Complete Guide to 1994 Nissan Sentra Repair Manual

In the world of automobiles, proper upkeep and troubleshooting play crucial roles in ensuring longevity and optimal performance. Enthusiasts and everyday drivers alike benefit from comprehensive resources that outline necessary procedures and techniques for effective vehicle care. This guide serves as a valuable reference for anyone looking to enhance their understanding of essential maintenance practices.

Understanding the intricacies of a specific vehicle model empowers owners to tackle issues with confidence. Whether it’s routine inspections, common repairs, or specialized techniques, having access to detailed information can make all the difference. This resource aims to equip readers with the knowledge needed to navigate the complexities of automotive maintenance with ease.

From basic servicing to more advanced repairs, a well-structured guide offers clarity and assurance. Armed with the right tools and insights, individuals can approach their automotive challenges proactively, saving time and money while fostering a deeper connection with their vehicles. Explore the essential tips and techniques that will help you maintain and troubleshoot with expertise.

Overview of the 1994 Nissan Sentra

This section provides a comprehensive look at a compact vehicle that gained popularity for its efficiency and practicality. Known for its reliable performance, this model has been a favorite among drivers seeking a balance between functionality and affordability.

Design and Features: The car boasts a sleek exterior with a design that remains timeless. Inside, the cabin is designed with user comfort in mind, featuring a straightforward layout and easy-to-reach controls. Ample space ensures that both passengers and cargo can be accommodated with ease.

Engine and Performance: Under the hood, this vehicle offers a variety of engine options that cater to different driving preferences. Known for its fuel efficiency, it provides an economical solution for daily commuting while still delivering a satisfying driving experience.

Safety and Reliability: Safety features were a priority in the design, incorporating essential elements that enhance driver and passenger security. With a reputation for durability, this model has stood the test of time, making it a sensible choice for budget-conscious buyers.

Overall, this compact car represents a blend of practicality and reliability, making it a noteworthy option in its category.

Common Issues and Fixes

Vehicles of this era often exhibit a range of typical problems that can affect performance and reliability. Identifying these issues early can save time and prevent further complications. Here, we will explore some frequent concerns and their corresponding solutions.

- Engine Overheating

Symptoms of overheating may include a rising temperature gauge and steam from the hood. Regularly check:

- Coolant levels

- Radiator function

- Thermostat operation

Fix: Ensure proper coolant levels and inspect the radiator for leaks. Replace the thermostat if necessary.

- Electrical Issues

Problems with starting or erratic electrical behavior can be traced back to:

- Battery condition

- Alternator function

- Wiring integrity

Fix: Test the battery and alternator, and repair any damaged wiring connections.

- Brake Wear

Signs of brake wear may include squeaking noises or a spongy pedal feel. Regular inspections are crucial:

- Check brake pads

- Inspect rotors

- Evaluate brake fluid levels

Fix: Replace worn brake pads and rotors as needed, and top off brake fluid.

- Transmission Slipping

If the vehicle struggles to shift gears or experiences unexpected changes in speed, consider:

- Fluid levels

- Filter condition

- Linkage adjustments

Fix: Check and replenish transmission fluid, replace the filter, and adjust linkage if necessary.

By addressing these common issues promptly, owners can maintain their vehicle’s functionality and ensure a smoother driving experience.

Essential Tools for DIY Repairs

Engaging in do-it-yourself projects can be both rewarding and cost-effective. Having the right instruments on hand is crucial for efficiently tackling various tasks. Here is a comprehensive list of must-have tools to enhance your experience and ensure successful outcomes.

- Wrenches: A variety of wrenches, including open-end, box-end, and adjustable types, are essential for loosening or tightening bolts and nuts.

- Screwdrivers: A set of both flathead and Phillips screwdrivers in various sizes will cover most fastening needs.

- Socket Set: A complete socket set allows for greater torque application and access to hard-to-reach fasteners.

- Pliers: Needle-nose and slip-joint pliers are versatile tools for gripping, bending, and cutting wires or small components.

- Jack and Stands: A hydraulic jack and jack stands are vital for safely lifting and securing vehicles during maintenance tasks.

- Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s specifications, preventing over-tightening or under-tightening.

- Multimeter: A multimeter is essential for diagnosing electrical issues and measuring voltage, current, and resistance.

- Oil Filter Wrench: Designed specifically for removing and installing oil filters, this tool simplifies the maintenance of engine oil systems.

- Work Light: Adequate lighting is crucial for visibility in tight spaces. A portable work light can illuminate dark areas effectively.

Equipping yourself with these basic tools will empower you to handle a wide range of tasks efficiently. Invest in quality instruments to ensure durability and reliability, making your DIY endeavors more enjoyable and successful.

Understanding the Engine Specifications

Having a clear grasp of the engine specifications is essential for any automotive enthusiast or mechanic. These details not only define the performance capabilities of a vehicle but also guide maintenance and repair efforts. By understanding the core components and their functions, one can ensure optimal operation and longevity of the engine.

Key Components

The heart of any automobile is its engine, which consists of several critical parts. Among these, the cylinder block serves as the main structure housing the cylinders, where combustion occurs. The pistons move within these cylinders, converting fuel energy into mechanical power. Additionally, the camshaft and crankshaft play vital roles in controlling the timing of valve openings and the movement of the pistons, respectively.

Performance Metrics

Engine performance is often measured through specifications such as horsepower and torque. Horsepower indicates the engine’s ability to perform work over time, while torque reflects the rotational force available at the crankshaft. Understanding these metrics helps in assessing the vehicle’s acceleration and overall driving experience. Proper tuning and regular maintenance are crucial to keeping these specifications within their optimal range.

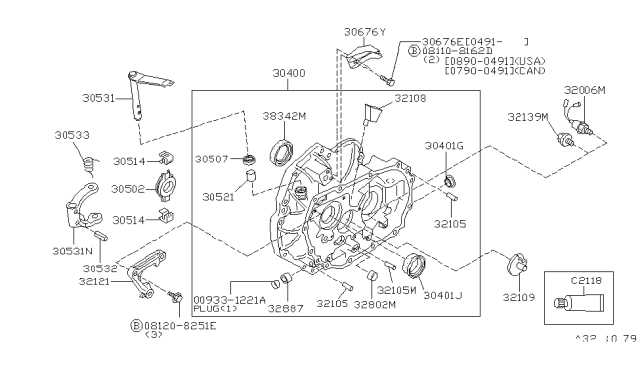

Transmission Maintenance Tips

Proper upkeep of the transmission system is essential for ensuring smooth performance and extending the lifespan of your vehicle. Regular attention to this critical component can prevent costly repairs and enhance driving experience. Below are some essential practices to keep in mind.

Regular Fluid Checks: Monitoring the transmission fluid level and condition is vital. Ensure that the fluid is at the recommended level and appears clean. If it looks dark or has a burnt smell, it may need replacement.

Scheduled Fluid Changes: Follow the manufacturer’s guidelines regarding fluid changes. Over time, transmission fluid can break down and lose its effectiveness, leading to potential issues.

Inspect Seals and Gaskets: Look for any signs of leaks around seals and gaskets. Addressing these issues promptly can prevent fluid loss and potential damage to the system.

Avoid Overheating: Excessive heat can cause significant damage. Ensure that the cooling system is functioning correctly and consider installing an auxiliary cooler if you frequently tow or carry heavy loads.

Monitor Shifting Performance: Pay attention to how the vehicle shifts gears. Delays, slipping, or unusual noises can indicate underlying problems that require immediate attention.

Consult Professionals: If you encounter any issues or have concerns, seeking help from qualified technicians can provide peace of mind and ensure that necessary repairs are performed correctly.

By following these guidelines, you can maintain the efficiency and reliability of your transmission, contributing to the overall performance and longevity of your vehicle.

Brake System Inspection Guidelines

Ensuring the proper functionality of the braking mechanism is crucial for vehicle safety and performance. Regular evaluations help identify potential issues before they escalate, maintaining both efficiency and reliability. A thorough examination involves checking various components and systems to ensure they operate seamlessly together.

Start by assessing the brake fluid level and its condition. Contaminated or low fluid can lead to decreased braking efficiency. Next, inspect the brake pads for wear; they should have sufficient material to provide adequate stopping power. Pay attention to any unusual noises during braking, which could indicate underlying problems.

Examine the rotors for signs of damage, such as warping or scoring, as these can affect the overall braking capability. Additionally, check the brake lines for leaks or cracks, which could compromise the entire system. Finally, ensure that the brake calipers are functioning properly, as they play a critical role in clamping the pads against the rotors.

Regular inspections and timely maintenance not only enhance safety but also extend the lifespan of the braking system. Following these guidelines can help maintain optimal performance and prevent costly repairs down the line.

Electrical System Troubleshooting

Diagnosing issues within a vehicle’s electrical framework is crucial for maintaining optimal performance. An effective approach involves systematic checks and observations to identify and resolve malfunctions. This section provides guidance on common problems and solutions related to the electrical system.

Start by understanding the primary components involved in the electrical system:

- Battery

- Alternator

- Starter motor

- Fuses and relays

- Wiring harnesses

- Electrical connectors

Here’s a step-by-step guide for troubleshooting:

- Visual Inspection: Examine the battery for corrosion or loose connections. Check wiring for any signs of wear or damage.

- Battery Test: Use a multimeter to measure the battery voltage. A fully charged battery should read around 12.6 volts.

- Alternator Function: With the engine running, measure the voltage at the battery terminals. A reading between 13.5 and 14.5 volts indicates proper alternator function.

- Starter Check: If the engine does not crank, ensure the starter is receiving power. Listen for clicking sounds, which may indicate a weak battery or faulty starter.

- Fuse Assessment: Inspect all fuses related to electrical components. Replace any blown fuses and check for underlying issues.

- Wiring Examination: Follow the wiring from components to ensure connections are secure and free of damage. Use dielectric grease on connectors to prevent corrosion.

By following these steps, you can effectively pinpoint electrical issues and implement the necessary repairs, ensuring reliable operation of the vehicle’s systems.

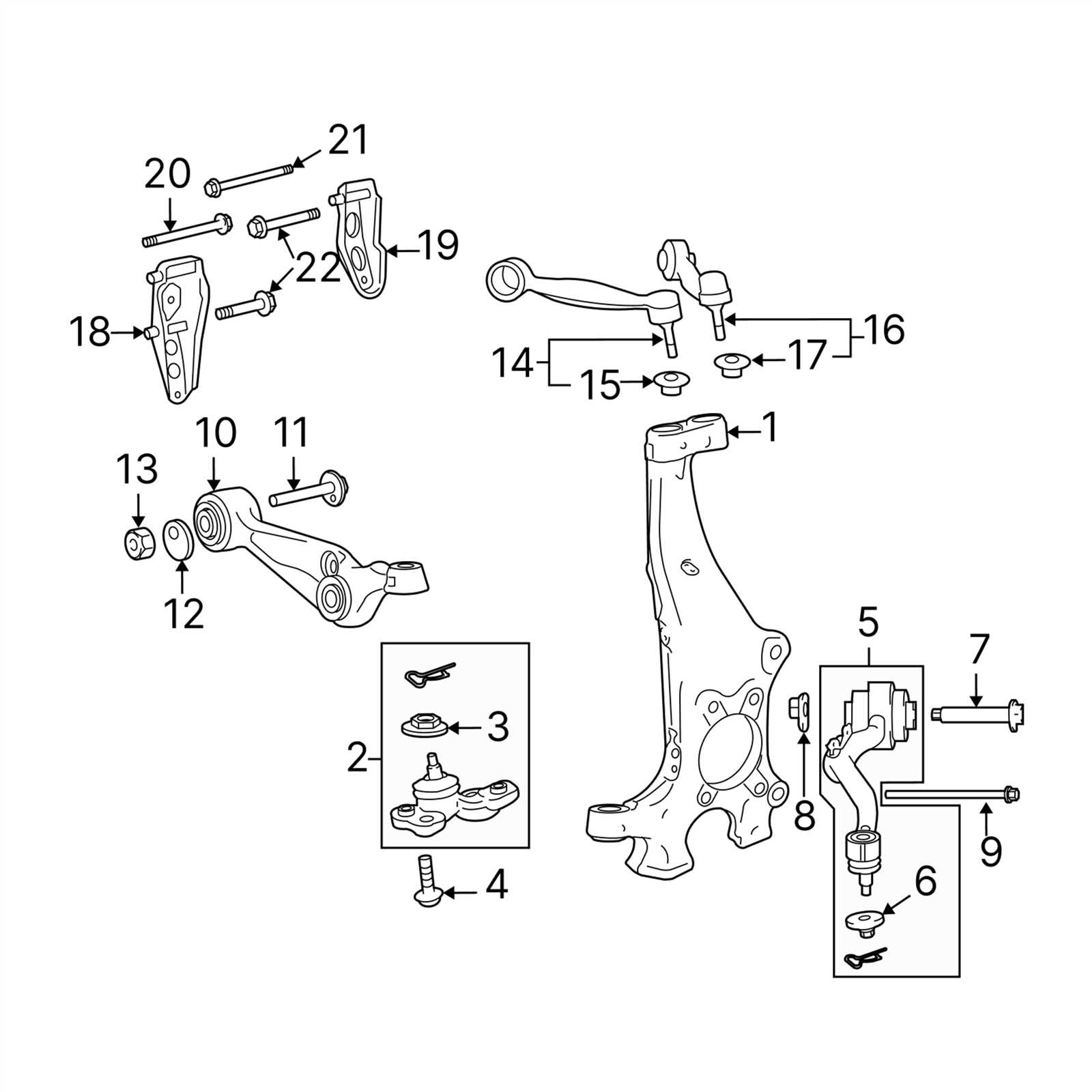

Suspension and Steering Repair Techniques

The suspension and steering systems are vital components that contribute to vehicle stability, handling, and comfort. Understanding the techniques for maintaining and addressing issues in these systems is crucial for ensuring optimal performance and safety on the road. This section outlines effective methods and best practices for diagnosing and resolving common problems in suspension and steering assemblies.

| Technique | Description |

|---|---|

| Visual Inspection | Conduct a thorough examination of all components for signs of wear, damage, or corrosion. Pay special attention to bushings, joints, and springs. |

| Wheel Alignment | Ensure proper alignment to prevent uneven tire wear and improve handling. Utilize alignment equipment to measure angles and adjust as necessary. |

| Shock Absorber Testing | Evaluate the performance of shock absorbers by checking for leaks or excessive bouncing. Replace worn units to restore ride quality. |

| Ball Joint Replacement | Inspect ball joints for play and noise. If found defective, replace them to maintain steering accuracy and prevent further damage. |

| Power Steering Fluid Check | Regularly check fluid levels and quality in the power steering system. Top up or replace fluid to ensure smooth steering operation. |

Implementing these techniques can significantly enhance the longevity and reliability of a vehicle’s suspension and steering systems. Regular maintenance and timely repairs will not only improve driving experience but also contribute to overall safety on the road.

Routine Maintenance Schedule

Regular upkeep is essential for ensuring the longevity and optimal performance of any vehicle. Adhering to a structured timetable for maintenance tasks helps identify potential issues before they escalate, ultimately enhancing reliability and safety. This schedule outlines key procedures and their recommended intervals to keep the vehicle running smoothly.

Every 3,000 to 5,000 miles, an oil change is crucial for maintaining engine health. This includes replacing the oil filter to ensure impurities do not affect engine performance. Tire rotation should occur every 6,000 to 8,000 miles to promote even wear and extend tire life.

Every 15,000 miles, it’s advisable to inspect and replace air filters, as a clean filter improves fuel efficiency and engine performance. Brake fluid should be checked and changed at least every two years to maintain effective braking capability.

Furthermore, every 30,000 miles, it’s important to flush the coolant system and replace the spark plugs, ensuring that the engine operates efficiently. Finally, a thorough inspection of belts and hoses should be performed every 60,000 miles to prevent breakdowns caused by wear and tear.

By following this maintenance schedule, vehicle owners can ensure optimal performance, safety, and longevity of their automobile.

Parts Replacement: What You Need

When it comes to maintaining your vehicle, understanding the essentials for component exchange is crucial. Properly replacing parts not only enhances performance but also ensures longevity and reliability. Whether you are a seasoned mechanic or a novice, knowing what tools and materials to have on hand will streamline the process and make it more efficient.

Essential Tools

Before starting any component swap, it’s vital to gather the necessary tools. Common items include a socket set, wrenches, screwdrivers, and pliers. Additionally, having a torque wrench is important for ensuring that all fasteners are tightened to the manufacturer’s specifications. A jack and jack stands will help safely elevate the vehicle for easier access to undercarriage components.

Replacement Parts

Identifying the right replacement components is key to a successful exchange. Always refer to the vehicle specifications to ensure compatibility. Whether it’s filters, belts, or suspension elements, sourcing quality parts from reputable suppliers can make a significant difference in performance. Keep in mind that OEM parts generally offer better reliability compared to aftermarket alternatives.

Safety Considerations During Repairs

Ensuring a secure working environment is crucial when performing maintenance tasks on any vehicle. Proper precautions can significantly reduce the risk of accidents and injuries. This section outlines essential safety practices that should be followed to protect both the individual and the surrounding environment during automotive service activities.

Personal Protective Equipment

Using appropriate personal protective equipment (PPE) is fundamental. Equip yourself with gloves to shield your hands from harmful substances and sharp edges. Safety goggles are essential for protecting your eyes from debris and chemicals. Additionally, wearing a respirator can help guard against inhaling toxic fumes, while sturdy footwear will protect your feet from heavy items.

Work Area Organization

A well-organized workspace can prevent accidents. Keep tools and parts neatly arranged to minimize the risk of tripping. Ensure that the area is well-ventilated to disperse harmful vapors. It’s also advisable to have a fire extinguisher readily available, especially when working with flammable materials. Lastly, always ensure that the vehicle is on a flat surface and properly secured to avoid unexpected movements.