Troy Bilt Pressure Washer Repair Guide

Understanding the intricacies of maintaining your outdoor cleaning equipment is essential for optimal performance. This section aims to provide comprehensive insights and strategies to enhance the longevity and efficiency of your machinery. By following these guidelines, you can ensure that your device operates smoothly, tackling various cleaning tasks with ease.

From troubleshooting common issues to implementing preventive measures, this guide will equip you with the knowledge needed to handle various situations. Emphasizing the importance of regular upkeep, it highlights key components and their functions, enabling you to diagnose and resolve problems effectively.

Whether you are a novice or an experienced user, familiarizing yourself with the maintenance processes will empower you to take charge of your equipment. Adopting a proactive approach not only improves functionality but also extends the lifespan of your device, making your investment worthwhile.

Common Issues and Solutions

This section addresses frequently encountered problems and their corresponding solutions, aimed at enhancing the performance and longevity of your equipment. Understanding these common challenges can assist users in effectively troubleshooting and maintaining their devices.

-

Device Won’t Start:

If the machine fails to initiate, check the following:

- Ensure that the power source is connected.

- Inspect the fuse or circuit breaker for any issues.

- Verify that the on/off switch is in the correct position.

-

Insufficient Output:

If the performance is lacking, consider these steps:

- Examine the nozzle for blockages or damage.

- Check the hose for kinks or leaks.

- Ensure that the filter is clean and unobstructed.

-

Unusual Noises:

Strange sounds can indicate various issues:

- Listen for any grinding noises, which may suggest internal wear.

- Check for loose components that might be vibrating during operation.

- Inspect the pump for signs of malfunction or debris buildup.

-

Leaks:

Water leakage can be troublesome:

- Identify the source of the leak, whether from hoses, fittings, or seals.

- Tighten any loose connections and replace worn-out seals.

- Ensure that all components are properly assembled.

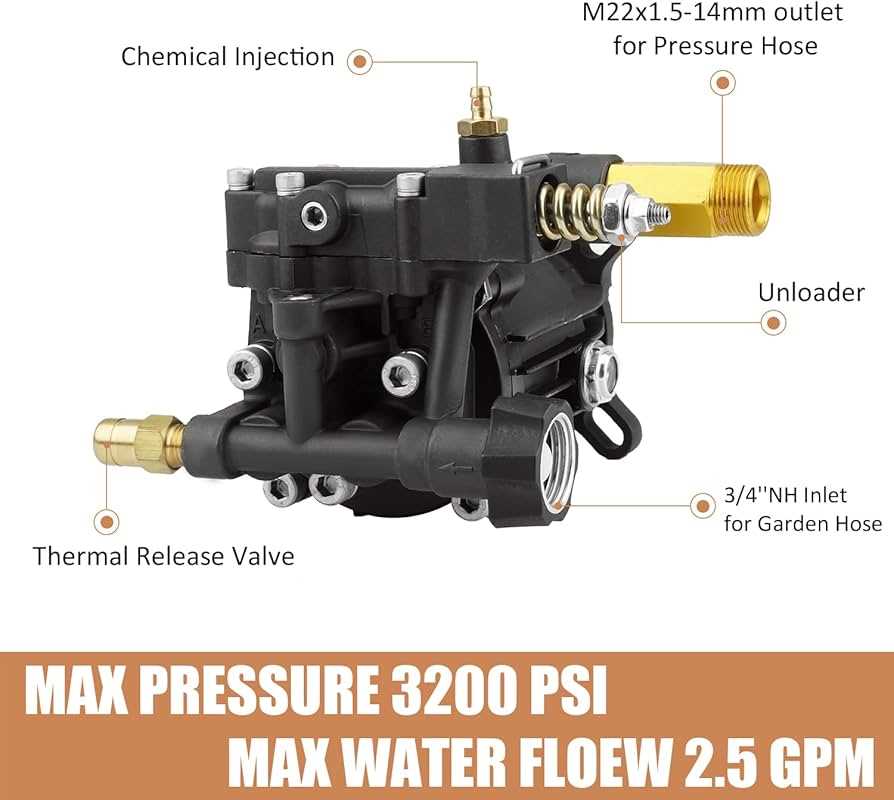

Understanding Pressure Washer Components

This section provides an overview of the essential elements that contribute to the efficient operation of high-powered cleaning equipment. Familiarity with these components can enhance maintenance practices and troubleshooting skills.

Main Elements

- Engine: The power source that drives the entire system, providing the necessary energy for operation.

- Water Pump: Responsible for drawing water and pressurizing it, enabling effective cleaning.

- Hoses: Facilitate the movement of water from the pump to the nozzle, often available in various lengths and diameters.

- Nozzle: Directs the flow of water, allowing for adjustable pressure and spray patterns based on the cleaning task.

- Frame: The structural foundation that supports and houses the various components, ensuring stability during use.

Additional Features

- Filters: Protect the pump from debris, ensuring a clean water supply and prolonging the lifespan of the equipment.

- Accessory Ports: Allow for the attachment of various tools, enhancing versatility for different cleaning applications.

- Control Panel: The interface for operating and adjusting settings, providing users with control over the machine’s functions.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires regular upkeep and attention. By following specific guidelines, you can enhance the lifespan of your device and maintain its efficiency throughout its use.

Regular Cleaning

- Remove any debris or dirt after each use.

- Clean filters and nozzles to prevent clogs.

- Inspect hoses for wear and replace if necessary.

Routine Inspections

- Check for leaks in connections and seals.

- Examine the motor for any unusual noises or vibrations.

- Ensure all moving parts are lubricated as recommended.

By implementing these maintenance practices, you will significantly extend the life of your equipment and ensure it operates smoothly for years to come.

Safety Precautions During Repairs

Ensuring a secure environment while addressing equipment issues is crucial for both personal safety and effective maintenance. Following proper guidelines can help prevent accidents and ensure a smooth process.

- Always wear appropriate personal protective equipment, such as gloves and safety goggles.

- Disconnect the power source before starting any work to avoid accidental activation.

- Work in a well-ventilated area to minimize exposure to harmful fumes.

- Keep your workspace organized to avoid tripping hazards and misplaced tools.

- Read the manufacturer’s instructions thoroughly to understand the equipment’s specifics.

By adhering to these essential safety measures, you can minimize risks and enhance your repair experience.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to diagnosing and resolving common issues that may arise with your equipment. By following these systematic steps, you can effectively identify the root cause of any malfunction and implement appropriate solutions.

1. Check Fuel Level

Ensure that there is an adequate supply of fuel in the tank. Insufficient fuel can lead to starting problems or inconsistent performance.

2. Inspect the Air Filter

A clogged air filter can restrict airflow, affecting efficiency. Remove the filter and clean or replace it as needed.

3. Examine the Spark Plug

Inspect the spark plug for signs of wear or damage. A faulty spark plug can prevent ignition. Clean or replace it to restore functionality.

4. Verify Hose Connections

Check all connections for leaks or blockages. Ensure that hoses are securely attached and free from kinks.

5. Test for Proper Pressure

If performance seems inadequate, measure the output pressure. Low pressure may indicate issues with the pump or nozzles.

6. Consult the Documentation

Refer to the user documentation for specific troubleshooting tips related to your model. This resource can provide valuable insights and detailed instructions.

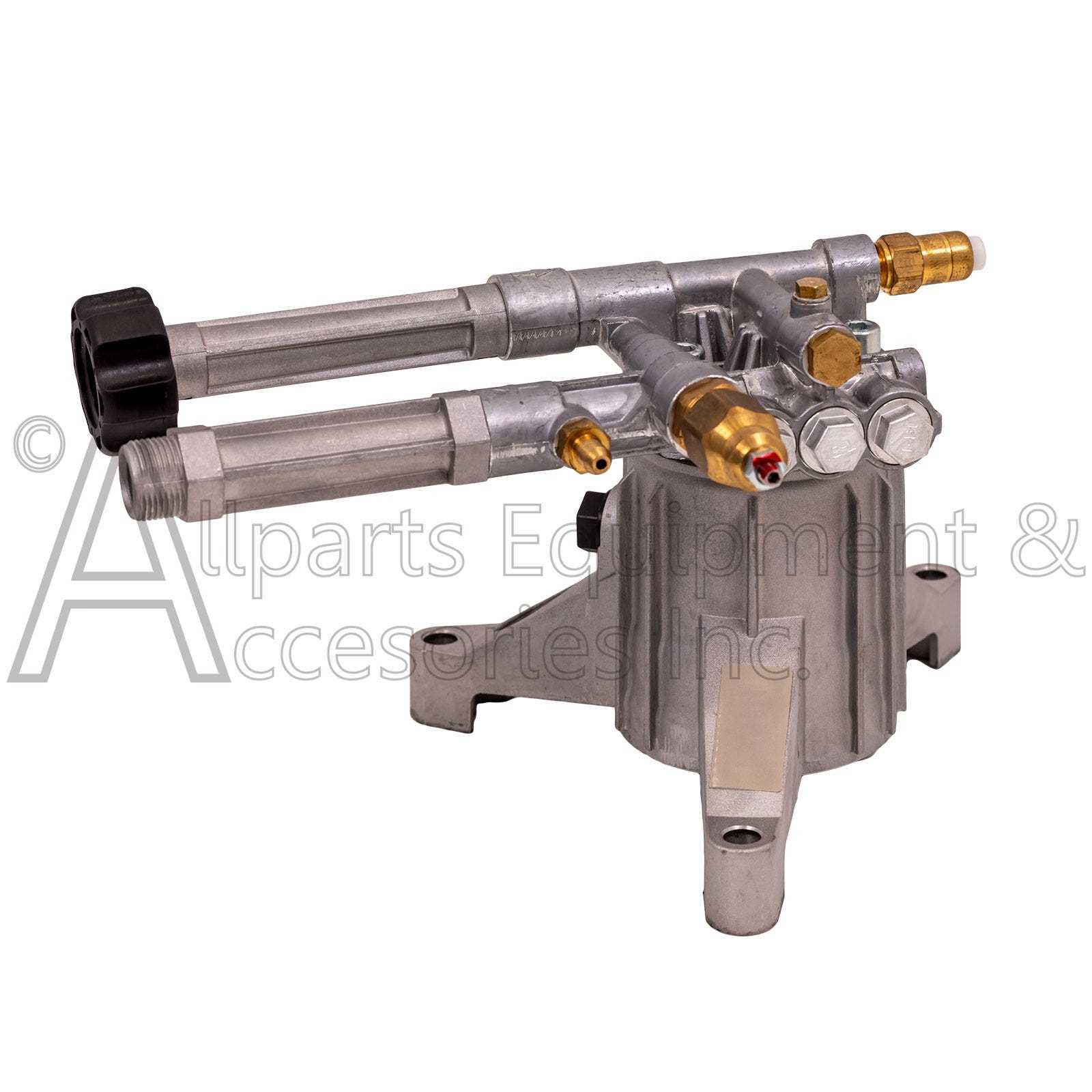

Replacing Worn or Damaged Parts

Maintaining optimal performance of your equipment often involves addressing components that show signs of wear or damage. Identifying and replacing these parts promptly can enhance efficiency and extend the lifespan of the device. This section outlines the essential steps to effectively replace any compromised elements in your system.

Identifying Worn Components

Before proceeding with any replacements, it is crucial to conduct a thorough inspection. Look for visible signs of damage, such as cracks, excessive wear, or corrosion. Pay particular attention to parts that experience frequent movement or high stress, as they are more likely to fail. Creating a checklist can help ensure that no critical components are overlooked during this assessment.

Replacement Procedure

Once you have identified the worn components, follow these general steps for replacement:

| Step | Description |

|---|---|

| 1 | Disconnect the power source to prevent any accidental operation during the process. |

| 2 | Carefully remove the damaged part using appropriate tools, ensuring no additional components are harmed. |

| 3 | Install the new component by aligning it correctly and securing it firmly in place. |

| 4 | Reconnect the power source and conduct a test run to verify that the replacement has resolved any issues. |

By following these steps and maintaining vigilance in monitoring your equipment, you can ensure its reliable operation and longevity.

Cleaning and Maintenance Procedures

Regular upkeep and sanitation are essential to ensure optimal functionality and longevity of your equipment. By following appropriate practices, you can prevent issues and enhance performance, keeping your tool in excellent working condition.

Routine Cleaning Steps

To maintain your device, adhere to these cleaning guidelines:

- Disconnect the unit from the power source before cleaning.

- Remove any debris or buildup from the exterior surfaces.

- Utilize a soft brush or cloth to wipe down all components.

- Inspect and clean the intake filters to prevent clogs.

Scheduled Maintenance Tasks

Implement the following maintenance activities at regular intervals:

| Task | Frequency |

|---|---|

| Check oil levels | Every 10 hours of operation |

| Change oil | After every 50 hours of use |

| Inspect hoses for wear | Monthly |

| Test pressure output | Every 30 hours of operation |

Using the Right Cleaning Agents

Choosing appropriate cleaning solutions is essential for achieving optimal results during maintenance tasks. The effectiveness of these substances can significantly influence the performance and longevity of your equipment. Understanding the various options available will help you select the best one for your specific needs.

When considering cleaning agents, it is crucial to recognize their composition and intended use. Some formulations are designed for specific surfaces, while others may offer versatility across multiple applications. Below is a table outlining common types of cleaning agents and their suitable uses:

| Cleaning Agent Type | Recommended Use | Surface Compatibility |

|---|---|---|

| Detergents | General cleaning | Most surfaces |

| Degreasers | Heavy-duty grease removal | Metal, concrete |

| Eco-friendly solutions | Gentle cleaning | Wood, plastic |

| Acid-based cleaners | Rust and mineral deposit removal | Tile, stone |

Always read the labels and follow manufacturer recommendations to ensure safe and effective use. The right choice not only enhances cleaning performance but also protects the integrity of your equipment.

Understanding Pressure Ratings

When selecting a cleaning device, comprehending the force measurements is crucial for ensuring effective operation. These ratings indicate the intensity at which water is expelled, directly impacting the unit’s ability to tackle various tasks. Familiarity with these specifications can enhance the user’s experience and improve overall performance.

Key Concepts

The primary figures to consider are the pounds per square inch (PSI) and gallons per minute (GPM). While PSI reflects the force of the water stream, GPM denotes the volume of water used. Together, they determine the cleaning efficiency and suitability for specific applications.

Comparison Table

| Application | Recommended PSI | Recommended GPM |

|---|---|---|

| Light Cleaning | 1300 – 1900 | 1.2 – 1.6 |

| Medium Cleaning | 1900 – 2900 | 1.6 – 2.5 |

| Heavy Cleaning | 2900 – 4200 | 2.5 – 4.0 |

Identifying Leaks and Fixes

Detecting fluid escapes in equipment is essential for maintaining optimal performance. Addressing these issues promptly not only enhances functionality but also prolongs the lifespan of the device. Understanding common areas where leaks may occur can significantly assist in troubleshooting.

Start by examining the connections and hoses. Loose fittings or worn-out seals often lead to unwanted fluid loss. Check for signs of wear, such as cracks or swelling, which indicate the need for replacement. Additionally, ensure all connections are tightened securely to prevent future escapes.

Inspecting the body of the unit is also crucial. Look for any visible cracks or damage that may allow fluid to escape. If you notice any irregularities, consider using an appropriate sealant to cover minor gaps. For larger cracks, replacement of the damaged part may be necessary to restore functionality.

Lastly, always monitor the performance during operation. Unusual sounds or decreased efficiency can signal underlying issues. Regular maintenance checks and addressing leaks immediately will help ensure your equipment operates smoothly.

When to Seek Professional Help

Understanding when to enlist the expertise of a specialist can be crucial for effective troubleshooting. Certain situations may require knowledge and skills beyond basic maintenance or minor adjustments.

Consider the following scenarios where professional assistance is advisable:

- Complex Issues: If the equipment exhibits persistent problems despite your efforts to resolve them.

- Safety Concerns: If you notice any signs of electrical faults, leaks, or other hazards that could pose a risk.

- Performance Decline: If there is a significant drop in efficiency or output that does not improve with routine checks.

- Component Replacement: If internal parts need to be replaced and you lack the tools or expertise for the task.

- Warranty Validity: If the equipment is still under warranty, attempting repairs without professional help may void it.

In these cases, reaching out to a trained technician ensures that the equipment is handled properly, reducing the risk of further damage and ensuring safety.

Frequently Asked Questions

This section addresses common inquiries regarding the maintenance and troubleshooting of various cleaning equipment. Here, users can find essential information to assist with typical challenges and enhance their understanding of the operational aspects of their devices.

What should I do if my equipment won’t start?

Ensure that the power source is connected and functioning. Check the fuel level and inspect for any blockages in the ignition system.

How can I improve the performance of my device?

Regularly clean filters and nozzles, and follow the manufacturer’s guidelines for routine maintenance to keep the unit running smoothly.

What is the best way to store the equipment during off-seasons?

Drain all fluids and store the unit in a dry, sheltered location to prevent damage from moisture and extreme temperatures.

How do I troubleshoot low pressure issues?

Check for clogs in the hoses and nozzles, and ensure that the water supply is adequate. Inspect seals and connections for any signs of wear or damage.

Is there a warranty available for my device?

Most manufacturers offer warranties that cover defects in materials and workmanship. Consult the documentation provided with your equipment for specific details.