Comprehensive Guide to Mercruiser Sterndrive Repair

Understanding the intricacies of aquatic propulsion mechanisms is essential for any enthusiast looking to maintain and enhance their maritime experience. This guide delves into the essential aspects of these systems, focusing on troubleshooting, maintenance, and best practices for optimal performance.

Every vessel owner encounters challenges related to propulsion units, which can significantly impact navigation and efficiency. By equipping yourself with the right knowledge, you can ensure longevity and reliability, ultimately enhancing your time on the water.

With a wealth of information at your fingertips, you will learn how to identify common issues, perform essential upkeep, and implement effective solutions. This resource aims to empower you with the skills needed to tackle potential hurdles confidently and efficiently.

Understanding Mercruiser Sterndrive Systems

This section delves into the intricacies of propulsion systems that connect the engine to the water. These mechanisms play a crucial role in the performance and maneuverability of boats, providing a seamless interface between power and movement. By comprehending how these systems operate, boat owners can ensure optimal functionality and longevity of their vessels.

Components of the System

The functionality of the propulsion assembly relies on several key components. Each part has a specific role that contributes to the overall performance and efficiency of the system.

| Component | Description |

|---|---|

| Drive Unit | Transfers power from the engine to the propeller, facilitating movement. |

| Propeller | Generates thrust by pushing water, enabling the vessel to move forward or backward. |

| Transom Assembly | Houses the drive unit and connects it to the boat’s hull, ensuring stability. |

| Shifting Mechanism | Allows the operator to change gears, enhancing control over speed and direction. |

Importance of Maintenance

Regular upkeep of these systems is essential for safe and efficient operation. Neglecting maintenance can lead to performance issues, increased wear, and potential failures. Understanding the components and their functions enables owners to identify signs of wear and address them proactively, ensuring a smooth and enjoyable boating experience.

Common Issues with Sterndrive Units

Watercraft propulsion systems often encounter various challenges that can affect performance and safety. Identifying these common problems is crucial for maintaining efficiency and ensuring smooth operation on the water.

Overheating is a frequent concern, often caused by inadequate cooling flow. This can result from clogged passages, malfunctioning pumps, or low coolant levels, leading to potential engine damage if not addressed promptly.

Gear shifting difficulties can arise due to worn components or improper adjustments. Issues in this area may lead to unresponsive shifting, causing frustration and compromising control during navigation.

Corrosion is another prevalent issue, particularly in saltwater environments. The combination of moisture and salt can deteriorate metal parts, which necessitates regular inspections and maintenance to prevent significant damage.

Leaking seals are also common, leading to fluid loss and affecting system functionality. Detecting and replacing damaged seals quickly can mitigate further complications and maintain performance.

Understanding these prevalent concerns allows boat owners to take proactive measures, ensuring their vessels remain reliable and enjoyable for every outing.

Essential Tools for Repairing Sterndrives

When it comes to maintaining marine propulsion systems, having the right instruments at hand is crucial for achieving optimal performance and longevity. The effectiveness of any service largely depends on the selection of tools, ensuring that each task is completed efficiently and accurately. Below, we highlight the fundamental items that should be included in your toolkit.

Basic Hand Tools

Among the most important instruments are the basic hand tools, which include wrenches, screwdrivers, and pliers. These items are essential for loosening and tightening various components, making them indispensable for any technician. Additionally, a ratchet set can greatly enhance the speed and ease of working in confined spaces, allowing for quicker adjustments and replacements.

Specialized Equipment

Beyond the basics, certain specialized equipment is necessary for more intricate tasks. Torque wrenches are vital for ensuring that components are fastened to manufacturer specifications, preventing damage from over-tightening. Furthermore, a multimeter is crucial for diagnosing electrical issues, ensuring that all systems are functioning properly. Investing in these tools will not only facilitate more effective maintenance but also contribute to the overall reliability of the vessel.

Step-by-Step Sterndrive Maintenance Guide

Proper upkeep of your marine propulsion system is essential for optimal performance and longevity. Regular maintenance can help prevent costly issues and ensure safe operation on the water. This guide provides a comprehensive approach to maintaining your equipment effectively.

1. Regular Inspection

- Check for any visible damage on the external components.

- Inspect hoses and connections for leaks or wear.

- Examine the propeller for signs of dings or corrosion.

2. Fluid Changes

- Drain the old oil from the gear housing.

- Replace with fresh lubricant according to manufacturer specifications.

- Change the engine oil and filter regularly to maintain performance.

3. Cooling System Maintenance

- Check the raw water intake for obstructions.

- Clean or replace the impeller as needed to ensure proper cooling.

- Flush the cooling system to remove any build-up or debris.

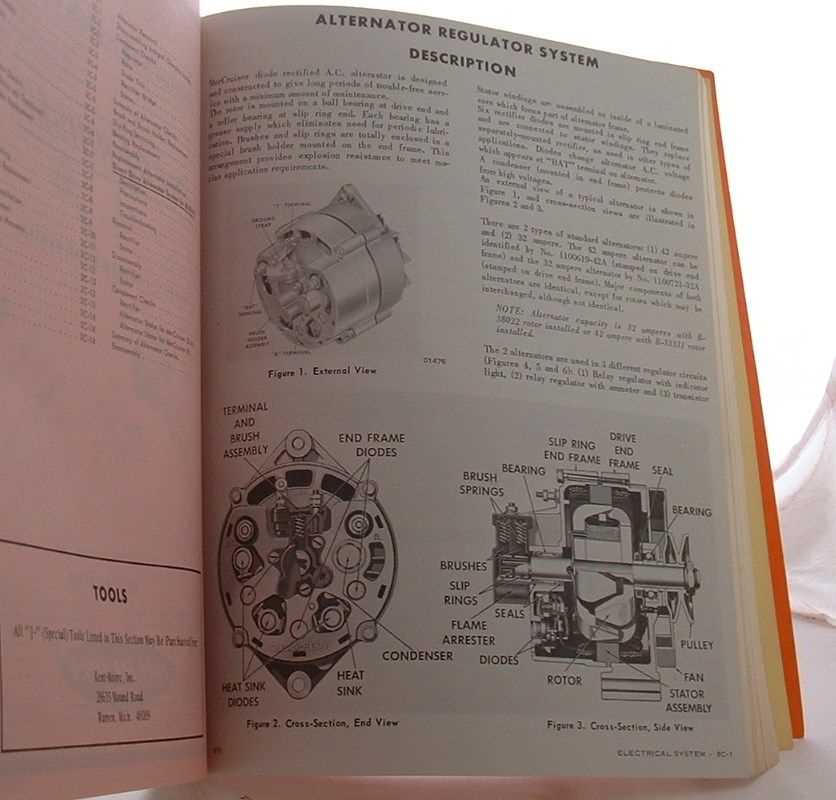

4. Electrical System Check

- Inspect all wiring for fraying or corrosion.

- Test battery health and connections to ensure reliable starts.

- Examine circuit breakers and fuses for proper function.

5. Final Preparations

- Store the equipment properly when not in use.

- Cover the unit to protect it from environmental factors.

- Document any maintenance performed for future reference.

By following these steps, you can ensure that your propulsion system remains in excellent condition, ready for all your marine adventures.

Diagnosing Engine Problems Related to Sterndrive

Identifying issues within the propulsion system is essential for maintaining optimal performance. Various symptoms may indicate underlying engine troubles that require thorough examination. Understanding these signs can help in pinpointing the source of the problem, ensuring effective solutions are applied.

Begin by observing any unusual noises coming from the propulsion unit, such as grinding or clunking sounds, which may suggest mechanical wear or misalignment. Additionally, pay attention to vibrations that could indicate imbalance or component failure. Monitoring engine temperature is crucial; overheating can signify coolant issues or blockage in the system.

Fuel delivery problems often manifest through poor acceleration or stalling. Inspect fuel lines, filters, and injectors for clogs or leaks. Electrical issues, such as faulty wiring or malfunctioning sensors, may also cause erratic performance. Conduct a visual inspection and utilize diagnostic tools to assess the electrical system.

Finally, consider the condition of the propeller and related components. Damage to the propeller can severely affect thrust and efficiency. Regular maintenance checks will help in identifying and rectifying these issues before they escalate, ensuring a smoother operation of the vessel.

Importance of Regular Lubrication Practices

Consistent application of lubricants is crucial for the longevity and efficiency of mechanical systems. Proper lubrication minimizes friction between moving parts, reducing wear and tear. This practice not only enhances performance but also contributes to the overall safety and reliability of the equipment.

Benefits of Regular Lubrication

Implementing a routine lubrication schedule brings numerous advantages, including:

| Benefit | Description |

|---|---|

| Reduced Friction | Minimizes wear on components, extending their lifespan. |

| Improved Efficiency | Ensures smooth operation, enhancing overall performance. |

| Corrosion Prevention | Protects surfaces from rust and degradation due to moisture. |

| Lower Maintenance Costs | Reduces the frequency of repairs and replacements. |

Best Practices for Lubrication

To achieve optimal results, adhere to the following guidelines:

- Choose the right type of lubricant for specific components.

- Follow manufacturer recommendations regarding lubrication intervals.

- Regularly inspect and replace old or contaminated lubricants.

- Ensure thorough application to all moving parts.

Replacing Components in Mercruiser Sterndrive

Maintaining optimal performance of marine propulsion systems often requires the careful replacement of various parts. This process is essential to ensure longevity and reliability, particularly in challenging marine environments. Understanding the steps involved in component substitution can significantly enhance the functionality of the entire system.

Common Components for Replacement

Several critical elements may need to be replaced during maintenance. Here are some of the most frequently serviced parts:

- Propeller

- Shift cable

- Water pump

- Trim motor

- Lower unit seals

Steps for Component Replacement

- Preparation: Gather all necessary tools and replacement parts before starting the process.

- Disassembly: Carefully remove the existing component, following the manufacturer’s guidelines to avoid damage.

- Inspection: Examine the surrounding area for any wear or damage that may need attention.

- Installation: Install the new part, ensuring proper alignment and secure connections.

- Testing: Once reassembled, conduct tests to confirm functionality and performance.

By following these guidelines, boat owners can ensure their propulsion systems remain in peak condition, ready for all maritime adventures.

Safety Precautions During Sterndrive Repairs

When engaging in maintenance tasks on marine propulsion systems, ensuring safety is paramount. Proper precautions not only protect the individual performing the work but also safeguard the equipment and the surrounding environment. Adopting a methodical approach can mitigate risks associated with mechanical failures and hazardous conditions.

First and foremost, personal protective equipment (PPE) should be worn at all times. This includes gloves to protect hands from sharp edges and hot surfaces, safety goggles to shield eyes from debris, and steel-toed boots to prevent injuries from heavy components. Additionally, consider wearing ear protection when working with loud tools.

Before beginning any task, ensure that the work area is well-ventilated and free from clutter. Clear away any flammable materials and ensure that fire extinguishers are readily accessible. It’s essential to have a clean workspace to reduce the risk of accidents.

Disconnecting power sources is critical. Always make sure to remove any electrical connections before starting your work to prevent shocks or unintentional activation of the system. It’s advisable to label wires and connections to simplify reassembly.

Lastly, follow manufacturer guidelines for handling equipment. Familiarize yourself with the specific components and tools required for the job at hand. Using the right tools not only enhances efficiency but also minimizes the chance of accidents resulting from improper handling.

Troubleshooting Electrical Systems in Sterndrives

Diagnosing issues within the electrical frameworks of marine propulsion systems is crucial for ensuring optimal performance and safety on the water. By systematically identifying potential faults, boat owners can address malfunctions before they escalate into more significant problems. This section provides an overview of common electrical challenges and practical approaches to resolving them.

Common Issues and Symptoms

Several signs may indicate electrical difficulties, including intermittent power loss, malfunctioning gauges, and failure of starting mechanisms. Understanding these symptoms is essential for pinpointing the source of the issue. For instance, if the engine fails to start, it could stem from a dead battery, faulty wiring, or a malfunctioning ignition switch. Each of these components should be inspected thoroughly.

Diagnostic Steps

Begin the troubleshooting process by examining the battery and connections. Ensure that terminals are clean and securely fastened. Next, test the voltage levels using a multimeter; a reading below 12.4 volts often indicates a need for charging or replacement. Following this, inspect fuses and circuit breakers for any signs of damage. If all components appear functional, consider checking the wiring harness for wear or loose connections.

By following these steps and maintaining a methodical approach, you can effectively resolve electrical issues, ensuring that your marine system operates smoothly and reliably.

Upgrading Your Sterndrive for Performance

Enhancing the efficiency and power of your marine propulsion system can significantly improve your overall boating experience. Whether you’re looking to increase speed, improve fuel economy, or boost handling, there are several modifications and upgrades that can help you achieve your performance goals.

One of the most effective ways to upgrade your setup is by optimizing the propeller. Choosing the right size and pitch can lead to better acceleration and higher top speeds. Additionally, considering a stainless steel propeller can provide improved durability and performance over standard aluminum options.

Another critical area to focus on is the engine’s calibration. Fine-tuning the engine management system, including adjusting fuel maps and ignition timing, can lead to notable gains in horsepower and torque. Performance chips or modules are also available to enhance engine output without extensive mechanical changes.

Upgrading the exhaust system is another excellent option. A high-performance exhaust can reduce back pressure, allowing the engine to breathe more freely and thus increase power. Additionally, this can contribute to a more aggressive sound, which many boaters find appealing.

Lastly, ensuring that your vessel’s weight distribution is optimized can enhance handling and stability. Consider removing any unnecessary gear and making modifications to the hull or trim tabs to improve lift and reduce drag.

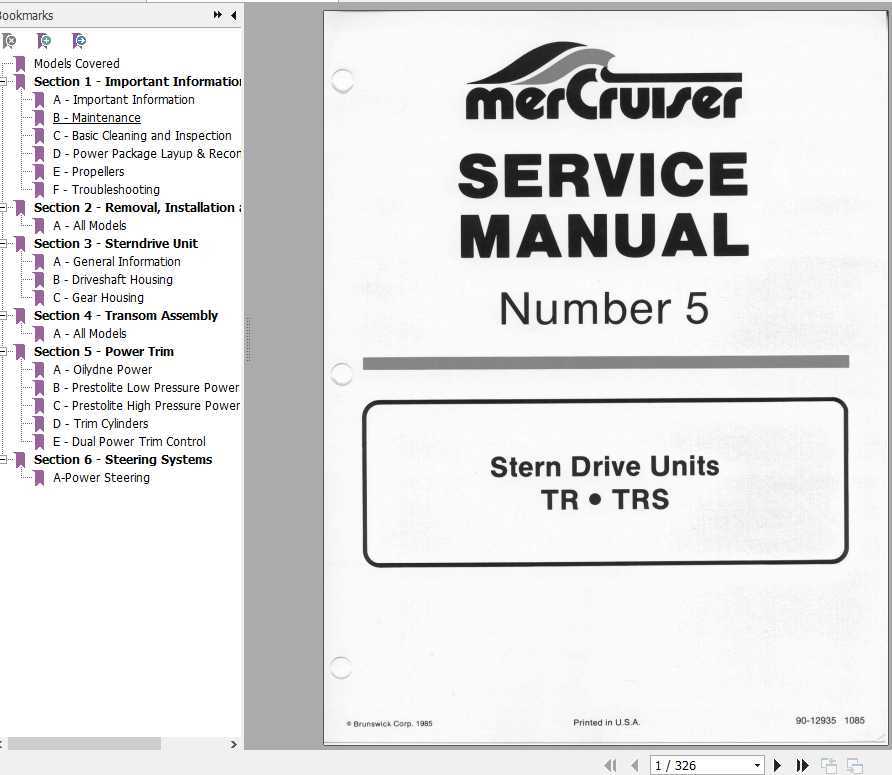

Resources for Finding Mercruiser Manuals

When it comes to maintaining and servicing marine engines, having access to accurate and comprehensive resources is crucial. A variety of materials are available to assist boat owners and mechanics in troubleshooting and performing necessary tasks effectively. This section explores various avenues for locating essential documentation related to these power systems.

Online Platforms

The internet offers a wealth of information, making it a valuable resource for enthusiasts and professionals alike. Numerous websites provide access to technical documentation, user guides, and troubleshooting tips. Here are some popular online platforms:

| Website | Description |

|---|---|

| Official Manufacturer Site | Direct access to technical documents and updates from the original manufacturer. |

| Marine Forums | Community-driven discussions where users share insights and resources. |

| Online Retailers | Sites that sell parts often include downloadable guides and manuals. |

Local Libraries and Bookstores

Physical resources remain invaluable, and many local libraries and bookstores stock specialized literature. These locations can be a great source of printed guides, ensuring you have a tangible reference at hand. Additionally, some libraries may offer interlibrary loan services to access more obscure publications.