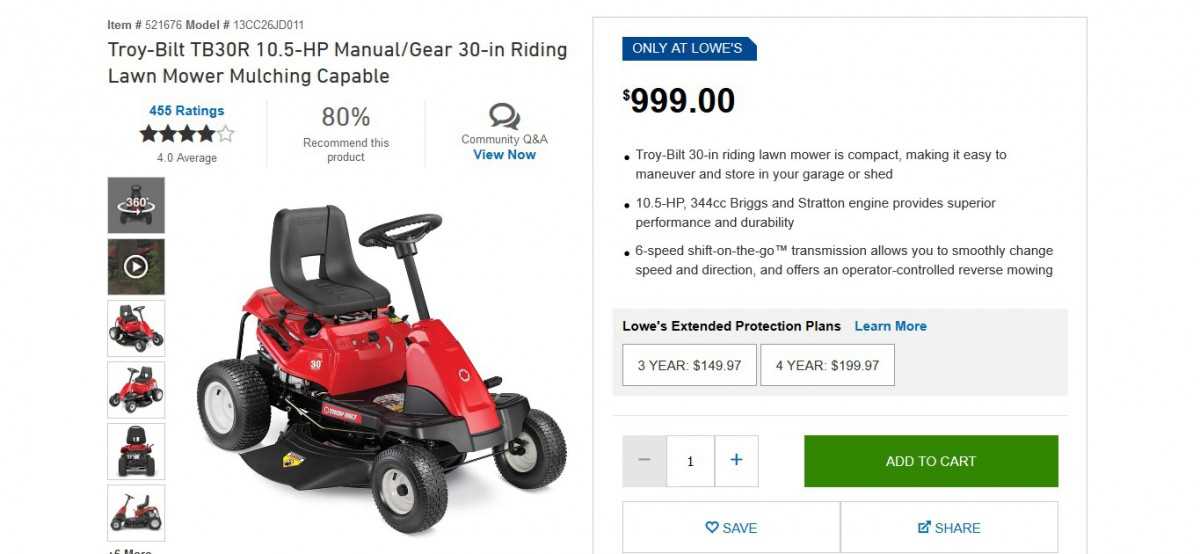

Troy Bilt TB30R Maintenance and Repair Guide

Understanding the intricacies of outdoor machinery is essential for ensuring longevity and optimal performance. This section focuses on the essential aspects of upkeep for a specific model, providing valuable insights into troubleshooting common issues and implementing effective solutions.

Maintaining your equipment not only enhances its efficiency but also reduces the likelihood of unexpected breakdowns. Regular attention to various components allows users to recognize early signs of wear and address them promptly.

Moreover, this guide emphasizes the significance of adhering to manufacturer recommendations for service intervals and necessary adjustments. By following these practices, users can significantly extend the lifespan of their machinery and enjoy seamless operation throughout the seasons.

Overview of the Lawn Equipment

This section provides insights into a popular model of garden machinery known for its efficiency and user-friendly features. The machine is designed to assist in maintaining lawns and gardens, making it an essential tool for both hobbyists and professionals.

Understanding the various components and functionalities of this equipment can enhance its usability and longevity. Here are some key aspects to consider:

- Design Features: The machinery is engineered with a focus on durability and ease of operation.

- Engine Performance: It boasts a powerful engine that ensures effective grass cutting and trimming.

- Maintenance Guidelines: Regular upkeep is crucial for optimal performance and to avoid common issues.

- Safety Precautions: Adhering to safety measures enhances user experience and prevents accidents.

By familiarizing oneself with these features, users can make informed decisions regarding operation and maintenance, ultimately leading to better performance and satisfaction with their gardening tasks.

Common Issues and Symptoms

Understanding the frequent problems that may arise with lawn care equipment is crucial for effective maintenance. Identifying these issues early can help prevent more significant malfunctions and ensure smooth operation.

Typical Problems

- Engine fails to start or runs inconsistently

- Unusual noises during operation

- Difficulty in cutting grass evenly

- Excessive vibrations while in use

Signs to Monitor

- Unresponsive controls

- Frequent stalling or hesitation

- Visible leaks from the engine or fuel system

- Smell of burning or unusual odors

Being aware of these common indicators can help users take timely actions, ensuring their equipment remains in optimal condition.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and troubleshooting of any machinery. Various instruments enable users to diagnose issues accurately and execute necessary adjustments or replacements efficiently.

Basic Hand Tools

Essential hand tools include wrenches, screwdrivers, and pliers. These instruments are fundamental for loosening or tightening components, allowing for easy access to the internal mechanisms.

Specialized Equipment

In addition to basic tools, specialized items such as torque wrenches and multimeters can greatly enhance repair capabilities. These tools help ensure that parts are adjusted correctly and that electrical systems are functioning properly.

Step-by-Step Repair Procedures

This section outlines a comprehensive approach to addressing common issues encountered with your outdoor equipment. By following these structured guidelines, you can ensure that the process remains straightforward and effective, leading to optimal performance.

Preparation and Tools Required

Before starting any maintenance tasks, it’s crucial to gather the necessary tools and prepare the workspace. Here’s a list of essential items:

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts |

| Screwdriver | To remove and secure screws |

| Fuel Stabilizer | To maintain fuel quality during storage |

| Oil | For lubrication of moving parts |

Step-by-Step Process

Follow these steps to effectively troubleshoot and resolve issues:

- Begin by assessing the condition of the equipment, checking for any visible signs of wear or damage.

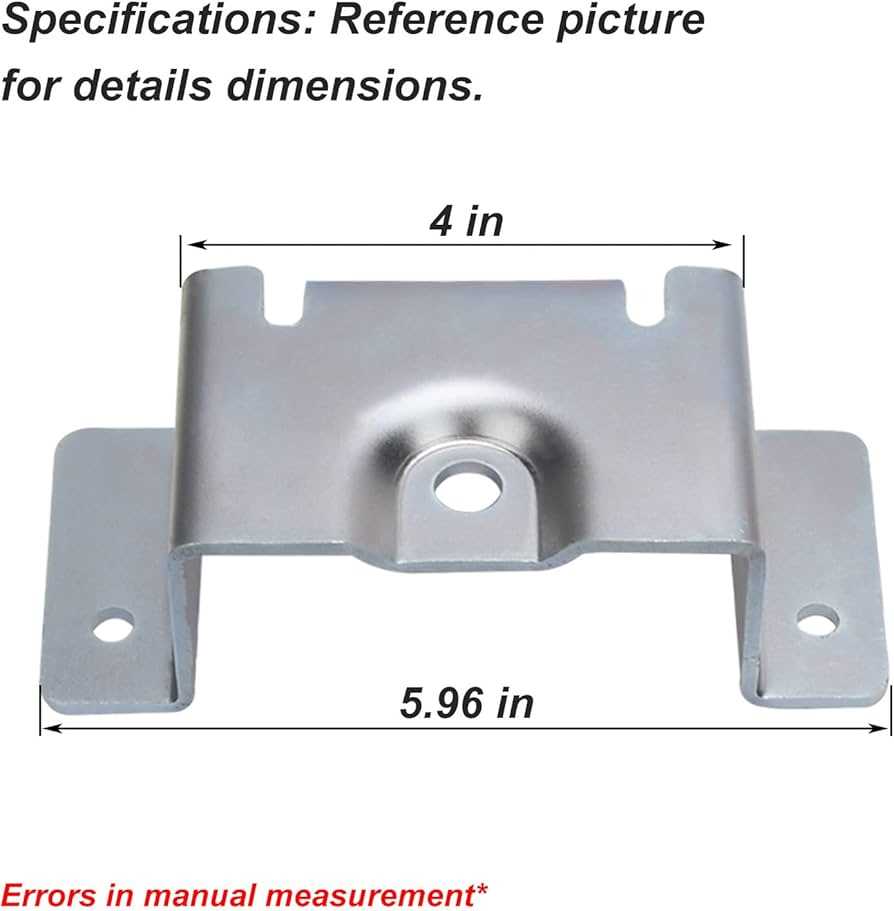

- Consult the specifications to determine if any parts need replacement.

- Carefully disassemble the affected components using the appropriate tools.

- Inspect each part, cleaning as necessary to remove debris or buildup.

- Reassemble the unit, ensuring all fasteners are securely tightened.

- Test the functionality to confirm that the issue has been resolved.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your equipment. Regular care not only enhances performance but also prevents unexpected breakdowns. By following a few straightforward practices, you can ensure your machine remains in top condition for years to come.

Regular Cleaning

Keep your device clean by removing debris and dirt after each use. This prevents buildup that can affect functionality. Pay special attention to filters and air vents to maintain optimal airflow.

Scheduled Inspections

Conduct periodic checks of all components to identify wear and tear early. Inspect belts, blades, and fluids regularly to ensure everything is functioning as intended. Address any issues promptly to avoid larger problems down the road.

Replacing the Engine Components

Maintaining the functionality of a motorized device often requires the replacement of various engine elements. This process can enhance performance, increase efficiency, and extend the lifespan of the equipment. Understanding the steps involved is crucial for achieving successful results.

Identifying the Components

Before starting the replacement process, it is essential to recognize the key engine components that may need attention. Common parts include the spark plug, air filter, and fuel filter. Each of these plays a vital role in the overall operation of the engine, and their proper functioning is necessary for optimal performance.

Steps for Replacement

To replace the identified components, begin by disconnecting the power source for safety. Next, carefully remove the old parts, taking note of their placement for accurate installation of the new items. Ensure that each new component is compatible with the engine specifications before securing it in place. Finally, reconnect the power source and test the engine to confirm that it operates smoothly.

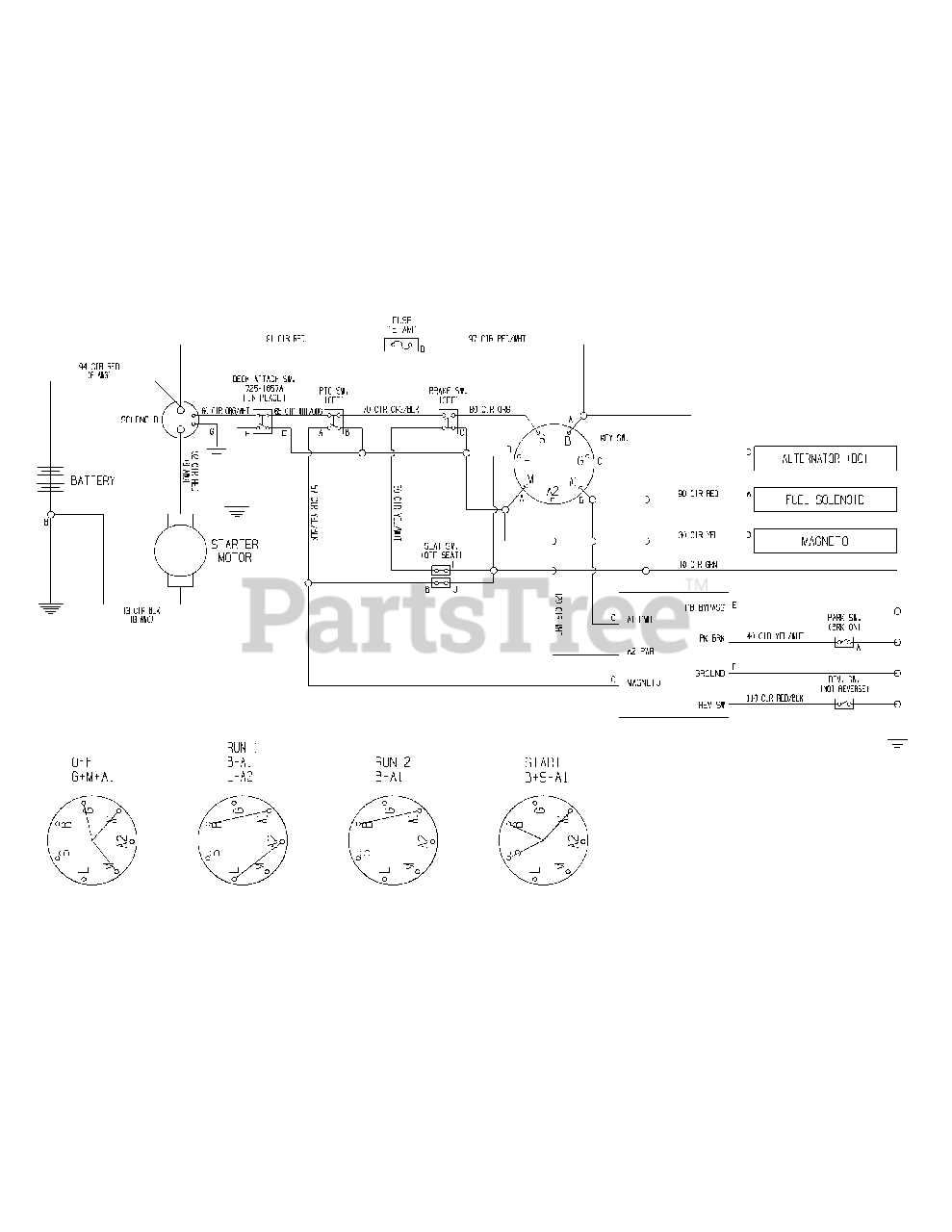

Understanding the Electrical System

The electrical framework of a machine plays a crucial role in its overall functionality. This section aims to explore the essential components and their interactions within the system, providing a clearer understanding of how each part contributes to optimal performance.

Key Components

- Battery: The power source that provides energy for operation.

- Wiring: Conducts electricity between different elements.

- Switches: Control the flow of electricity and enable or disable functions.

- Fuse: Protects the system from overload by breaking the circuit when necessary.

System Interactions

Each component interacts within the network to ensure the equipment operates efficiently. A well-functioning electrical system not only enhances reliability but also prevents potential malfunctions. Understanding these interactions is vital for effective troubleshooting and maintenance.

Troubleshooting Starting Problems

Starting issues can arise from various factors, and identifying the root cause is essential for effective resolution. This section will guide you through common challenges that may prevent your equipment from starting properly, along with practical steps to diagnose and rectify these problems.

First, ensure that the fuel supply is adequate and that the fuel is fresh. Stale or contaminated fuel can hinder ignition. Next, inspect the battery connections for corrosion or looseness, as a weak battery can significantly affect starting performance. Additionally, check the ignition system components, such as the spark plug, to ensure they are functioning correctly.

If the engine still fails to start, examine the air intake system for any blockages that may restrict airflow. A clean air filter is vital for optimal engine performance. Lastly, review the safety features, as some models have mechanisms that prevent starting if certain conditions are not met, such as engaging the brake or ensuring the throttle is in the correct position.

Inspecting and Fixing the Transmission

Regular examination and maintenance of the drive system are crucial for ensuring smooth operation and longevity of the equipment. Identifying potential issues early can prevent more significant problems down the line and enhance overall performance.

Begin by checking the fluid levels, as insufficient lubrication can lead to increased wear and tear. Look for any leaks around the transmission housing, which may indicate damage or a faulty seal. It’s essential to inspect the fluid for any discoloration or debris, as these can signal contamination or degradation.

Next, examine the connections and cables associated with the transmission. Ensure that all links are secure and free from corrosion. If any parts appear worn or frayed, consider replacing them to maintain proper functionality.

If the unit exhibits irregular shifting or unusual noises, deeper diagnostics may be required. Testing the engagement of gears and listening for any strange sounds can help pinpoint specific issues that may need addressing.

After conducting these checks, performing any necessary repairs or adjustments will restore the transmission to optimal working condition. Regular upkeep and attention to these components are vital for reliable performance.

Blades and Cutting Deck Maintenance

Proper upkeep of the cutting components is essential for achieving optimal performance and longevity of the equipment. Ensuring that blades and the deck are in top condition not only enhances efficiency but also contributes to a healthier lawn.

Regular Inspection

Frequent checks of the blades and deck are crucial. Look for signs of wear, damage, or debris accumulation. Addressing these issues promptly can prevent further complications.

- Examine blades for nicks or dullness.

- Clear any grass clippings or dirt from the cutting deck.

- Check for loose bolts and fasteners.

Sharpening and Replacement

Keeping blades sharp is vital for clean cuts and overall effectiveness. Dull blades can lead to uneven cuts and stress on the grass.

- Remove the blades from the deck carefully.

- Sharpen using an appropriate tool or take them to a professional.

- Replace blades that show significant wear or damage.

By following these maintenance practices, users can ensure that their cutting equipment remains efficient and effective throughout the mowing season.

Seasonal Care Guidelines

Maintaining equipment throughout the year is essential for optimal performance and longevity. Seasonal care ensures that your tools are prepared to handle varying conditions, minimizing wear and tear.

Spring Preparation: As the weather warms up, inspect your machinery for any damage from winter storage. Check fluids, sharpen blades, and clean any debris that may have accumulated. This will enhance efficiency during use.

Summer Maintenance: During the hotter months, monitor the cooling systems closely. Ensure that vents are clear and that the engine is running smoothly. Regularly check the air filters and replace them if necessary to avoid overheating.

Autumn Readiness: As temperatures begin to drop, it’s important to prepare for the colder months. Drain any fuel that may go stale and winterize the equipment by adding appropriate additives. Clean and store items properly to prevent rust and damage.

Winter Care: While equipment may not be in regular use, periodic checks are crucial. Keep machines in a dry environment and inspect for any potential issues, ensuring they remain in good condition for the upcoming season.

Resources for Further Assistance

When seeking help with equipment maintenance and troubleshooting, various sources can provide valuable information. These resources can guide users in effectively resolving issues and enhancing their understanding of the machinery.

Online Forums and Communities

Engaging in online discussions can be beneficial. Numerous platforms allow users to share experiences, ask questions, and receive advice from fellow enthusiasts and experts. Participating in these communities fosters knowledge exchange and can lead to practical solutions.

Official Support and Documentation

Accessing the official support channels and documentation is crucial. Manufacturers often provide detailed guides and technical specifications on their websites. Utilizing these resources ensures that users follow proper procedures and stay informed about the latest updates.

Frequently Asked Questions

This section aims to address common inquiries related to maintenance and troubleshooting for garden equipment. Understanding these aspects can enhance the user experience and ensure optimal performance.

What should I do if the engine won’t start?

If the engine fails to start, check the fuel level and ensure that the ignition system is functioning properly. Additionally, inspect the battery and connections, as these can significantly affect the starting process.

How can I improve cutting efficiency?

To enhance cutting efficiency, keep the blades sharp and well-maintained. Regular cleaning of the equipment and ensuring that the wheels and drive system are free of debris will also contribute to better performance.