Kymco Agility 50 Complete Repair Guide

Owning a 50cc two-wheeler brings a unique sense of freedom and excitement, especially for those navigating urban environments. However, like any mechanical device, it requires regular attention and care to ensure optimal performance. Understanding the intricacies of your vehicle can help maintain its longevity and enhance your riding experience.

This resource aims to provide essential insights into the upkeep and troubleshooting of your compact scooter. From basic maintenance tips to more complex procedures, you’ll find detailed instructions that cater to both novice and experienced riders. Knowing how to address common issues not only saves time and money but also fosters a deeper connection with your mode of transport.

Equipped with the right knowledge, you can tackle repairs and enhancements with confidence. Whether you’re looking to replace a worn part or simply perform routine checks, this guide will empower you to keep your scooter in top shape, ensuring smooth rides and reliability on the road.

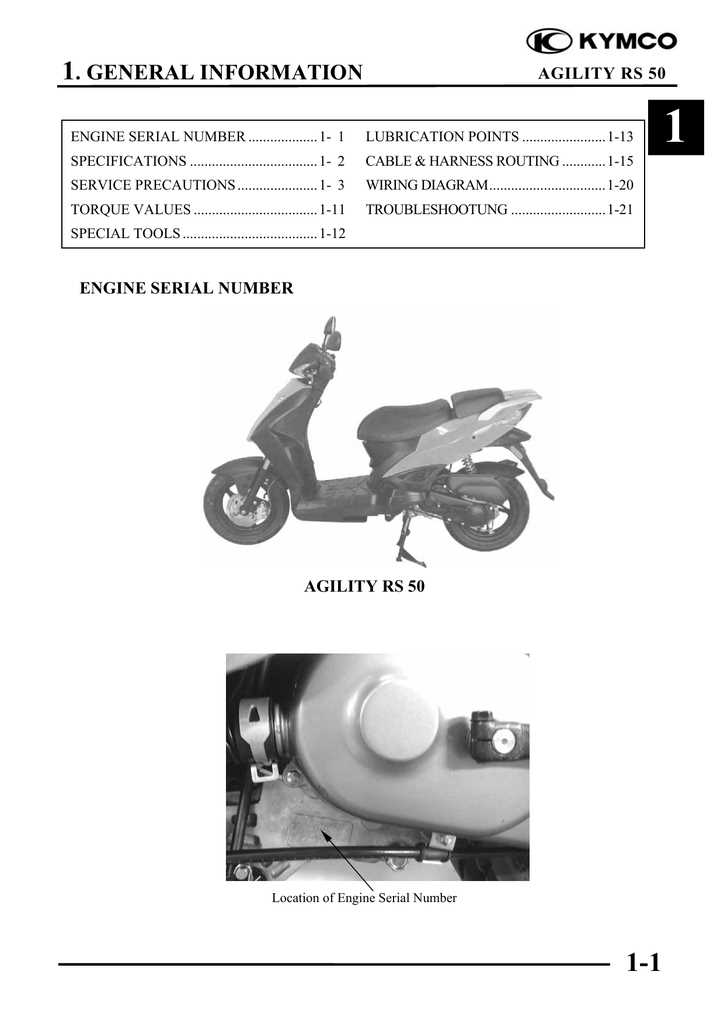

Kymco Agility 50 Overview

This section provides a comprehensive look at a popular two-wheeled vehicle designed for urban commuting and leisure riding. With its blend of practicality and style, it has become a favored choice for many riders.

Key features of this model include:

- Compact size for easy maneuverability in city traffic.

- Fuel-efficient engine, ideal for economical travel.

- Ergonomic seating for comfortable rides over short and medium distances.

- Modern design that appeals to a wide range of riders.

Performance is a significant aspect of this vehicle. Riders can expect:

- Smooth acceleration, making it suitable for both beginners and experienced users.

- Reliable braking system, enhancing safety on the road.

- Durable construction, ensuring longevity and minimal maintenance needs.

This model stands out not only for its functionality but also for its vibrant community of enthusiasts who appreciate its capabilities and ease of use.

Common Issues and Troubleshooting

When operating a lightweight scooter, it’s essential to be aware of potential challenges that may arise during its use. Understanding common problems can help riders maintain optimal performance and enhance safety. This section outlines frequent issues encountered, along with practical solutions to address them effectively.

One prevalent concern is difficulty in starting the engine. This may stem from a weak battery, faulty spark plug, or issues with the fuel supply. Ensuring that the battery is charged, the spark plug is clean and functional, and the fuel line is free from obstructions can resolve these problems.

An additional issue is inconsistent acceleration, which can be caused by clogged air filters or fuel injectors. Regular cleaning or replacement of these components can restore proper power delivery and improve overall responsiveness.

Furthermore, riders may notice unusual noises while operating the vehicle. These sounds could indicate problems with the drivetrain or suspension. Inspecting these systems for wear and tear, and addressing any loose parts, can prevent more significant damage and ensure a smoother ride.

Lastly, poor braking performance is a critical concern. Worn brake pads or low fluid levels can significantly compromise safety. Regularly checking the braking system and replacing any worn components is vital for maintaining reliable stopping power.

Essential Tools for Repairs

When undertaking maintenance on your two-wheeled vehicle, having the right equipment is crucial for efficient and effective work. A well-stocked toolkit not only makes tasks easier but also enhances safety and precision. Below are some indispensable items that every enthusiast should consider.

Wrenches and Sockets: A variety of sizes is essential to tackle different fasteners. Both open-end and socket types allow for versatility, enabling you to reach tight spaces and apply adequate torque without damaging components.

Screwdrivers: Flathead and Phillips screwdrivers are fundamental for loosening and tightening screws. Having multiple sizes ensures that you can handle various fasteners found in the assembly.

Pliers: These tools are invaluable for gripping, twisting, and cutting wires. Needle-nose pliers, in particular, provide access to confined areas, making them a must-have in any toolkit.

Torque Wrench: For precision, a torque wrench is necessary to apply the correct amount of force to nuts and bolts. This helps prevent over-tightening, which can lead to damage.

Multimeter: An electrical tester is essential for diagnosing issues related to the electrical system. It helps you check battery voltage and continuity, ensuring all electrical components function correctly.

Oil and Grease: Proper lubrication is key to the longevity of moving parts. Keeping high-quality oils and greases on hand allows for smooth operation and reduces wear and tear.

Cleaning Supplies: A clean workspace is crucial for any maintenance task. Basic cleaning agents and rags help maintain components and ensure that no dirt interferes with the mechanics.

Having these fundamental tools readily available can significantly improve the maintenance process, ensuring that every task is completed with confidence and skill.

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring optimal performance and longevity of your two-wheeled vehicle. This section outlines systematic procedures to maintain your machine, promoting safety and reliability on the road. Following these steps will help you keep your vehicle in top condition and avoid potential issues.

The following table summarizes the key maintenance tasks and their recommended frequency:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 1,000 miles | Replace engine oil to ensure proper lubrication and performance. |

| Air Filter Inspection | Every 1,500 miles | Check and clean the air filter to prevent dirt from entering the engine. |

| Tire Pressure Check | Monthly | Ensure tires are inflated to the correct pressure for optimal handling and safety. |

| Brake System Inspection | Every 2,000 miles | Examine brake pads and fluid levels to maintain effective stopping power. |

| Battery Maintenance | Every 3 months | Check battery connections and charge level to ensure reliable starting. |

By adhering to these maintenance guidelines, you can significantly enhance the reliability and efficiency of your vehicle. Each task contributes to the overall health of the machine, ensuring a smoother and safer riding experience.

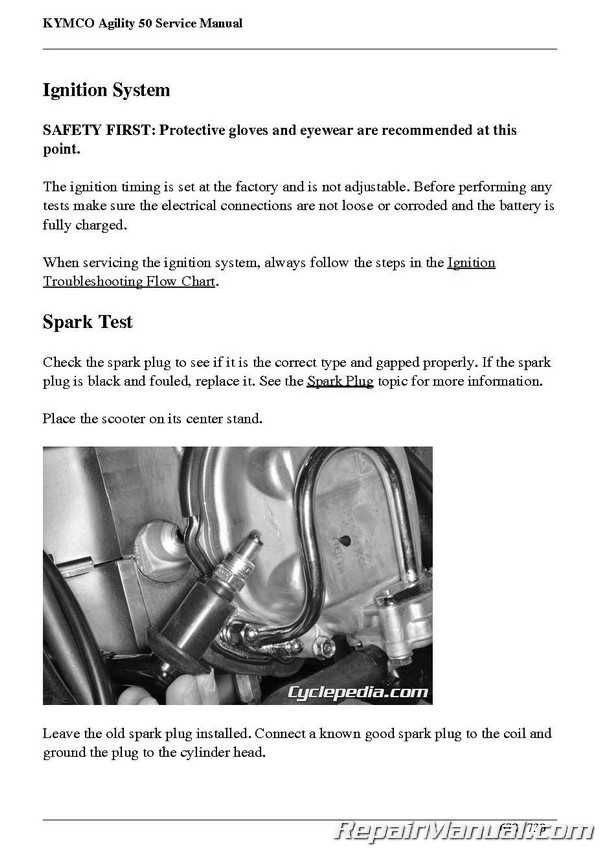

Electrical System Diagnosis

The electrical system of a two-wheeled vehicle plays a crucial role in its overall performance and functionality. Diagnosing issues within this system requires a systematic approach to identify faults that may affect the ignition, lighting, and other critical components. Understanding the fundamentals of the electrical architecture can aid in troubleshooting effectively.

Begin by checking the battery condition, as a weak or dead battery is often the root cause of various electrical failures. Use a multimeter to measure the voltage; it should ideally read around 12.6 volts when fully charged. Next, inspect the connections and wiring for signs of wear or corrosion, which can lead to poor conductivity and intermittent issues.

Testing individual components, such as the starter motor, fuses, and relays, is essential. Ensure that all fuses are intact and replace any that are blown. For components like the ignition coil, check for continuity and proper output to guarantee they are functioning as intended.

Lastly, be mindful of any abnormal indicators or warning lights on the dashboard, as these can provide vital clues to underlying electrical problems. A methodical approach to diagnosing the electrical system will enhance reliability and prolong the lifespan of the vehicle.

Engine Component Inspection

Evaluating the various parts of the power unit is crucial for ensuring optimal performance and longevity of the vehicle. This process involves a thorough examination of essential elements to identify wear, damage, or potential issues that may affect operation. Regular checks can prevent minor problems from escalating into significant repairs.

Key Components to Inspect

Begin with the cylinder head, checking for cracks or signs of overheating. Next, assess the piston and rings for wear and proper fit, ensuring they maintain an effective seal. Don’t overlook the valve assembly, as issues here can lead to poor engine efficiency.

Inspection Techniques

Utilize both visual and tactile methods during the examination. A compression test can provide valuable insights into the internal condition, while a leak-down test can pinpoint air loss issues. Ensure that all components are cleaned prior to inspection to allow for accurate assessment of their condition.

Wheel and Tire Care

Proper maintenance of wheels and tires is essential for ensuring optimal performance and safety of your two-wheeled vehicle. Regular checks and timely interventions can prolong the lifespan of your tires and enhance your riding experience.

Begin by monitoring tire pressure, as incorrect inflation can lead to handling issues and increased wear. Inspect the tread depth regularly to ensure sufficient grip on various surfaces. Additionally, pay attention to any signs of damage, such as cracks or bulges, which can compromise safety.

Cleaning the wheels is also important to prevent buildup of dirt and debris. Use appropriate cleaners to maintain the aesthetic and functional quality of the rims. Lastly, regular rotation of the tires can promote even wear, maximizing their lifespan.

| Task | Frequency |

|---|---|

| Tire Pressure Check | Weekly |

| Tread Depth Inspection | Monthly |

| Visual Damage Check | Monthly |

| Wheel Cleaning | As Needed |

| Tire Rotation | Every 3,000 miles |

Braking System Adjustments

Proper calibration of the braking mechanism is essential for ensuring safety and optimal performance. Adjustments can enhance responsiveness and prevent premature wear, contributing to a smoother riding experience. Regular checks and modifications will not only improve efficiency but also extend the lifespan of components.

Checking Brake Lever Play

Start by examining the brake lever for appropriate free play. Excessive play can lead to decreased braking efficiency, while insufficient play may cause the brakes to drag. To adjust, locate the adjuster on the lever and turn it until the play falls within the manufacturer’s specifications. This simple step can significantly affect the overall functionality of the system.

Inspecting Brake Pads and Discs

Regular inspection of the pads and discs is crucial for effective stopping power. Worn pads can lead to increased stopping distances and potential damage to the discs. Ensure the pads are not overly thin, and check for any signs of cracking or warping in the discs. If replacement is necessary, cho

Fuel System Cleaning Tips

Maintaining the cleanliness of the fuel system is crucial for optimal performance and longevity of your vehicle. A clean fuel system ensures proper fuel flow and combustion, reducing the risk of engine issues and improving efficiency. Here are some effective methods to keep your fuel system in top shape.

- Use Quality Fuel: Always opt for high-quality fuel from reputable sources to minimize contaminants and deposits.

- Regular Fuel Filter Replacement: Change the fuel filter as per the manufacturer’s recommendations to prevent clogging and ensure smooth fuel flow.

- Add Fuel System Cleaner: Incorporate a fuel system cleaning additive into your tank periodically to help dissolve deposits and improve injector performance.

- Inspect Fuel Lines: Regularly check fuel lines for leaks or cracks, and replace any damaged sections to maintain proper pressure and flow.

- Clean Fuel Injectors: Consider professional cleaning of the injectors to remove built-up residue that can hinder performance.

- Monitor Fuel Quality: If your vehicle is stored for an extended period, use a fuel stabilizer to prevent degradation of fuel quality.

By following these guidelines, you can enhance the performance and efficiency of your engine, ensuring a smoother ride and longer lifespan for your vehicle.

Understanding Transmission Mechanics

The transmission system plays a crucial role in the overall performance of a vehicle, facilitating the transfer of power from the engine to the wheels. It is essential to comprehend how this system operates to ensure optimal functionality and longevity. This section will explore the various components and their interactions, shedding light on the mechanics behind efficient power delivery.

Components of the Transmission System

The transmission consists of several key elements, including gears, clutches, and the drive shaft. Each component serves a distinct purpose, working in harmony to convert engine output into usable power. Gears change the torque and speed, while clutches enable smooth engagement and disengagement of power flow. Understanding these elements is vital for troubleshooting issues that may arise during operation.

Operational Principles

At its core, the transmission operates based on the principles of torque multiplication and gear ratios. When the vehicle accelerates, the system adjusts the gear ratios to match the required power output, allowing for efficient movement. This adaptability is crucial for maintaining performance across various driving conditions, from stop-and-go traffic to highway speeds.

Common Issues and Maintenance

When to Seek Professional Help

Understanding the limits of your own skills is crucial when it comes to maintenance and troubleshooting of your vehicle. While some issues can be easily addressed with basic knowledge and tools, others require the expertise of trained professionals. Recognizing when to consult an expert can save time, money, and ensure safety on the road.

Signs That Indicate Professional Assistance is Needed

- Persistent Issues: If a problem continues despite your attempts to fix it, seeking help is advisable.

- Unusual Noises: Strange sounds that were not present before can signal underlying issues.

- Fluid Leaks: Any signs of leaking fluids should be investigated by a specialist.

- Electrical Problems: Complex electrical systems often require professional diagnostics.

- Safety Concerns: If a malfunction compromises safety, it’s essential to consult an expert immediately.

Benefits of Professional Assistance

- Expertise: Professionals possess the training and experience necessary to diagnose issues accurately.

- Proper Tools: Specialized equipment can facilitate repairs that are beyond standard tools.

- Warranty Protection: Professional services may help maintain any warranties that could be affected by DIY repairs.

- Time Efficiency: Experts can often complete repairs faster than an inexperienced individual.