Comprehensive Guide to New Idea 5209 Repair

In the realm of machinery and equipment, understanding the nuances of upkeep and diagnostics is essential for optimal performance. This section aims to equip users with invaluable insights and practical solutions for various challenges they may encounter. By delving into the intricacies of care and repair, one can enhance both the longevity and efficiency of their devices.

With a focus on systematic approaches, this resource offers detailed explanations and step-by-step procedures. Users will discover effective techniques to address common issues, ensuring that their equipment remains in peak condition. Through clear illustrations and thorough instructions, individuals can navigate the complexities of maintenance with confidence.

Whether you are a novice or an experienced technician, this compilation serves as an indispensable tool. By fostering a deeper understanding of operational dynamics, readers will be empowered to tackle repairs and enhancements effectively. Embrace the opportunity to elevate your skills and ensure your machinery operates seamlessly for years to come.

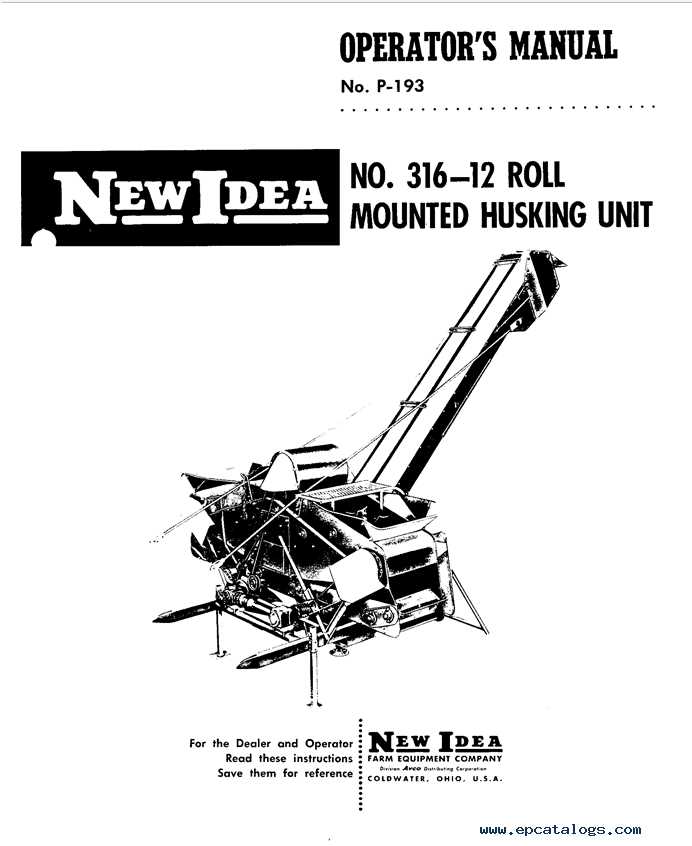

New Idea 5209 Repair Manual Overview

This section provides a comprehensive understanding of the documentation designed to assist users in maintaining and troubleshooting their agricultural equipment. It serves as an essential resource, offering insights into operational procedures, maintenance schedules, and problem-solving techniques tailored for specific models.

Key Features

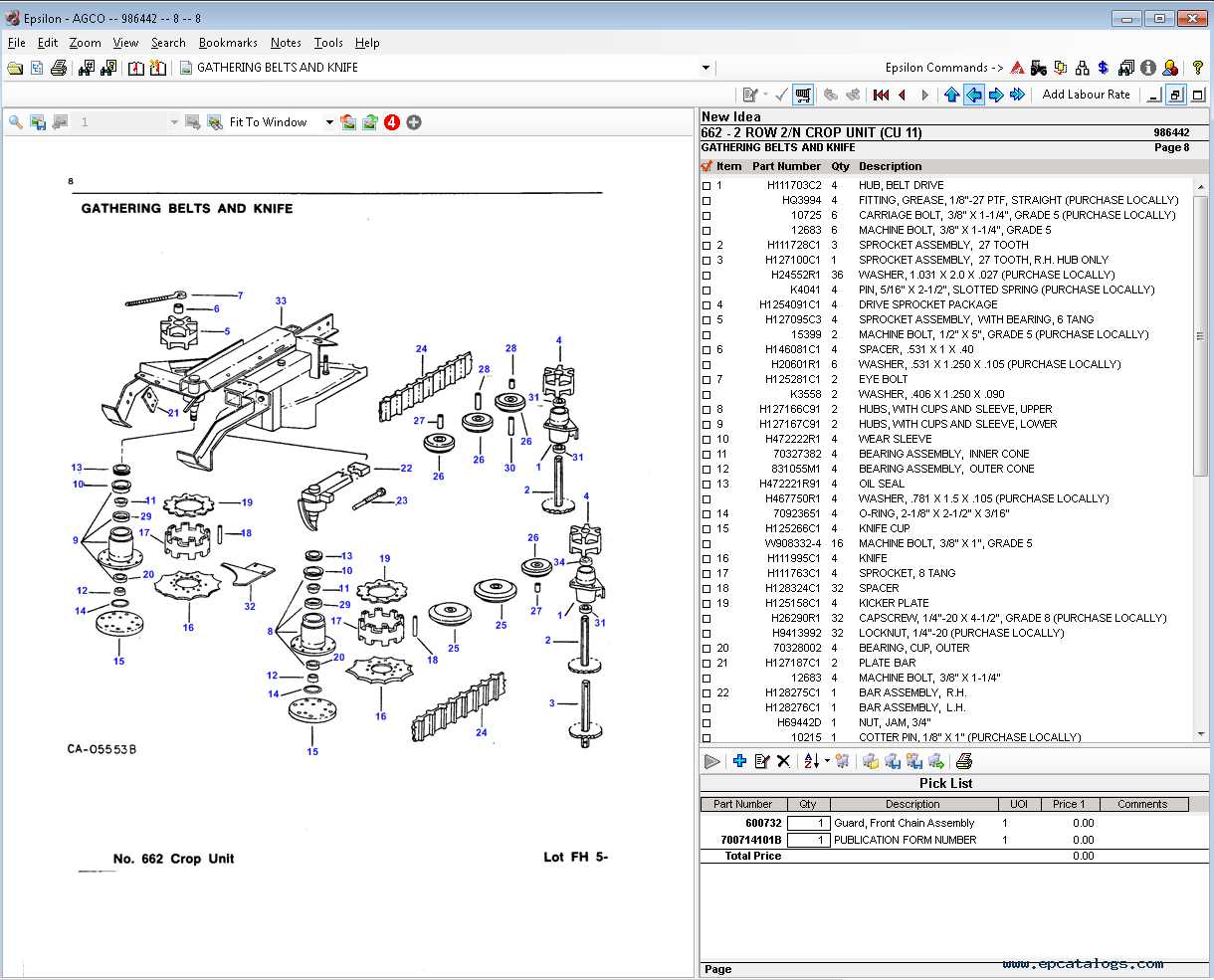

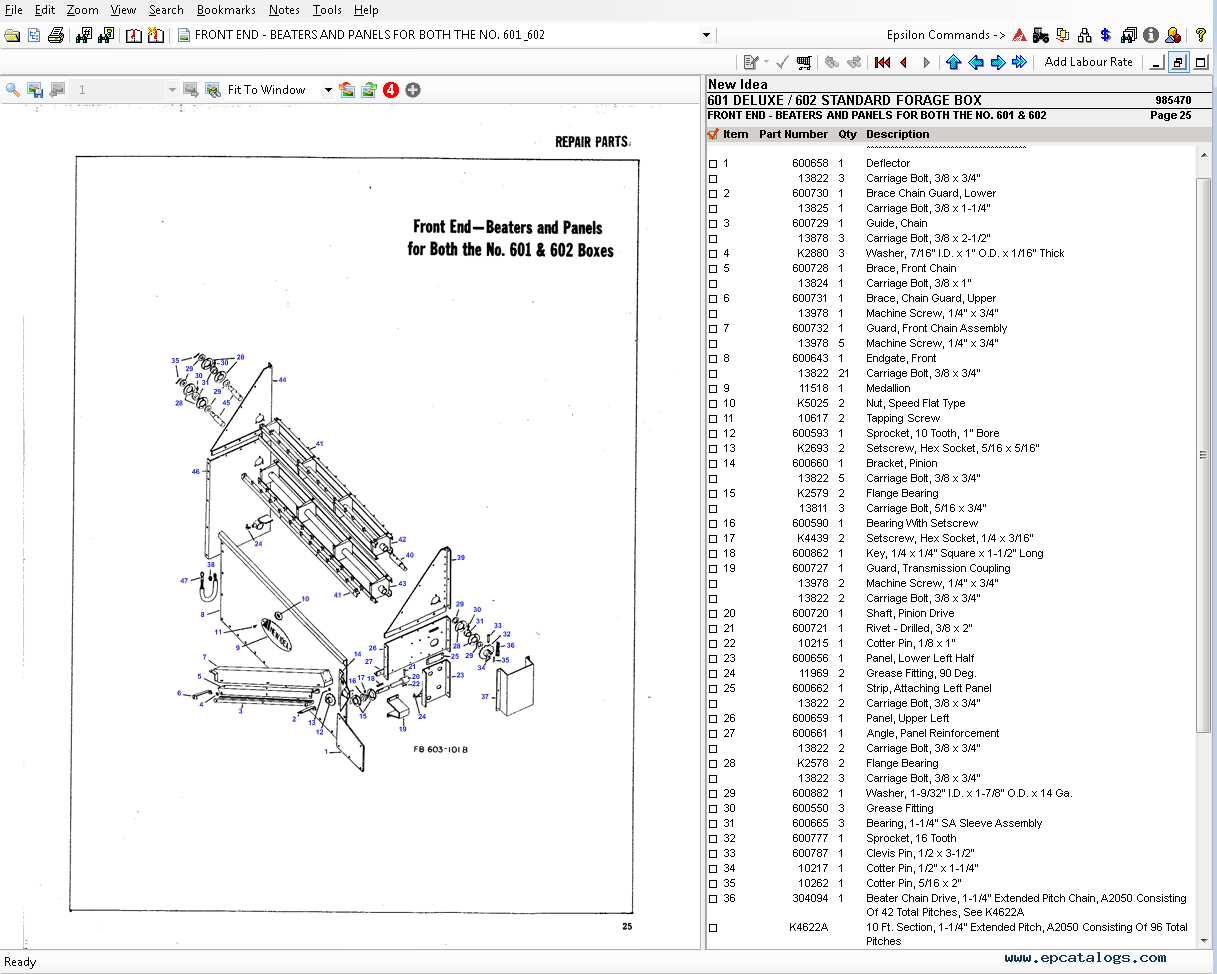

The documentation includes various elements that enhance the user experience, such as detailed diagrams, step-by-step instructions, and a glossary of terms relevant to machinery operation. These features aim to empower users to perform tasks with confidence and efficiency.

| Section | Description |

|---|---|

| Introduction | Overview of equipment and its applications. |

| Maintenance Guidelines | Scheduled upkeep procedures for optimal performance. |

| Troubleshooting | Common issues and solutions for efficient problem resolution. |

| Parts and Accessories | Information on compatible components and upgrades. |

Conclusion

This documentation serves as a vital tool for anyone looking to enhance their understanding of the equipment’s functionalities and care. By utilizing the provided information, users can ensure longevity and reliability in their agricultural practices.

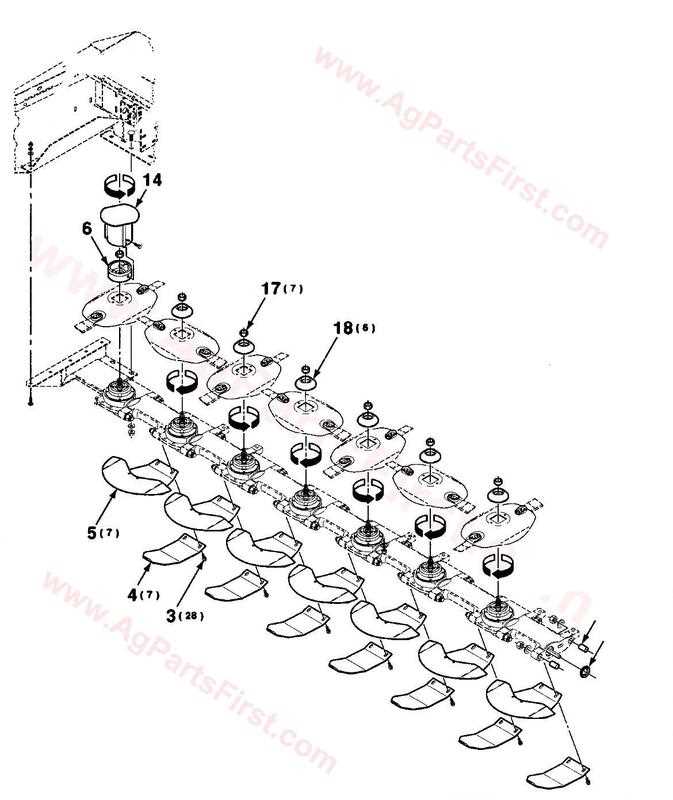

Understanding the New Idea 5209

This section delves into the intricacies of a specific agricultural implement that plays a vital role in modern farming practices. By exploring its features and functionalities, users can enhance their familiarity with the equipment, ensuring optimal performance and longevity.

Key Features

The machinery is equipped with several innovative attributes designed to improve efficiency and productivity. These include advanced mechanical systems that allow for seamless operation, as well as user-friendly controls that facilitate ease of use. Such characteristics not only simplify tasks but also contribute to better overall results in the field.

Maintenance Tips

Proper upkeep is essential for maintaining the functionality of this agricultural device. Regular inspections and timely servicing can prevent common issues, thereby prolonging its lifespan. Additionally, familiarizing oneself with the maintenance schedule and following recommended procedures ensures that the equipment operates at peak performance. Attention to detail in care and servicing can yield significant benefits for any farming operation.

Common Issues with the Model

This section outlines typical challenges encountered with this particular design. Understanding these issues can aid users in diagnosing problems more effectively and implementing appropriate solutions.

| Issue | Description | Possible Solutions |

|---|---|---|

| Power Failure | The device may not turn on or respond. | Check the power source and connections. Replace the fuse if necessary. |

| Overheating | The unit may become excessively hot during operation. | Ensure proper ventilation. Clean dust from vents and consider reducing load. |

| Performance Lag | Users may experience slow operation or delays. | Restart the system. Clear unnecessary files or applications. |

| Unresponsive Controls | Buttons or touch interfaces may not react as expected. | Inspect for physical damage. Reset the device or update software if applicable. |

| Display Issues | The screen may flicker or show distorted images. | Check connections and cables. Adjust settings or replace the display if needed. |

Tools Needed for Repairs

When undertaking maintenance tasks, having the right instruments is essential for efficiency and effectiveness. The proper equipment not only streamlines the process but also ensures safety and precision. Below is a list of essential items that will assist you in accomplishing various tasks successfully.

- Basic Hand Tools:

- Wrenches

- Screwdrivers

- Pliers

- Hammers

- Power Tools:

- Drills

- Grinders

- Saws

- Sanders

- Measuring Instruments:

- Tape measure

- Caliper

- Level

- Square

- Safety Gear:

- Gloves

- Safety goggles

- Ear protection

- Dust mask

With these tools at your disposal, you will be well-prepared to tackle a wide range of tasks efficiently and safely.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to identifying and resolving common issues that may arise. By following these organized steps, users can systematically narrow down problems and implement effective solutions.

- Identify the Problem:

- Gather information about the issue.

- Note any unusual behavior or error messages.

- Determine the conditions under which the problem occurs.

- Check Basic Connections:

- Ensure all cables and connectors are secure.

- Inspect for visible damage or wear on components.

- Verify that the power source is functional.

- Test Functions:

- Perform a basic functionality check.

- Use built-in diagnostics if available.

- Document any anomalies during testing.

- Consult Documentation:

- Refer to relevant product literature for troubleshooting tips.

- Look for troubleshooting charts or flow diagrams.

- Check for firmware or software updates that may resolve issues.

- Implement Solutions:

- Follow recommended procedures to rectify identified issues.

- Test after each adjustment to confirm resolution.

- Keep a record of changes made and their outcomes.

- Seek Further Assistance:

- If problems persist, reach out to customer support or forums.

- Provide detailed information to facilitate better assistance.

- Consider professional help for complex issues.

By adhering to this structured guide, users can effectively troubleshoot and resolve difficulties, ensuring optimal performance and longevity of the equipment.

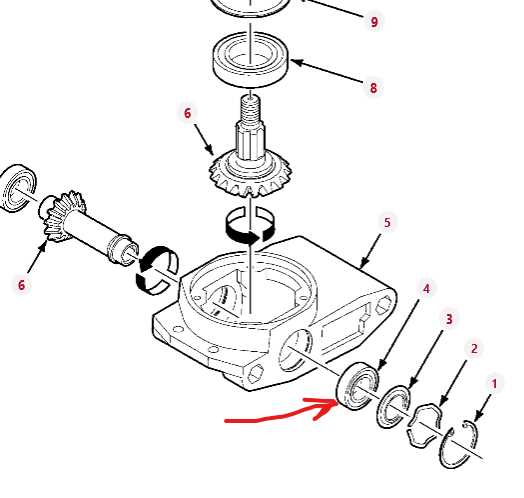

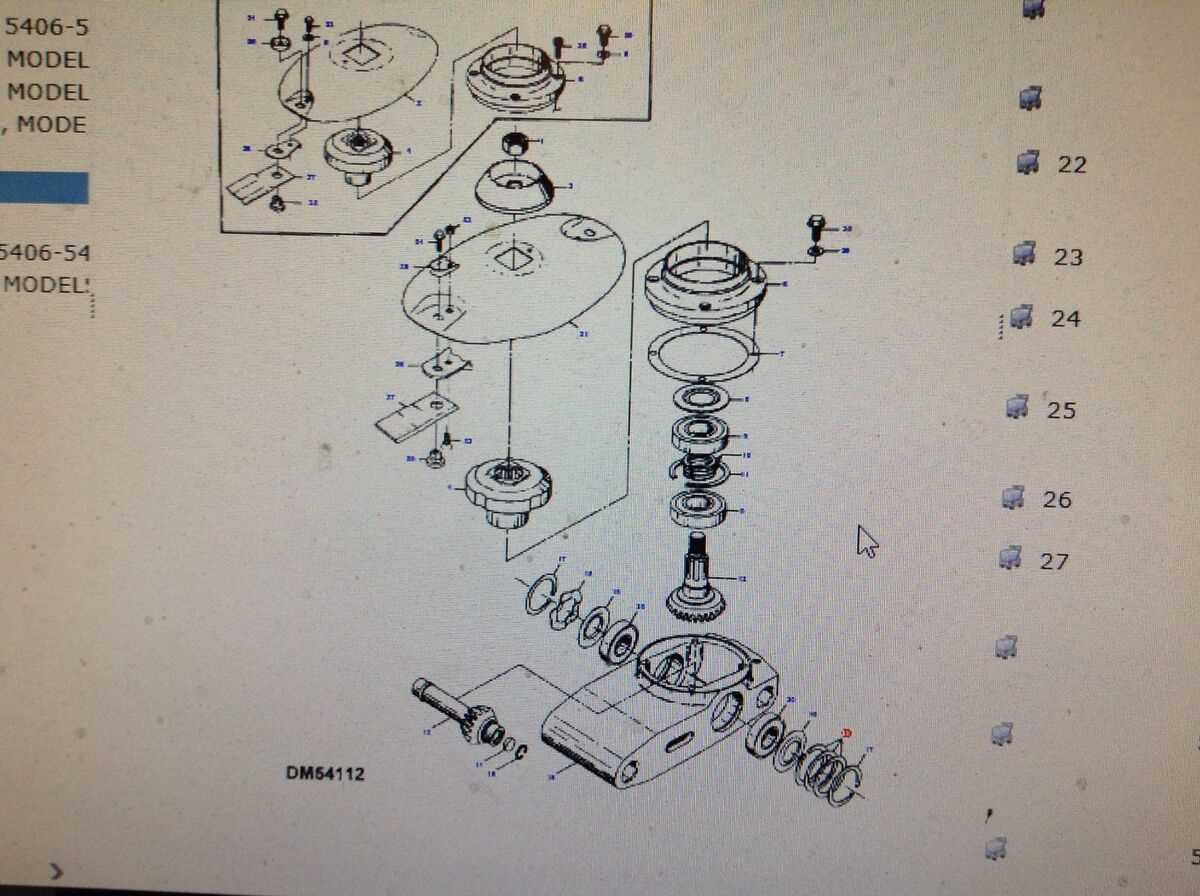

Replacing Worn-Out Components

Over time, various parts of a system may degrade due to usage and environmental factors. Recognizing when these elements need to be swapped out is crucial for maintaining optimal performance and extending the lifespan of the equipment. This section outlines the process and considerations involved in addressing worn components effectively.

| Component | Signs of Wear | Replacement Tips |

|---|---|---|

| Bearing | Noisy operation, increased friction | Ensure proper alignment and lubrication during installation. |

| Seals | Leaks, cracks | Choose high-quality materials to avoid future leaks. |

| Filters | Clogged appearance, reduced flow | Follow manufacturer specifications for type and size. |

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires a systematic approach to care and upkeep. Regular attention to various components can prevent issues and enhance performance, ultimately saving time and resources.

1. Regular Inspections: Conduct frequent evaluations of your device to identify any wear or damage. Early detection of problems can lead to simpler and more cost-effective solutions.

2. Cleanliness: Keep all surfaces free from dust and debris. Accumulation of dirt can impede functionality and lead to overheating. Utilize appropriate cleaning materials to avoid damage.

3. Lubrication: Ensure moving parts are adequately lubricated to reduce friction and wear. Refer to the specifications for the correct type of lubricant, as using the wrong product can lead to adverse effects.

4. Proper Storage: When not in use, store your equipment in a dry and safe location. Protect it from extreme temperatures and moisture, which can accelerate deterioration.

5. Follow Manufacturer Guidelines: Adhere to any provided instructions for upkeep and operation. This helps maintain warranty coverage and ensures optimal performance standards.

Implementing these practices can significantly enhance the reliability and durability of your equipment, making it a valuable asset for years to come.

Electrical System Diagnosis Techniques

Understanding the intricacies of an electrical system is crucial for effective troubleshooting. This section delves into various methodologies that facilitate the identification of issues within electrical circuits. Employing systematic approaches not only enhances accuracy but also streamlines the repair process.

Common Diagnostic Tools

Utilizing appropriate instruments is fundamental in assessing electrical components. Tools such as multimeters and oscilloscopes play vital roles in measuring voltage, current, and resistance. These devices help pinpoint anomalies and ensure that each part of the system is functioning as intended. Familiarity with these tools is essential for any technician aiming for precision in diagnostics.

Step-by-Step Troubleshooting Process

Establishing a methodical approach can greatly improve the efficiency of diagnosing electrical issues. Start by observing symptoms and gathering relevant data. Next, isolate components systematically, checking each for proper functionality. Documenting findings throughout this process helps in tracing the root cause of problems, ultimately leading to effective solutions. Always remember to adhere to safety protocols while conducting tests, ensuring a secure working environment.

Hydraulic System Maintenance Procedures

The upkeep of hydraulic systems is crucial for ensuring optimal performance and longevity. Regular attention to these systems not only prevents unexpected failures but also enhances operational efficiency. Below are key procedures for maintaining hydraulic systems effectively.

- Regular Inspections:

- Check for leaks in hoses and fittings.

- Inspect fluid levels and conditions regularly.

- Examine components for signs of wear or damage.

- Fluid Management:

- Change hydraulic fluid at recommended intervals.

- Use high-quality fluid that meets system specifications.

- Monitor for contamination and address it promptly.

- Filter Maintenance:

- Replace filters according to manufacturer guidelines.

- Clean reusable filters to prevent clogging.

- Check for any signs of filter bypassing.

- Component Checks:

- Ensure seals and O-rings are intact and functioning.

- Test the operation of valves and actuators regularly.

- Lubricate moving parts as per specifications.

Implementing these practices will contribute to the reliable operation of hydraulic systems, minimizing downtime and extending service life.

Adjusting Operational Settings Effectively

Fine-tuning the functionality of equipment is essential for optimal performance. By understanding the various parameters and making precise adjustments, users can significantly enhance efficiency and longevity. This section outlines key considerations for achieving effective operational settings.

- Understand the Equipment: Familiarize yourself with the specifications and capabilities of your device.

- Identify Key Parameters: Focus on critical settings that impact performance, such as speed, power, and calibration.

- Utilize Diagnostic Tools: Employ available tools to monitor performance and identify areas for adjustment.

Adjustments should be made systematically to avoid unintended consequences. Here are some steps to follow:

- Baseline Measurement: Record initial performance metrics before making any changes.

- Incremental Adjustments: Make small modifications and observe their effects closely.

- Documentation: Keep a detailed log of changes and their impacts for future reference.

- Seek Expert Guidance: Consult manuals or professionals when unsure about specific adjustments.

By following these guidelines, users can ensure that their equipment operates at peak efficiency, ultimately leading to better results and reduced wear over time.

Safety Precautions During Repairs

Ensuring safety while undertaking maintenance tasks is paramount to avoid accidents and injuries. Adhering to specific guidelines can significantly reduce risks and enhance the overall experience of handling equipment or machinery. Here are essential practices to follow.

- Wear appropriate personal protective equipment (PPE) such as gloves, goggles, and helmets.

- Ensure the work area is well-lit and free from clutter.

- Disconnect power sources before beginning any work to prevent electrical hazards.

- Use tools that are suitable for the task and in good condition.

- Follow manufacturer instructions carefully to avoid missteps.

In addition to the above measures, consider the following:

- Maintain a safe distance from hazardous materials.

- Keep a first aid kit readily available in case of minor injuries.

- Inform others in the vicinity about the ongoing activities.

- Take breaks to prevent fatigue, which can lead to errors.

- Have an emergency plan in place for serious incidents.

By following these precautions, individuals can create a safer environment for themselves and others while engaging in technical tasks.

Resources for Further Assistance

Finding reliable information and support can significantly enhance your understanding and ability to address various challenges. This section outlines several avenues where you can seek additional guidance and insights to help you navigate your project effectively.

Online Communities

Engaging with others who share similar interests can provide valuable advice and troubleshooting tips. Here are some platforms to consider:

- Forums: Websites dedicated to discussions often have sections specifically for troubleshooting and advice.

- Social Media Groups: Platforms like Facebook and Reddit host groups where users share experiences and solutions.

- Video Tutorials: YouTube features countless tutorials that can offer visual guidance on specific issues.

Official Support and Documentation

Utilizing official resources can ensure that you receive accurate and detailed information. Here are some useful options:

- Manufacturer’s Website: Most manufacturers provide documentation, FAQs, and customer support options.

- Customer Service: Contacting support directly can yield personalized help for your specific needs.

- Instructional Guides: Many companies offer downloadable guides that cover a range of topics related to their products.