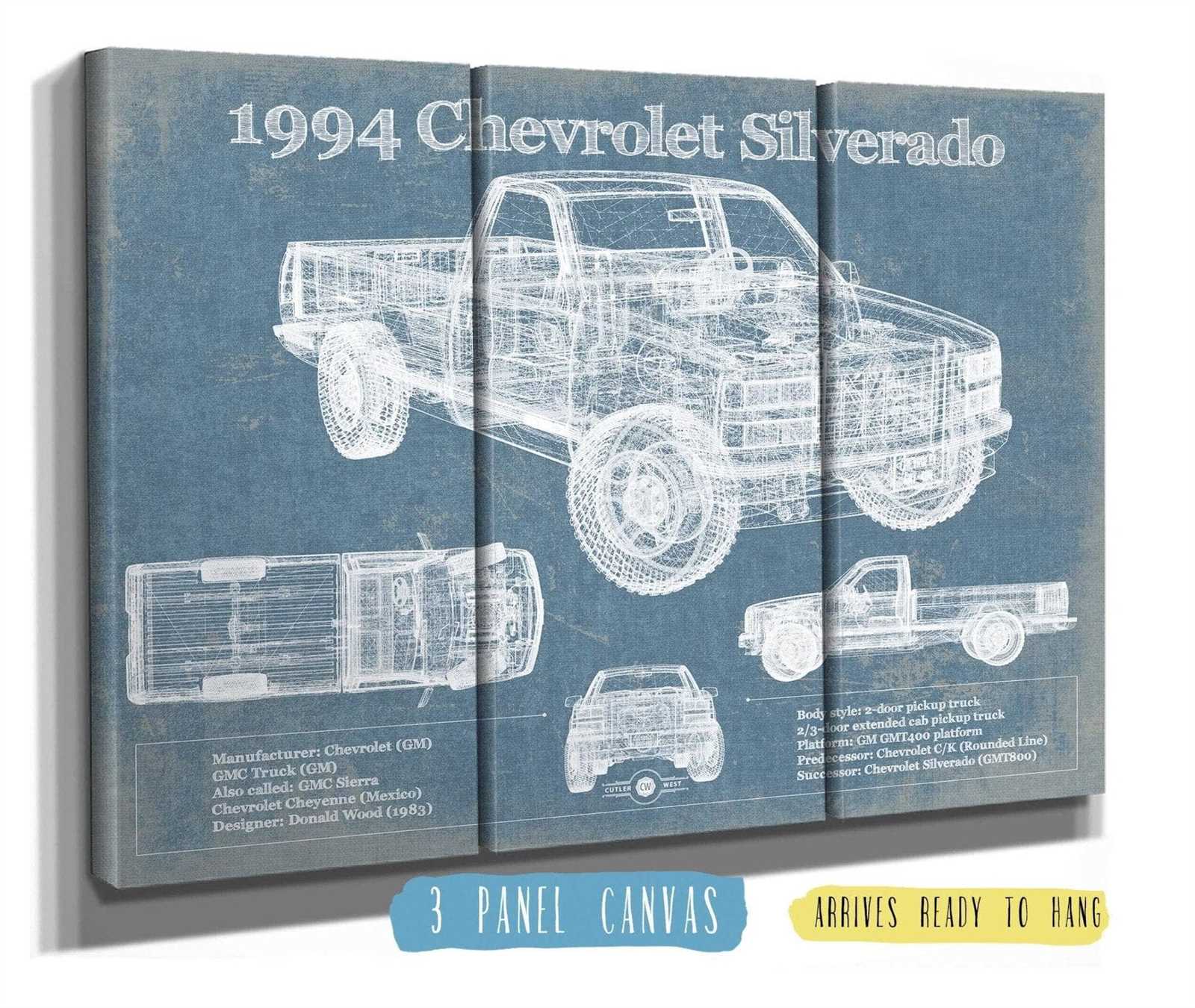

1994 Chevy Silverado 1500 Repair Manual Guide for Maintenance and Repairs

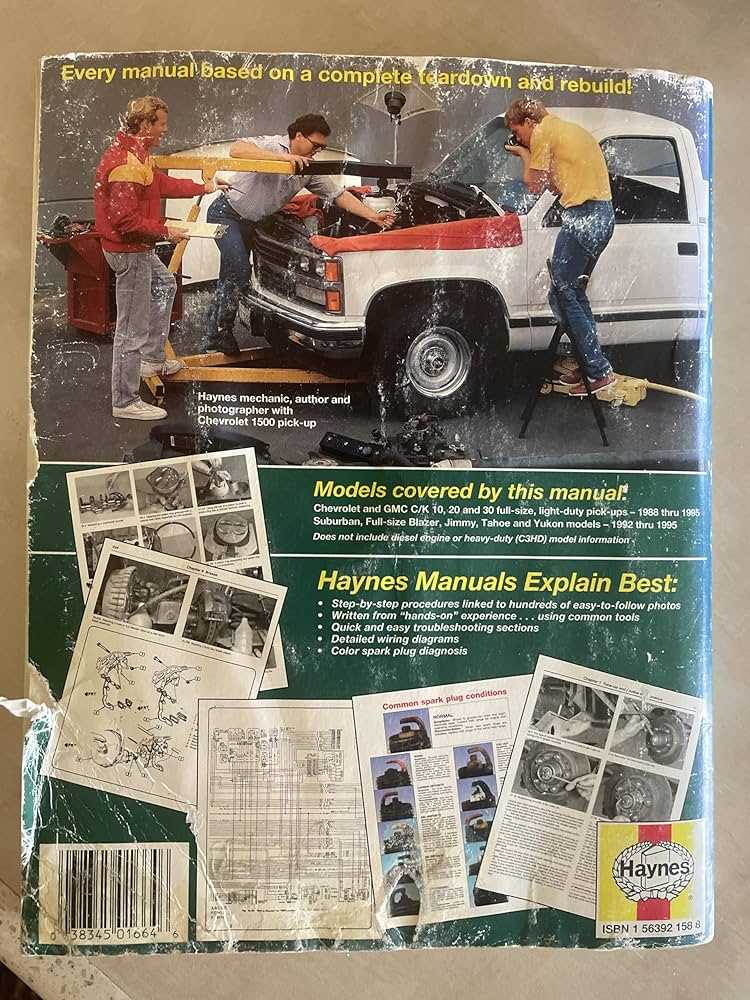

Owning a classic pickup truck brings a unique blend of pride and responsibility. Over the years, regular upkeep becomes essential not only to keep the vehicle running smoothly but also to preserve its timeless appeal. This guide aims to provide enthusiasts and owners with a thorough understanding of key maintenance tasks and troubleshooting techniques, ensuring longevity and reliability on the road.

From engine components to electrical systems, the sections cover crucial areas that often require attention in an older vehicle. You’ll find detailed explanations, step-by-step instructions, and helpful tips for diagnosing issues, as well as practical advice on handling the most common service needs. Whether you’re a seasoned mechanic or a beginner, this resource will guide you through each aspect of keeping your truck in top shape.

Preserving functionality is one of the main objectives for any vintage vehicle owner, and this guide is designed to make the process accessible and straightforward. By following these insights, you’ll not only enhance your vehicle’s performance but also extend its life, allowing you to enjoy many more miles down the road.

1994 Chevy Silverado 1500 Repair Manual

Understanding the mechanics and inner workings of this classic pickup is essential for effective maintenance and problem-solving. By exploring key maintenance areas and common component adjustments, owners can keep the vehicle running smoothly and efficiently.

Engine and Transmission Care plays a crucial role in the vehicle’s longevity. Regular inspection of these components, including oil changes and monitoring fluid levels, helps prevent major issues. Additionally, ensuring that the transmission operates smoothly can contribute to fuel efficiency and vehicle performance.

Brake System Essentials are another critical part of the upkeep. Consistent checks on brake pads, rotors, and hydraulic lines will ensure safe operation and prevent wear that can lead to costly repairs. Paying close attention to these parts is essential for both performance and safety.

By systematically inspecting these core systems, owners can address minor concerns before they develop into significant issues, ultimately extending the lifespan of this reliable vehicle.

Engine Maintenance Essentials

Regular engine maintenance is key to extending the life and performance of any vehicle. Consistent care and routine inspections help prevent major issues and ensure reliable operation, making maintenance an essential part of vehicle ownership. This section provides a guide to the most important areas to check and maintain for optimal engine performance.

| Maintenance Area | Frequency | Key Actions | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Oil and Filter Change | Every 5,000 to 7,500 miles | Replace oil and filter to ensure smooth engine function and reduce wear. | |||||||||||||

| Air Filter Replacement | Every 15,000 miles or as needed | Maintain air intake efficiency by replacing the filter to keep debris out of the engine. | |||||||||||||

| Spark Plug Inspection | Every 30,000 miles | Inspect and replace if necessary to maintain efficient combustion and power. | |||||||||||||

| Coolant System Flush | Every 50,000 miles | Flush the cooling system to prevent overheating and corrosion inside the engine. | |||||||||||||

| Timing Belt Replacement | Every 60,000 to 100,000 miles | Replace the timing belt to pre

Transmission Troubleshooting Techniques

Identifying and addressing transmission issues promptly ensures long-term reliability and smoother vehicle operation. This section covers essential techniques for diagnosing common transmission problems and offers insights into how small adjustments or maintenance practices can prevent significant malfunctions. Understanding these methods will enable vehicle owners to maintain optimal performance and avoid costly repairs. Recognizing Warning Signs

Early symptoms, such as unusual noises, slipping gears, or delayed responses, often indicate underlying transmission issues. Paying attention to these signs and taking immediate action can prevent problems from escalating. For instance, whining or humming noises may signal low fluid levels or worn components, while jerking movements when shifting may indicate a deeper mechanical problem. Addressing these warning signs early is key to effective maintenance. Testing and Adjustments

One of the most effective ways to troubleshoot transmission issues is through basic testing and fluid checks. Verifying that transmission fluid is at the correct level and condition is critical, as dirty or burnt fluid can cause various operational issues. Additionally, testing the clutch and observing shifts at different speeds helps identify specific areas that may require adjustment or replacement. Regular inspections and timely adjustments can significantly enhance transmission lifespan and performance. Brake System Inspection GuideMaintaining a safe and efficient braking system is essential for vehicle performance and passenger safety. Regular inspections help identify issues early, preventing potential breakdowns and costly repairs. This guide outlines key steps to evaluate each part of the braking system to ensure optimal function and longevity. Inspecting Brake Pads and Rotors

Begin by examining the brake pads for signs of wear, such as thinning or uneven surfaces. Pads with significant wear reduce braking efficiency and should be replaced promptly. Next, inspect the rotors for grooves, rust, or warping. If the rotors display any of these signs, resurfacing or replacement may be necessary to restore a smooth braking experience. Checking Brake Fluid Levels

Brake fluid is essential for maintaining pressure in the braking system. Check the fluid reservoir to ensure levels are within the recommended range and observe the fluid’s color, as dark or contaminated fluid may require a flush and refill. Replenishing and replacing brake fluid at recommended intervals helps maintain consistent braking performance. Consistent inspection of these components supports a reliable and safe driving experience. Routine maintenance prevents excessive wear, enhances longevity, and ensures your vehicle remains ready for the road. Electrical Component DiagnosticsUnderstanding how to diagnose and troubleshoot electrical components is crucial for maintaining optimal vehicle performance. This section provides a structured approach to identifying common issues with essential parts, such as sensors, relays, and wiring systems, helping ensure reliable operation. Common Diagnostic ToolsAccurate diagnostics rely on using the right tools. A multimeter is often indispensable for measuring voltage, current, and resistance in circuits. Additionally, a test light and circuit tester aid in verifying power flow. These tools help pinpoint failures quickly and precisely, minimizing guesswork and time spent on repairs. Typical Electrical Components and Their IssuesKey electrical components can encounter distinct issues based on wear, environmental factors, or wiring conditions. Below is a summary table of commonly affected parts and symptoms to assist in efficient troubleshooting:

|