Ultimate Guide to John Deere 800 Swather Repair Manual

Maintaining complex agricultural equipment is essential for optimal performance and longevity. Proper care ensures that these machines operate efficiently, minimizing downtime and enhancing productivity on the farm. This section aims to provide crucial insights into the maintenance processes that can significantly improve the functionality of specific machinery.

Understanding the nuances of upkeep is vital for operators and technicians alike. Familiarizing oneself with the intricacies of components and systems allows for effective troubleshooting and enhances the ability to perform necessary interventions when issues arise. With a focus on practical advice, this guide serves as a valuable resource for those seeking to improve their technical skills.

By delving into the specifics of equipment care, users can uncover the ultimate strategies for preserving their machinery’s reliability and performance. Whether tackling routine inspections or addressing more complex challenges, a thorough knowledge base is indispensable for successful agricultural operations.

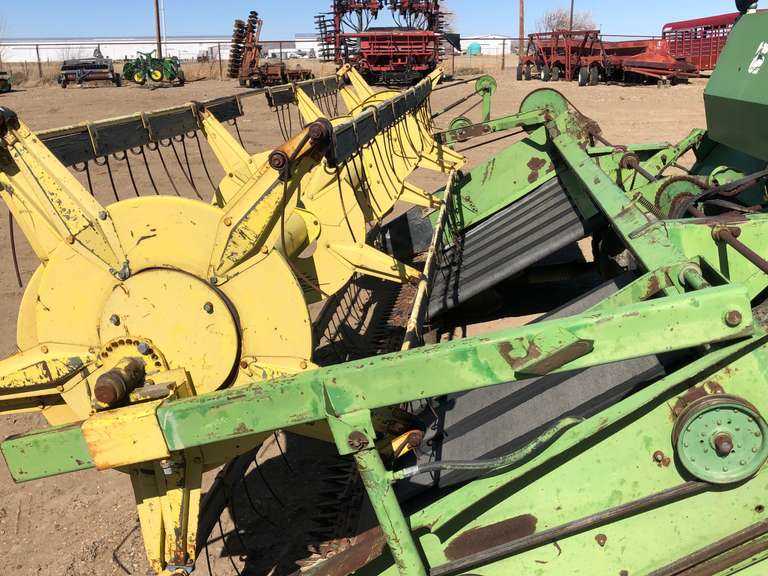

Overview of John Deere 800 Swather

This section provides a comprehensive understanding of a versatile agricultural machine designed for efficient crop management. Its primary function is to facilitate the harvesting process, ensuring that the crops are gathered in a timely and effective manner.

The equipment is characterized by several key features:

- Design: Engineered for optimal performance in various field conditions.

- Efficiency: Capable of maximizing yield through rapid cutting and gathering.

- Durability: Built with high-quality materials to withstand rigorous usage.

In addition to its functional advantages, the machine offers several operational benefits:

- Ease of Use: User-friendly controls allow for straightforward operation.

- Maintenance: Designed with accessible components for simplified servicing.

- Versatility: Adaptable to various crop types, enhancing its utility across different agricultural practices.

Overall, this machinery stands out as an essential tool for farmers seeking to improve their harvesting processes and increase productivity.

Common Issues with John Deere 800

Understanding frequent problems associated with agricultural equipment can greatly enhance maintenance efforts and prolong the lifespan of the machinery. Below are some of the typical challenges that operators may encounter.

- Mechanical Failures:

Issues such as broken gears or malfunctioning hydraulics can severely impact performance.

- Electrical Problems:

Faulty wiring or malfunctioning sensors may lead to unexpected shutdowns or erratic behavior.

- Wear and Tear:

Components like belts and blades often suffer from deterioration, requiring regular inspection and replacement.

- Fuel System Issues:

Clogs or leaks in the fuel system can result in decreased efficiency and power loss.

- Cooling System Failures:

Overheating due to coolant leaks or radiator blockages is a common concern.

Addressing these issues promptly can ensure that the machinery remains in optimal working condition and reduces downtime during critical operations.

Importance of a Repair Manual

A comprehensive guide is essential for maintaining and troubleshooting complex machinery. It serves as a valuable resource, providing detailed instructions and insights that can significantly enhance the efficiency and longevity of equipment. Understanding the intricacies of operational tools is crucial for optimal performance and safety.

Enhanced Understanding of Equipment

A well-structured guide offers clarity on the functioning of various components. It enables operators to grasp the mechanics involved, ensuring they can identify issues before they escalate. This knowledge not only fosters confidence but also contributes to informed decision-making regarding maintenance and usage.

Cost Efficiency and Time Saving

Utilizing a detailed reference can lead to substantial savings. By following the outlined procedures for upkeep and repairs, users can avoid costly mistakes and minimize downtime. Access to precise information ensures that tasks are completed efficiently, ultimately enhancing productivity and reducing the need for professional assistance.

Tools Required for Maintenance

Proper upkeep of agricultural machinery is essential for ensuring optimal performance and longevity. Utilizing the right equipment during maintenance tasks not only enhances efficiency but also promotes safety. This section outlines the necessary tools that will aid in the upkeep process.

- Hand Tools

- Wrenches (various sizes)

- Screwdrivers (flathead and Phillips)

- Pliers (needle-nose and regular)

- Socket set

- Diagnostic Equipment

- Multimeter

- Pressure gauge

- Hydraulic fluid tester

- Maintenance Supplies

- Lubricants and oils

- Filters (air, oil, fuel)

- Cleaning solvents

- Safety Gear

- Gloves

- Safety glasses

- Hearing protection

Equipping yourself with these tools will facilitate effective maintenance and contribute to the machinery’s operational efficiency.

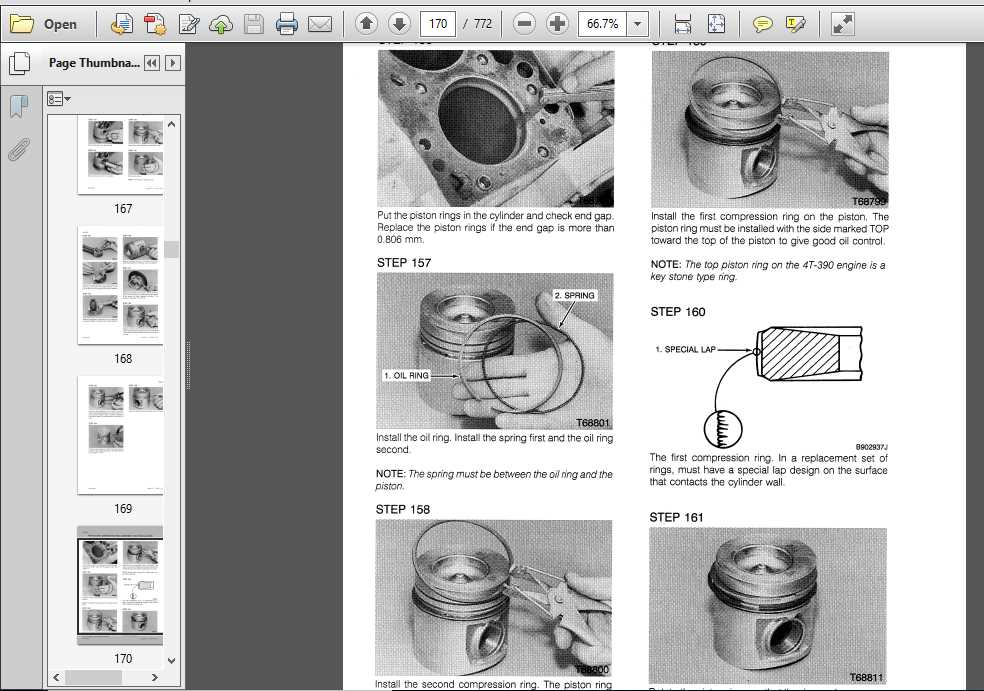

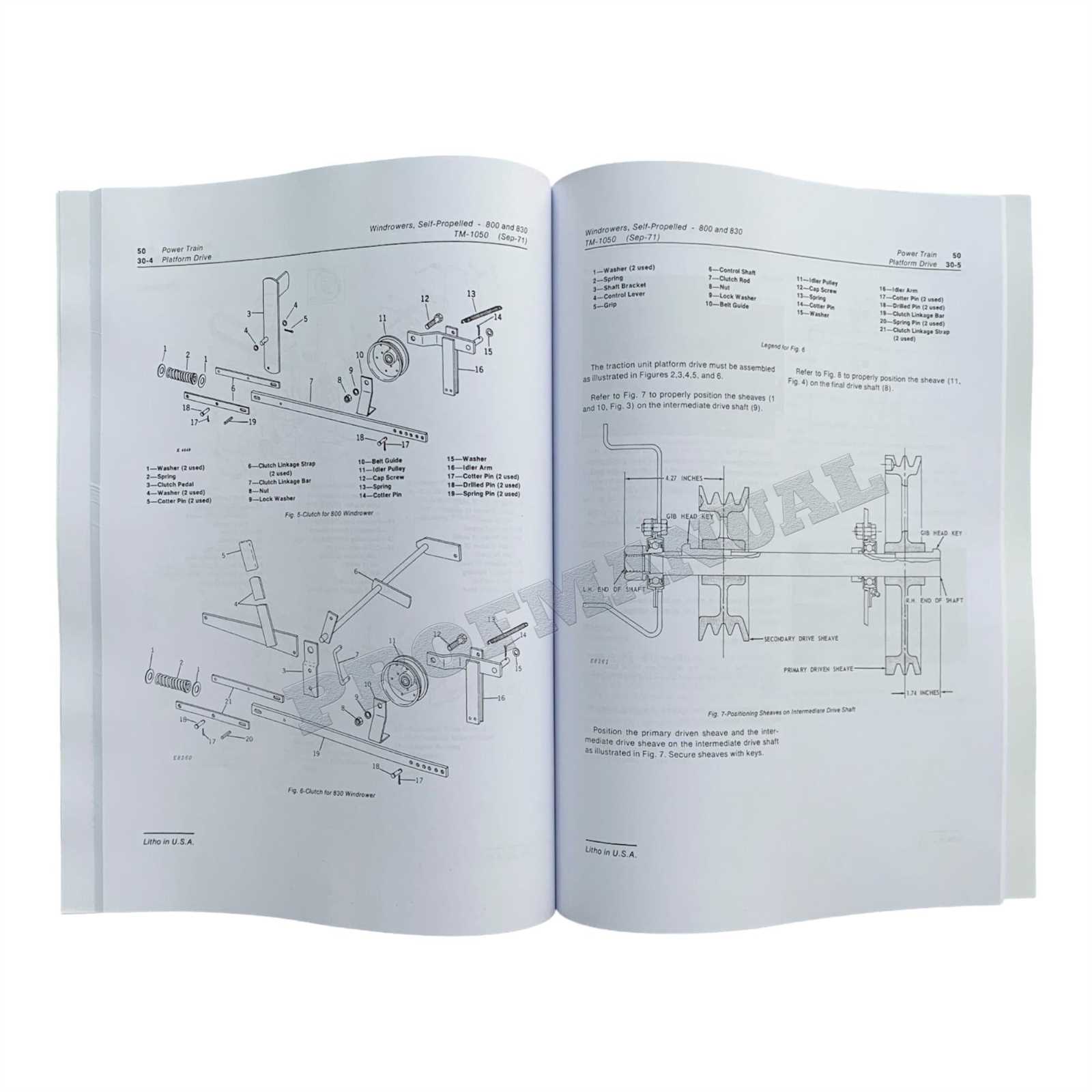

Step-by-Step Repair Instructions

Maintaining agricultural machinery requires a systematic approach to ensure optimal performance and longevity. This section provides a detailed guide to troubleshoot and address common issues that may arise, empowering operators to handle repairs efficiently.

1. Gather Necessary Tools

Before starting any task, collect all required tools and equipment. Essential items typically include wrenches, screwdrivers, pliers, and safety gear. Having everything on hand will streamline the process and minimize downtime.

2. Identify the Issue

Begin by observing the machinery and noting any unusual sounds or behaviors. Check for leaks, abnormal vibrations, or error codes. This initial assessment is crucial in determining the necessary steps for resolution.

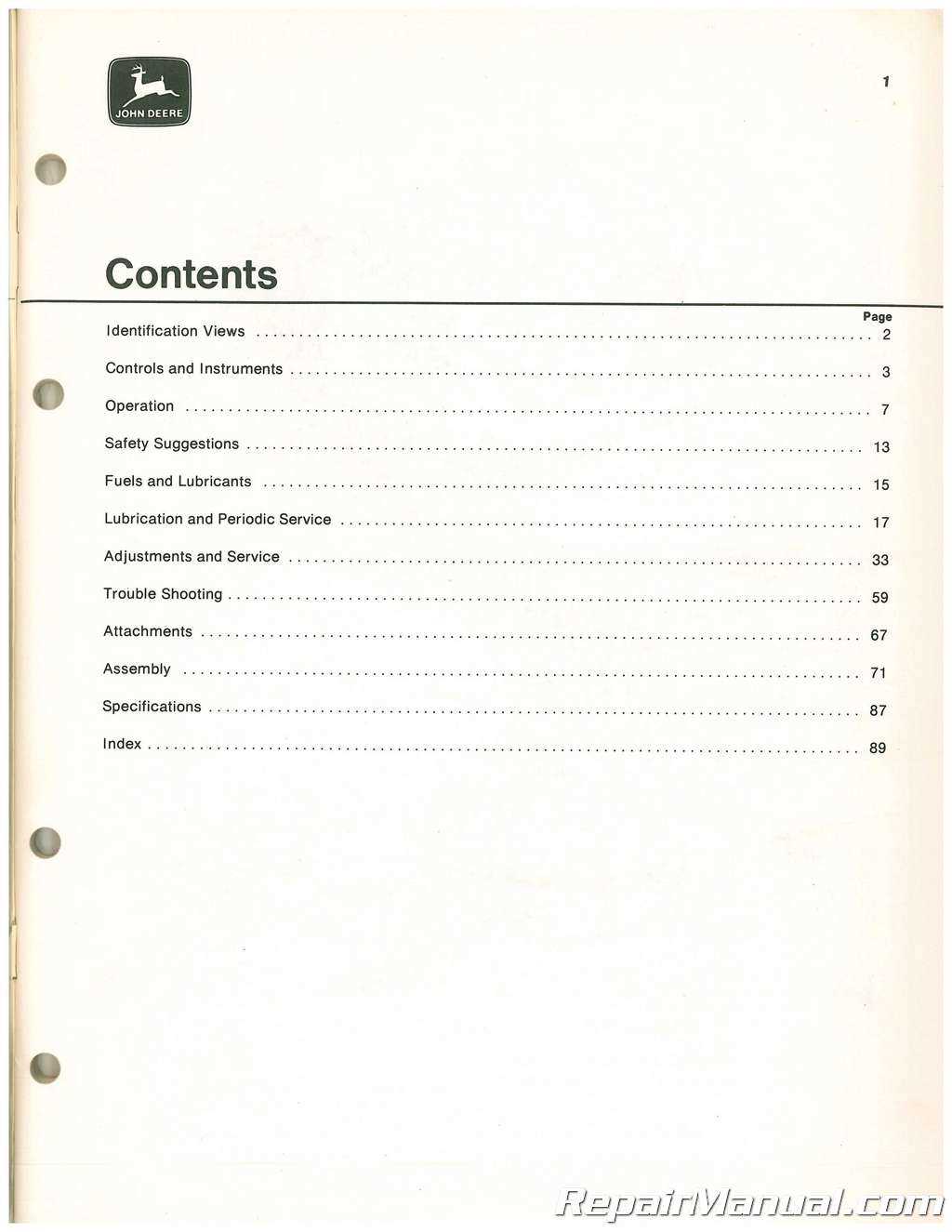

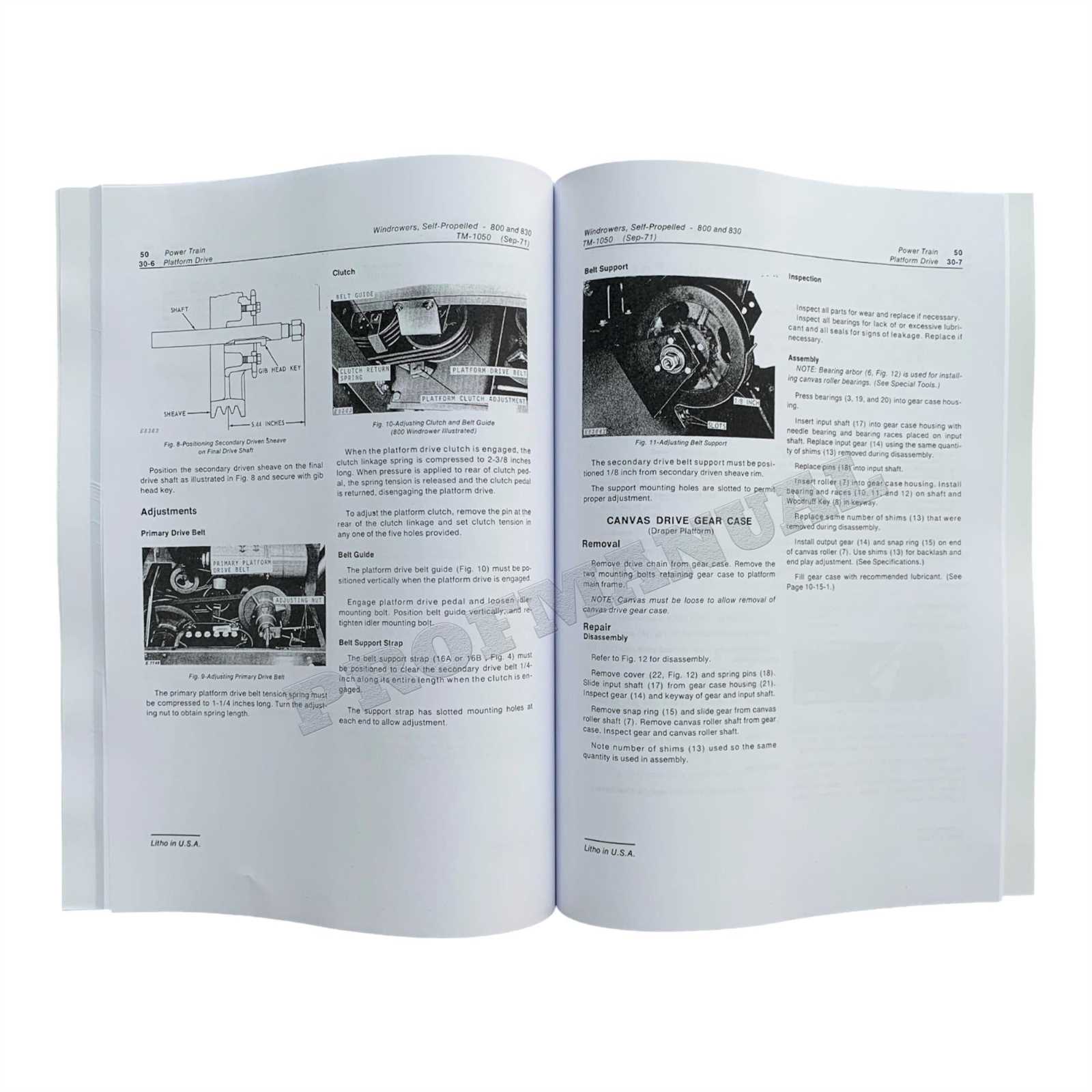

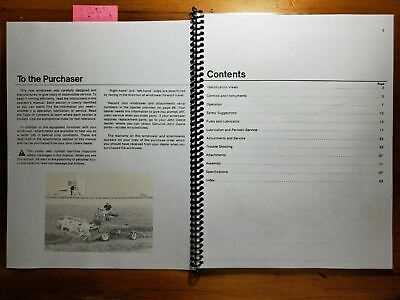

3. Consult Documentation

Refer to the provided documentation for specifications and troubleshooting tips. These resources often include diagrams that illustrate components, making it easier to pinpoint issues and follow repair protocols.

4. Perform Basic Checks

Conduct routine inspections such as checking fluid levels, filters, and belts. Clean or replace parts as needed. Regular maintenance can prevent more significant problems down the line.

5. Execute Repairs

Follow the outlined procedures to address the identified problem. Whether it involves replacing a component or adjusting settings, ensure each step is completed thoroughly. Document any changes made for future reference.

6. Test Functionality

After completing repairs, conduct a series of tests to ensure everything is operating correctly. Monitor for any remaining issues and make adjustments as necessary to achieve optimal performance.

7. Maintain Records

Keep detailed records of all maintenance and repairs performed. This information will be invaluable for future troubleshooting and can help in maintaining the resale value of the equipment.

Safety Precautions During Repairs

When conducting maintenance tasks on agricultural machinery, ensuring a secure working environment is paramount. Adhering to safety protocols not only protects the individual performing the work but also safeguards the equipment from potential damage. Awareness and preparation are essential components in preventing accidents and injuries.

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Before beginning any task, familiarize yourself with the machinery’s operating manual and safety guidelines.

- Ensure the equipment is powered down and secured to prevent accidental startup.

- Maintain a clean workspace to avoid tripping hazards and facilitate easy access to tools.

- Utilize proper tools and equipment designed for specific tasks to minimize risk.

In addition to personal safety measures, consider the following precautions:

- Work with a partner whenever possible to provide assistance in case of emergencies.

- Keep fire extinguishers and first aid kits readily accessible in case of unexpected incidents.

- Regularly inspect tools and equipment for wear and damage to ensure they are in good working condition.

- Stay hydrated and take regular breaks to maintain focus and reduce fatigue.

By prioritizing safety during maintenance activities, individuals can effectively reduce the likelihood of mishaps and contribute to a more efficient working environment.

Recommended Replacement Parts

When maintaining and enhancing the performance of agricultural machinery, selecting the right components is crucial. Quality replacement parts not only ensure optimal functionality but also extend the lifespan of the equipment. This section provides insights into essential components that should be considered for replacement during routine maintenance or repairs.

Key Components to Consider

Belts and Chains: Regular inspection and replacement of belts and chains are vital. Worn or damaged belts can lead to inefficient operation and potential breakdowns. Ensure to choose high-quality options that match the original specifications for durability and performance.

Filters and Fluids:

Air, Oil, and Fuel Filters: Maintaining clean filters is essential for the optimal functioning of the machinery. Regular replacement prevents contaminants from affecting the engine and other critical systems. Fluids should also be checked and changed according to the manufacturer’s guidelines to ensure smooth operation.

Troubleshooting Electrical Problems

Addressing electrical issues can be a daunting task for operators. A systematic approach is essential to identify and resolve problems effectively. Understanding the components involved and how they interact is the first step toward troubleshooting.

Common Electrical Issues

- Blown fuses or circuit breakers

- Faulty wiring or connections

- Malfunctioning sensors or switches

- Inconsistent power supply

Troubleshooting Steps

- Inspect fuses and circuit breakers for signs of damage or failure.

- Examine wiring for wear, corrosion, or loose connections.

- Test sensors and switches to ensure proper functionality.

- Use a multimeter to check voltage levels and continuity.

- Consult schematics to verify correct wiring and component placement.

Following these guidelines will assist in diagnosing and correcting electrical malfunctions, ensuring optimal performance and safety of the equipment.

Maintaining Hydraulic Systems

Hydraulic systems play a crucial role in ensuring the efficient operation of various machinery. Proper maintenance is essential to enhance performance, prevent failures, and extend the lifespan of these systems. Regular attention to key components can significantly reduce the risk of malfunctions and improve overall functionality.

First and foremost, it is vital to monitor fluid levels regularly. Maintaining the correct hydraulic fluid level ensures optimal pressure and prevents overheating. Additionally, the type and quality of the fluid used should meet the manufacturer’s specifications, as this affects the system’s efficiency and longevity.

Inspecting hoses and fittings for signs of wear or leaks is another important aspect of maintenance. Cracked or damaged hoses can lead to fluid loss and reduced system performance. Promptly replacing any compromised components helps to avoid more serious issues down the line.

Another key area is the filtration system. Clogged filters can impede fluid flow, leading to increased pressure and potential system failure. Regularly checking and replacing filters according to the maintenance schedule will help ensure smooth operation.

Finally, periodic testing of hydraulic pressure and performance is essential. This involves using appropriate gauges to assess whether the system operates within the recommended pressure range. Identifying any irregularities early can prevent costly repairs and downtime.

Seasonal Maintenance Tips

Maintaining agricultural machinery is crucial for optimal performance throughout the year. Regular upkeep not only extends the lifespan of your equipment but also ensures efficient operation during peak seasons. By following a seasonal maintenance schedule, you can identify potential issues before they escalate, ultimately saving time and resources.

| Season | Maintenance Tasks | Notes |

|---|---|---|

| Spring | Check fluid levels, inspect belts and hoses, clean filters | Ensure all parts are in good condition before the busy season. |

| Summer | Monitor tire pressure, check cooling systems, clean exterior | Heat can strain machinery; regular checks help prevent overheating. |

| Fall | Inspect for wear, lubricate moving parts, test electrical systems | Prepare for storage by addressing any issues found during inspections. |

| Winter | Store in a dry place, cover with protective materials, check for pests | Protect against moisture and pests during off-season storage. |

By adhering to these seasonal maintenance tips, you can keep your equipment running smoothly and effectively throughout the agricultural year.

Finding Authorized Service Centers

Locating certified service facilities is crucial for maintaining and troubleshooting equipment effectively. These centers ensure that repairs and maintenance are conducted with high standards, utilizing genuine parts and knowledgeable technicians.

Here are some steps to help you find an authorized service center:

- Visit the official website of the manufacturer.

- Use the locator tool provided on the site to find nearby facilities.

- Contact customer service for recommendations on trusted centers.

- Consult your local dealer for additional guidance.

When selecting a service center, consider the following factors:

- Proximity to your location.

- Reputation and customer reviews.

- Availability of specialized tools and equipment.

- Experience with your specific type of machinery.

By taking these steps, you can ensure that your equipment is serviced by qualified professionals, leading to optimal performance and longevity.

Customer Reviews on Repair Manuals

Feedback from users provides invaluable insights into the quality and effectiveness of maintenance guides. These evaluations highlight personal experiences, showcasing how these resources assist in troubleshooting and upkeep tasks.

Many customers appreciate the clarity and detail found within these documents, noting that well-structured information facilitates a smoother repair process. Clear illustrations and step-by-step instructions are frequently mentioned as key elements that enhance usability.

However, some users express frustration over missing information or vague descriptions, which can hinder efficient repairs. They often emphasize the need for comprehensive coverage of various models and issues.

Overall, customer feedback serves as a vital tool for potential buyers, guiding them toward resources that best meet their needs while also offering manufacturers a chance to improve their offerings.