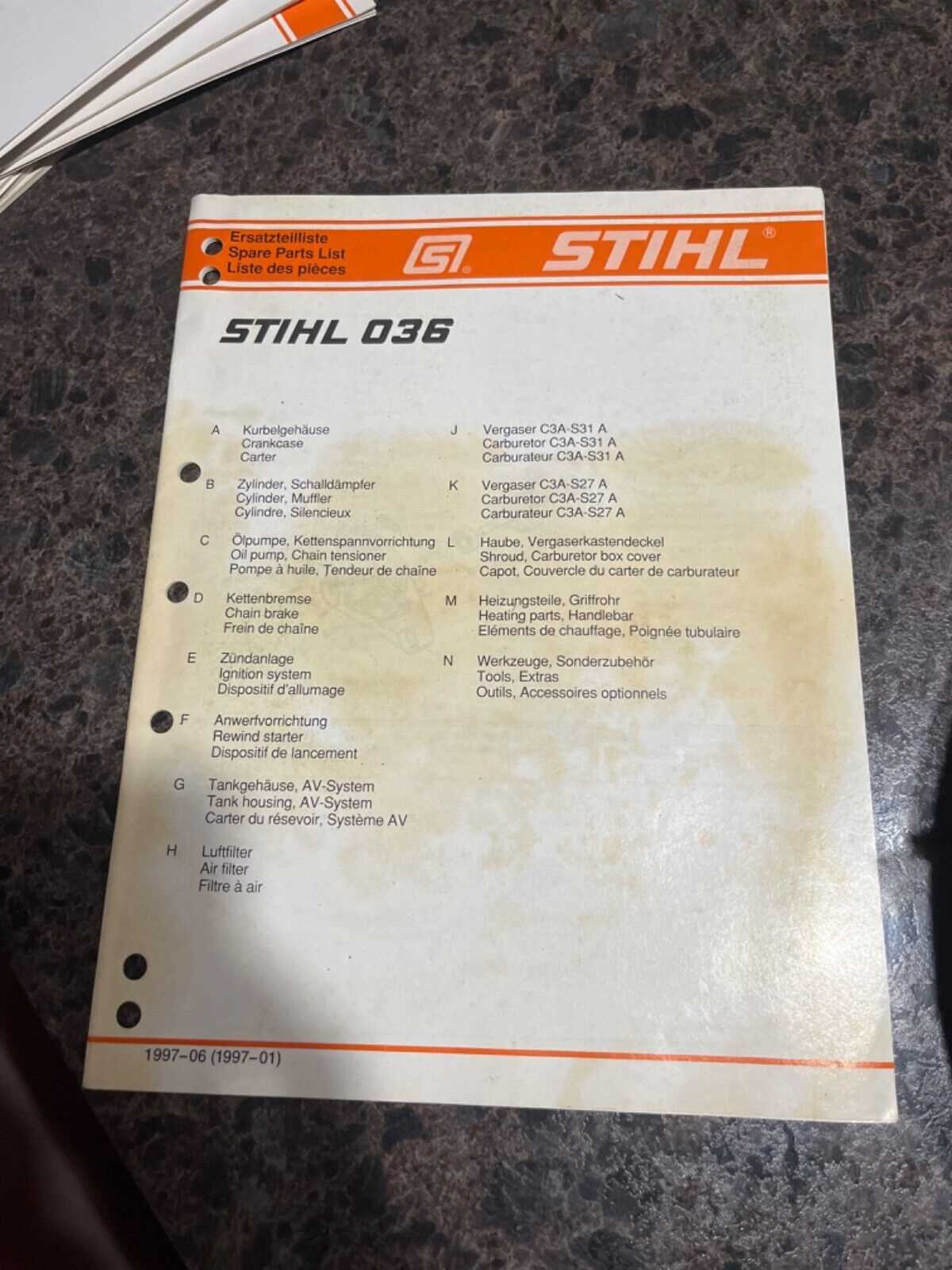

Stihl 036 Repair Guide

The effective upkeep of chain saws is essential for ensuring their longevity and optimal performance. This section focuses on essential insights and practices that can help users understand their equipment better. Familiarity with various components and their functions lays the groundwork for effective troubleshooting and servicing.

Understanding common issues that arise during operation can significantly enhance the user experience. This guide provides valuable information on recognizing signs of wear, addressing minor malfunctions, and performing routine maintenance tasks. By following these recommendations, users can keep their equipment running smoothly and efficiently.

In addition to practical advice, this guide emphasizes the importance of safety precautions during maintenance tasks. Proper handling and understanding of safety measures are crucial for preventing accidents and ensuring a secure working environment. By prioritizing safety, users can confidently engage in the upkeep of their chain saws.

Common Issues with Stihl 036

Every mechanical device may encounter certain challenges over time, and this particular model is no exception. Understanding the frequent problems can aid users in troubleshooting and maintaining optimal performance. Below are some of the prevalent difficulties faced by operators.

| Issue | Description | Possible Solutions |

|---|---|---|

| Starting Problems | Difficulty in initiating the engine, which may result from fuel blockage or spark plug issues. | Check the fuel line for clogs and inspect or replace the spark plug if necessary. |

| Overheating | Excessive heat generation during operation, potentially due to insufficient lubrication or airflow. | Ensure proper oil levels and clean the cooling fins to enhance air circulation. |

| Chain Stopping | The cutting chain may stop unexpectedly, which can be frustrating during use. | Examine the tension of the chain and adjust it if it’s too loose. Also, inspect the chain brake mechanism. |

| Fuel Leaks | Unwanted fuel leakage can occur, posing safety risks and affecting performance. | Inspect fuel lines and seals for damage and replace any worn components. |

Essential Tools for Repair

When it comes to maintaining and fixing machinery, having the right equipment is crucial for achieving efficient results. Proper tools not only facilitate the repair process but also ensure safety and precision during work. This section outlines the fundamental instruments required for effective servicing.

Firstly, a quality set of hand tools, including wrenches, screwdrivers, and pliers, forms the backbone of any repair task. These instruments enable you to disassemble and assemble components with ease. Additionally, specialized tools such as torque wrenches are invaluable for applying the correct force to fasteners, preventing damage to parts.

Moreover, having access to measuring devices like calipers and micrometers is essential for checking tolerances and ensuring that parts fit together perfectly. A good workbench with a sturdy vise provides a secure workspace for handling various tasks safely.

Lastly, safety equipment, including gloves and goggles, should never be overlooked. These protective items are vital for safeguarding yourself against potential hazards while working on intricate machinery. By equipping yourself with these essential tools, you will be well-prepared to tackle any maintenance or service challenge effectively.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to the upkeep of your outdoor power equipment, ensuring optimal performance and longevity. Regular maintenance not only enhances efficiency but also prevents potential issues that could lead to costly repairs. Follow these systematic steps to maintain your tool effectively.

Start by cleaning the exterior and removing any debris or dirt accumulation. A clean surface allows for better inspection and prevents damage to components. Next, check the air filter; a clean filter promotes efficient airflow and enhances engine performance. Replace it if it appears dirty or clogged.

Inspect the spark plug for wear and replace it if necessary. A faulty spark plug can lead to starting difficulties and inefficient combustion. Additionally, examine the fuel system, ensuring that the fuel is fresh and free from contaminants. Replace old fuel and clean the fuel lines to prevent clogs.

Next, lubricate the moving parts according to the manufacturer’s recommendations. Proper lubrication reduces friction and wear, prolonging the life of the equipment. Finally, sharpen the cutting blades regularly to ensure clean cuts and improve overall efficiency.

By adhering to this maintenance routine, you can significantly enhance the performance and durability of your outdoor power tools, allowing for reliable operation throughout the seasons.

Replacing the Fuel Filter

The fuel filter is a crucial component in ensuring optimal performance of your equipment. Regular maintenance, including filter replacement, helps prevent dirt and debris from clogging the fuel system, which can lead to engine issues. This section will guide you through the steps to efficiently change the fuel filter.

Tools and Materials Needed

- New fuel filter

- Wrench set

- Fuel line clamps

- Safety goggles

- Work gloves

Steps for Replacement

- Ensure the equipment is turned off and cool before beginning the replacement.

- Locate the fuel filter, typically found along the fuel line.

- Use the wrench to loosen the clamps securing the fuel line to the filter.

- Carefully disconnect the fuel lines from the old filter, allowing any residual fuel to drain into a container.

- Install the new filter, ensuring the flow direction matches the markings on the filter.

- Reconnect the fuel lines and tighten the clamps securely.

- Check for any leaks by starting the engine and observing the connections.

By following these steps, you can ensure a clean fuel system, promoting the longevity and reliability of your equipment.

Chain Brake Adjustment Techniques

Proper adjustment of the chain brake is essential for optimal performance and safety of cutting equipment. Ensuring that this component operates effectively helps prevent accidents and enhances the user experience. In this section, we will explore various methods to fine-tune the chain brake mechanism, focusing on key practices that maintain its functionality.

Understanding the Chain Brake Mechanism

The chain brake functions as a crucial safety feature, designed to stop the chain from rotating in the event of kickback or sudden movement. Familiarizing yourself with its operation is vital before attempting any adjustments. The mechanism typically includes a lever and a spring that engages the brake when activated.

Adjustment Procedure

To achieve the desired tension, follow these steps:

- Inspect the Lever: Ensure that the lever moves freely and is not obstructed by debris.

- Tighten or Loosen the Spring: Depending on the resistance felt when engaging the brake, adjust the spring tension accordingly.

- Test the Brake: After making adjustments, conduct a functional test to confirm that the brake engages and disengages smoothly.

Regular maintenance and checks on the chain brake will not only prolong the life of your equipment but also contribute to safer operation. Following these techniques will help in keeping the chain brake in excellent working condition.

Troubleshooting Starting Problems

Starting difficulties can often be a source of frustration for users. This section aims to identify common issues that may prevent your equipment from firing up and offers practical solutions to help get it back in working order.

Common Causes of Starting Issues

Several factors can contribute to starting challenges. These include:

- Fuel-related issues, such as stale gasoline or improper fuel mixtures.

- Ignition system problems, which may involve a faulty spark plug or ignition coil.

- Air filter blockages that restrict airflow to the engine.

Solutions to Consider

To effectively address starting problems, consider the following steps:

- Check the Fuel: Ensure that the fuel is fresh and properly mixed according to specifications.

- Inspect the Ignition System: Replace any worn or damaged components, including spark plugs and wires.

- Clean the Air Filter: Remove and clean or replace the air filter to ensure adequate airflow.

By following these guidelines, you can systematically eliminate potential causes of starting problems and restore optimal functionality.

Cleaning and Sharpening the Chain

Proper maintenance of the cutting tool is essential for optimal performance and longevity. Keeping the chain clean and well-sharpened ensures efficient cutting and reduces wear on the equipment. This section provides guidance on how to effectively clean and sharpen the chain, which can significantly enhance its functionality.

Cleaning the Chain

Before sharpening, it is crucial to clean the chain thoroughly. Dirt, oil, and wood residues can accumulate and affect the cutting performance. Here’s how to clean it effectively:

| Step | Description |

|---|---|

| 1 | Remove the chain from the guide bar. |

| 2 | Use a brush and soapy water to scrub off debris. |

| 3 | Rinse the chain with clean water and dry it thoroughly. |

| 4 | Inspect for any damage or wear before proceeding to sharpening. |

Sharpening the Chain

After cleaning, the next step is sharpening the chain. A sharp chain cuts more efficiently and requires less effort. Follow these steps to sharpen:

| Step | Description |

|---|---|

| 1 | Use a round file that matches the gauge of the chain. |

| 2 | Position the file at the correct angle, typically 30 degrees. |

| 3 | File each tooth evenly, applying consistent pressure. |

| 4 | Check the sharpness after several strokes and repeat as necessary. |

Understanding the Ignition System

The ignition system plays a crucial role in the operation of small engines, ensuring that the combustion process occurs efficiently. This system is responsible for generating a spark that ignites the fuel-air mixture within the combustion chamber. A well-functioning ignition system is essential for optimal engine performance and reliability.

There are several key components that make up the ignition system:

- Ignition Coil: This component transforms low voltage from the battery into high voltage, which is necessary to create a spark.

- Spark Plug: The spark plug delivers the electrical spark to the combustion chamber, igniting the fuel-air mixture.

- Flywheel Magnet: As the engine runs, the flywheel’s magnet generates electrical current, which is then sent to the ignition coil.

- Ignition Module: This regulates the timing of the spark and ensures it occurs at the right moment in the engine cycle.

Proper maintenance of the ignition system is vital to prevent performance issues. Common problems may include:

- Poor spark quality due to worn spark plugs.

- Faulty ignition coils that fail to generate sufficient voltage.

- Misaligned components causing timing issues.

Regular inspection and timely replacement of worn parts can enhance the longevity and efficiency of the engine. Understanding how each component functions and interacts within the ignition system will enable effective troubleshooting and maintenance.

Recommended Replacement Parts

When maintaining and servicing outdoor power equipment, it is essential to consider specific components that may require periodic replacement. Utilizing high-quality parts ensures optimal performance and longevity of the machinery. This section provides a curated list of essential replacement items that are commonly needed for efficient operation.

Among the critical components, the air filter plays a vital role in ensuring proper airflow and engine performance. Regularly replacing this filter can prevent debris buildup and enhance the machine’s efficiency. Additionally, the spark plug should be inspected frequently and changed as necessary to maintain smooth ignition and engine operation.

Another important part is the fuel filter, which prevents contaminants from entering the fuel system. Replacing it at recommended intervals can improve fuel delivery and overall performance. The chain and bar are also key elements that may require replacement due to wear and tear, affecting cutting efficiency.

Finally, consider the importance of checking the oil filter and seals regularly. Replacing these components helps maintain proper lubrication and prevents leaks, contributing to the equipment’s durability. By focusing on these recommended parts, users can ensure their machinery remains in peak condition for years to come.

Safety Precautions During Repairs

When undertaking maintenance tasks on machinery, adhering to safety measures is essential to prevent accidents and injuries. Proper preparation and awareness of potential hazards can significantly enhance the safety of the process.

Firstly, ensure that you are equipped with the necessary personal protective equipment (PPE). This includes gloves, goggles, and hearing protection to shield yourself from debris, noise, and other risks associated with the maintenance environment.

Additionally, before starting any work, verify that the equipment is turned off and disconnected from any power sources. This simple step can prevent unexpected activations that could lead to serious injuries.

Furthermore, familiarize yourself with the specific components you will be working on. Understanding the machinery’s layout and functionality will enable you to navigate it safely and effectively, minimizing the risk of accidents.

Finally, maintain a clean and organized workspace. Clutter can lead to slips, trips, and falls, so keeping tools and materials in designated areas ensures a safer environment for conducting repairs.