Comprehensive Guide to Repairing John Deere LA135

When it comes to ensuring the longevity and efficiency of your outdoor machinery, having access to comprehensive resources is essential. Understanding the intricacies of your equipment can make a significant difference in its performance and durability. This guide serves as a valuable tool for owners looking to enhance their knowledge and tackle various challenges associated with maintaining their machines.

Every piece of lawn equipment has its unique set of features and requirements. By familiarizing yourself with these details, you can better manage routine upkeep and address potential issues before they escalate. A well-informed owner is not only more capable but also empowered to make the best decisions regarding care and troubleshooting.

This document will provide insights into common procedures, tips for effective management, and troubleshooting techniques that will help you keep your machinery running smoothly. With the right approach, you can ensure that your investment remains reliable and efficient for years to come.

Overview of John Deere LA135

This section provides a comprehensive look at a popular model of lawn care equipment, known for its reliability and efficiency in maintaining grassy areas. Designed for homeowners, this machine combines power and user-friendly features, making it an excellent choice for various landscaping tasks.

Key attributes include:

- Robust engine performance for effective grass cutting.

- Easy maneuverability, allowing for navigation in tight spaces.

- Comfortable seating and ergonomic controls enhancing user experience.

- Durable construction that withstands regular use and varied weather conditions.

Maintenance and care are crucial for optimal performance. Regular checks and servicing ensure longevity and efficiency, allowing owners to maximize their investment.

This model is particularly suited for residential properties, offering a balance of power and ease of use that appeals to both novice and experienced users alike.

Common Issues with LA135 Models

The model in question is known for its reliable performance; however, users may encounter several frequent challenges that can affect functionality. Understanding these common problems can help in maintaining optimal operation and prolonging the lifespan of the machine.

Engine Problems

One of the prevalent issues involves the engine not starting or stalling unexpectedly. This can be attributed to factors such as fuel contamination, a clogged air filter, or a malfunctioning spark plug. Regular maintenance checks are essential to ensure that these components are in good working condition. Cleaning or replacing the air filter and ensuring proper fuel quality can mitigate many of these concerns.

Transmission Difficulties

Another common area of concern is the transmission system, which may exhibit sluggish response or failure to engage properly. This can be caused by low hydraulic fluid levels or issues with the drive belt. Inspecting fluid levels regularly and replacing worn belts can help resolve these issues and improve overall performance.

Essential Maintenance Tips for Longevity

Proper upkeep of your machinery is crucial for extending its lifespan and ensuring optimal performance. By following a few fundamental practices, you can enhance the reliability of your equipment and reduce the likelihood of unexpected breakdowns. These essential tips focus on regular checks, proper cleaning, and timely servicing to keep your machinery running smoothly.

Regular Inspection and Cleaning

Routine inspections play a vital role in identifying potential issues before they escalate. Check for signs of wear and tear, such as loose bolts or frayed belts, and address them promptly. Additionally, keeping the machine clean is essential. Debris accumulation can lead to overheating and damage. Regularly clear grass, dirt, and other materials from critical areas to ensure efficient operation.

Fluid Maintenance and Replacement

Monitoring and replacing fluids is another key aspect of maintenance. Ensure that oil, coolant, and other essential fluids are at appropriate levels and free from contamination. Regular oil changes and timely replacements of filters can significantly improve engine performance and longevity. Don’t forget to consult the guidelines for recommended intervals to maintain optimal functionality.

Step-by-Step Repair Procedures

This section provides a comprehensive guide to effectively addressing common issues encountered with your equipment. By following the outlined steps, you can ensure a systematic approach to troubleshooting and maintenance, thereby prolonging the lifespan of your machinery.

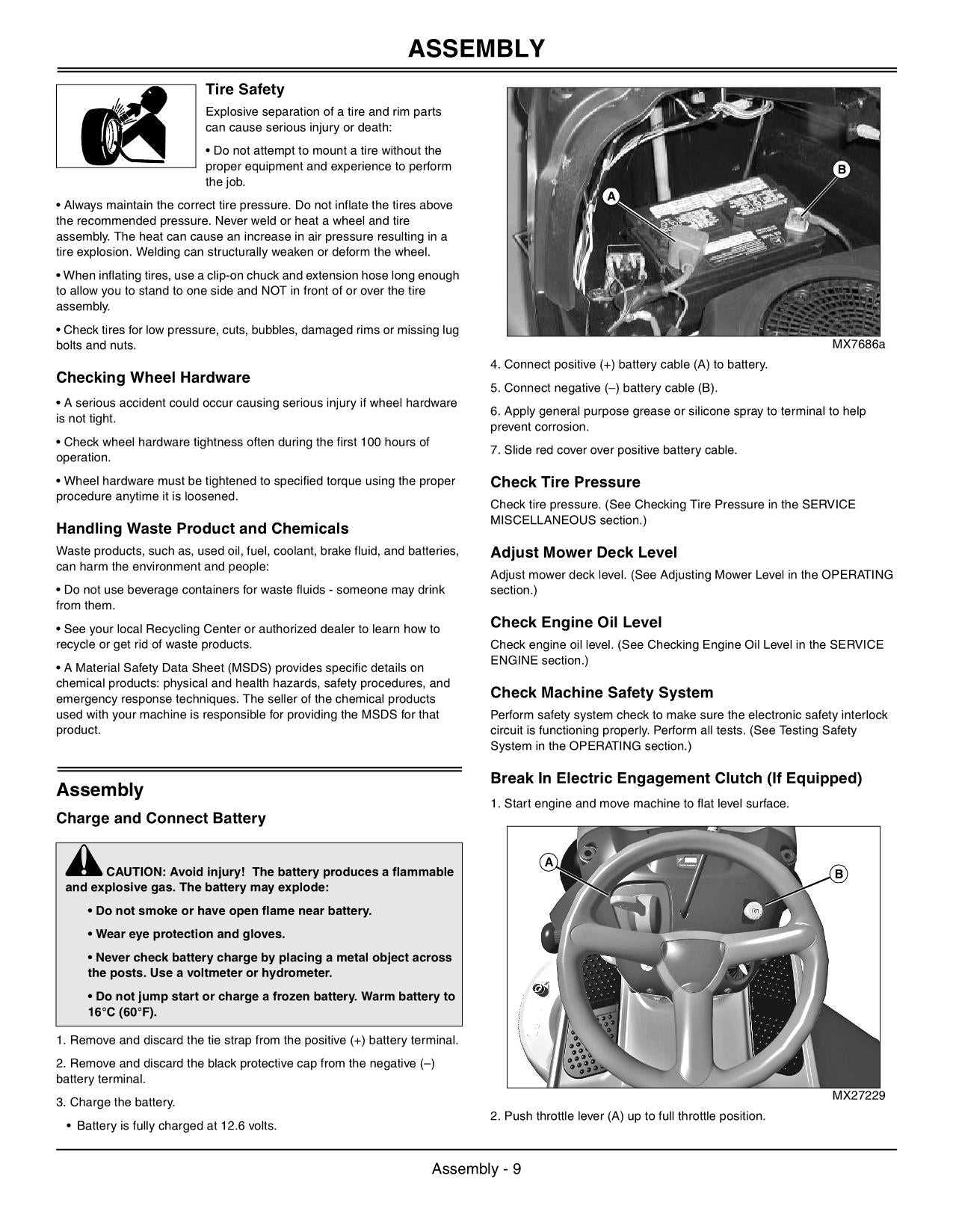

Preparation and Safety Measures

Before initiating any work, it’s essential to gather the necessary tools and safety gear. Ensure that the area is well-ventilated and free from obstructions. Always disconnect the power source to avoid any accidents. Familiarize yourself with the specific components and their functions to streamline the repair process.

Identifying and Fixing Issues

Start by diagnosing the problem accurately. Inspect the machinery for visible signs of wear or damage. Utilize a systematic approach to dismantle parts as needed, documenting each step for reassembly. Replace any defective components with high-quality replacements. After completing the repairs, conduct thorough tests to verify that everything operates smoothly.

Tools Required for Effective Repairs

Ensuring the longevity and optimal performance of your machinery involves having the right equipment at hand. Proper tools not only facilitate smoother operation but also enhance safety and efficiency during the maintenance process. Understanding which instruments are essential can make a significant difference in how effectively tasks are completed.

Essential Hand Tools

Basic hand tools form the foundation of any maintenance toolkit. These include wrenches, screwdrivers, and pliers, which are crucial for loosening and tightening various components. Having a comprehensive set ensures you can address a wide range of issues that may arise. Additionally, socket sets are invaluable for reaching fasteners in tight spaces, making them a must-have for any enthusiast.

Power Tools and Accessories

While hand tools are vital, power tools can significantly expedite the repair process. A drill with multiple bit attachments allows for versatile applications, from boring holes to driving screws efficiently. Furthermore, a grinder can help in shaping or smoothing parts, while a compressor is essential for tasks involving pneumatic tools. Investing in quality power tools can save time and enhance the precision of your work.

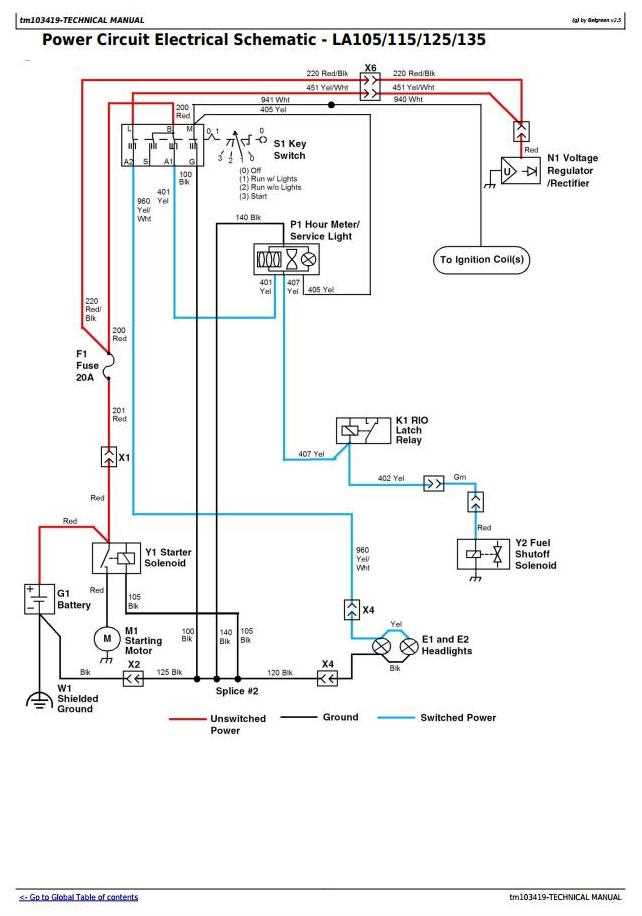

Troubleshooting Electrical Problems

Addressing electrical issues can be daunting, but understanding common symptoms and solutions is essential for effective resolution. This section provides a systematic approach to diagnosing and fixing electrical malfunctions that may arise in your equipment.

Start by identifying any visible signs of problems, such as flickering lights, non-starting engines, or malfunctioning accessories. These indicators often point to underlying electrical faults that can be traced to specific components.

| Symptom | Possible Cause | Solution |

|---|---|---|

| Lights not working | Burnt-out bulb or blown fuse | Replace the bulb or check/replace the fuse |

| Engine won’t start | Weak battery or faulty starter | Charge or replace the battery; test or replace the starter |

| Intermittent power loss | Loose connections or damaged wiring | Inspect and tighten connections; replace damaged wires |

| Accessories not functioning | Faulty switch or relay | Test and replace the switch or relay as needed |

By systematically examining each symptom and applying the corresponding solutions, you can effectively troubleshoot and restore electrical functionality to your machinery.

Engine Maintenance and Optimization

Proper care and enhancement of an engine play a crucial role in ensuring its longevity and efficiency. Regular attention not only maximizes performance but also prevents potential issues that could lead to costly repairs. By following a systematic approach, owners can maintain optimal functionality.

Key practices for maintaining and optimizing engine performance include:

- Regular oil changes to ensure lubrication and reduce wear.

- Checking and replacing air filters to improve airflow and combustion efficiency.

- Inspecting fuel systems for cleanliness and optimal delivery.

- Monitoring coolant levels and temperatures to prevent overheating.

- Conducting routine inspections for leaks, wear, and other signs of trouble.

In addition to basic maintenance, consider the following optimization techniques:

- Upgrade to high-performance spark plugs for better ignition.

- Utilize premium fuels to enhance combustion quality.

- Adjust engine tuning settings to match specific performance needs.

- Install aftermarket components designed for efficiency gains.

- Regularly clean and maintain exhaust systems to improve airflow.

By adhering to these guidelines, engine operators can achieve a well-functioning machine that not only meets but exceeds performance expectations.

Transmission Repair Techniques Explained

Understanding the intricacies of power transfer systems is crucial for maintaining optimal performance in various machinery. Effective troubleshooting and restoration methods can significantly enhance the lifespan and efficiency of these components. This section will explore various approaches to diagnosing and resolving common issues found in these systems.

Common Issues and Diagnostic Steps

Identifying problems within the power transfer system requires a systematic approach. Typical symptoms may include unusual noises, slipping gears, or unresponsive movements. Start by conducting a thorough inspection of fluid levels, condition, and potential leaks. Next, check the alignment and condition of belts and pulleys, as misalignment can lead to significant operational failures.

Repair Techniques

Once issues are diagnosed, several techniques can be employed to restore functionality. Depending on the severity of the damage, solutions may range from simple adjustments to component replacements. Below is a table summarizing these techniques:

| Technique | Description |

|---|---|

| Fluid Replacement | Draining old fluid and refilling with fresh lubricant to ensure proper function. |

| Belt Adjustment | Tightening or realigning belts to prevent slippage and wear. |

| Seal Replacement | Changing worn or damaged seals to prevent fluid leaks. |

| Gear Inspection | Examining gears for wear and replacing them if necessary. |

| Testing Components | Utilizing diagnostic tools to assess the functionality of specific parts. |

Implementing these techniques will not only resolve current issues but also help prevent future complications, ensuring reliable operation of the power transfer system.

Best Practices for Safety During Repairs

Ensuring a secure environment while conducting maintenance tasks is essential for preventing accidents and injuries. By following a set of well-defined safety protocols, individuals can minimize risks and create a safer workspace. Adopting a proactive approach to safety not only protects the technician but also enhances the overall efficiency of the task at hand.

Here are some crucial guidelines to consider:

| Safety Practice | Description |

|---|---|

| Wear Protective Gear | Always use appropriate safety equipment such as gloves, goggles, and steel-toed boots to safeguard against potential hazards. |

| Use Proper Tools | Utilize the right tools for the job to prevent injuries and ensure effective completion of tasks. |

| Maintain a Clean Workspace | Keep the area organized and free of clutter to reduce the chances of tripping or misplacing tools. |

| Read Instructions Carefully | Thoroughly review all guidelines and procedures before starting to understand the risks involved. |

| Be Mindful of Surroundings | Stay aware of the environment and any potential hazards, such as electrical outlets or flammable materials. |

By adhering to these recommendations, individuals can foster a culture of safety that benefits everyone involved in the maintenance process.

Where to Find Replacement Parts

Finding suitable components for your equipment is essential for maintaining its performance and longevity. Whether you are dealing with routine maintenance or addressing specific issues, sourcing the right parts can make a significant difference. There are various avenues to explore when searching for reliable replacements, ensuring you can keep your machinery in optimal condition.

Authorized Dealers

One of the most dependable sources for components is authorized dealerships. These outlets typically offer a comprehensive selection of genuine parts that meet manufacturer standards. Additionally, staff members are usually well-informed and can assist in identifying the correct components based on your specific needs. Purchasing from authorized dealers often provides peace of mind, as you are assured of the quality and compatibility of the parts.

Online Marketplaces

The internet has transformed the way we shop for replacement components. Numerous online marketplaces specialize in equipment parts, offering a vast array of options at competitive prices. It’s essential to research sellers to ensure they provide quality items and reliable customer service. Reading reviews and checking return policies can also help you make informed purchasing decisions.