Continuously Variable Transmission (CVT): Provides a smooth range of gear ratios, enhancing fuel efficiency and performance consistency.Cooling System Maintenance Tips

The cooling system plays a crucial role in keeping the engine at an optimal temperature during operation. Proper maintenance of this system helps prevent overheating, ensuring that the vehicle runs smoothly and extends the overall engine life. By regularly inspecting and servicing the cooling components, you can avoid costly repairs and keep the vehicle operating efficiently.

Inspecting Coolant Levels

Regularly checking the coolant level is essential for maintaining a well-functioning cooling system. A low coolant level can lead to engine overheating, which can cause serious damage. When inspecting, make sure the coolant reservoir is filled to the recommended level. If the level is low, refill it with the correct type of coolant as specified for the system. Avoid overfilling, as this may lead to pressure issues within the system.

Cleaning and Flushing the Cooling System

Over time, debris and mineral deposits can build up within the cooling system, reducing its effectiveness. Flushing the system periodically removes these contaminants, allowing coolant to flow freely and effectively cool the engine. A full system flush involves draining the old coolant, cleaning the system with a flushing solution, and refilling with fresh coolant. Aim to perform this task at the intervals recommended for the specific system to maintain optimal performance.

Check for Leaks: A quick visual inspection for leaks around hoses, the radiator, and other cooling components can help detect issues early. If you notice any coolant under the vehicle, it’s essential to address these leaks promptly. Even small leaks can lead to bigger problems if left unchecked.

Maintaining a healthy cooling system is vital to vehicle performance. Regular checks, along with routine flushing, will help ensure your engine stays cool and efficient on the road.

Protecting the Engine from Overheating

Maintaining an optimal temperature within the engine is crucial for ensuring its longevity and efficiency. Overheating can lead to severe damage, affecting various components and ultimately resulting in costly repairs. It is essential to implement preventive measures and regularly monitor the cooling system to avoid such issues.

Key Strategies for Temperature Control

- Regular Maintenance: Routine checks of the cooling system are vital. This includes inspecting hoses, clamps, and connections for leaks or wear.

- Coolant Quality: Using the correct type and mixture of coolant helps maintain effective heat dissipation. Regularly check and replace coolant as needed.

- Thermostat Functionality: Ensure the thermostat operates correctly. A malfunctioning thermostat can hinder the cooling process and cause the engine to overheat.

- Radiator Condition: Inspect the radiator for blockages or damage. Cleaning the radiator fins can enhance airflow and improve cooling efficiency.

Monitoring Temperature Levels

- Temperature Gauge: Regularly observe the temperature gauge on the dashboard. If it shows higher than normal readings, investigate immediately.

- Warning Lights: Pay attention to any warning indicators that may illuminate on the dashboard. These alerts can indicate potential overheating issues.

- Engine Oil: Check oil levels and quality. Proper lubrication is essential for preventing excessive heat buildup within the engine.

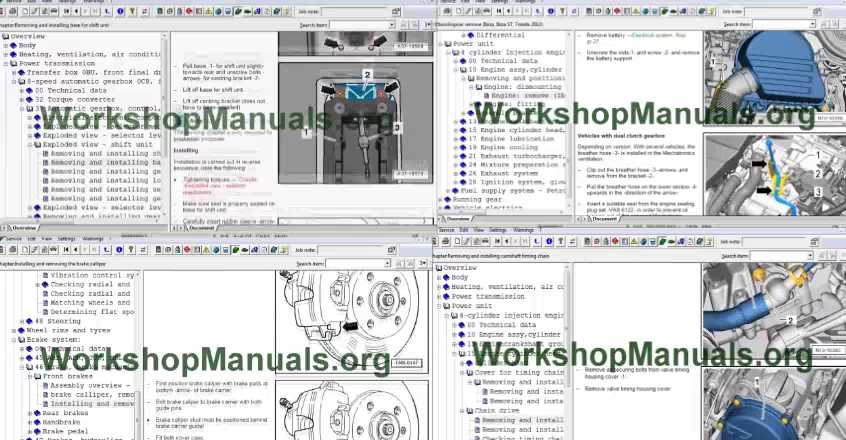

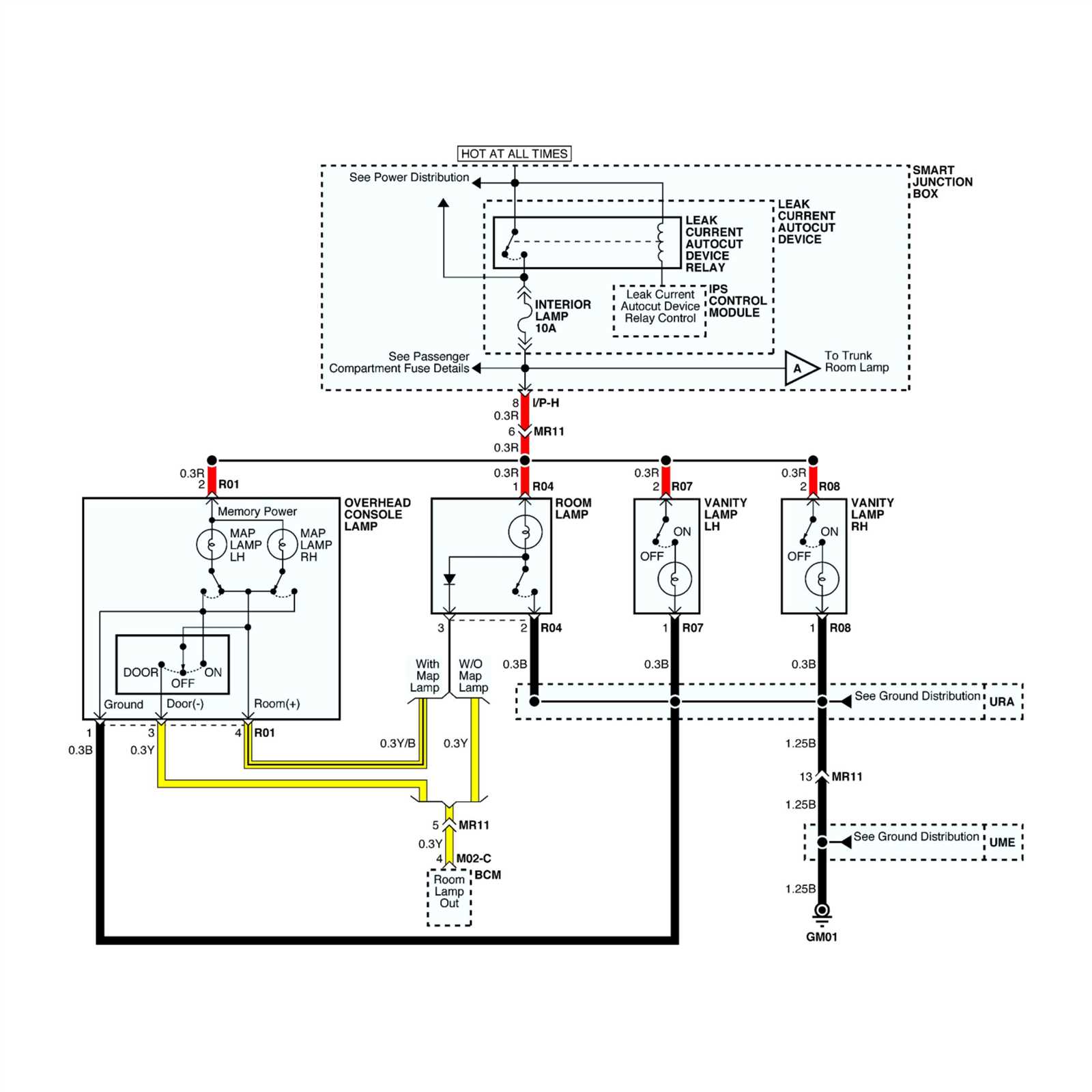

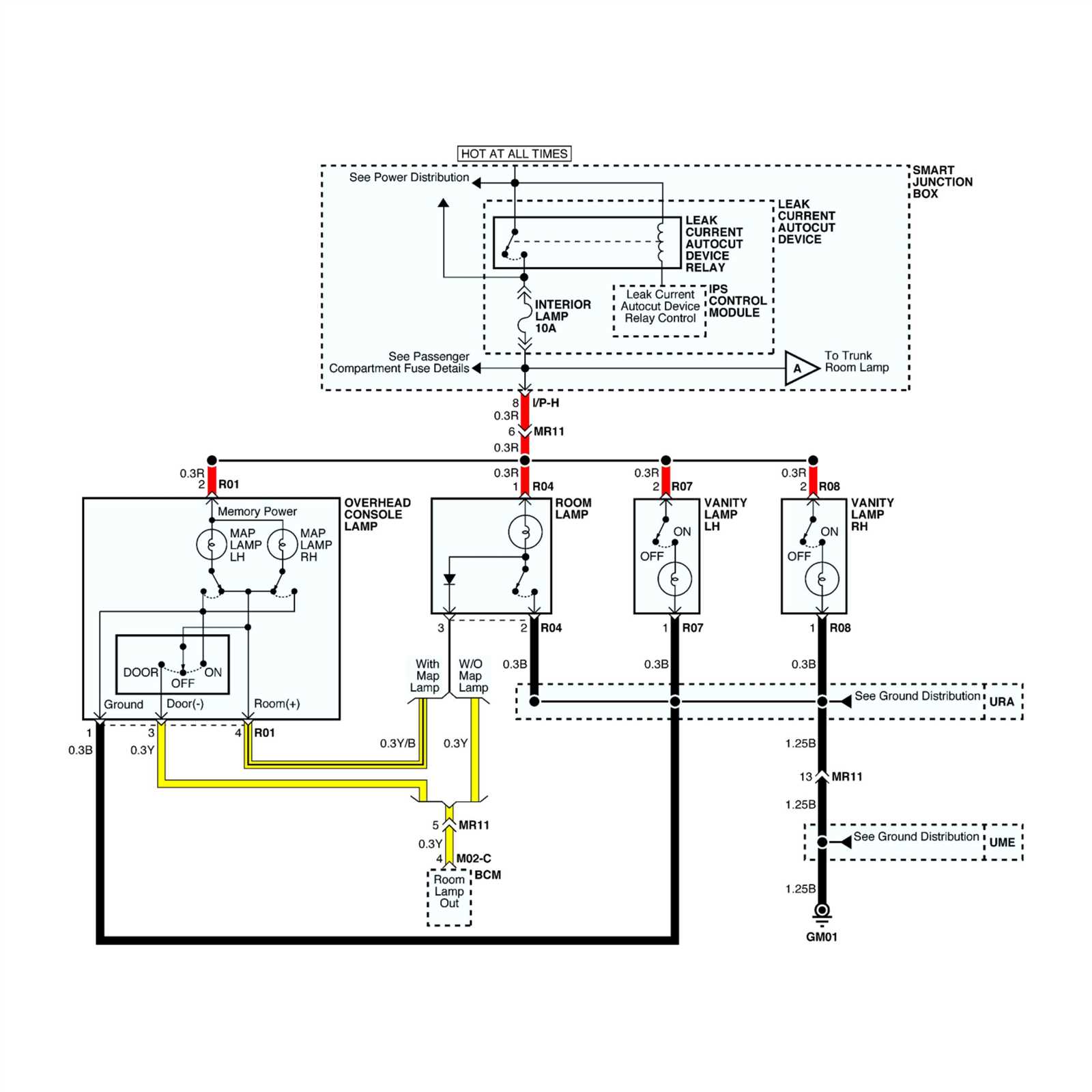

Electrical System Troubleshooting Guide

This section focuses on identifying and resolving issues within the electrical system of a vehicle. Proper diagnosis is essential to ensure that all components function correctly, preventing potential failures that could affect performance and safety.

Follow these steps to effectively troubleshoot electrical problems:

-

Gather Tools:

- Multimeter

- Wrenches and screwdrivers

- Wire strippers and connectors

- Repair manual for reference

-

Visual Inspection:

Begin with a thorough visual check of the electrical components:

- Inspect wires for fraying or damage.

- Check connections for corrosion or looseness.

- Look for signs of overheating on connectors.

-

Test Battery Voltage:

Ensure the battery is charged and functioning:

- Use a multimeter to check voltage; it should read between 12.4V and 12.6V.

- Test the battery terminals for a secure connection.

-

Check Fuses:

Examine the fuse box for any blown fuses:

- Replace any blown fuses with ones of the same amperage.

- Inspect the fuse box for corrosion or damage.

-

Component Testing:

Test individual electrical components:

- Examine relays by switching them with known good ones.

- Check sensors and switches for continuity.

-

Examine Grounds:

A poor ground connection can lead to various electrical issues:

- Inspect ground points for tightness and corrosion.

- Clean any corroded connections to ensure a proper ground.

By following these troubleshooting steps, you can systematically identify and rectify electrical system issues, ensuring reliable operation and safety on the road.

Solving Common Electrical Issues

Electrical systems in vehicles are critical for their overall performance and functionality. Addressing typical electrical problems can enhance reliability and prevent more significant issues down the road. This section outlines common symptoms and solutions that can assist in troubleshooting electrical challenges effectively.

Here are some frequent electrical concerns encountered:

- Battery Issues:

- Symptoms: Difficulty starting, dim lights, or electrical accessories malfunctioning.

- Solutions: Check battery connections for corrosion, ensure the battery is charged, and consider replacing it if it’s old or faulty.

- Fuses and Relays:

- Symptoms: Non-functioning lights or accessories.

- Solutions: Inspect fuses and relays for damage; replace any that are blown or malfunctioning.

- Wiring Problems:

- Symptoms: Intermittent electrical failures or shorts.

- Solutions: Examine wiring for fraying or breaks, ensuring all connections are secure. Repair or replace damaged wires as necessary.

- Starter Motor Malfunction:

- Symptoms: Clicking sound when turning the key, or no response at all.

- Solutions: Check the starter connections and battery voltage. If necessary, test the starter motor and replace it if it fails.

By systematically diagnosing these common issues, individuals can restore electrical functionality and maintain optimal vehicle performance. Regular checks and maintenance can also prevent many of these problems from arising in the first place.

Suspension and Steering Insight

The suspension and steering system plays a crucial role in the overall performance and handling of a vehicle. This complex arrangement is designed to provide comfort while ensuring stability and control during various driving conditions. Proper functioning of these components is essential for safety and the driving experience.

Suspension components are responsible for absorbing shocks from the road and maintaining tire contact with the surface. This is achieved through a combination of springs, shock absorbers, and linkages that work together to mitigate the effects of bumps and uneven terrain. An effective suspension system enhances ride quality while reducing wear on tires and other parts.

Steering mechanisms enable drivers to direct the vehicle with precision. A well-maintained steering system ensures that the response is immediate and predictable, which is vital for navigating turns and maintaining control. Elements such as the steering wheel, column, and rack-and-pinion setup work in harmony to provide feedback and enhance maneuverability.

Regular inspections and maintenance of the suspension and steering assemblies can prevent issues such as uneven tire wear, drifting, and steering wheel vibrations. Addressing problems early can lead to improved performance and a more enjoyable driving experience.

Maintaining Smooth Handling

Ensuring a vehicle operates with optimal handling is essential for both safety and comfort. A well-maintained suspension and steering system contribute significantly to the overall driving experience. This section will cover key aspects to consider for achieving a smooth ride and effective maneuverability.

Regular Inspections

Conducting routine assessments of various components can prevent handling issues before they arise. Key areas to focus on include:

- Tires: Check for proper inflation and tread wear.

- Suspension: Inspect shocks and struts for leaks or damage.

- Steering: Ensure that all linkages and joints are functioning correctly.

- Brakes: Examine brake pads and rotors for wear.

Proper Alignment and Balancing

Misalignment and imbalance can lead to uneven tire wear and handling difficulties. To maintain smooth performance:

- Schedule a wheel alignment if you notice pulling to one side or uneven tire wear.

- Have the wheels balanced regularly, especially after tire installation or rotation.

- Pay attention to any vibrations felt through the steering wheel, indicating potential balancing issues.

By adhering to these maintenance practices, drivers can enhance the handling characteristics of their vehicle, ensuring a safe and enjoyable experience on the road.

Brake System Repair Tips

Ensuring the optimal performance of the braking mechanism is crucial for vehicle safety. Regular maintenance and timely interventions can help avoid costly issues and enhance the overall driving experience. This section offers practical suggestions to address common concerns related to the braking system.

Inspect Brake Components Regularly: Frequent examination of the braking elements is essential. Look for signs of wear, such as thinning pads or uneven rotor surfaces. Early detection of problems can prevent further damage and ensure effective braking action.

Maintain Proper Fluid Levels: The brake fluid plays a vital role in the functionality of the braking system. Ensure that the fluid is at the correct level and check for any signs of contamination or moisture. Flushing the fluid periodically can also enhance braking performance.

Listen for Unusual Noises: Pay attention to any unusual sounds when applying the brakes. Squeaking or grinding noises often indicate worn pads or other underlying issues. Addressing these sounds promptly can prevent more extensive damage.

Check Brake Lines and Hoses: The integrity of the brake lines and hoses is paramount for safe braking. Inspect them for any leaks, cracks, or bulges. Damaged lines should be replaced immediately to ensure reliable braking capabilities.

Test Brake Performance: Regularly evaluate the effectiveness of the braking system. This includes checking for responsiveness, any pulling to one side, or vibrations during braking. Conducting these tests helps identify potential issues early on.

Ensuring Safe Stopping Power

Maintaining effective braking performance is crucial for vehicle safety. Properly functioning brakes ensure that a driver can slow down or come to a complete stop when needed, significantly reducing the risk of accidents. Regular inspection and maintenance of the braking system are essential practices that every vehicle owner should prioritize to guarantee reliable stopping capabilities.

Key Components of the Braking System

The braking system comprises several critical components, including brake pads, rotors, calipers, and brake fluid. Each part plays a vital role in the overall functionality of the brakes. Worn brake pads can lead to reduced friction, causing longer stopping distances and potential brake failure. Similarly, issues with rotors, such as warping or excessive wear, can negatively affect braking efficiency. Regular checks and timely replacements of these components can significantly enhance safety on the road.

Importance of Brake Fluid Maintenance

Brake fluid is another essential element that requires attention. It absorbs moisture over time, which can lower its boiling point and lead to brake failure under heavy use. Regularly flushing and replacing the brake fluid according to the manufacturer’s recommendations ensures optimal performance. Monitoring the fluid level and checking for leaks are simple yet effective ways to maintain the braking system’s integrity.

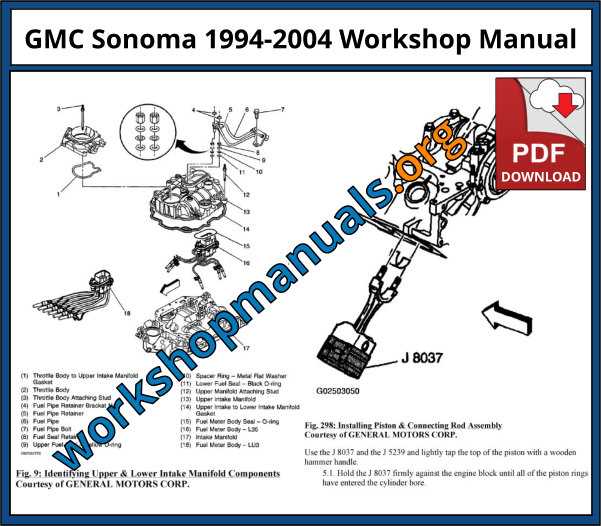

Fuel System Component Check

Ensuring the proper functionality of the fuel system is crucial for optimal vehicle performance. A thorough inspection of various components can help identify potential issues that may affect the engine’s efficiency and overall operation. This section outlines the essential elements to examine when assessing the fuel delivery system.

- Fuel Pump: Verify the operational status of the pump. Listen for any unusual sounds, such as whining or grinding, which may indicate failure.

- Fuel Filter: Check the filter for clogs or debris. A restricted filter can hinder fuel flow, leading to performance issues.

- Fuel Injectors: Inspect injectors for proper spray patterns and leaks. Clean any buildup that may affect fuel atomization.

- Fuel Lines: Examine the lines for cracks, leaks, or wear. Ensure all connections are secure to prevent fuel loss.

- Fuel Pressure Regulator: Test the regulator to ensure it maintains the correct pressure in the system. A faulty regulator can lead to fuel delivery problems.

Regular checks of these components can prevent more significant issues down the road and ensure the fuel system operates efficiently. Addressing any identified problems promptly will contribute to the longevity and reliability of the engine.