Comprehensive Guide to Air Gun Repair Manuals

Understanding the intricacies of precision tools is essential for enthusiasts and professionals alike. These devices require careful attention and knowledge to ensure optimal functionality and longevity. By exploring various aspects of these instruments, users can enhance their skills and foster a deeper appreciation for their mechanics.

In this section, readers will discover invaluable insights into maintaining and troubleshooting these specialized devices. With detailed guidance, individuals will learn how to address common issues and perform routine checks effectively. This knowledge empowers users to take proactive measures, ensuring their tools remain in peak condition.

The art of maintenance not only preserves the performance of these instruments but also enriches the overall experience of using them. By delving into the specifics of care and management, users can build confidence in their abilities, transforming potential challenges into opportunities for growth and expertise.

This section aims to provide an overview of the fundamental principles governing the operation of compressed-air devices. By grasping these concepts, enthusiasts can better appreciate how these tools function and the necessary steps for their maintenance.

Key Components and Their Functions

Understanding the main parts of these devices is crucial for effective handling and maintenance. Below are the primary components and their roles:

- Power Source: This element generates the necessary pressure for operation.

- Barrel: The pathway through which the projectile travels, impacting accuracy.

- Trigger Mechanism: Controls the release of energy, allowing for precise firing.

- Sights: Aid in aiming and enhancing shooting precision.

Common Issues and Troubleshooting Tips

Even with proper usage, problems may arise. Recognizing these challenges can lead to effective resolutions. Here are frequent issues and their potential fixes:

- Loss of pressure – Check seals and connections.

- Inconsistent firing – Inspect the trigger mechanism for debris.

- Accuracy problems – Ensure the barrel is clean and free of obstructions.

Common Issues in Air Guns

In the realm of pneumatic devices, various challenges can arise that may hinder their performance and reliability. Understanding these frequent complications is essential for maintaining optimal functionality and ensuring a satisfying experience for users.

Some typical problems include:

- Inconsistent velocity: Fluctuations in speed can affect accuracy and precision.

- Leaks: Air loss can occur due to worn seals or fittings, reducing efficiency.

- Jamming: Blockages in the loading mechanism can disrupt operation.

- Accuracy issues: Poor alignment or wear can lead to decreased precision.

Identifying and addressing these matters promptly can prolong the lifespan of these devices and enhance overall performance.

Tools Needed for Repairs

To successfully maintain and restore your equipment, having the right instruments is essential. The following items will facilitate various tasks, ensuring efficient handling and optimal results.

- Wrenches: Useful for loosening or tightening components.

- Screwdrivers: Both flathead and Phillips varieties are needed for different fasteners.

- Pliers: Essential for gripping and manipulating parts.

- Lubricants: Important for ensuring smooth operation of moving parts.

- Cleaning cloths: Necessary for maintaining cleanliness during the process.

By gathering these essential items, you’ll be well-equipped to address any issues that may arise with your equipment, leading to improved performance and longevity.

Step-by-Step Maintenance Guide

Proper upkeep of your equipment ensures optimal performance and longevity. Following a systematic approach helps identify issues early and maintains functionality.

- Gather Necessary Tools:

- Cleaning brush

- Lubricant

- Screwdriver set

- Protective gloves

- Initial Inspection:

Examine the device for any visible damage, wear, or loose components. This initial step is crucial for determining the maintenance needs.

- Cleaning Process:

Utilize the cleaning brush to remove debris and dirt from all accessible areas. Ensure all parts are free from obstructions.

- Lubrication:

Apply a suitable lubricant to moving parts to reduce friction and wear. Follow manufacturer recommendations for specific products.

- Reassembly:

Carefully reassemble any disassembled components. Ensure that everything is secured and functions correctly.

- Final Testing:

Conduct a thorough test to ensure everything operates as intended. Make any necessary adjustments based on performance.

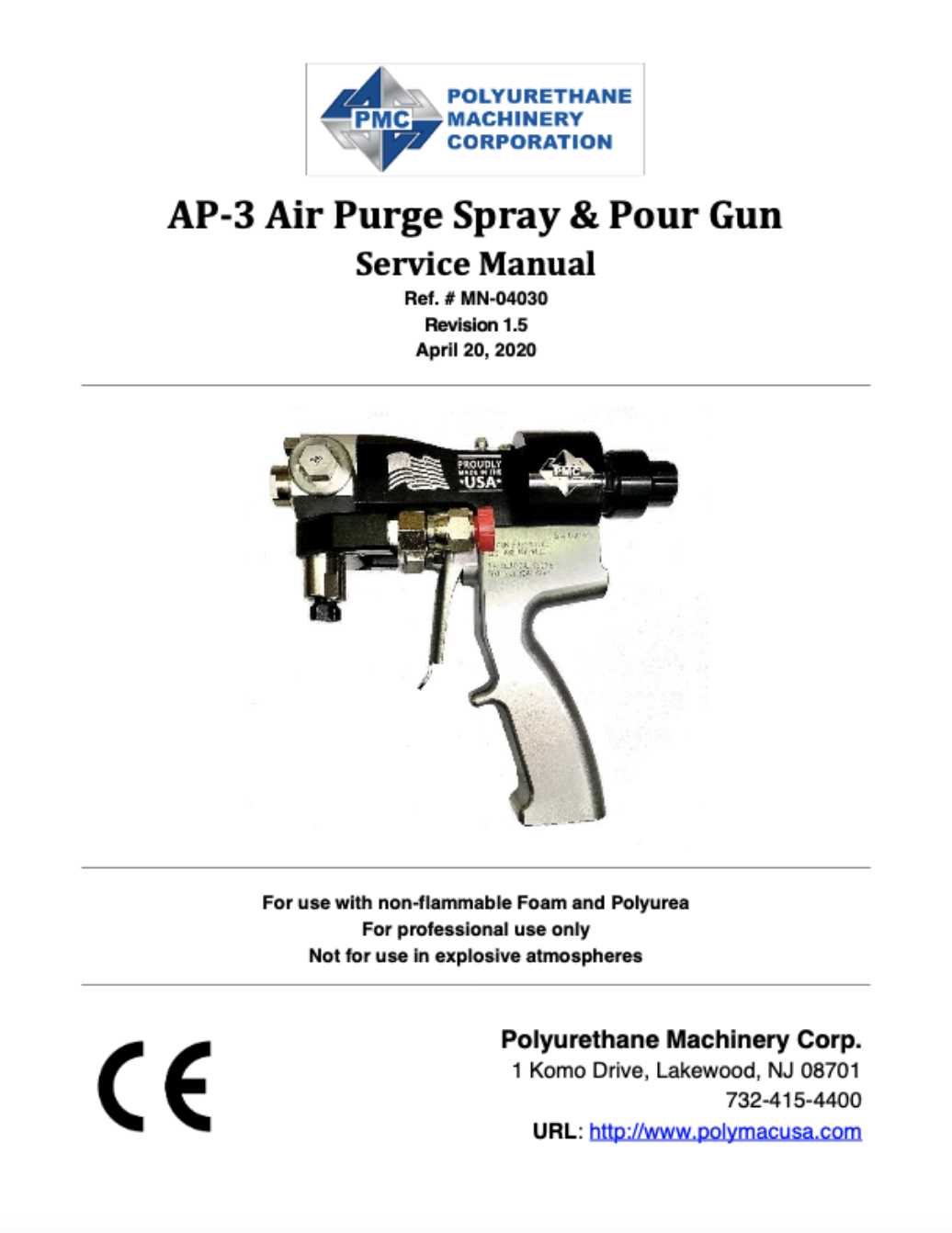

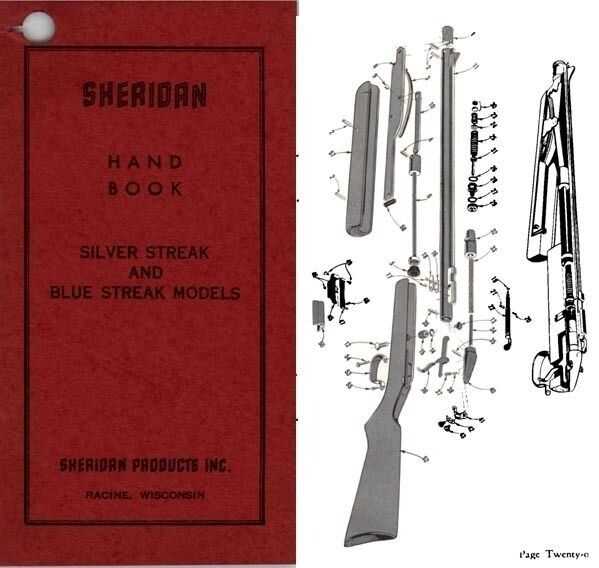

Identifying Parts and Components

Understanding the various elements and their functions within a device is crucial for effective maintenance and troubleshooting. Each component plays a specific role, contributing to the overall performance and efficiency.

To accurately identify these elements, one should familiarize themselves with the general layout and design. Key components often include the housing, mechanism, and trigger system. Recognizing these parts helps in diagnosing issues and ensuring proper functionality.

Additionally, consulting diagrams or exploded views can be invaluable. These visual aids provide a clear representation of how parts fit together, making it easier to locate and assess individual elements during inspections.

By developing a keen eye for detail and understanding the purpose of each part, users can enhance their ability to maintain and optimize their devices effectively.

Cleaning and Lubrication Techniques

Maintaining optimal performance of precision equipment requires regular attention to cleanliness and proper lubrication. These practices not only enhance functionality but also extend the lifespan of the device. Understanding effective methods for both tasks is crucial for achieving reliable operation.

Essential Cleaning Methods

Regular cleaning should focus on removing debris and residues that accumulate during usage. Here are some recommended techniques:

| Method | Description |

|---|---|

| Dry Wipe | Use a soft, dry cloth to remove loose dirt and dust from surfaces. |

| Wet Cleaning | Utilize a damp cloth with mild detergent for stubborn stains; ensure no moisture enters sensitive areas. |

| Compressed Air | Blow out particles from hard-to-reach spaces using compressed air; maintain a safe distance to avoid damage. |

Proper Lubrication Techniques

Applying appropriate lubricants is vital to ensure smooth operation and prevent wear. Consider the following recommendations:

| Type of Lubricant | Application |

|---|---|

| Oil | Apply sparingly to moving parts to reduce friction; use a dropper for precision. |

| Grease | Use for components that experience heavier loads; ensure even distribution. |

| Silicone Spray | Ideal for protecting surfaces from moisture and corrosion; spray lightly on external areas. |

Troubleshooting Air Pressure Problems

When dealing with issues related to compressed air systems, it’s essential to identify the root causes of pressure irregularities. These problems can stem from various factors, including leaks, blockages, or faulty components. Understanding how to systematically approach these challenges can lead to effective solutions and restore optimal functionality.

Common Symptoms: Users may notice insufficient pressure or inconsistent output, which often indicates an underlying issue. Pay attention to unusual noises or a sudden drop in performance, as these can be key indicators of malfunction.

Identifying Leaks: Start by inspecting all connections and hoses for any signs of leakage. Utilize a solution of soap and water to pinpoint small leaks; bubbles will form where air escapes. Ensure all fittings are tight and secure.

Checking Blockages: If air flow is restricted, check filters and valves for clogs. Cleaning or replacing these components may resolve pressure issues. Regular maintenance is vital to prevent build-up that can impede functionality.

Component Inspection: Examine internal parts such as pistons and seals for wear or damage. Replacing worn components can significantly improve efficiency and restore proper pressure levels.

By following these troubleshooting steps, users can effectively diagnose and rectify pressure-related challenges, ensuring their systems operate smoothly and efficiently.

Replacing Worn-Out Seals

Over time, the components responsible for maintaining pressure and preventing leaks can deteriorate, leading to diminished performance. Replacing these essential parts is crucial for ensuring optimal functionality and longevity of the device.

Before starting the process, gather the necessary tools and replacement seals. Make sure to follow the specific guidelines for disassembling the unit carefully to avoid damaging any surrounding parts. Take note of the configuration of the seals for accurate reinstallation.

Once the old seals are removed, clean the seating areas thoroughly to eliminate any debris that could hinder the new seals’ effectiveness. Apply a light lubricant to facilitate a smooth installation, then place the new seals in their designated spots. Ensure they are seated evenly to prevent any leaks.

After reassembly, conduct a test to confirm that the device functions properly and is free from leaks. Regular maintenance checks can help identify wear and tear early, allowing for timely replacements and ensuring optimal performance.

Adjusting Sight Settings

Fine-tuning the optical components of your device is essential for achieving optimal accuracy. Proper alignment ensures that your aim is consistent, enhancing overall performance during use. This section provides guidance on how to effectively adjust these settings for improved results.

Understanding the Components

The primary elements involved in sight adjustment include elevation and windage. Elevation refers to the vertical alignment, while windage addresses horizontal positioning. Familiarity with these components is crucial for successful adjustments.

Adjustment Process

To initiate the adjustment process, follow these steps:

| Step | Action |

|---|---|

| 1 | Identify the current alignment by observing the target. |

| 2 | Utilize the elevation knob to raise or lower the sight as needed. |

| 3 | Adjust the windage knob to shift the aim left or right. |

| 4 | Test the adjustments by taking practice shots. |

| 5 | Repeat the process as necessary until satisfactory accuracy is achieved. |

Rebuilding the Trigger Mechanism

The process of revitalizing the release system is essential for enhancing the performance and reliability of your device. Understanding the components involved and the steps necessary for reassembly will ensure a smooth operation and improved accuracy.

Disassembly Steps

Begin by carefully taking apart the mechanism, noting the arrangement of each piece. Use appropriate tools to avoid damaging any components. Keep track of screws and small parts, as they are crucial for successful reassembly.

Reassembly and Testing

Once all components are cleaned and inspected for wear, begin the reassembly process. Ensure that each part fits snugly and operates smoothly. After reassembly, conduct a series of tests to verify functionality and make any necessary adjustments for optimal performance.

Safety Precautions During Repairs

Engaging in maintenance tasks requires a thorough understanding of safety practices to prevent accidents and ensure effective outcomes. Adhering to specific guidelines is essential for both the user and the equipment being serviced.

Personal Protective Equipment

Utilizing appropriate personal protective equipment (PPE) is crucial. Items such as safety goggles, gloves, and dust masks safeguard against potential hazards. Always ensure that your workspace is well-lit and organized to minimize risks.

Proper Handling Techniques

When working with complex devices, it is vital to handle components with care. Ensure that all tools are in good condition and appropriate for the task. Following manufacturer guidelines will enhance safety and promote effective handling.

Resources for Parts and Supplies

Finding reliable sources for components and materials is crucial for maintaining and enhancing performance. A variety of suppliers offer extensive inventories to meet the needs of enthusiasts and professionals alike. Exploring different options ensures you have access to quality items that can improve functionality.

| Supplier Name | Website | Specialty |

|---|---|---|

| Precision Components | precisioncomponents.com | High-quality parts for various models |

| Parts Depot | partsdepot.com | General supplies and accessories |

| Craftsman’s Store | craftsmanstore.com | Specialty items for hobbyists |

Upgrades and Modifications Tips

Enhancing your shooting device can significantly improve performance and user experience. Whether you are looking to increase accuracy, reduce noise, or enhance overall functionality, various adjustments can make a noticeable difference.

Start with the basics: Ensure that all components are well-maintained and clean. Regular maintenance not only prolongs the lifespan of the equipment but also prepares it for modifications. Inspect seals, lubricate moving parts, and tighten any loose screws.

Consider barrel upgrades: A high-quality barrel can dramatically affect precision. Opting for a barrel made from superior materials may lead to better consistency and tighter shot grouping.

Weight adjustments: Modifying the weight of your device can enhance stability. Adding or removing weight can help improve handling and reduce recoil, making it easier to aim accurately.

Custom stocks: Upgrading to a custom stock can enhance comfort and ergonomics. Look for options that fit your grip style and shooting stance to improve overall control and aim.

By implementing these enhancements, you can tailor your shooting experience to better meet your preferences and performance needs.