Zexel Injector Pump Repair Guide

The intricacies of fuel distribution mechanisms are critical to the optimal performance of engines. Understanding the various components involved and their functions is essential for anyone looking to maintain or enhance the efficiency of these systems. This section delves into the processes and considerations necessary for effective servicing and troubleshooting.

When addressing issues within these complex systems, it is important to approach the task with a comprehensive plan. Familiarity with the construction and functionality of each part allows for precise diagnostics and effective interventions. This guide provides insights into systematic techniques that facilitate the rejuvenation of these vital assemblies.

By equipping oneself with the right knowledge and tools, one can significantly extend the lifespan and reliability of fuel delivery units. The following sections will outline step-by-step procedures and offer tips to ensure successful maintenance practices that contribute to enhanced engine performance.

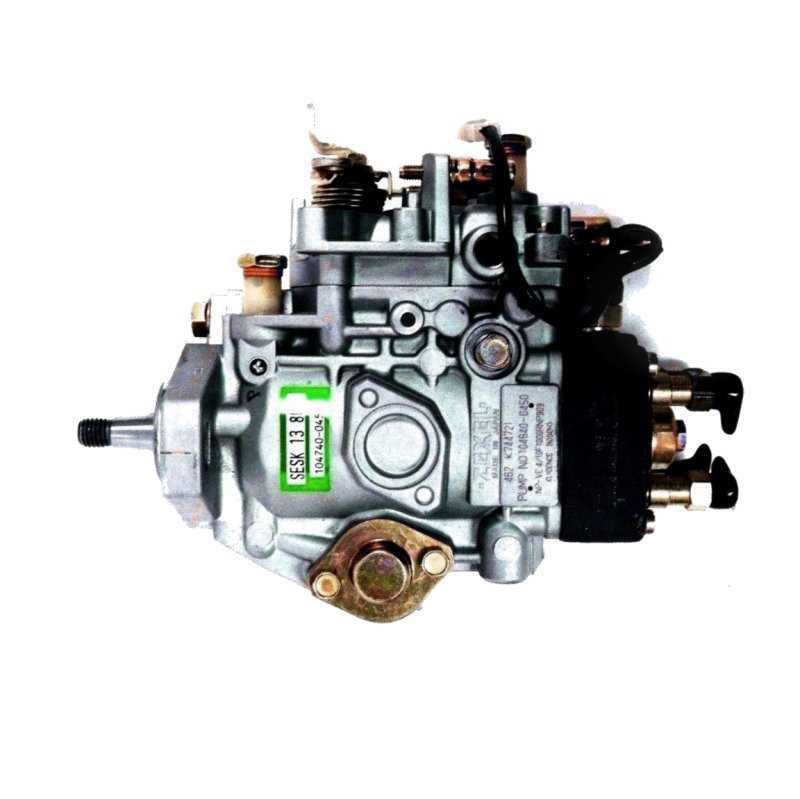

Understanding Zexel Injector Pumps

This section delves into the intricacies of a specific fuel delivery device widely utilized in various engine systems. These units play a crucial role in optimizing combustion efficiency and ensuring reliable performance across a range of applications.

The essential function of this mechanism revolves around managing the precise timing and amount of fuel fed into the combustion chamber. By facilitating an efficient mix of air and fuel, it enhances overall engine performance, reduces emissions, and promotes smoother operation.

Maintaining the functionality of such components is vital for vehicle longevity. Regular assessments and appropriate interventions can prevent common issues that may arise, such as improper fuel distribution or wear and tear on critical parts. Understanding the operational principles and potential faults is crucial for effective upkeep.

Overall, knowledge of this technology empowers users and technicians alike to ensure optimal performance and longevity, ultimately contributing to enhanced vehicle reliability.

Common Issues with Injector Pumps

Fuel delivery mechanisms are crucial components in diesel engines, and various problems can arise that affect their performance. Understanding these common challenges can help in maintaining efficiency and reliability.

One frequent issue is leakage, which can occur due to worn seals or damaged components. This can lead to reduced pressure and inconsistent fuel flow, ultimately impacting engine performance.

Another common concern is clogging, often caused by contaminants in the fuel. This blockage can restrict the flow and lead to inefficient operation, resulting in poor engine response and increased emissions.

Noise is also a key indicator of underlying problems. Unusual sounds may signal misalignment or internal damage, necessitating immediate attention to avoid further complications.

Finally, inaccurate timing can severely affect engine operation. Misalignment of the timing mechanism can lead to improper fuel delivery, causing a range of performance issues from hard starting to rough idling.

Tools Needed for Repair

When undertaking maintenance on complex fuel delivery systems, having the right equipment is essential for achieving optimal results. The proper tools not only facilitate the process but also ensure accuracy and efficiency, reducing the likelihood of errors that could lead to further complications.

Essential Equipment

Start with basic hand tools such as wrenches and screwdrivers, which are vital for loosening and tightening components. Additionally, specialty tools designed for specific tasks, such as alignment gauges and torque wrenches, can enhance precision during assembly. A reliable socket set will also be beneficial for accessing hard-to-reach fasteners.

Safety Gear

Safety should never be overlooked. Protective gloves and eyewear are necessary to shield against potential hazards. Moreover, a well-lit workspace is crucial for visibility, ensuring that every step of the process can be performed safely and effectively.

Step-by-Step Disassembly Guide

This section provides a comprehensive approach to taking apart a specific assembly, ensuring that each component is handled with care. Understanding the sequence of actions required for disassembly is crucial for successful reassembly and functionality.

1. Preparation: Begin by gathering all necessary tools, such as screwdrivers, wrenches, and safety equipment. Ensure that the workspace is clean and organized to facilitate a smooth process.

2. Safety Measures: Before starting, disconnect any power sources to prevent accidental activation. It’s essential to wear appropriate safety gear, including gloves and goggles, to protect against potential hazards.

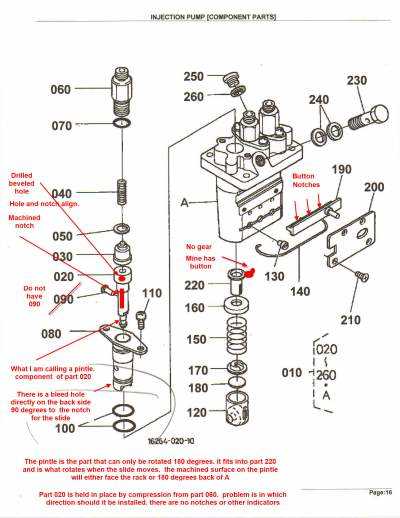

3. Initial Assessment: Examine the assembly carefully, noting the arrangement of parts and any specific connectors or fasteners. This will help in identifying the steps to follow during disassembly.

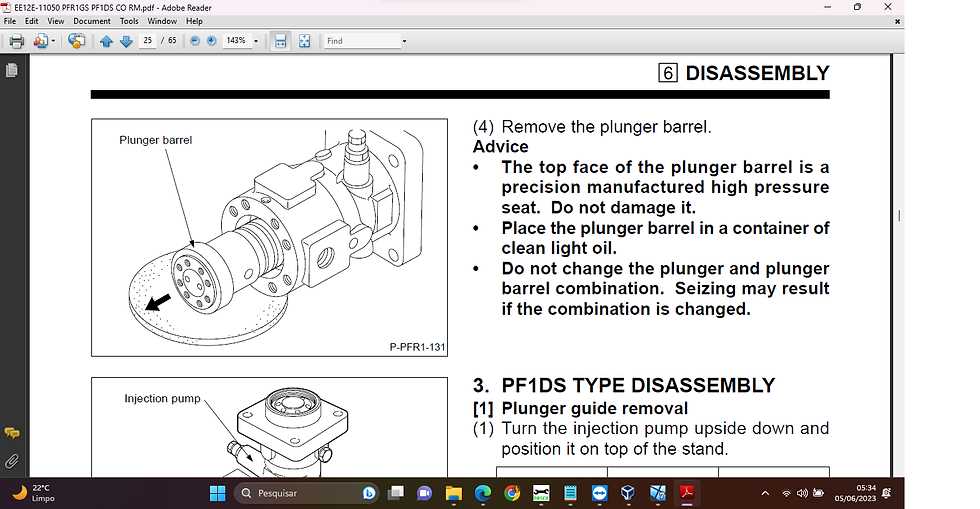

4. Removal of Outer Components: Start by detaching any outer casings or covers. This typically involves unscrewing bolts or clips that secure the outer parts to the assembly.

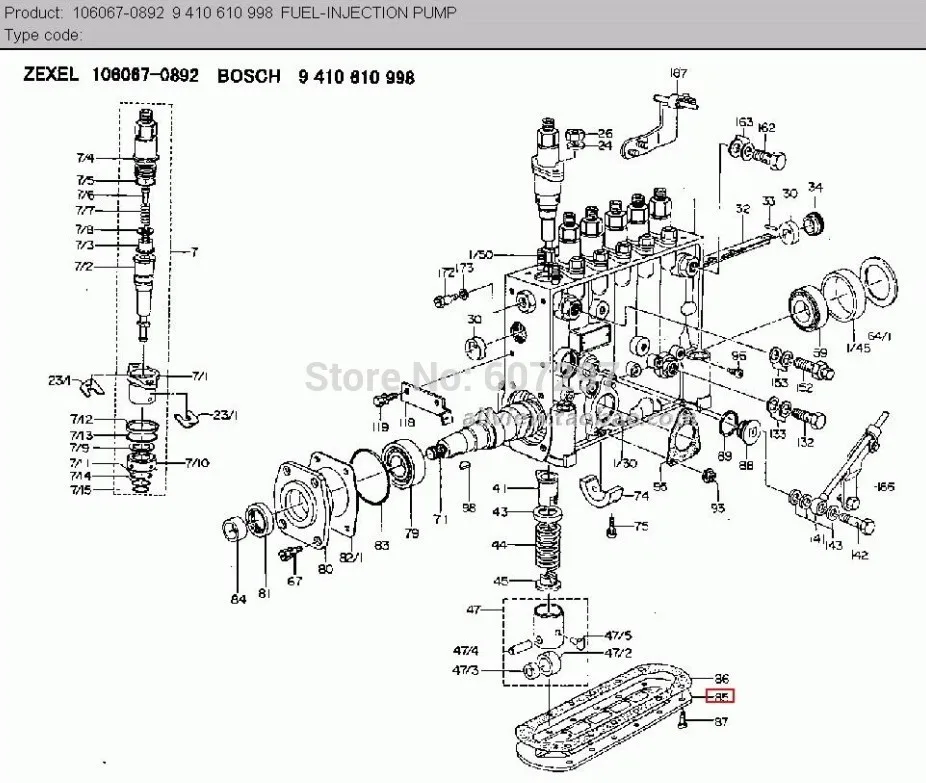

5. Accessing Internal Parts: Once the outer components are removed, locate and unfasten any internal elements. Take care to keep track of all screws and small pieces, as they are vital for reassembly.

6. Component Separation: Gradually separate the internal parts, ensuring to follow the correct order. Use gentle pressure to avoid damaging any sensitive areas during the process.

7. Documentation: Throughout the disassembly, document each step taken and the condition of the components. This record will serve as a valuable reference for reassembly and troubleshooting.

8. Final Inspection: After all parts are removed, conduct a thorough inspection of each component for wear or damage. This will inform any necessary maintenance or replacement before reassembly.

Following these steps diligently will facilitate a successful disassembly process, preparing the assembly for further work or modifications.

Identifying Component Failures

Recognizing malfunctions within critical machinery is essential for maintaining optimal performance. Understanding the signs of wear or dysfunction can aid in diagnosing issues before they escalate into more significant problems. This section will outline key indicators of component failures that operators and technicians should monitor regularly.

Common symptoms may manifest through unusual sounds, fluctuating performance, or inconsistent functionality. By systematically evaluating these signs, one can effectively pinpoint the source of the trouble. The following table summarizes various indicators along with their potential implications:

| Indicator | Possible Cause | Recommended Action |

|---|---|---|

| Unusual noises | Worn bearings or internal components | Inspect and replace affected parts |

| Inconsistent operation | Blockages or leaks | Clean and check for leaks |

| Overheating | Insufficient lubrication or excessive load | Verify lubrication levels and reduce load |

| Reduced efficiency | Wear and tear on moving parts | Conduct a thorough inspection and service |

Regular monitoring and timely intervention can significantly extend the lifespan of equipment and ensure its reliable operation. By staying vigilant and proactive, potential failures can be mitigated effectively.

Reassembly Techniques for Efficiency

Effective reassembly is crucial for maintaining optimal functionality and longevity of mechanical systems. Employing systematic techniques can significantly enhance the efficiency of this process, ensuring that each component aligns perfectly and operates smoothly.

Organizing Components

Before beginning the reassembly, categorize and arrange all parts logically. This method not only minimizes confusion but also streamlines the workflow. Utilizing trays or containers to separate components by type or size can facilitate quick access during the reassembly process.

Utilizing Proper Tools

Employing the right instruments is essential for achieving precision during reassembly. Ensure that all tools are in good condition and suited for the specific tasks at hand. Utilizing torque wrenches and calibrated measuring tools can help maintain the integrity of the assembly, preventing damage and enhancing overall performance.

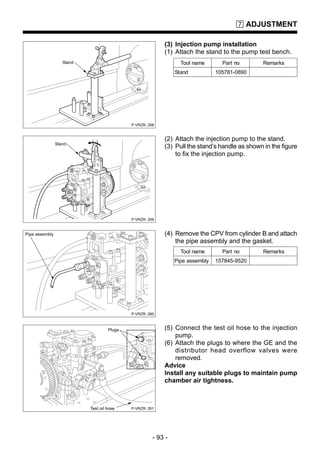

Testing Injector Pump Functionality

Assessing the performance of fuel delivery systems is essential to ensure optimal operation and efficiency. Proper evaluation helps identify issues that may hinder performance or lead to greater complications if not addressed promptly.

To initiate the assessment, it is crucial to inspect various components for any signs of wear or damage. Visual inspections can reveal leaks, cracks, or other irregularities that may affect functionality. After the initial examination, functional testing is performed to measure the system’s response under controlled conditions.

Utilizing specialized equipment allows for the measurement of pressure and flow rates, providing valuable insights into performance metrics. Comparing these values to manufacturer specifications helps determine if the system operates within acceptable parameters. Regular testing and maintenance can significantly enhance longevity and reliability.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires consistent care and attention. Implementing a routine maintenance schedule can greatly enhance performance and extend the lifespan of critical components.

Regular Inspections: Conduct thorough assessments of all parts to identify wear and tear. Early detection of issues can prevent more significant problems down the line.

Proper Cleaning: Keep the system clean to avoid the buildup of debris and contaminants. Use appropriate cleaning agents that won’t harm the internal mechanisms.

Lubrication: Ensure that all moving parts are adequately lubricated. This reduces friction and minimizes the risk of overheating, which can lead to premature failure.

Quality Fuel: Always use high-quality fuel to prevent clogging and damage to sensitive components. Contaminated fuel can drastically reduce efficiency and cause operational issues.

Timely Replacement: Replace worn-out components as soon as they are identified. Ignoring these can lead to further damage and costly repairs.

Operating Conditions: Avoid operating under extreme conditions whenever possible. Excessive heat, cold, or moisture can adversely affect performance and longevity.

Common Mistakes to Avoid

When undertaking maintenance tasks, it’s essential to be aware of typical pitfalls that can lead to complications or suboptimal performance. Recognizing these common errors can save time, resources, and ensure a more effective outcome.

Neglecting Proper Calibration

One of the most frequent oversights is failing to adjust settings correctly. Inaccurate calibration can lead to inefficiencies and damage. Always double-check specifications before proceeding.

Using Incorrect Components

Another major mistake is opting for unsuitable parts. Choosing the wrong elements can compromise the entire system’s integrity. Always verify compatibility and specifications to ensure optimal functionality.

Upgrading Components for Performance

Enhancing the efficiency of fuel delivery systems can lead to significant improvements in overall vehicle performance. By focusing on specific elements within the assembly, one can achieve better fuel atomization, increased power output, and enhanced responsiveness. This section explores key upgrades that can elevate performance metrics while ensuring reliability.

When considering modifications, it is crucial to evaluate components that have the most impact on functionality. The following table outlines common upgrades and their benefits:

| Component | Upgrade Type | Benefits |

|---|---|---|

| Fuel Distribution | High-Flow Nozzles | Improved fuel spray pattern and atomization |

| Control Unit | Performance Chip | Enhanced engine mapping for optimized fuel delivery |

| Pressure Regulation | Adjustable Pressure Regulator | Increased fuel pressure for better combustion efficiency |

| Fuel Filtration | High-Performance Filter | Superior filtration for cleaner fuel supply |

By strategically upgrading these components, one can unlock greater potential in the system, resulting in a more powerful and efficient operation.

Safety Precautions During Repair

Ensuring safety during maintenance activities is crucial to prevent accidents and ensure the well-being of the technician. Various risks are associated with handling machinery and components, and adhering to specific guidelines can significantly reduce these dangers.

Essential Safety Guidelines

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and steel-toed boots.

- Work in a well-ventilated area to avoid inhaling harmful fumes and ensure proper airflow.

- Keep the workspace clean and organized to minimize the risk of slips and falls.

Handling Tools and Equipment

- Inspect tools before use to ensure they are in good condition and safe for operation.

- Use tools only for their intended purpose to avoid damage and potential injury.

- Store tools properly after use to prevent accidents and maintain an orderly workspace.

By following these guidelines, technicians can create a safer environment while working on machinery, reducing the likelihood of accidents and injuries. Prioritizing safety not only protects individuals but also contributes to the overall efficiency of the maintenance process.

Frequently Asked Questions

This section addresses common inquiries related to the maintenance and functionality of fuel delivery systems. Here, you will find answers that help clarify processes, enhance understanding, and provide guidance for troubleshooting various issues.

What are the common signs of malfunctioning components?

Typically, signs include poor engine performance, unusual noises, and excessive emissions. It is essential to monitor these indicators to ensure optimal operation.

How often should maintenance be performed?

Regular upkeep is crucial for longevity. It’s advisable to check components at specified intervals, usually every few thousand miles or as recommended by manufacturers. Timely interventions can prevent more severe complications.

Resources for Further Learning

For those seeking to deepen their understanding of fuel delivery systems, a variety of educational materials and references are available. These resources can enhance knowledge and skills related to the maintenance and functionality of these vital components in vehicles.

Consider exploring the following types of materials:

- Books and Guides: Look for comprehensive texts that cover the fundamentals and advanced topics related to fuel systems.

- Online Courses: Various platforms offer courses that provide detailed insights into system operation and troubleshooting techniques.

- Technical Journals: Academic and industry journals can provide the latest research and developments in fuel technology.

- Video Tutorials: Online video platforms host numerous tutorials that visually demonstrate repair and maintenance processes.

- Forums and Communities: Engage with fellow enthusiasts and professionals in online forums to share experiences and gather advice.

Utilizing these resources can significantly improve proficiency and confidence in managing and understanding fuel system components.