Comprehensive Guide to New Holland TL100A Repair Manual

Understanding the intricacies of agricultural machinery is essential for efficient operation and longevity. This section aims to equip operators with the knowledge needed to maintain their equipment effectively, ensuring optimal performance and minimizing downtime.

From identifying common issues to implementing preventive measures, this guide delves into essential practices that contribute to the ultimate functionality of your machinery. Whether you are a seasoned professional or a novice, familiarizing yourself with these insights can enhance your skill set and confidence in handling equipment.

By exploring detailed procedures and offering practical tips, this resource serves as a valuable companion for anyone seeking to enhance their maintenance capabilities. Empower yourself with the tools to tackle challenges head-on and ensure your machinery remains in peak condition.

Understanding the New Holland TL100A

This section aims to explore the features and functionality of a specific agricultural machine designed for efficiency and versatility in various farming tasks. By delving into its specifications and capabilities, we can gain insights into how it enhances productivity on the field.

Key Features

The equipment is equipped with a robust engine that ensures reliable performance, making it suitable for heavy-duty applications. Its user-friendly interface allows operators to manage operations seamlessly, while the ergonomic design contributes to comfort during long working hours. Furthermore, the machine’s adaptability enables it to perform a range of tasks, from plowing to lifting, meeting the diverse needs of modern agriculture.

Maintenance Considerations

Common Issues in TL100A Tractors

Tractors in this category often encounter a variety of challenges that can affect their performance and efficiency. Understanding these common problems is crucial for operators and owners to ensure smooth operation and longevity of their machinery.

One frequent concern is the overheating of the engine, which can arise from inadequate coolant levels or a malfunctioning thermostat. Regular checks of the cooling system can help prevent this issue from escalating.

Another typical problem involves the transmission system, where operators may experience difficulty in shifting gears. This can be attributed to low fluid levels or worn components within the gearbox. Addressing these issues promptly is essential to maintain seamless functionality.

Additionally, electrical faults can disrupt operations, manifesting as battery drain or malfunctioning lights. These issues often stem from corroded connections or faulty wiring, necessitating thorough inspections of the electrical system.

Lastly, hydraulic system failures can lead to a decrease in operational effectiveness. Common signs include sluggish or unresponsive hydraulic functions, which may indicate leaks or air in the system. Regular maintenance is vital to keep these systems in optimal condition.

Essential Tools for Repairing TL100A

When undertaking maintenance or troubleshooting of agricultural machinery, having the right equipment is crucial for effective outcomes. This section highlights the key instruments and gadgets that facilitate the proper functioning and longevity of your equipment.

Basic Hand Tools

Start with a reliable set of wrenches, including both standard and metric sizes. These are essential for loosening and tightening various fasteners. Additionally, a quality screwdriver set is indispensable for dealing with different types of screws. Don’t forget pliers, which are invaluable for gripping and manipulating components.

Specialized Instruments

For more intricate tasks, consider investing in a multimeter to diagnose electrical issues. A torque wrench ensures that bolts are tightened to the manufacturer’s specifications, preventing potential damage. Lastly, a reliable hydraulic jack is necessary for safely lifting heavy parts during maintenance operations.

Step-by-Step Maintenance Guide

Regular upkeep is essential for ensuring optimal performance and longevity of your machinery. By following a structured approach, you can address various components effectively, preventing costly breakdowns and enhancing efficiency. This guide outlines systematic procedures to keep your equipment in peak condition.

1. Daily Checks

Begin each day with a thorough inspection. Check fluid levels, including engine oil, coolant, and hydraulic fluids. Ensure that all filters are clean and free from obstructions. Examine belts and hoses for wear or damage, and inspect tires for proper inflation and tread condition.

2. Weekly Maintenance

Conduct a more detailed review on a weekly basis. Clean the exterior to remove dirt and debris that could lead to corrosion. Lubricate moving parts as specified in your guidelines, and tighten any loose fasteners. Additionally, review safety systems to ensure they are fully operational.

Electrical System Troubleshooting Tips

Maintaining the integrity of an electrical system is crucial for optimal performance and longevity of machinery. When issues arise, systematic troubleshooting can help identify the root causes and restore functionality efficiently. Here are some essential strategies to guide you through diagnosing electrical problems.

1. Visual Inspection

Start with a thorough visual examination of all wiring, connectors, and components. Look for signs of wear, corrosion, or loose connections. Frayed wires or damaged insulation can lead to short circuits or failures. Make sure to check that all terminals are securely fastened, as a loose connection can disrupt the flow of electricity.

2. Use of Diagnostic Tools

Employing diagnostic equipment can significantly enhance your troubleshooting efforts. A multimeter is invaluable for checking voltage, current, and resistance levels. By testing circuit continuity, you can pinpoint problematic areas. Always ensure the equipment is calibrated for accurate readings, and consult any available schematics to understand the system layout better.

Engine Repair Techniques Explained

Understanding the methods involved in engine restoration is essential for maintaining optimal performance and longevity. This section will explore various approaches that can be employed to troubleshoot and enhance engine functionality, ensuring smooth operation and reliability.

Diagnosing Engine Issues

Effective diagnosis is the cornerstone of any successful engine intervention. It involves a systematic examination of symptoms, which may include unusual noises, poor performance, or excessive emissions. Utilizing tools such as compression testers, diagnostic scanners, and multimeters can aid in pinpointing underlying problems. Accurate assessment allows for targeted solutions, ultimately saving time and resources.

Reconditioning Components

Once issues have been identified, the next phase involves reconditioning critical components. Techniques such as cylinder honing and valve seat grinding can restore worn parts to their original specifications. Additionally, replacing gaskets and seals is crucial in preventing leaks and maintaining pressure. By focusing on these key areas, one can enhance overall engine efficiency and performance.

Hydraulic System Maintenance Essentials

Proper upkeep of hydraulic systems is crucial for ensuring optimal performance and longevity. Regular attention to key components can prevent costly failures and maintain efficiency. This section outlines fundamental practices that contribute to the smooth operation of hydraulic machinery.

Routine Inspections

Conducting frequent inspections is essential for identifying potential issues before they escalate. Look for signs of leaks, wear, or damage in hoses, fittings, and cylinders. Monitoring fluid levels and quality is equally important, as contaminated or low fluid can significantly impair system function.

Fluid Maintenance

Maintaining the right hydraulic fluid is vital for effective operation. Regularly change the fluid as recommended, and always use the manufacturer-recommended type. Filtration systems should also be checked and cleaned to ensure that impurities do not compromise the system’s integrity.

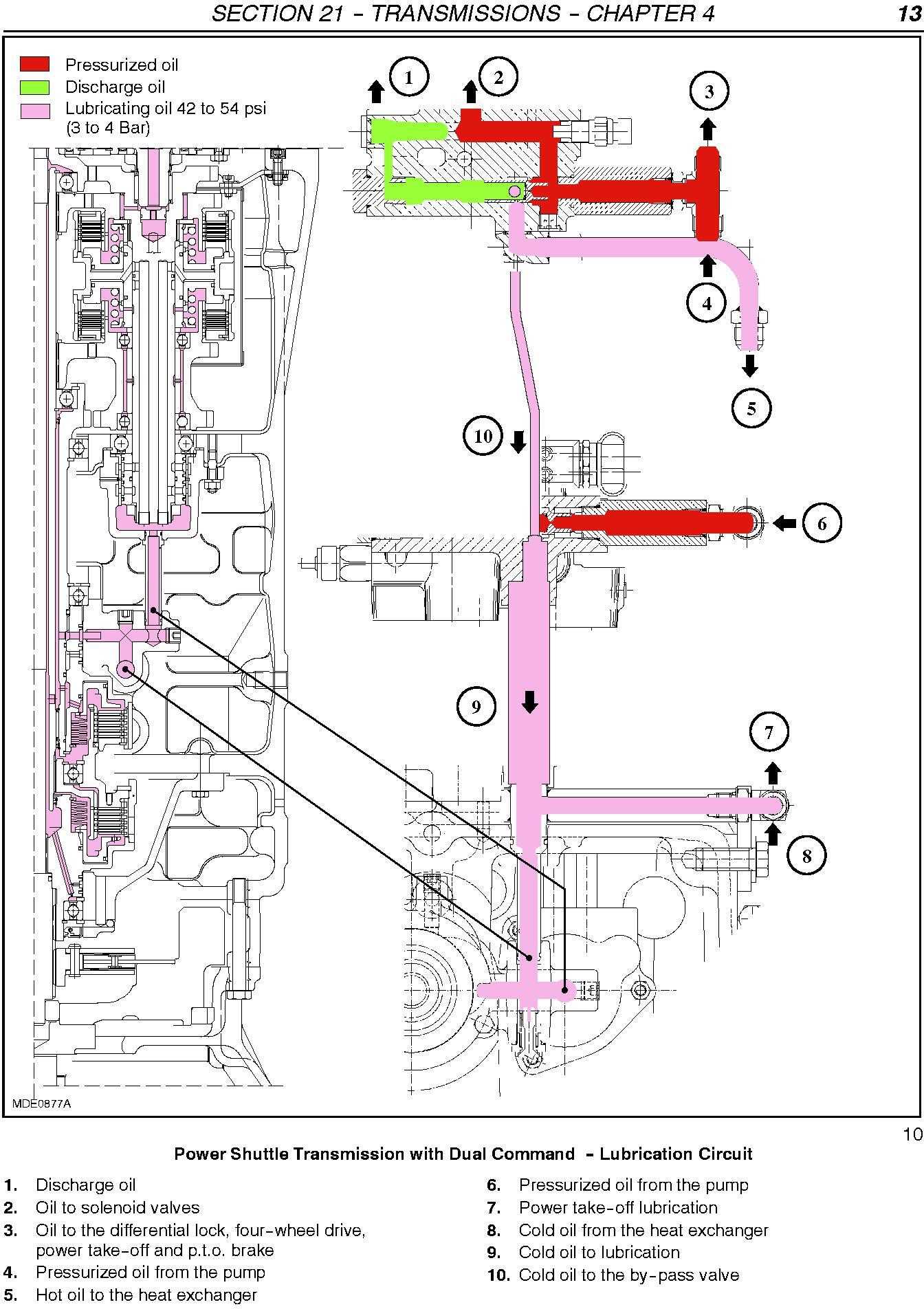

Transmission Problems and Solutions

Issues with the transmission can significantly impact the performance and efficiency of agricultural machinery. Recognizing common symptoms and understanding potential solutions is crucial for maintaining optimal functionality. Addressing these concerns promptly can prevent further complications and ensure seamless operation.

One frequent issue is slipping gears, which may be caused by low fluid levels or contaminated fluid. To resolve this, regularly check and replace the fluid according to the manufacturer’s recommendations. Additionally, inspect the seals and gaskets for wear, as this can lead to leaks that diminish fluid levels.

Another common challenge is difficulty in shifting gears, often resulting from worn-out components or inadequate lubrication. Ensure that the gear linkage is properly adjusted and lubricated. If problems persist, it may be necessary to examine the internal parts for signs of damage or excessive wear.

Overheating is also a significant concern, usually stemming from a blocked cooling system or low fluid levels. Regularly clean the cooling system and check for obstructions. Maintaining proper fluid levels and quality can also help mitigate overheating issues.

Finally, unusual noises during operation can indicate internal issues. Listen for grinding or clunking sounds, which may suggest worn gears or bearings. If such sounds are detected, a thorough inspection and replacement of damaged components may be necessary to restore proper function.

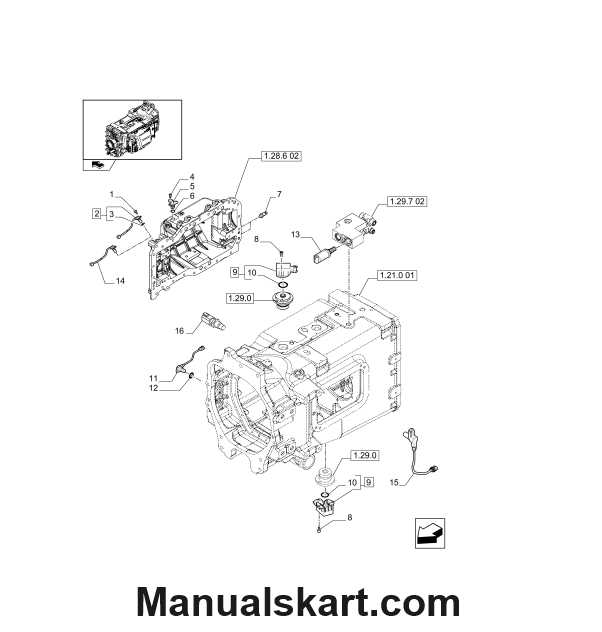

Common Parts Replacement Procedures

Replacing components in agricultural machinery is essential for maintaining optimal performance and longevity. Understanding the general steps involved in this process can enhance efficiency and reduce downtime.

Here are some common procedures to follow when replacing parts:

- Preparation:

- Ensure the equipment is turned off and secured.

- Gather all necessary tools and replacement parts.

- Refer to the appropriate documentation for guidance.

- Removal:

- Identify the component that needs to be replaced.

- Carefully disconnect any electrical or hydraulic connections.

- Unscrew or unfasten the part using the correct tools.

- Installation:

- Align the new component with the existing fittings.

- Secure it in place using the original screws or fasteners.

- Reconnect any electrical or hydraulic lines as needed.

- Testing:

- Turn on the machinery to check for proper operation.

- Look for any leaks or unusual noises.

- Perform a final inspection to ensure everything is secure.

By following these procedures, users can effectively manage part replacements, ensuring the machinery operates smoothly and reliably.

Safety Precautions During Repairs

Ensuring a secure working environment is paramount when undertaking maintenance tasks on machinery. Following essential safety guidelines can prevent accidents and promote a more efficient workflow. This section outlines critical measures to observe before, during, and after any service activities.

- Personal Protective Equipment (PPE):

- Wear safety goggles to protect your eyes from debris.

- Use gloves to safeguard your hands from sharp edges and chemicals.

- Ensure appropriate footwear is worn to minimize foot injuries.

- Workspace Preparation:

- Keep the area clean and organized to reduce trip hazards.

- Ensure proper ventilation, especially when working with chemicals.

- Have a first-aid kit readily accessible in case of emergencies.

- Equipment Safety:

- Always consult the operation guidelines before beginning any task.

- Disconnect power sources to prevent accidental starts.

- Use tools as intended to avoid malfunctions or injuries.

- Emergency Procedures:

- Know the location of emergency exits and fire extinguishers.

- Have a plan in place for reporting accidents or injuries.

- Practice safe lifting techniques to avoid back injuries.

By adhering to these essential safety protocols, individuals can mitigate risks and enhance their overall experience while working on machinery.

Where to Find Replacement Parts

Finding suitable components for machinery can be a challenging task, but several resources can simplify the process. Whether you’re looking for original or aftermarket options, exploring various avenues can lead you to the right solutions for your equipment needs.

- Authorized Dealers: Start with manufacturers’ authorized dealerships. They often stock genuine components that guarantee compatibility and quality.

- Online Retailers: Websites dedicated to machinery parts provide a wide range of choices. Popular platforms include:

- eBay

- Amazone

- Specialized machinery parts sites

- Local Parts Suppliers: Visit local suppliers who may carry essential items. Building a relationship with these vendors can also yield helpful advice.

- Salvage Yards: For those on a budget, salvage yards can be a treasure trove. You might find used but functional parts at a fraction of the cost.

- Forums and Community Groups: Engaging with online forums and local community groups can provide insights and recommendations on where to find specific components.

By exploring these options, you can enhance your chances of locating the right parts for your machinery efficiently and affordably.

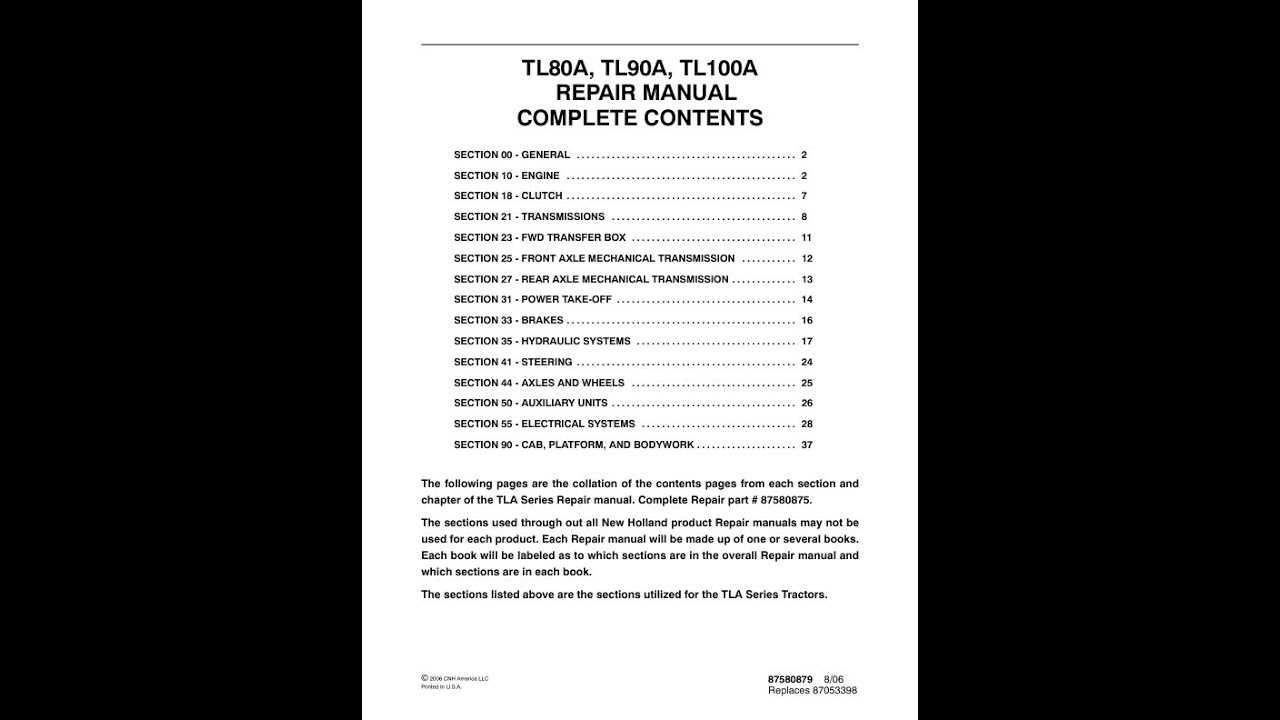

Using the Repair Manual Effectively

Utilizing a comprehensive guide can significantly enhance the efficiency and accuracy of maintenance tasks. By familiarizing yourself with the layout and content of the document, you can streamline your troubleshooting process and ensure that you follow the correct procedures for repairs and upkeep.

Here are some strategies to make the most of your guide:

- Familiarize Yourself with the Structure: Begin by understanding how the information is organized. Most guides are divided into sections such as diagnostics, maintenance, and specifications.

- Utilize the Index and Table of Contents: These tools help you quickly locate the specific information you need without wasting time.

- Read the Safety Precautions: Always prioritize safety by reviewing any warnings or safety tips before commencing work.

Additionally, consider these practical tips:

- Highlight Key Sections: Mark essential information for easy reference during repairs.

- Take Notes: Document your findings and observations as you work through the steps, which can be invaluable for future reference.

- Practice Patience: Some repairs may require time and careful attention. Rushing can lead to mistakes.

By approaching the guide methodically and with an organized mindset, you can enhance your skills and improve the reliability of your machinery.

Tips for Long-Term Tractor Care

Maintaining your agricultural machinery is essential for ensuring its longevity and optimal performance. By following a few best practices, you can significantly extend the lifespan of your equipment and minimize downtime. This section provides valuable insights into effective maintenance strategies that will keep your tractor in excellent working condition.

Regular Inspections: Schedule routine checks to identify any wear and tear before they become serious issues. Pay attention to critical components such as the engine, transmission, and hydraulic systems. Early detection can save time and costs in the long run.

Proper Lubrication: Ensure that all moving parts are adequately lubricated. This reduces friction and prevents premature wear. Always use the recommended lubricants specified in the manufacturer’s guidelines to maintain efficiency.

Fluid Levels: Regularly check and maintain appropriate fluid levels, including engine oil, coolant, and hydraulic fluid. Clean fluids promote better performance and prevent damage due to overheating or inadequate lubrication.

Cleanliness: Keep your equipment clean by washing it regularly to remove dirt, debris, and chemicals that can lead to corrosion. A clean machine is easier to inspect and can function more efficiently.

Storage Conditions: When not in use, store your tractor in a sheltered environment to protect it from the elements. Use tarps or covers to shield it from dust and moisture, which can cause deterioration over time.

Follow the Maintenance Schedule: Adhere to the manufacturer’s recommended maintenance schedule. This includes servicing, part replacements, and inspections to ensure that your machinery operates smoothly and reliably.

By implementing these practices, you can achieve a high level of care for your tractor, enhancing its reliability and efficiency for years to come.