Comprehensive Guide to 2 Stroke Repair

In the world of small engines, understanding the intricacies of their function is essential for optimal performance. This section offers valuable insights into maintaining and troubleshooting two-cycle engines, which are widely used in various applications, from lawn equipment to motorcycles. By gaining a deeper understanding of these powerhouses, enthusiasts can enhance their efficiency and longevity.

The importance of regular upkeep cannot be overstated. Issues can arise from a variety of factors, including improper use and lack of maintenance. This guide aims to equip users with the knowledge needed to identify common problems and implement effective solutions, ensuring that your equipment remains in peak condition.

From understanding the components that make up these engines to learning how to address typical malfunctions, this resource serves as a practical companion. With the right information at your fingertips, you can tackle any challenge and enjoy the full benefits of your two-cycle engine.

This section aims to provide a comprehensive overview of a specific type of engine known for its efficiency and simplicity. These engines are widely utilized in various applications, including recreational vehicles and small machinery, due to their lightweight design and power output.

Understanding the fundamentals of this engine type is crucial for anyone involved in its maintenance or operation. Unlike their counterparts, these engines operate on a unique cycle that enables them to complete a power cycle in fewer movements, resulting in enhanced performance.

| Key Features | Benefits |

|---|---|

| Lightweight design | Easy to handle and transport |

| Simplified construction | Lower manufacturing costs |

| Higher power-to-weight ratio | Improved acceleration and speed |

| Versatile applications | Widely used in various machines |

By delving into the specifics of this engine’s operation, users can gain insights that enhance their understanding and ability to work with these efficient power sources effectively.

Common Issues in Two-Stroke Motors

Two-stroke engines are popular for their simplicity and efficiency, but they can experience a range of problems that affect performance and reliability. Understanding these issues is crucial for maintaining optimal functionality and ensuring longevity.

- Fuel Quality: Poor fuel quality can lead to engine knocking and reduced efficiency. Always use fresh, high-octane fuel to avoid deposits and damage.

- Oil Mixture: An incorrect oil-to-fuel ratio can cause inadequate lubrication or excessive smoke. It’s essential to follow manufacturer guidelines for mixing ratios.

- Clogged Exhaust: Blockages in the exhaust system can restrict airflow, leading to overheating and decreased power. Regularly inspect and clean the exhaust ports.

- Worn Components: Over time, piston rings and bearings can wear out, leading to loss of compression and performance issues. Regular checks can help identify wear early.

- Cooling Problems: Insufficient cooling can result in overheating. Ensure that the cooling system is functioning properly and free from obstructions.

By addressing these common issues, you can enhance the reliability and efficiency of your two-stroke engine, allowing for smoother operation and prolonged use.

Essential Tools for Repair Work

When undertaking maintenance or fixing tasks, having the right instruments at your disposal is crucial for achieving effective outcomes. This section outlines the necessary items that can facilitate your work and enhance efficiency in any project.

| Tool | Purpose |

|---|---|

| Wrenches | Used for gripping and turning nuts and bolts. |

| Screwdrivers | Essential for driving screws into various materials. |

| Pliers | Helpful for gripping, bending, and cutting wire and other materials. |

| Jack | Used for lifting heavy components safely. |

| Torque Wrench | Ensures fasteners are tightened to the correct specification. |

| Measuring Tape | For accurate measurement of lengths and distances. |

| Cleaning Supplies | Essential for maintaining cleanliness and ensuring proper functionality. |

Step-by-Step Engine Disassembly

Disassembling an engine is a meticulous process that requires careful attention to detail and a systematic approach. This procedure not only allows for a thorough inspection of components but also ensures that each part is properly categorized and stored for reassembly. Following a structured method can greatly enhance the efficiency of the overall project.

Preparation and Tools

Before starting, gather all necessary tools such as wrenches, screwdrivers, and pliers. Additionally, ensure that you have a clean workspace where components can be organized easily. Having a detailed plan or diagram of the engine layout will aid in keeping track of parts during disassembly.

Disassembly Steps

Begin by removing any external components such as the air filter and exhaust system. Next, carefully detach the casing and other outer components to expose the internal mechanisms. As you proceed, label each part and take photographs to document their arrangement. This will assist in the reassembly process. Finally, disassemble the internal parts, starting with the moving components, ensuring that you handle each piece with care to avoid damage.

Diagnosing Fuel System Problems

Understanding issues within the fuel delivery mechanism is crucial for maintaining optimal engine performance. A variety of symptoms may indicate that the fuel system is not functioning properly, and identifying these problems early can prevent further complications.

Common Symptoms of Fuel System Issues

- Difficulty starting the engine

- Inefficient acceleration or sluggish performance

- Unusual engine sounds, such as sputtering

- Reduced fuel efficiency

- Engine stalling during operation

Steps to Diagnose the Problem

- Check the fuel level in the tank to ensure it is adequate.

- Inspect fuel lines for leaks, cracks, or blockages.

- Examine the fuel filter for signs of clogging or dirt accumulation.

- Test the fuel pump to confirm it is delivering the correct pressure.

- Evaluate the injectors for proper spray patterns and functionality.

By systematically addressing these areas, you can pinpoint the source of the issue and take appropriate action to restore the system’s efficiency.

Inspecting the Ignition System

Evaluating the ignition system is essential for ensuring optimal engine performance. A well-functioning ignition setup is crucial for reliable starting and smooth operation. This process involves checking various components that work together to create a spark necessary for combustion.

Key Components to Examine

Begin by inspecting the spark plug. Look for signs of wear or fouling, as these can hinder ignition efficiency. Ensure that the gap between the electrodes is within the specified range, allowing for a strong spark. Next, examine the ignition coil, which generates the high voltage needed to ignite the fuel-air mixture. Test for continuity and inspect the wiring for any signs of damage.

Troubleshooting Common Issues

If the engine is hard to start or misfires, further investigation is required. Check the connections and wiring for corrosion or looseness. Ensure that the ignition timing is set correctly, as improper timing can lead to poor engine performance. By methodically evaluating these elements, you can identify and rectify issues that may affect ignition efficiency.

Rebuilding the Carburetor

This section focuses on the process of restoring the fuel delivery system to its optimal functionality. A well-maintained unit ensures efficient engine performance, making it essential to follow proper procedures during the overhaul.

Before starting the rebuilding process, gather the necessary tools and materials:

- Clean workspace

- Carburetor rebuild kit

- Screwdrivers (flat and Phillips)

- Wrenches

- Compressed air

- Cleaning solvents

- Safety goggles

Follow these steps to effectively rebuild the fuel delivery system:

- Disassemble the Carburetor: Carefully remove the screws and separate the components. Take note of the order of parts to facilitate reassembly.

- Clean the Parts: Use cleaning solvents and compressed air to eliminate any dirt, debris, or residue. Ensure all passages are clear.

- Inspect Components: Check for wear or damage on gaskets, O-rings, and other essential parts. Replace any that are worn out.

- Install New Components: Using the rebuild kit, replace the necessary parts according to the instructions provided. Ensure everything fits snugly.

- Reassemble the Unit: Carefully put the carburetor back together, following the order noted during disassembly. Tighten screws evenly to avoid warping.

- Test for Leaks: Once reassembled, check for any fuel leaks. Ensure that all connections are secure.

By following these steps, you can restore the carburetor’s functionality, contributing to overall engine efficiency and longevity.

Replacing Worn Components Effectively

Maintaining optimal performance of machinery requires timely replacement of degraded parts. Addressing wear and tear not only enhances functionality but also prolongs the lifespan of the equipment. Understanding the right approach to swapping out old components ensures that the system operates smoothly and efficiently.

Identifying Worn Parts

Regular inspections are crucial for detecting signs of deterioration. Look for indicators such as unusual noises, reduced power output, or visible damage. Using diagnostic tools can help pinpoint specific areas that need attention, making it easier to plan replacements effectively.

Choosing Quality Replacements

Selecting high-quality parts is essential for maintaining performance standards. Opt for components that meet or exceed original specifications. This not only guarantees compatibility but also ensures durability, thereby minimizing the frequency of future replacements.

Adjusting the Timing Settings

Properly configuring the timing parameters is crucial for optimal engine performance. Adjustments in this area can significantly influence how effectively the engine operates, affecting both power output and fuel efficiency. Ensuring precise alignment of these settings allows for smoother functioning and can prevent potential mechanical issues.

To initiate the adjustment process, it is essential to refer to the specific guidelines provided for your engine model. Typically, this involves identifying the timing marks and using a reliable timing light to gauge alignment. Start the engine and allow it to reach operating temperature; this ensures that the components are functioning as intended during adjustments.

Key Steps to Follow:

1. Locate the timing marks on the flywheel and engine casing. These indicators are vital for establishing the correct timing position.

2. Use a timing light to illuminate the marks while the engine is running. Observe the alignment of the marks to determine if adjustments are necessary.

3. If misalignment is detected, proceed to loosen the bolts securing the ignition or stator plate. Carefully rotate the plate until the timing marks align as per specifications.

4. Once aligned, tighten the bolts while ensuring that the timing does not shift. A second check with the timing light may be beneficial to confirm accuracy.

5. After adjustments, it is advisable to take the vehicle for a test run, observing performance and responsiveness. Make further adjustments if required, as fine-tuning can lead to enhanced efficiency.

In summary, meticulous adjustment of the timing settings is fundamental for achieving peak performance. Regular checks and precise calibrations will not only improve operation but also extend the life of your engine components.

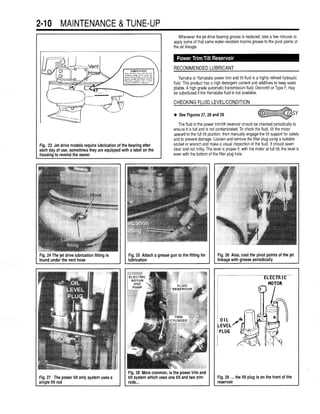

Proper Lubrication Techniques

Effective lubrication is essential for maintaining optimal performance and longevity of engines. Proper application of lubricants reduces friction and wear, ensuring smooth operation. Understanding the various methods and types of lubricants available can greatly enhance efficiency and reliability.

Choosing the Right Lubricant

Selecting the appropriate lubricant involves considering several factors:

- Type of engine

- Operating conditions

- Manufacturer recommendations

Different engines may require specific formulations to function correctly. Always refer to guidelines to determine the best option for your particular unit.

Application Methods

There are several techniques for applying lubricants:

- Manual Application: Using a brush or cloth to apply lubricant directly to moving parts.

- Spray Lubrication: Employing aerosol sprays for an even coat on larger surfaces.

- Automated Systems: Utilizing built-in systems that dispense lubricant at set intervals.

Regardless of the method chosen, ensure that all areas are adequately covered without excessive buildup, which can lead to operational issues.

Testing Engine Performance Post-Repair

After completing the necessary adjustments and modifications to the engine, it is crucial to evaluate its operational capabilities to ensure everything functions as intended. This process allows for the identification of any lingering issues and confirms that the performance meets the expected standards.

Key Steps for Performance Evaluation

- Initial Visual Inspection

- Fluid Levels Check

- Ignition System Assessment

- Fuel System Verification

Conducting a Performance Test

To accurately gauge the engine’s performance, follow these steps:

- Start the engine and let it idle, observing any unusual noises or vibrations.

- Gradually increase the throttle, paying attention to responsiveness and stability.

- Monitor exhaust emissions to ensure they are within acceptable limits.

- Check the temperature to avoid overheating during operation.

Document all findings meticulously to track improvements and address any concerns that arise during the evaluation. Regular performance testing is essential for maintaining engine longevity and efficiency.

Maintenance Tips for Longevity

To ensure your engine remains in optimal condition for an extended period, regular upkeep is essential. Implementing a few simple practices can greatly enhance its performance and lifespan.

- Regularly check and change the oil to keep the internal components lubricated.

- Inspect air filters frequently and replace them as needed to maintain airflow.

- Keep the fuel system clean by using high-quality fuel and additives.

- Perform routine inspections of spark plugs and replace them if they show signs of wear.

- Ensure that cooling systems are functioning properly to prevent overheating.

By adhering to these guidelines, you can effectively prolong the functionality and reliability of your engine.

Resources for Further Learning

Expanding your knowledge about engine maintenance and troubleshooting can significantly enhance your skills and understanding. Various materials and platforms are available to help you delve deeper into this subject. Below are some valuable resources that can provide you with further insights and practical guidance.

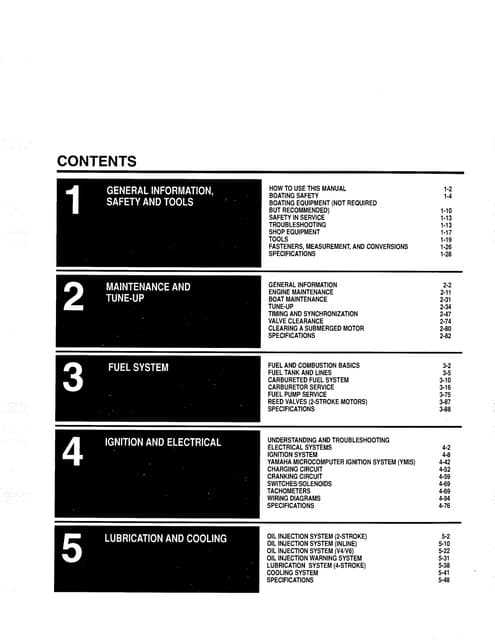

- Books and Manuals:

- Comprehensive guides on engine mechanics

- Specialized literature focusing on two-cycle engines

- Online Courses:

- Interactive classes covering engine fundamentals

- Workshops focusing on specific components and troubleshooting techniques

- Video Tutorials:

- Step-by-step guides available on platforms like YouTube

- Webinars hosted by industry experts

- Forums and Communities:

- Online discussion groups for knowledge sharing

- Local clubs where enthusiasts can exchange tips and experiences

- Manufacturer Resources:

- Official websites offering technical specifications and support

- Access to original parts and specialized tools

Utilizing these resources can greatly enhance your understanding and ability to work on various engines, empowering you to tackle challenges with confidence.