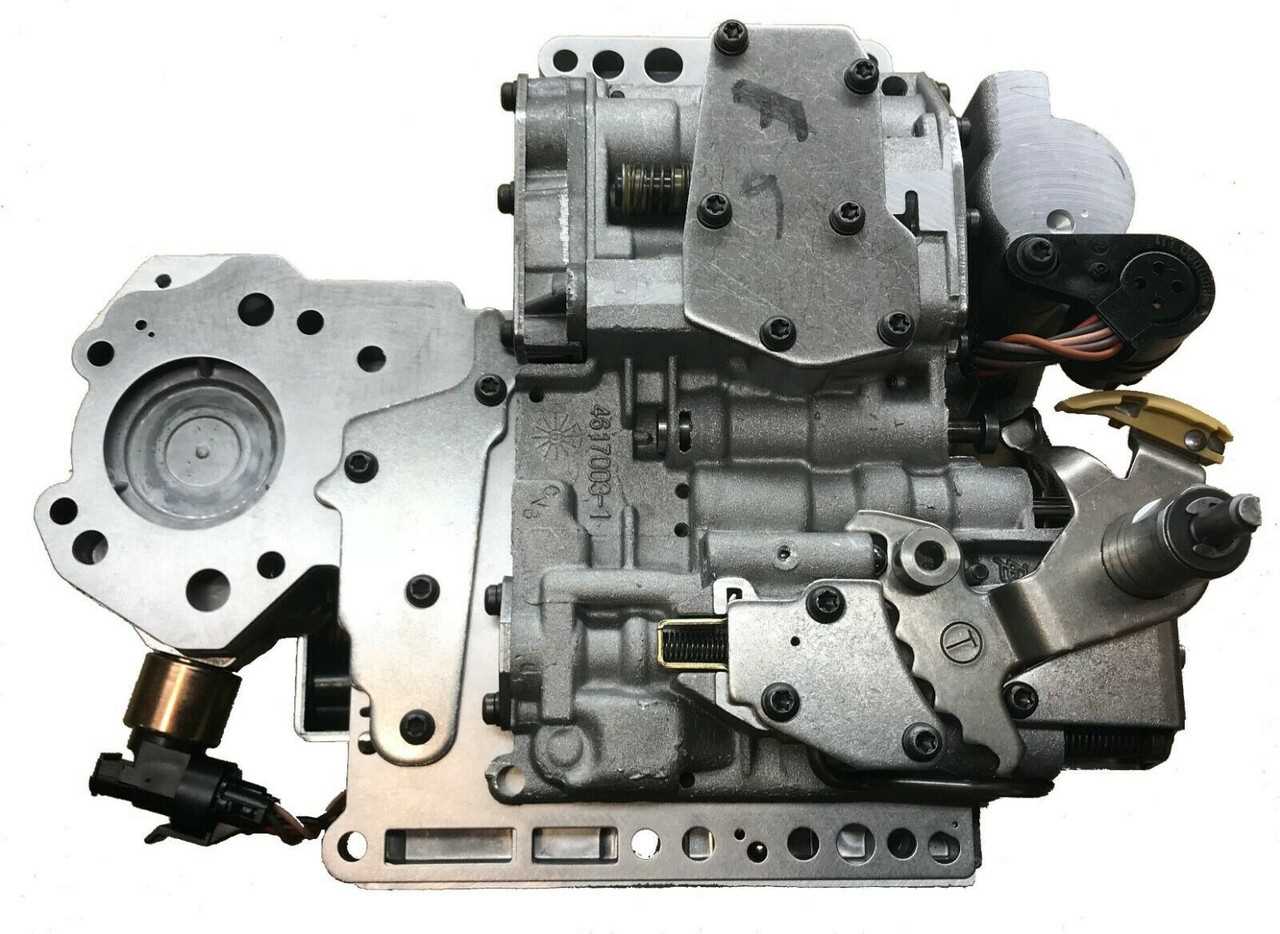

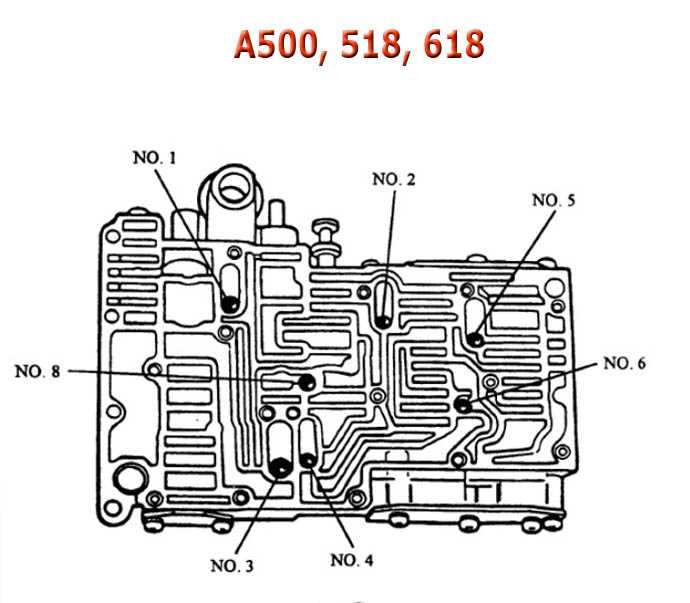

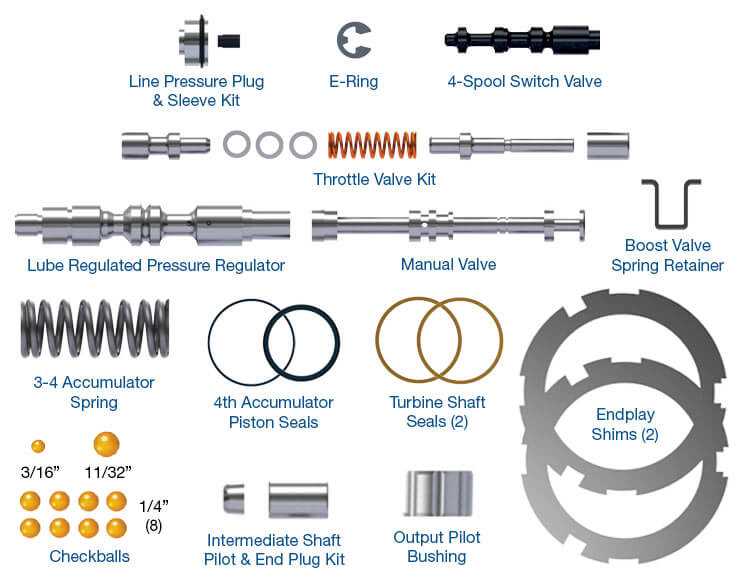

- Valve Body: Directs fluid flow, allowing smooth gear changes by controlling hydraulic pressure.

- Clutches and Bands: Responsible for engaging and disengaging gears, crucial for vehicle motion control.

- Pump Assembly: Supplies fluid throughout the system, ensuring optimal pressure and lubrication.

- Torque Converter: Transfers power from the engine, enabling efficient gear transitions.

Steps to Troubleshoot and Restore

For smooth operations, specific sequences of actions are recommended to assess and rectify common issues. Following a methodical approach can lead to effective, lasting results:

- Initial Inspection: Begin by examining fluid levels and checking for signs of leaks, which may indicate internal wear.

- Testing Pressure: Measure hydraulic pressure to identify any irregularities in fluid flow that might impede smooth shifting.

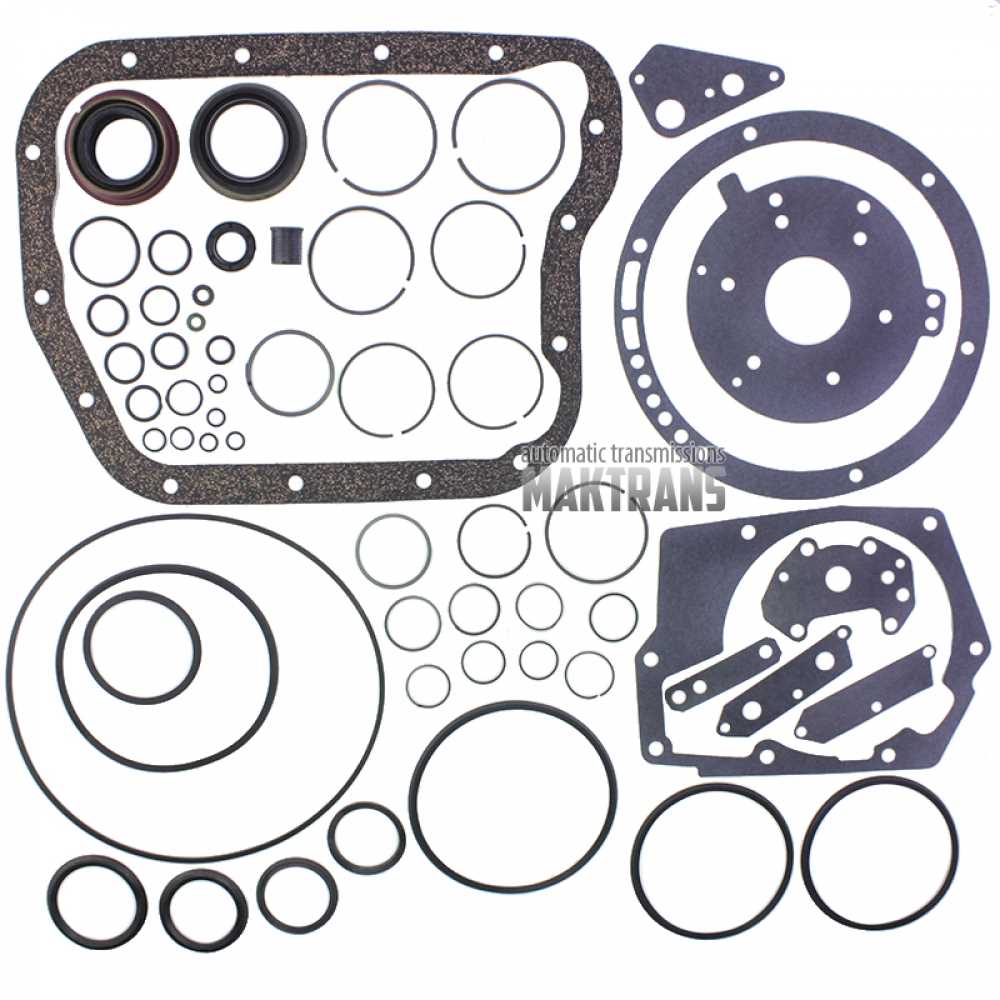

- Component Replacement: Replace worn parts, including clutch plates and seals, to restore full functionality.

- Fluid Change: Ensure that the fluid is clean and at the correct level, as contamination can lead to mechanical issues.

By following these steps, it is possible to achieve a reliable operation, minimizing the risk of recurring issues and enhancing the vehicle’s overall functionality.

Understanding the Basics of 46RE

Exploring this component of a vehicle’s power system unveils its critical role in managing engine output and ensuring smooth motion control. This model is a type of device built to handle different levels of power and speed, dynamically adjusting to the driving needs and road conditions. Often featured in larger vehicles, this device helps distribute energy efficiently and keeps the driving experience controlled and responsive.

Within this system, key elements interact to manage and modify how energy flows. Components like fluid-based mechanisms and multi-geared designs play a central role, allowing for gradual speed changes while maintaining performance consistency. These elements are designed to withstand significant stress, contributing to the reliability and longevity of the entire setup.

The model’s structure combines various technologies, including hydraulic and electronic elements, to deliver precise control. With the support of these technologies, the system adapts to a wide range of scenarios, whether during low-speed maneuvers or higher-speed travel. This dynamic adaptability helps it respond to different situations on the road, making it a crucial part of modern automotive engineering.

Common Symptoms of Transmission Issues

Detecting early signs of operational problems in a vehicle’s power system is essential to maintaining smooth and reliable performance. Recognizing these indicators can help prevent minor issues from escalating into costly repairs.

Unusual Sounds and Vibrations

One of the first signs of a malfunction can be unexpected noises or vibrations during driving. These sounds often vary from whining or grinding to a more pronounced clunking. If vibrations or unusual sounds increase with acceleration or gear changes, they may indicate underlying issues that need attention.

Difficulty in Shifting

If shifting between gears feels rough or delayed, or if the vehicle unexpectedly slips between settings, it could be a sign of internal wear. Hesitations in switching gears or sudden movements may indicate reduced fluid quality, component wear, or sensor problems. Addressing these issues early can help restore smooth shifting and prevent further deterioration.

In summary, paying attention to these common indicators can help identify and resolve operational issues early, keeping the vehicle running efficiently and reducing the chance of more severe breakdowns.

Tools Needed for Effective Repairs

In order to achieve successful and lasting results, having the right set of equipment is essential. Proper preparation with specialized and reliable tools ensures each task is completed smoothly and minimizes the risk of complications during maintenance processes. Whether you’re working on mechanical or electronic components, a well-chosen toolkit can greatly impact the efficiency and quality of your work.

Basic Hand Tools

Basic tools like screwdrivers, wrenches, and ratchets are essential for nearly any adjustment or part removal. For precise tightening and loosening, consider using a torque wrench, which allows you to apply the exact pressure needed to avoid over-tightening. High-quality screwdrivers with magnetic tips can make handling small parts easier and help prevent them from falling into hard-to-reach areas.

Specialized Equipment

To handle complex parts, certain specialized tools are crucial. A hydraulic jack provides stability, allowing for safe lifting, while diagnostic tools help pinpoint issues with accuracy. A sturdy set of clamps and pliers helps manage and secure components, and a vacuum pump can assist with fluid management. These items streamline the repair process and contribute to a safer work environment.

Disassembly Process for 46RE

The purpose of this section is to guide you through the step-by-step process of breaking down and examining each key part in this specific assembly. Following a precise approach will help ensure you identify and address any internal issues effectively.

Initial Preparations: Begin by securing the unit on a sturdy workbench, ensuring it’s stable to prevent movement. Gather the necessary tools, including basic hand tools and specialty ones suited for disassembly. It’s important to keep each removed piece in a designated area to prevent misplacement.

Step-by-Step Dismantling: Start with the outer components. Remove the pan, which covers many of the inner workings, and drain any remaining fluid. Next, detach the bolts systematically, ensuring that you remember their locations. Carefully take out each section, moving from the outer parts to the internal elements, such as the housing, various seals, and gears. Use caution with seals and gaskets, as these may require gentle handling to avoid unnecessary damage.

Inspecting Each Component: As you remove each part, examine it closely for any signs of wear, such as scratches, warping, or excessive debris buildup. Cleaning components as you go will help maintain a clear workspace and allow for a thorough inspection. Identifying damaged parts early can help streamline the later stages of reassembly.

Tip: Document each stage, either through photos or notes, to assist with the accurate reassembly later on. Organizing components in the order of removal will help reduce errors and ensure a smoother process.

Inspecting Internal Components Thoroughly

Conducting a comprehensive evaluation of the inner parts is crucial to ensure optimal functionality and longevity of the system. Each component plays a significant role in overall performance, making it essential to examine them with diligence. This process not only aids in identifying potential issues but also helps in understanding how different elements interact with each other.

To perform an effective inspection, follow these key steps:

- Disassemble Carefully: Begin by methodically disassembling the unit, taking care to keep track of each component and its corresponding fasteners.

- Visual Examination: Look for any signs of wear, damage, or irregularities. Common issues to check include:

- Cracks or fractures in housing

- Worn bearings or seals

- Discoloration or burning on surfaces

- Any foreign debris or contamination

By adhering to these steps, one can ensure that all internal components are in prime condition, ultimately leading to enhanced performance and reliability of the entire system.

Cleaning and Replacing Worn Parts

Maintaining optimal performance in any mechanical system requires regular attention to its components. Over time, parts may become dirty or damaged, leading to decreased efficiency and potential failures. Proper cleaning and timely replacement of these elements are crucial for ensuring smooth operation and extending the lifespan of the entire assembly.

When addressing issues related to component wear, consider the following steps:

- Inspection: Thoroughly examine all parts for signs of wear, damage, or accumulation of debris. Look for cracks, discoloration, or other irregularities.

- Cleaning: Use appropriate cleaning solutions and tools to remove dirt and grime. Consider the following methods:

- Soaking parts in a degreaser solution

- Using brushes to scrub hard-to-reach areas

- Rinsing with water or solvent to ensure all residues are removed

- Choose parts that meet or exceed manufacturer specifications

- Verify compatibility with existing components

- Follow proper installation procedures to avoid future issues

By regularly cleaning and replacing worn components, you can significantly enhance performance and reliability, ultimately leading to more efficient operation of the entire system.

Reassembling the Transmission Safely

Careful reconstruction of complex machinery is crucial for ensuring optimal performance and longevity. This process requires attention to detail and adherence to best practices to avoid potential issues that could arise during operation. By following systematic procedures, you can minimize the risk of errors and ensure that every component functions harmoniously.

Here are key steps to consider during the assembly process:

- Preparation:

- Ensure that all parts are clean and free from debris.

- Gather all necessary tools and components before starting.

- Review the assembly guidelines to understand the sequence of steps.

- Inspection:

- Examine each component for wear or damage.

- Replace any worn parts to maintain functionality.

- Check seals and gaskets to prevent leaks.

- Assembly Sequence:

- Follow the prescribed order to avoid misalignment.

- Align all parts precisely before fastening them together.

- Use appropriate torque specifications for all fasteners.

- Testing:

- Perform a visual inspection after assembly.

- Test functionality in a controlled environment.

- Address any issues immediately to prevent future complications.

By adhering to these guidelines, you can effectively reassemble the machinery while ensuring safety and reliability for future operation. Proper technique and care will contribute to a successful outcome.

Testing for Proper Functionality

Ensuring optimal performance of your vehicle’s components is crucial for its longevity and efficiency. Proper assessment involves a series of checks that verify each part’s effectiveness and reliability. By conducting systematic evaluations, one can identify potential issues before they escalate, ensuring smooth operation.

To begin the evaluation process, follow these essential steps:

- Gather the necessary tools and equipment, such as a pressure gauge, diagnostic scanner, and fluid level dipstick.

- Inspect fluid levels to ensure they meet the manufacturer’s specifications, as low or contaminated fluids can impact functionality.

- Check for leaks around seals and connections, which can indicate wear or damage.

After initial inspections, perform operational tests:

- Road Test: Take the vehicle for a drive, paying attention to shifting patterns and responsiveness.

- Diagnostic Scans: Use a scanner to retrieve any error codes that may signal underlying problems.

- Pressure Tests: Measure hydraulic pressure during various operational phases to ensure it falls within specified ranges.

By methodically working through these tests, one can achieve a comprehensive understanding of the component’s functionality, ultimately leading to informed decisions regarding maintenance or repairs. Regular assessments contribute significantly to the overall health and performance of the vehicle.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of automotive systems and ensuring optimal performance. Regular attention to key components not only enhances reliability but also minimizes the likelihood of unexpected issues. Implementing a routine maintenance schedule can significantly contribute to the longevity of your vehicle’s mechanisms.

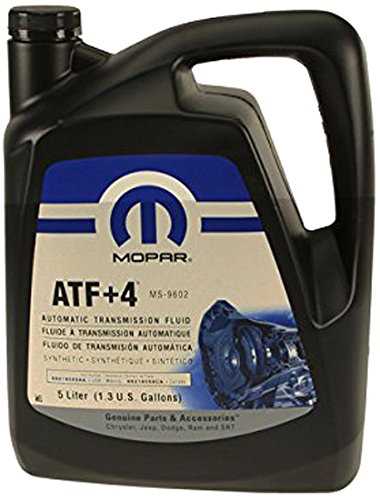

1. Regular Fluid Checks: Frequent inspection and replacement of fluids play a crucial role in maintaining smooth operations. Ensure that hydraulic fluids are at the appropriate levels and free from contamination, as this can prevent wear and tear on vital parts.

2. Scheduled Inspections: Conduct routine assessments of your vehicle to identify any potential problems early. Engaging a qualified technician for periodic evaluations can uncover hidden issues that may escalate if left unaddressed.

3. Cleanliness Matters: Keeping the surrounding areas free from dirt and debris is essential. A clean environment reduces the risk of contaminants entering crucial systems, thereby enhancing overall performance and reliability.

4. Avoid Overloading: Adhering to recommended weight limits is vital. Excessive loads can place undue stress on mechanical systems, leading to premature failure. Always consider the manufacturer’s guidelines when transporting heavy items.

5. Smooth Driving Habits: Gentle acceleration and deceleration can minimize strain on your vehicle’s components. Avoiding sudden starts and stops contributes to a smoother operation, enhancing the lifespan of critical systems.

6. Keep Software Updated: For vehicles equipped with electronic systems, regular software updates can improve performance and efficiency. Stay informed about the latest updates and enhancements to ensure your vehicle operates at its best.

Troubleshooting Common Errors

This section addresses frequent issues encountered during the operation of automatic gear systems. Understanding these common malfunctions can help diagnose and resolve problems effectively, ensuring optimal performance and longevity of the unit.

Identifying Performance Issues

One of the most noticeable symptoms of malfunctioning gear mechanisms is erratic shifting. Users may experience hard or delayed changes in gears, often accompanied by unusual noises. These symptoms can indicate a variety of underlying issues, such as fluid contamination, low fluid levels, or worn components. Conducting a thorough inspection of the fluid quality and ensuring the correct levels can often resolve these problems.

Electrical System Failures

Another common area of concern lies within the electrical system, which controls the gear shifting process. Faulty sensors or wiring can lead to improper functioning, resulting in warning lights or error codes. It is crucial to check the electrical connections and test the sensors to ensure they are operating correctly. A systematic approach to troubleshooting these components can prevent unnecessary replacements and restore normal operation.

When to Seek Professional Help

Understanding when to consult an expert can significantly impact the outcome of issues related to your vehicle’s functionality. Many enthusiasts may feel confident tackling basic challenges themselves, but certain situations require the knowledge and experience that only a trained technician can provide. Recognizing these instances can save time, money, and potential complications in the long run.

Consider seeking assistance in the following scenarios:

| Situation | Why Seek Help? |

|---|---|

| Unusual Noises | Strange sounds may indicate serious underlying problems that need immediate attention. |

| Fluid Leaks | Leaks can lead to further damage if not addressed quickly by a professional. |

| Warning Lights | Dashboard indicators often signal critical issues requiring expert diagnostics. |

| Performance Issues | Significant drops in performance may stem from complex issues that need specialized tools and knowledge. |

| Failed DIY Repairs | Attempted fixes that don’t resolve the issue may require a technician to avoid further complications. |

In summary, while DIY approaches can be rewarding, recognizing the limitations of your skills is crucial. Engaging a qualified professional at the right time can prevent exacerbating existing issues and ensure your vehicle operates smoothly and safely.