Kubota L2850 Comprehensive Repair Manual Guide

In the world of agricultural machinery, ensuring optimal performance and longevity is crucial for any operator. The intricacies of machinery demand a comprehensive understanding of their components and systems. A reliable reference source can be invaluable for those seeking to address issues and enhance the efficiency of their equipment.

This resource serves as a practical guide for owners and operators, offering insights into the common challenges faced during operation. By following systematic procedures, users can effectively diagnose and resolve various malfunctions, leading to a smoother workflow and increased productivity.

With detailed instructions and tips, this guide empowers individuals to undertake necessary interventions confidently. Whether addressing minor adjustments or more significant concerns, having a structured approach can make a significant difference in the upkeep of essential machinery.

Kubota L2850 Overview and Features

This section provides a comprehensive look at a compact yet powerful agricultural machine, designed to enhance productivity and efficiency in various farming tasks. Known for its reliability and robust performance, this model stands out in its class, making it a favorite among operators.

Equipped with a formidable engine, the unit offers impressive horsepower, enabling it to tackle demanding jobs with ease. Its hydraulic system is engineered for optimal performance, allowing for smooth operation of attachments and implements.

Key features include a user-friendly control layout, which enhances operator comfort and minimizes fatigue during long hours of work. The four-wheel drive system ensures superior traction, making it versatile in different terrains and weather conditions.

Additionally, the compact design allows for easy maneuverability in tight spaces, making it suitable for a variety of tasks, from tilling and plowing to hauling and mowing. Overall, this machine is a reliable partner for those looking to improve their agricultural efficiency and effectiveness.

Common Issues with Kubota L2850

This section discusses typical challenges encountered with a specific agricultural machine, providing insights for owners and operators. Understanding these issues can aid in effective troubleshooting and maintenance, ensuring optimal performance over time.

Frequent Mechanical Problems

- Engine starting difficulties: Commonly attributed to battery issues or fuel delivery problems.

- Transmission malfunctions: Often caused by low fluid levels or worn components.

- Hydraulic system failures: May arise from leaks or clogged filters.

Maintenance-Related Concerns

- Neglected oil changes: Can lead to engine wear and reduced efficiency.

- Clogged air filters: Result in decreased performance and increased fuel consumption.

- Worn belts and hoses: May cause operational disruptions if not regularly inspected.

Essential Tools for Repairing L2850

When it comes to maintaining agricultural machinery, having the right instruments at hand is crucial for effective servicing. The appropriate equipment not only ensures a smoother workflow but also enhances the longevity of the machine. Here’s a list of indispensable tools that will aid in the upkeep and troubleshooting of your equipment.

Basic Hand Tools

- Wrenches: A set of adjustable wrenches is essential for loosening and tightening various fasteners.

- Screwdrivers: Both flathead and Phillips screwdrivers are necessary for accessing different components.

- Pliers: Needle-nose and regular pliers can assist with gripping and manipulating small parts.

- Socket Set: A comprehensive socket set will help with nuts and bolts in hard-to-reach areas.

Specialized Equipment

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications, preventing damage.

- Multimeter: Useful for diagnosing electrical issues within the system.

- Oil Filter Wrench: Specifically designed for easy removal of oil filters during servicing.

- Hydraulic Jacks: Important for lifting heavy components safely during maintenance tasks.

Equipping yourself with these tools will streamline the process of servicing and enhance the overall efficiency of your machinery. Regular upkeep not only prevents costly repairs but also guarantees optimal performance in the field.

Step-by-Step Maintenance Procedures

Regular upkeep of your machinery is essential for optimal performance and longevity. Following a systematic approach not only enhances efficiency but also minimizes the risk of unexpected breakdowns. This section outlines a series of straightforward tasks designed to ensure your equipment remains in peak condition.

1. Fluid Checks and Changes

Begin by inspecting all fluid levels, including engine oil, coolant, and hydraulic fluid. Low levels can lead to operational issues, so top them off as necessary. Additionally, schedule regular oil changes according to the manufacturer’s guidelines to maintain engine health and performance.

2. Filter Maintenance

Replace air and fuel filters at specified intervals to ensure proper airflow and fuel delivery. Clogged filters can lead to decreased efficiency and increased wear on engine components. Regularly inspecting and cleaning these filters can significantly enhance the machine’s reliability.

Engine Troubleshooting Techniques

Diagnosing issues within an engine can be a complex task that requires a systematic approach. Identifying symptoms accurately and utilizing appropriate methods can significantly streamline the troubleshooting process. A thorough understanding of the engine’s components and their functions is essential for effective diagnostics.

Visual Inspection: Begin by conducting a comprehensive visual examination. Look for obvious signs of wear, leaks, or damage to various parts. Pay close attention to belts, hoses, and connections, as these can often reveal underlying problems.

Listen for Unusual Sounds: Sounds can be indicative of specific issues. Unusual noises such as knocking, grinding, or hissing should not be ignored. They often signal malfunctions that need immediate attention.

Check Fluid Levels: Regularly monitoring fluid levels is crucial. Low oil or coolant can lead to severe engine problems. Always ensure that fluids are at recommended levels and look for any signs of contamination.

Utilize Diagnostic Tools: Employing diagnostic equipment can provide invaluable insights. Tools such as OBD-II scanners can help identify error codes that pinpoint issues, making the troubleshooting process more efficient.

Test Compression: Conducting a compression test can reveal the health of the engine’s cylinders. Low compression readings may indicate problems with valves, piston rings, or head gaskets, necessitating further investigation.

Examine Electrical Systems: Many engine problems stem from electrical failures. Check the battery, wiring, and sensors for any signs of malfunction. Ensuring proper electrical function is vital for overall engine performance.

By employing these techniques, one can effectively identify and address engine issues, ensuring optimal functionality and longevity. Systematic troubleshooting not only resolves current problems but also aids in preventing future complications.

Hydraulic System Repair Guidelines

Maintaining and troubleshooting the hydraulic system is essential for ensuring optimal performance and longevity of machinery. A thorough understanding of the components and their functions will aid in identifying issues and implementing effective solutions. Regular inspection and proactive measures can prevent major breakdowns and enhance overall efficiency.

Component Inspection

Begin by examining all hydraulic components for signs of wear, leaks, or damage. Hoses should be free from cracks and abrasions, while connections must be secure to prevent fluid loss. Check the filter for clogs and replace it as needed to maintain proper fluid flow. Regularly monitoring these elements can significantly reduce the risk of system failures.

Troubleshooting Common Issues

When facing performance problems, such as decreased lifting capacity or erratic operation, it is crucial to isolate the cause. Start by assessing the fluid levels; low fluid can lead to inadequate pressure. If the fluid is contaminated, it should be drained and replaced. Additionally, inspect the pump for any signs of malfunction, as it plays a vital role in maintaining pressure within the system. Addressing these common challenges promptly will help restore functionality and prevent further complications.

Transmission Issues and Solutions

When it comes to machinery, transmission problems can significantly impact performance and efficiency. Understanding the common issues that arise within the transmission system and their corresponding solutions is crucial for maintaining optimal operation. This section will explore various transmission challenges and effective strategies to address them.

Common Transmission Problems

One prevalent issue is slipping, where the gears fail to engage properly, resulting in a loss of power. This can be caused by low fluid levels or contaminated fluid. Another frequent concern is difficulty in shifting gears, which may stem from worn components or misadjusted cables. Recognizing these symptoms early can help prevent further damage and costly repairs.

Solutions and Maintenance Tips

To resolve slipping, first check the transmission fluid levels and top off if necessary. If contamination is suspected, a fluid change may be required. For shifting difficulties, inspecting and adjusting cables or replacing worn parts can restore proper functionality. Regular maintenance, including fluid checks and replacements, can prolong the lifespan of the transmission and enhance overall performance.

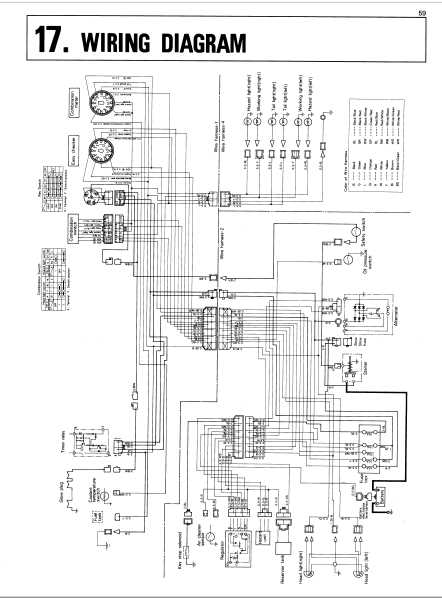

Electrical System Diagnostics for L2850

Diagnosing electrical issues in machinery is crucial for maintaining optimal performance and ensuring longevity. This section provides a structured approach to identifying and resolving problems within the electrical framework of the equipment.

To effectively assess the electrical system, follow these essential steps:

- Visual Inspection:

- Check for frayed wires or loose connections.

- Inspect connectors for corrosion or dirt buildup.

- Examine fuses for continuity and any signs of damage.

- Testing Voltage:

- Utilize a multimeter to measure voltage at various points.

- Confirm that voltage levels meet specified requirements.

- Identify any significant drops that may indicate a fault.

- Component Functionality:

- Test individual components such as relays and switches.

- Ensure sensors are providing accurate readings.

- Evaluate the battery and charging system for performance.

- Diagnostic Codes:

- Check for error codes using diagnostic tools.

- Refer to manufacturer specifications for code meanings.

- Address any identified issues based on codes.

Following these steps will enhance the efficiency of the diagnostic process, helping to pinpoint electrical faults and facilitate timely repairs. Regular maintenance and thorough checks are key to preventing future electrical failures.

Replacing Parts: A Practical Guide

Maintaining the functionality of your machinery often requires the timely replacement of worn or damaged components. This guide aims to provide a clear and structured approach to part replacement, ensuring efficiency and reliability in the process. Understanding the steps involved will help you tackle repairs with confidence and precision.

Identifying Components for Replacement

Before you begin the replacement process, it is crucial to accurately identify which parts need attention. Common indicators include unusual noises, decreased performance, or visible wear. Utilizing the right diagnostic tools can aid in pinpointing issues swiftly.

| Symptoms | Possible Parts to Replace |

|---|---|

| Unusual Noise | Bearings, Belts |

| Decreased Performance | Filters, Fuel Injectors |

| Visible Wear | Gaskets, Seals |

Steps for Safe Replacement

Once you’ve identified the necessary components, follow these steps to ensure a safe and effective replacement:

- Gather the required tools and new parts.

- Consult technical specifications to understand installation procedures.

- Disconnect power sources and ensure the machine is secure.

- Carefully remove the old part, taking note of its positioning and connections.

- Install the new component, ensuring it is properly aligned and secured.

- Reconnect any power sources and conduct a functionality test.

By adhering to these guidelines, you can effectively manage part replacements and enhance the longevity of your equipment.

Safety Precautions During Repairs

When engaging in maintenance tasks, it is crucial to prioritize safety to prevent accidents and injuries. Proper precautions not only protect the individual performing the work but also ensure that the equipment remains in good condition for future use. Understanding and implementing these measures is essential for a successful and safe working environment.

Always wear appropriate personal protective equipment (PPE). This includes gloves, goggles, and steel-toed boots, which safeguard against various hazards such as sharp objects, chemical splashes, and heavy components. Additionally, ensuring that clothing is fitted and free of loose ends can help prevent entanglement in moving parts.

Before beginning any task, it is vital to disconnect power sources. This action prevents unintentional activation of machinery, significantly reducing the risk of injury. Always double-check that all energy sources are isolated and secured before proceeding with any adjustments or inspections.

Maintain a clean and organized workspace. Clutter can lead to slips, trips, and falls. Ensuring that tools and materials are neatly arranged not only enhances efficiency but also minimizes hazards associated with disorganization.

Familiarize yourself with the equipment. Understanding the specific mechanisms and functions of the machinery involved is essential for safe handling. Referencing documentation or seeking guidance from knowledgeable individuals can provide valuable insights and help avoid potential dangers.

In case of emergencies, always have a first aid kit nearby. Knowing how to use the items within it can be critical in addressing minor injuries promptly. Additionally, being aware of emergency contacts and procedures ensures quick response in more serious situations.

By adhering to these safety guidelines, individuals can significantly reduce the risk of accidents during maintenance activities, promoting a safer and more efficient working environment.