Repairing Your Singer Treadle Sewing Machine

Maintaining and rejuvenating classic devices can be a rewarding endeavor, connecting enthusiasts with the craftsmanship of the past. This section focuses on the essential techniques and guidelines to breathe new life into a beloved apparatus, ensuring its functionality and aesthetic appeal.

Understanding the fundamental components and their interrelations is crucial for successful revitalization. By delving into troubleshooting strategies and upkeep tips, users can confidently navigate common challenges. With the right approach, even the most aged items can regain their former glory, becoming cherished pieces for generations to come.

Preservation and restoration not only enhance the operational capabilities of these vintage treasures but also preserve their historical significance. Engaging with this process fosters a deeper appreciation for the intricate design and engineering that went into creating such enduring pieces.

Vintage sewing devices often present a range of challenges that can affect their performance. Understanding these issues can help enthusiasts maintain and restore functionality.

- Unresponsive Foot Pedal: The foot pedal may become stuck or fail to engage properly, leading to a lack of power transfer.

- Thread Snags: Improper threading can cause frequent snags, disrupting the stitching process.

- Uneven Stitching: Variations in stitch length or tension may occur, often due to mechanical wear or incorrect settings.

- Rust and Corrosion: Exposure to moisture can lead to rust on metal components, hindering movement and function.

- Worn Belts: Belts that drive the mechanism may become frayed or stretched over time, reducing efficiency.

Regular maintenance and prompt attention to these common problems can ensure that these classic devices remain functional and enjoyable to use.

Tools Needed for Repairs

To successfully address issues with your vintage apparatus, having the right instruments at hand is essential. These implements will facilitate the process, ensuring effective adjustments and enhancements.

Essential Instruments

Gather items such as precision screwdrivers, pliers, and a sturdy work surface. These tools will allow you to carefully access and manipulate various components.

Additional Supplies

It’s also beneficial to have lubricants and cleaning materials. Proper maintenance can significantly improve functionality and prolong the lifespan of your equipment. Regular upkeep is crucial for optimal performance.

Step-by-Step Repair Process

This section outlines a comprehensive approach to addressing common issues encountered with vintage crafting tools. By following these systematic steps, users can restore functionality and extend the lifespan of their equipment.

Preparation

- Gather necessary tools and materials, including screwdrivers, lubricants, and cleaning cloths.

- Ensure the workspace is clean and well-lit to facilitate detailed work.

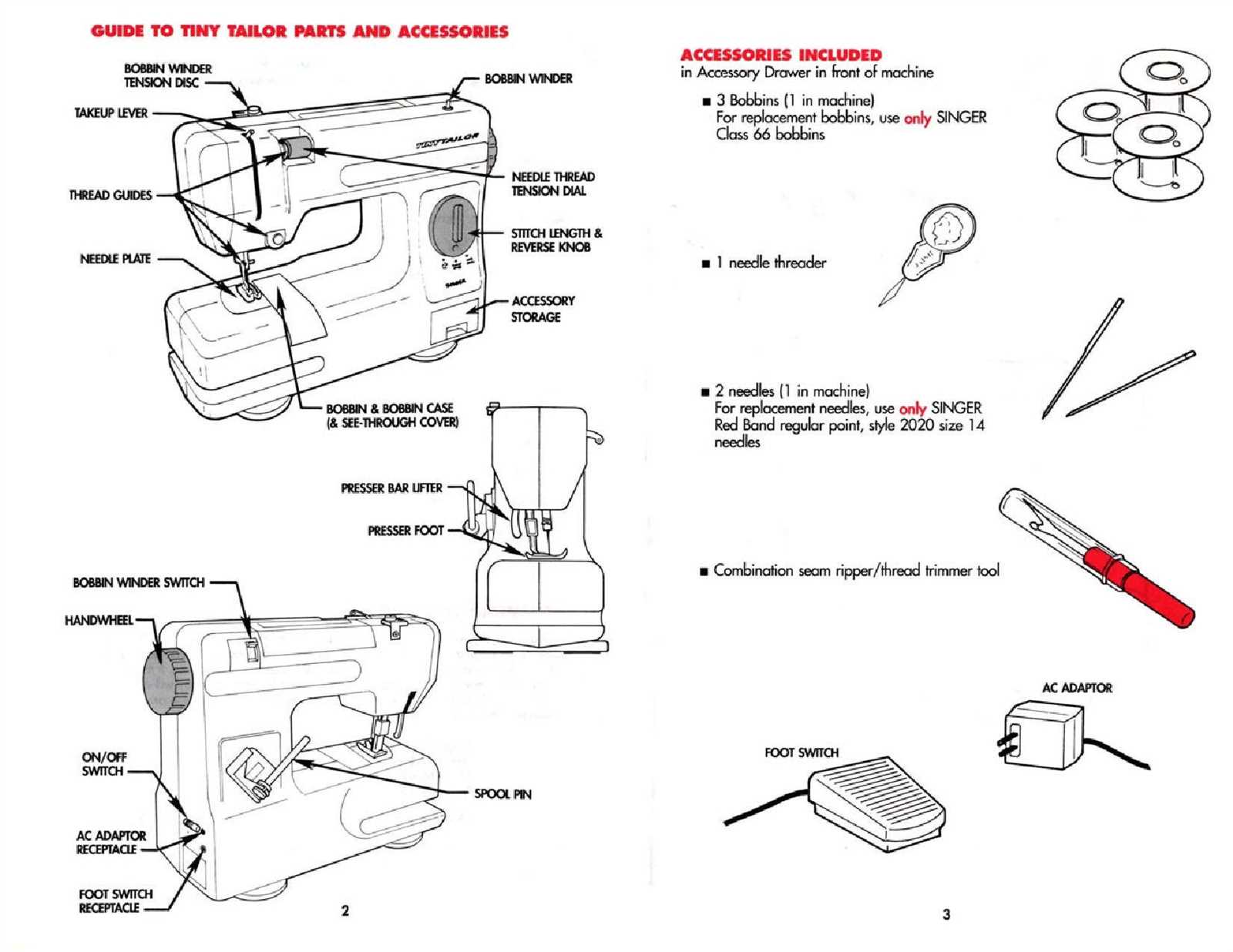

- Review any available documentation to familiarize yourself with the specific components.

Inspection

- Carefully examine the apparatus for visible signs of wear or damage.

- Test the movement of moving parts to identify any obstructions or stiffness.

- Check for loose screws and fittings that may affect operation.

Following these initial steps will help identify potential issues that need to be addressed during the restoration process.

How to Maintain Your Machine

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By incorporating simple habits into your routine, you can prevent potential issues and enhance the functionality of your device.

Routine Cleaning

Cleaning your device regularly is crucial. Dust and debris can accumulate, affecting its efficiency. Use a soft cloth to wipe down the exterior and a gentle brush to remove any particles from moving parts. Lubrication of key components is also necessary to ensure smooth operation.

Periodic Inspections

Conducting frequent inspections can help identify wear and tear before it becomes a serious problem. Check belts and other vital components for signs of damage. If you notice any irregularities, it’s best to address them promptly to avoid more extensive repairs in the future. Maintaining awareness of your equipment’s condition will help extend its life.

Troubleshooting Threading Problems

Addressing issues related to the threading process is essential for ensuring smooth operation of your equipment. Common challenges may arise during this stage, leading to frustration and interruptions in your workflow.

To begin, check that the thread is properly seated within the tension discs. If the thread is not positioned correctly, it can lead to inconsistent stitching or even breakage. Additionally, ensure that the threading path follows the designated route outlined in your guidelines.

Next, inspect the needle for any signs of damage or wear. A bent or dull needle can disrupt the threading and cause problems while in use. Replacing the needle with a new one can often resolve these issues.

Lastly, consider the quality of the thread itself. Using the wrong type or an inferior quality can result in complications during the threading process. Opt for a high-quality thread that is suitable for your specific requirements.

Adjusting Tension Settings Correctly

Properly calibrating the tension settings is crucial for achieving optimal results when working with fabric. When the tension is too tight or too loose, it can lead to various issues such as puckering or uneven stitches. Understanding how to adjust these settings will greatly enhance your crafting experience.

Understanding Tension Settings

Tension refers to the amount of pull on the thread during the stitching process. It is important to find the right balance for different types of fabrics. Different materials may require varying degrees of tension to produce clean, professional-looking seams.

Steps to Adjust Tension

Follow these steps to ensure your thread tension is set correctly:

| Step | Action |

|---|---|

| 1 | Identify the tension dial on your apparatus. |

| 2 | Start with a moderate setting, usually indicated on the dial. |

| 3 | Test on a scrap piece of the same fabric. |

| 4 | Observe the stitching. Adjust the dial up or down as needed. |

| 5 | Repeat the test until the desired result is achieved. |

Cleaning and Lubricating Parts

Regular maintenance is essential to ensure optimal performance and longevity of your equipment. This section focuses on the importance of cleaning and lubricating components, helping to prevent wear and tear and maintain smooth operation.

Essential Tools and Materials

- Soft cloths

- Brushes (small and soft-bristled)

- Lubricating oil

- Grease (if applicable)

- Compressed air (optional)

Cleaning Process

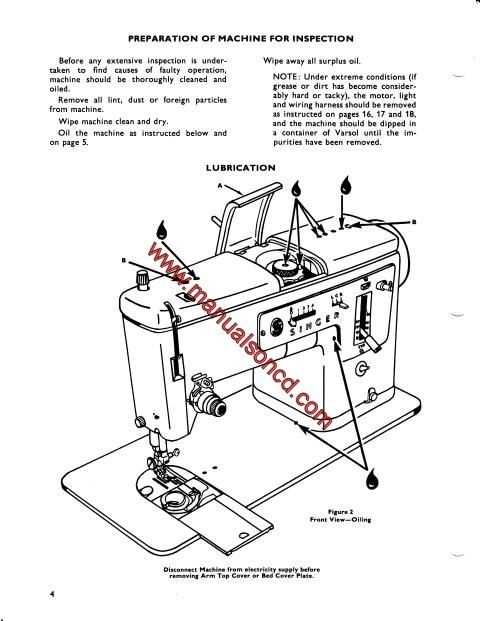

- Begin by unplugging the device to ensure safety.

- Use a soft cloth to wipe down the exterior surfaces, removing dust and debris.

- For intricate parts, employ a small brush to dislodge particles from hard-to-reach areas.

- If necessary, use compressed air to blow away stubborn dust from crevices.

Maintaining cleanliness is vital, as accumulated dirt can hinder performance and cause damage over time.

Lubrication Tips

- Identify the parts that require lubrication, such as moving components and pivot points.

- Apply a small amount of lubricating oil to each specified area, being careful not to over-saturate.

- For any components that require grease, use an appropriate amount and ensure even distribution.

Proper lubrication reduces friction and promotes smooth functionality, enhancing the overall efficiency of the unit.

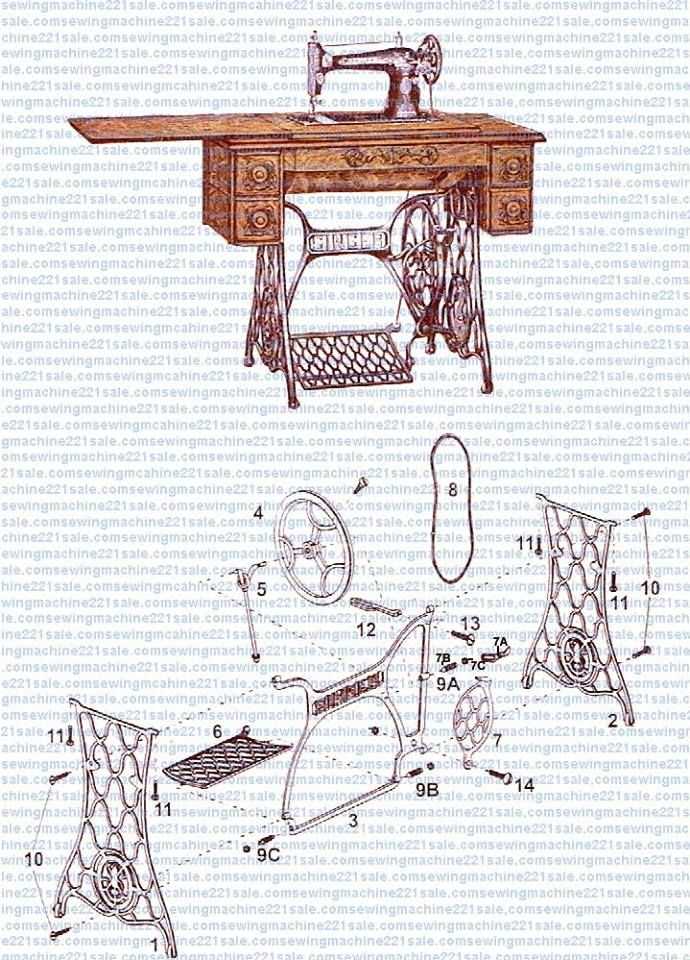

Replacing Worn-Out Components

Over time, certain elements of your unit may experience wear and tear, impacting its overall functionality. Addressing these issues promptly can enhance performance and extend the lifespan of your equipment. Understanding how to identify and replace these components is essential for maintaining efficiency.

Here are the common parts that may need replacement:

- Belts: These can become stretched or cracked, affecting motion.

- Bobbin case: A damaged or worn bobbin case can lead to thread jams.

- Needles: Dull or bent needles can result in poor stitching quality.

- Feed dogs: Worn feed dogs can cause inconsistent fabric feeding.

To effectively replace these components, follow these steps:

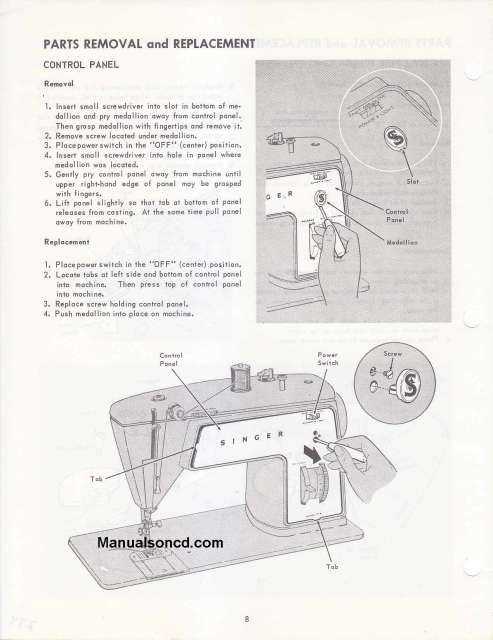

- Identify the worn part by examining the unit during operation.

- Carefully remove the old component using appropriate tools.

- Install the new part, ensuring it fits securely and functions correctly.

- Test the unit after replacement to confirm proper operation.

Regular maintenance and timely replacement of components will ensure optimal performance and longevity of your unit.

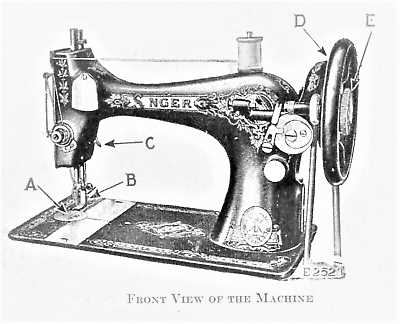

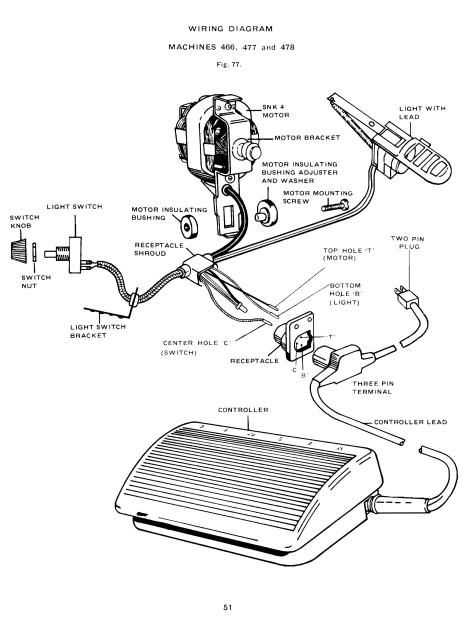

Understanding the Mechanism Functionality

This section delves into the intricate workings of a traditional foot-operated apparatus, highlighting its essential components and their roles in ensuring smooth operation. By comprehending how these elements interact, users can better appreciate the craftsmanship involved and identify areas for enhancement or maintenance.

Key Components

- Foot Pedal: This element initiates movement and controls speed, allowing the operator to adjust as needed.

- Connecting Rod: This component transfers motion from the foot pedal to the driving mechanism, playing a crucial role in the overall functionality.

- Flywheel: A vital part that stores rotational energy, helping to maintain a steady pace during operation.

- Needle Bar: Responsible for holding and guiding the needle, this part is integral for creating stitches.

Operational Principles

Understanding the principles behind operation is essential for effective use. The synergy between the foot pedal and the connecting rod allows for precise control of speed and rhythm. The flywheel’s momentum ensures consistent performance, while the needle bar’s precision affects the quality of the output.

Upgrading Your Treadle Machine

Enhancing your vintage foot-powered device can bring new life and functionality to a cherished item. This process not only improves performance but also maintains its historical charm. By making thoughtful upgrades, you can enjoy a more efficient and enjoyable experience.

Modern Features to Consider

Incorporating contemporary elements can greatly enhance usability. Here are some features to contemplate:

| Upgrade | Benefits |

|---|---|

| High-Quality Needles | Improved stitching accuracy and smoother operation. |

| Enhanced Tension System | Better control over fabric handling and stitch quality. |

| Upgraded Belt | Increased durability and responsiveness during use. |

| Reinforced Frame | Greater stability and longevity under regular use. |

Maintaining Authenticity

While modernizing, it’s essential to preserve the original character. Choose upgrades that complement the vintage aesthetic, ensuring the essence of the device remains intact. This balance between innovation and tradition will create a unique experience for users.

Resources for Further Assistance

For individuals seeking additional guidance on maintaining and restoring vintage equipment, a variety of valuable resources are available. These tools can enhance your understanding and help troubleshoot common issues.

- Online Forums: Engaging with communities dedicated to vintage apparatus can provide insights and solutions from experienced enthusiasts.

- YouTube Tutorials: Video guides offer visual demonstrations, making it easier to grasp complex tasks and techniques.

- Local Workshops: Many communities host classes or workshops focused on restoration and upkeep, allowing hands-on learning.

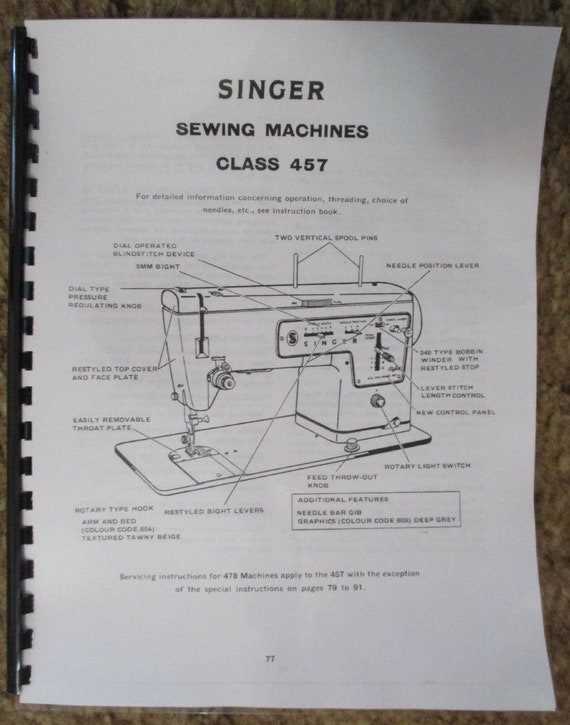

- Books and Guides: Numerous publications cover the history and maintenance of classic equipment, offering in-depth information.

Utilizing these resources can significantly improve your skills and confidence in working with vintage tools, ensuring they remain functional for years to come.

Historical Significance of Treadle Machines

The evolution of domestic textile fabrication tools marked a pivotal moment in the history of craftsmanship and industry. These tools transformed the way individuals engaged in garment creation and revolutionized household productivity.

During the 19th century, these devices became accessible to a broader audience, influencing social and economic dynamics. Their introduction played a crucial role in empowering individuals, particularly women, to take control of their clothing production.

- Accessibility: The rise of these devices allowed more families to engage in textile production without relying solely on commercial outlets.

- Independence: Users gained the ability to create personalized garments, fostering a sense of autonomy and creativity.

- Innovation: The mechanical advancements associated with these tools contributed to industrial progress and inspired further technological developments.

The impact of these instruments extends beyond practical use; they symbolize a shift in societal roles and economic structures. The ability to craft clothing at home not only alleviated financial burdens but also nurtured skills that would be passed down through generations.

In summary, the historical importance of these devices lies in their transformative influence on domestic life, empowering individuals and shaping societal norms.