Carrier Reefer Maintenance Guide

Effective maintenance of temperature-controlled transport systems is essential for ensuring the integrity of perishable goods during transit. This section focuses on essential practices and knowledge required to keep these specialized units functioning optimally, minimizing downtime and maximizing efficiency.

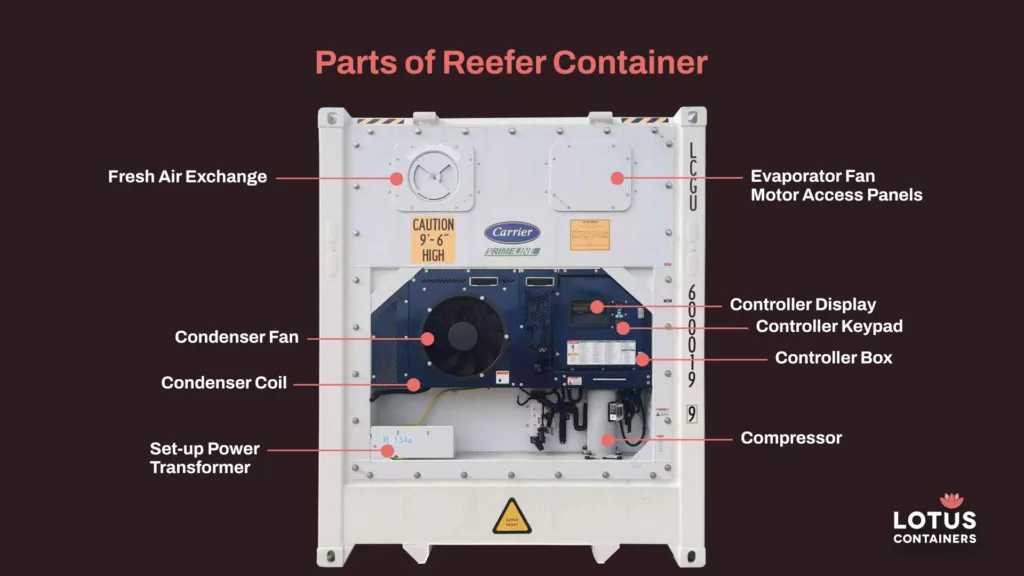

Understanding the Components is crucial for anyone involved in the upkeep of these systems. Familiarity with the various parts and their functions will enable technicians to diagnose issues accurately and implement appropriate solutions. Knowledge of how each element interacts within the system is fundamental for effective oversight.

Moreover, routine checks and servicing play a vital role in prolonging the lifespan of cooling apparatuses. Scheduled inspections and preventive measures can help identify potential problems before they escalate, ensuring continuous operation and reliability in transporting sensitive materials.

Common Issues in Refrigerated Units

Refrigeration systems are essential for maintaining optimal temperatures in various applications. However, they can experience a range of challenges that affect their efficiency and performance. Identifying these common problems early can help in minimizing downtime and ensuring the reliability of temperature-controlled environments.

Temperature Fluctuations

One of the most prevalent issues is temperature instability. This can occur due to a malfunctioning thermostat, poor insulation, or a refrigerant leak. Regular monitoring and maintenance are crucial to prevent significant losses of perishable goods.

Unusual Noises

Another sign of potential trouble is the presence of unusual sounds coming from the unit. Noises such as grinding, squealing, or hissing may indicate problems with the compressor, fans, or other components. Addressing these sounds promptly can help avoid more severe damages and costly repairs.

Essential Tools for Repair Work

Having the right equipment is crucial for any maintenance task. These implements not only facilitate the process but also enhance efficiency and safety during operations. Understanding the essential instruments can make a significant difference in achieving successful outcomes.

Among the key items, wrenches and screwdrivers stand out as fundamental tools. Wrenches come in various sizes and types, allowing for effective fastening and loosening of different components. Similarly, screwdrivers are indispensable for accessing tight spots and ensuring secure connections.

Additionally, multimeters are vital for diagnosing electrical issues. They help in measuring voltage, current, and resistance, providing essential information to troubleshoot problems. Alongside these, pliers are versatile tools that assist in gripping and bending materials, making them invaluable in many situations.

Furthermore, investing in a quality toolbox is essential for organizing and protecting these implements. A well-structured toolbox not only saves time but also prevents damage to the tools themselves, ensuring longevity and reliability.

Ultimately, being equipped with the right set of tools empowers technicians to perform tasks with confidence and precision, leading to improved performance and satisfaction.

Step-by-Step Maintenance Procedures

Regular upkeep of cooling systems is essential for optimal performance and longevity. This section outlines a series of organized tasks designed to ensure that your equipment functions efficiently. By following these procedures, you can prevent unexpected failures and maintain the integrity of your units.

- Inspection of Components:

- Check the exterior for any signs of damage or wear.

- Inspect insulation for integrity.

- Examine hoses and connections for leaks.

- Cleaning the Unit:

- Remove debris from vents and external surfaces.

- Clean the evaporator and condenser coils using a suitable cleaner.

- Ensure that drainage channels are clear and unobstructed.

- Checking Refrigerant Levels:

- Verify that the refrigerant levels are within the manufacturer’s specifications.

- Look for signs of leakage in the system.

- Electrical System Assessment:

- Inspect wiring for fraying or damage.

- Test electrical connections for proper functionality.

- Ensure all safety features are operational.

- Operational Testing:

- Start the unit and monitor its performance.

- Listen for unusual noises that may indicate issues.

- Check temperature readings against standard benchmarks.

By adhering to these systematic steps, you can significantly enhance the reliability of your cooling equipment, ensuring it operates smoothly throughout its lifespan.

Diagnosing Temperature Control Problems

Temperature regulation issues can significantly impact the performance of cooling units. Understanding how to identify and address these problems is crucial for maintaining efficiency and reliability. This section outlines common symptoms, potential causes, and steps for effective troubleshooting.

Common Symptoms of Temperature Issues

- Inconsistent temperature readings

- Unit cycling on and off frequently

- Excessive frost buildup on coils

- Unusual noises from the system

Steps for Troubleshooting

- Check the thermostat settings to ensure they are correct.

- Inspect the temperature sensors for proper functioning.

- Examine airflow around the unit to prevent obstruction.

- Look for refrigerant leaks that may affect cooling efficiency.

- Review the electrical connections for signs of damage or wear.

By systematically addressing these aspects, technicians can effectively diagnose and resolve temperature control challenges, ensuring optimal operation of the cooling system.

Electrical Components and Troubleshooting

This section focuses on the essential electrical parts of cooling units and the common issues that may arise. Understanding these components and their functionalities is crucial for maintaining optimal performance and resolving any electrical faults that may occur.

Key Electrical Parts

The electrical system consists of several critical components that work together to ensure efficient operation. These include power sources, control panels, and sensors. Each element plays a vital role in monitoring and regulating the unit’s functionality.

| Component | Function |

|---|---|

| Power Supply | Provides the necessary voltage to operate the system. |

| Control Board | Manages the overall operation and regulates the cooling process. |

| Temperature Sensor | Monitors the internal temperature and communicates with the control board. |

| Relay | Controls the power flow to various components based on signals from the control board. |

Troubleshooting Common Issues

Identifying and resolving electrical problems can enhance the longevity and efficiency of the cooling system. Common symptoms include inconsistent temperatures, unresponsive controls, or unusual noises. Conducting a systematic evaluation of each electrical part can help pinpoint the source of the issue.

Refrigerant Types and Management

Understanding the various cooling substances and their effective handling is crucial for optimal performance and efficiency in temperature-controlled transport systems. Proper management of these agents not only ensures compliance with regulations but also enhances the longevity of the cooling systems.

There are several categories of cooling agents commonly used in temperature maintenance equipment:

- Hydrochlorofluorocarbons (HCFCs): These substances have been widely used but are being phased out due to environmental concerns.

- Hydrofluorocarbons (HFCs): These are more environmentally friendly alternatives, though they still require careful handling to minimize potential impacts.

- Natural Refrigerants: Options like ammonia, carbon dioxide, and hydrocarbons offer sustainable choices with low global warming potential.

Effective management strategies include:

- Regular Monitoring: Frequent checks on refrigerant levels help identify leaks and maintain system efficiency.

- Leak Detection: Utilizing advanced technologies can quickly identify and rectify leaks, minimizing environmental impact.

- Proper Charging: Ensuring the correct amount of refrigerant is used enhances system performance and efficiency.

By focusing on these aspects, operators can ensure that their temperature regulation systems operate effectively and sustainably.

Preventative Maintenance Practices

Implementing routine upkeep measures is essential for ensuring the longevity and efficiency of temperature-controlled transport systems. By adopting proactive maintenance strategies, operators can prevent breakdowns and optimize performance, ultimately leading to cost savings and improved reliability.

- Regularly inspect and clean condenser and evaporator coils to enhance airflow and cooling efficiency.

- Check and replace filters as needed to maintain air quality and system efficiency.

- Monitor refrigerant levels and address leaks promptly to ensure optimal functioning.

- Test and calibrate temperature controls to guarantee precise monitoring and regulation.

- Examine electrical components for wear or damage, and replace as necessary to prevent failures.

By adhering to these practices, operators can significantly reduce the likelihood of unexpected issues and extend the lifespan of their temperature-sensitive transportation equipment.

Safety Guidelines for Technicians

Ensuring the safety of personnel during maintenance activities is paramount. Proper precautions and adherence to established protocols minimize risks and promote a secure working environment. This section outlines essential recommendations for technicians engaged in servicing cooling systems.

Personal Protective Equipment

Technicians must always wear appropriate personal protective gear, including gloves, safety goggles, and protective clothing. These items are crucial in preventing injuries from hazardous materials and sharp objects commonly encountered in the field.

Tool and Equipment Safety

Before commencing any task, verify that all tools and equipment are in good working condition. Regular inspections help to identify potential issues that could lead to accidents. Additionally, ensure that all devices are used according to the manufacturer’s instructions to avoid misuse and enhance safety.

Replacement Parts and Sourcing

When maintaining temperature-controlled units, the availability of components is crucial for ensuring optimal performance. Identifying the right suppliers and understanding the components required can significantly enhance the efficiency and longevity of these systems.

Key factors to consider when sourcing replacement components include:

- Quality: Choose parts that meet or exceed the original specifications to maintain reliability.

- Compatibility: Ensure that components are suitable for the specific model being serviced.

- Supplier Reputation: Select vendors known for their customer service and product quality.

Here are some recommended sources for acquiring necessary components:

- Authorized distributors who provide original equipment.

- Reputable aftermarket suppliers offering quality alternatives.

- Online marketplaces with established seller ratings and reviews.

By carefully selecting replacement parts and sourcing them from trusted providers, the efficiency and performance of temperature-controlled units can be maintained effectively.

Best Practices for Efficient Repairs

Maintaining optimal functionality of refrigeration units is crucial for ensuring consistent performance and minimizing downtime. Implementing effective strategies during the service process can significantly enhance the efficiency and quality of the work performed. These practices not only streamline the workflow but also contribute to long-term reliability.

Thorough Diagnostics

Conducting comprehensive assessments before initiating any work is essential. Utilizing advanced diagnostic tools helps identify underlying issues accurately. This proactive approach enables technicians to address potential problems early, reducing the likelihood of recurring faults.

Regular Maintenance Schedule

Establishing a routine maintenance timetable is vital for sustaining unit performance. Regular inspections and timely interventions can prevent unexpected breakdowns and extend the lifespan of the equipment. Keeping a detailed log of all service activities ensures that critical tasks are not overlooked.