Comprehensive Guide to Snapper Lawn Mower Repair

This section offers an in-depth overview of essential techniques and strategies for maintaining and troubleshooting outdoor equipment. Understanding how to properly care for your machinery can extend its lifespan and enhance its performance, ensuring that it remains reliable throughout the seasons.

With the right knowledge and resources, tackling common issues becomes manageable. From diagnosing minor faults to executing more complex adjustments, this guide serves as a valuable resource for enthusiasts and professionals alike. By following best practices, users can effectively address challenges and keep their devices in optimal condition.

Whether you are a seasoned expert or a novice looking to learn more, this informative resource equips you with the tools necessary to enhance your skills. Embrace the journey of maintenance with confidence and ensure your equipment operates smoothly for years to come.

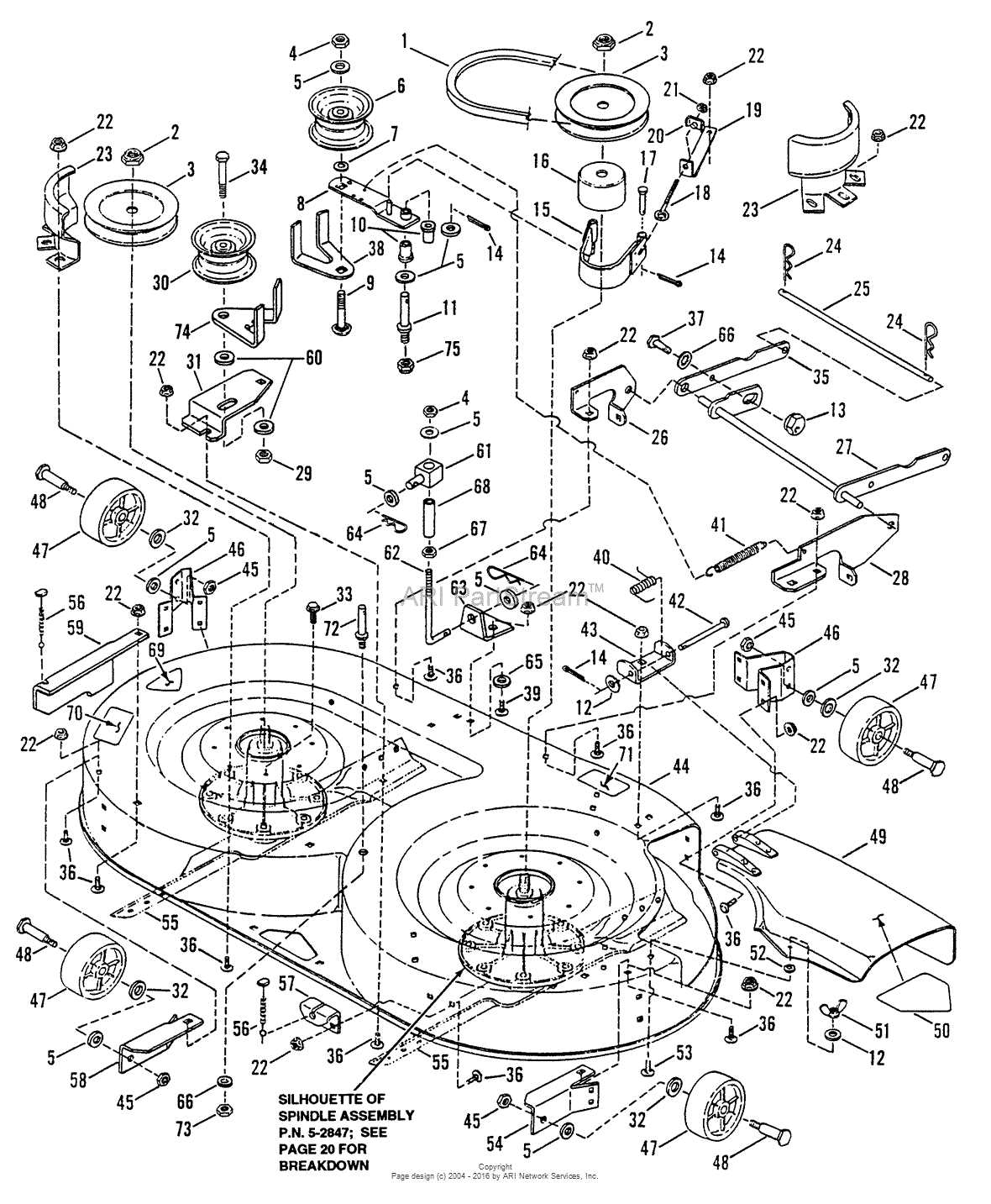

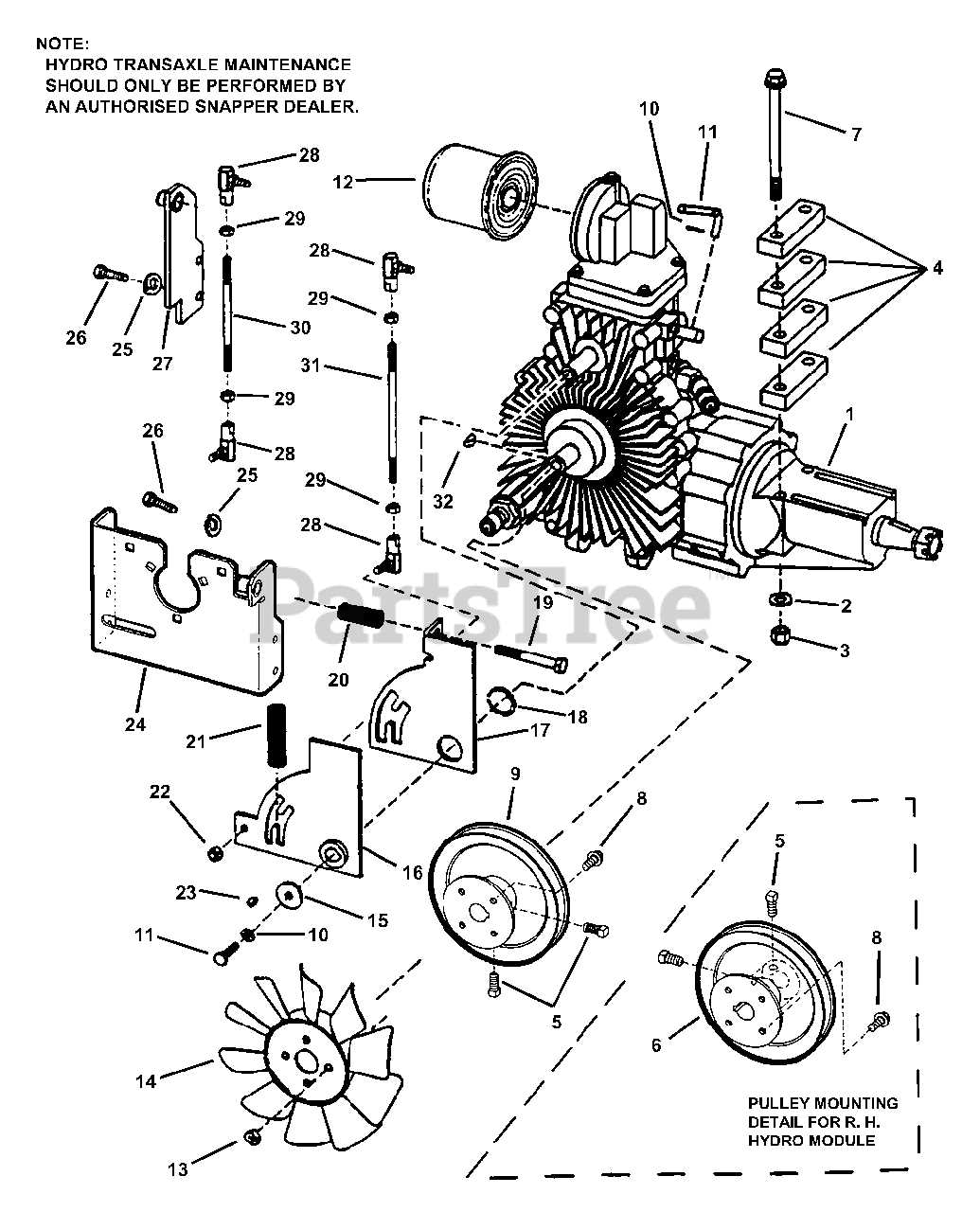

Understanding Snapper Mower Components

Exploring the essential parts of outdoor cutting machines provides insight into their functionality and maintenance. Each element plays a crucial role in ensuring optimal performance and longevity. Familiarity with these components aids in troubleshooting and enhances overall user experience.

| Component | Function |

|---|---|

| Engine | Power source that drives the entire system. |

| Blade | Primary cutting tool that trims grass to the desired height. |

| Deck | Housing that protects internal mechanisms and supports the blade. |

| Wheels | Facilitate movement across various terrains. |

| Handle | Provides control and maneuverability for the operator. |

Common Issues with Lawn Mowers

Maintaining outdoor equipment can present a variety of challenges. Understanding the frequent problems that arise can help users troubleshoot effectively and ensure smooth operation throughout the season.

Typical Problems Encountered

- Engine Won’t Start: This can be caused by fuel issues, battery problems, or spark plug failures.

- Uneven Cutting: Dull blades, incorrect cutting height, or uneven tire pressure may lead to this issue.

- Excessive Vibration: Loose components or damaged blades can cause noticeable shaking during use.

Maintenance Tips

- Regularly check and replace fuel and oil.

- Sharpen blades at least once a season.

- Inspect belts and cables for wear and tear.

Step-by-Step Maintenance Procedures

Proper upkeep is essential for optimal performance and longevity of your equipment. Following a systematic approach to maintenance can help prevent issues and enhance efficiency. This section outlines essential procedures to ensure smooth operation throughout the year.

1. Regular Inspection

Conducting frequent assessments is crucial. Look for signs of wear and tear, and ensure all components are functioning correctly. Here are key areas to check:

- Blades for sharpness and damage

- Belts for fraying or slackness

- Fuel system for leaks and clogs

- Wheels for proper alignment and wear

2. Cleaning Procedures

Keeping your equipment clean will help maintain performance. Regularly removing debris prevents buildup that can lead to malfunctions. Follow these cleaning steps:

- Disconnect the spark plug to ensure safety.

- Use a brush or compressed air to remove grass and dirt from under the deck.

- Wipe down all surfaces with a damp cloth.

- Inspect and clean the air filter according to the manufacturer’s guidelines.

Diagnosing Engine Problems Effectively

Identifying issues within an engine requires a systematic approach to pinpoint the underlying causes of malfunctions. By following a few essential steps, operators can streamline the diagnostic process and efficiently address performance problems.

Initial Observations

Begin by noting any unusual sounds or vibrations that may indicate specific issues. Additionally, pay attention to the overall behavior during operation, including difficulty in starting, irregular idling, or reduced power output. These observations can provide valuable clues for further investigation.

Systematic Testing

After making initial assessments, perform tests to isolate the problem. Check the fuel system, ensuring that it is delivering the correct mixture to the combustion chamber. Examine the ignition system for any signs of wear or malfunction. Utilizing a multimeter can help diagnose electrical components effectively. Regular maintenance can prevent many of these issues, so keep a detailed service history to aid in troubleshooting.

In conclusion, a methodical approach to diagnosing engine issues not only enhances performance but also extends the lifespan of the equipment. By focusing on systematic observations and tests, operators can ensure their machinery remains in optimal condition.

Replacing Blades: A Quick Guide

Maintaining cutting components is essential for optimal performance. This guide offers a streamlined approach to replacing these parts efficiently, ensuring your equipment operates at its best.

Before you begin, gather the necessary tools:

- Wrench or socket set

- Protective gloves

- Safety goggles

- New blades

Follow these steps for a successful replacement:

- Disconnect Power: Ensure the machine is turned off and disconnect the spark plug to prevent accidental starts.

- Lift the Equipment: Raise the device securely to access the cutting assembly. A stable surface or jack may be necessary.

- Remove Old Blades: Use the wrench to loosen and detach the existing blades. Keep track of any washers or spacers for reinstallation.

- Install New Blades: Align the new components in the same position as the old ones. Secure them tightly using the wrench.

- Reattach the Assembly: Lower the equipment back to its operating position and reconnect any necessary components.

- Reconnect Power: Reattach the spark plug and perform a safety check before starting the device.

By following these straightforward steps, you can ensure effective cutting performance and longevity of your equipment.

Tuning the Carburetor for Performance

Adjusting the fuel delivery system is essential for optimizing engine efficiency and overall operation. Proper tuning can enhance performance, improve fuel economy, and ensure smoother functionality during use.

Begin by checking the air-fuel mixture. An imbalance can lead to poor combustion, resulting in a sluggish performance. Use the adjustment screws to fine-tune this mixture, ensuring that the engine receives the right amount of fuel for optimal operation.

Next, inspect the idle speed. A well-calibrated idle allows for better responsiveness and reduces stalling. Turn the idle adjustment screw to achieve the recommended RPM, ensuring the engine runs smoothly at low speeds.

Regular maintenance of the carburetor components is also vital. Cleaning the jets and passages prevents blockages, which can hinder performance. Using a carburetor cleaner can help remove any deposits that may affect the fuel flow.

Finally, after making adjustments, test the engine under various conditions. This ensures that the modifications have had the desired effect and allows for further fine-tuning if necessary. Consistent checks will help maintain optimal performance over time.

Essential Tools for Lawn Care

Maintaining a beautiful green space requires a variety of essential implements to ensure efficiency and effectiveness. The right selection of tools can simplify tasks, enhance productivity, and contribute to a healthier outdoor environment.

To begin, a reliable cutting device is crucial for achieving a neat appearance. Look for one that is easy to maneuver and suitable for your specific terrain. Additionally, a quality trimmer is indispensable for reaching areas that are difficult to access, ensuring every corner is well-groomed.

Another important aspect is the use of aerators, which help promote healthy growth by allowing air and nutrients to penetrate the soil. Moreover, a sturdy rake can assist in clearing debris, ensuring a tidy and well-maintained area.

Finally, investing in proper safety gear, such as gloves and goggles, is essential to protect yourself while working outdoors. With the right collection of tools, you can achieve a stunning and vibrant green area that enhances the beauty of your surroundings.

Winterizing Your Lawn Equipment

Preparing your outdoor machinery for the colder months is essential for maintaining its longevity and efficiency. Properly winterizing ensures that your tools remain in optimal condition, preventing damage from harsh weather and preserving their functionality for the next season.

Here are key steps to consider when getting your equipment ready for winter:

- Clean Thoroughly: Remove any grass clippings, dirt, and debris from all surfaces.

- Drain Fluids: Empty the fuel tank and oil reservoir to prevent stagnation and contamination.

- Inspect for Damage: Check for any worn or broken parts that need replacement before storage.

- Sharpen Blades: Ensure cutting edges are sharp to maintain performance in the upcoming season.

- Store Properly: Keep equipment in a dry, sheltered location away from extreme temperatures.

By following these guidelines, you can safeguard your machinery and ensure it is ready for use when the warmer months return. Taking the time to winterize not only protects your investment but also enhances its efficiency and performance in the future.

Tips for Safe Operation

Ensuring a secure and effective experience while using outdoor equipment is essential for preventing accidents and maintaining optimal performance. Familiarizing oneself with safety guidelines not only protects the operator but also enhances the longevity of the machine.

Before starting any task, inspect the surroundings and ensure that the area is free from obstacles or hazards. Proper attire, including closed-toe shoes and protective eyewear, is crucial for safeguarding against potential injuries.

| Safety Tip | Description |

|---|---|

| Read the Instruction Guide | Thoroughly review the operating guidelines to understand the functions and safety features. |

| Check Fuel Levels | Always ensure sufficient fuel is available and avoid refueling while the engine is running. |

| Use Caution on Slopes | When working on inclines, take extra care to maintain stability and control. |

| Keep Hands and Feet Clear | Maintain a safe distance from moving parts to prevent injury during operation. |

| Turn Off the Engine | Always shut down the engine before performing any maintenance or adjustments. |

By adhering to these guidelines, users can promote a safer working environment and enhance the effectiveness of their equipment. Regularly revisiting these practices will ensure safe and efficient operation throughout the lifespan of the machine.

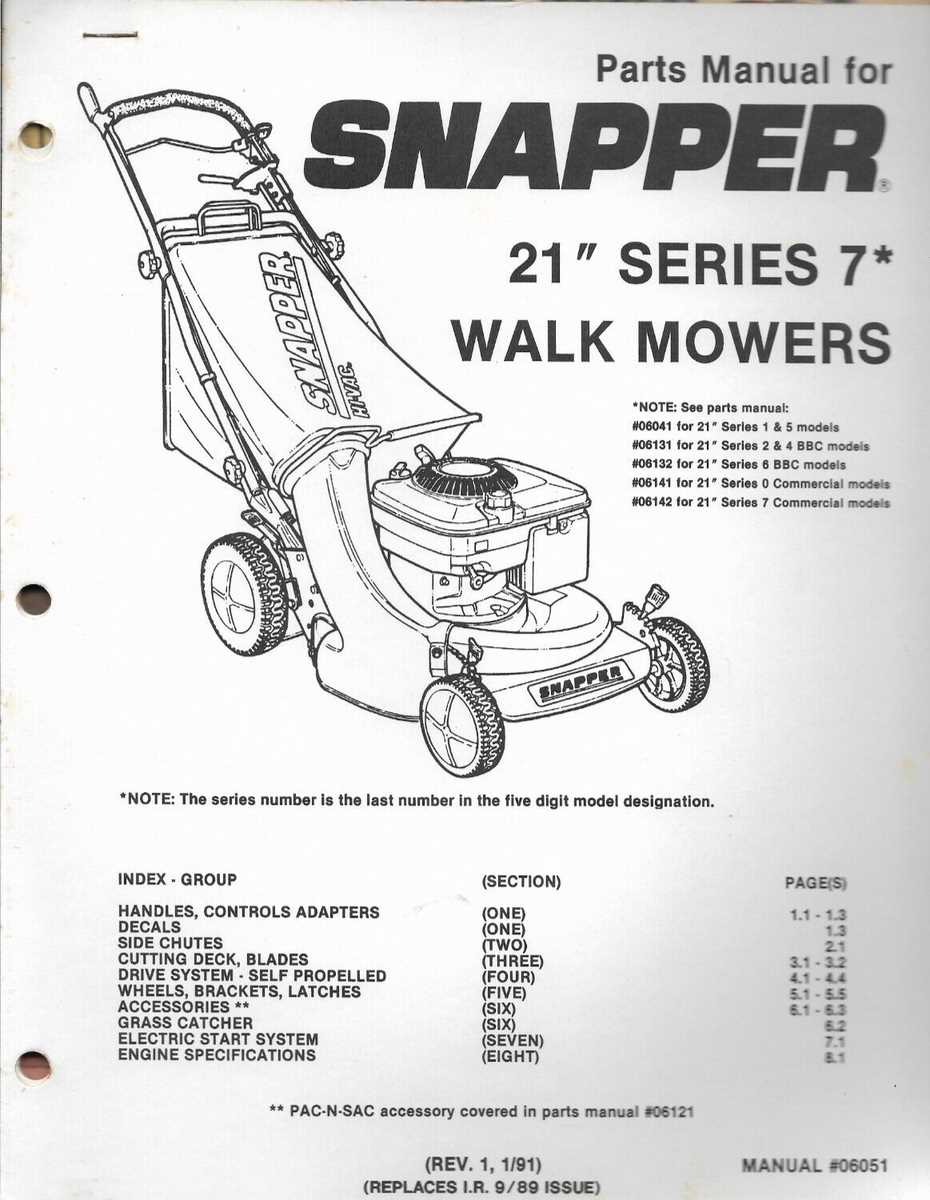

Finding Replacement Parts Online

Locating suitable components for your equipment can often be a straightforward process if you know where to look. The internet offers a plethora of resources that allow you to find exactly what you need with just a few clicks. Whether you are seeking original or compatible parts, various online platforms can assist you in your search.

Begin by identifying the specific components required for your device. It’s beneficial to have the model number and any relevant specifications at hand. This information will streamline your search and help you avoid confusion when browsing through different listings.

| Website | Description |

|---|---|

| eBay | A marketplace for both new and used components, often featuring competitive pricing. |

| Amazon | A trusted platform with a wide selection of parts, many with customer reviews to guide your decision. |

| Manufacturer’s Website | Direct source for original components, ensuring compatibility and quality. |

| Specialty Parts Retailers | Websites dedicated to specific equipment types, often with expert advice available. |

Once you’ve found potential sources, compare prices and shipping options. Check return policies to ensure a hassle-free experience if the parts do not meet your expectations. By utilizing these online resources effectively, you can ensure your equipment remains in optimal working condition.

Warranty Information and Support Resources

This section provides essential details regarding coverage and assistance available for your equipment. Understanding the terms of service and the resources at your disposal can enhance your ownership experience and ensure optimal performance.

Coverage Details: The warranty typically encompasses parts and labor for a specified duration, protecting against defects in manufacturing. It’s crucial to review the documentation to comprehend what is included and any exclusions that may apply.

Support Channels: For additional help, customers can reach out through various platforms. Consider utilizing the official website for FAQs, troubleshooting guides, and customer service contacts. Many manufacturers also offer community forums where users share insights and solutions.

Maintenance Tips: Regular upkeep is essential to prolong the lifespan of your equipment. Consult the resources provided to understand recommended service intervals and maintenance practices that can help maintain optimal functionality.