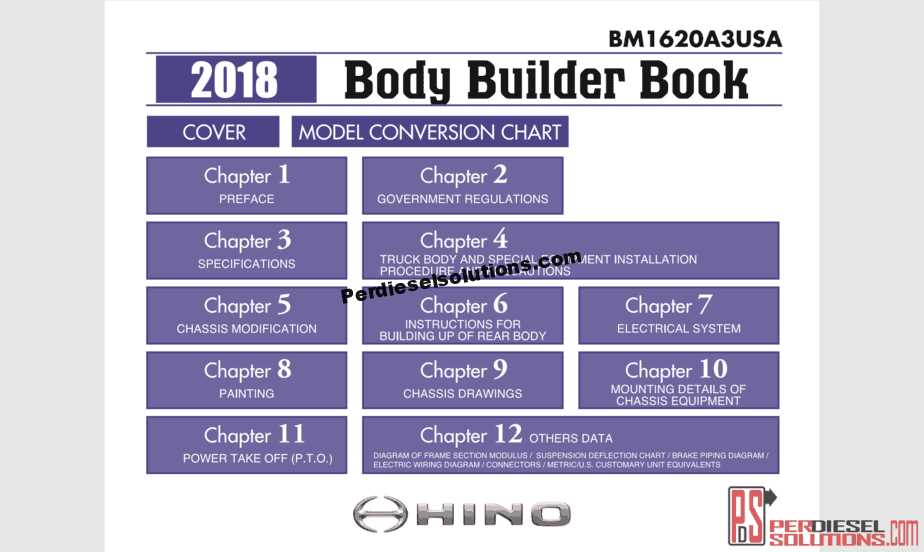

Comprehensive Guide to Hino Truck Repairs

This section provides an in-depth overview aimed at assisting individuals with the upkeep of their heavy-duty vehicles. The focus is on essential practices and techniques that ensure optimal performance and longevity.

Understanding the intricacies of vehicle functionality is vital for owners and operators. With a clear grasp of maintenance procedures, one can effectively address common issues, enhancing reliability and safety on the road.

By utilizing this guide, readers will gain insights into troubleshooting, servicing, and general care, equipping them with the knowledge needed to manage their vehicles efficiently. Emphasis is placed on proactive measures, enabling smoother operations and minimizing downtime.

Common Maintenance Procedures Explained

Proper upkeep of vehicles is essential to ensure their longevity and optimal performance. Regular maintenance tasks help prevent breakdowns and extend the life of essential components. Understanding these procedures is key for any operator aiming to maintain efficiency and safety.

Routine Checks

- Fluid Levels: Regularly inspect and replenish engine oil, coolant, and brake fluid.

- Filters: Change air and fuel filters according to the manufacturer’s guidelines to ensure optimal airflow and fuel efficiency.

- Tire Condition: Monitor tire pressure and tread depth to ensure safe handling and fuel economy.

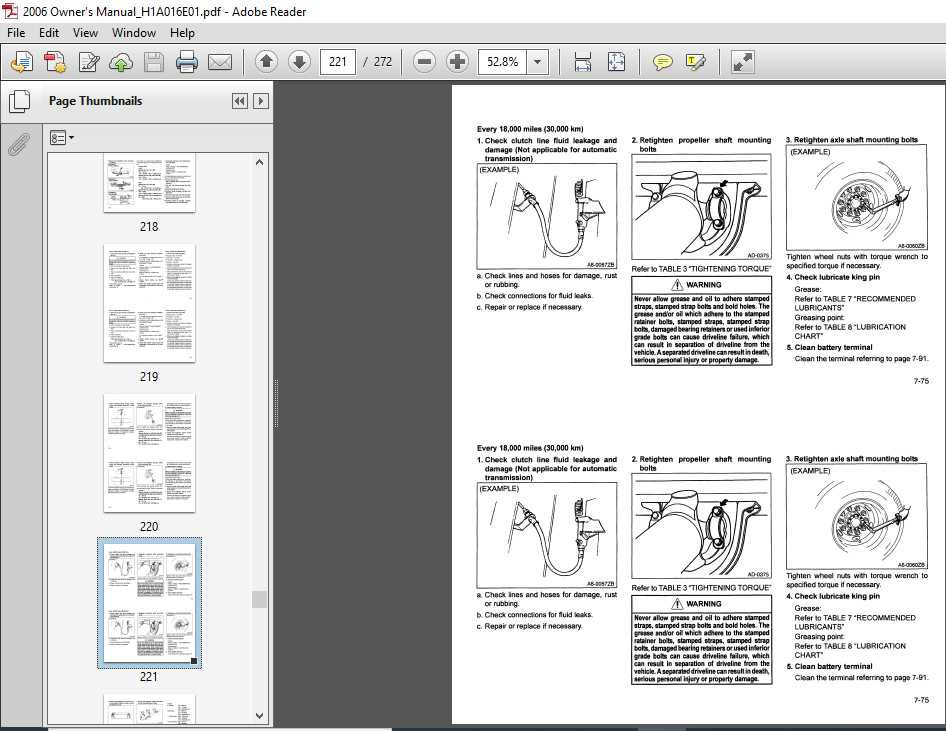

Scheduled Servicing

- Oil Change: Replace engine oil and filter every specified mileage to maintain engine health.

- Brake Inspection: Check brake pads, rotors, and hydraulic systems for wear and tear.

- Belt and Hose Evaluation: Inspect drive belts and hoses for cracks or fraying, replacing them as necessary to avoid failures.

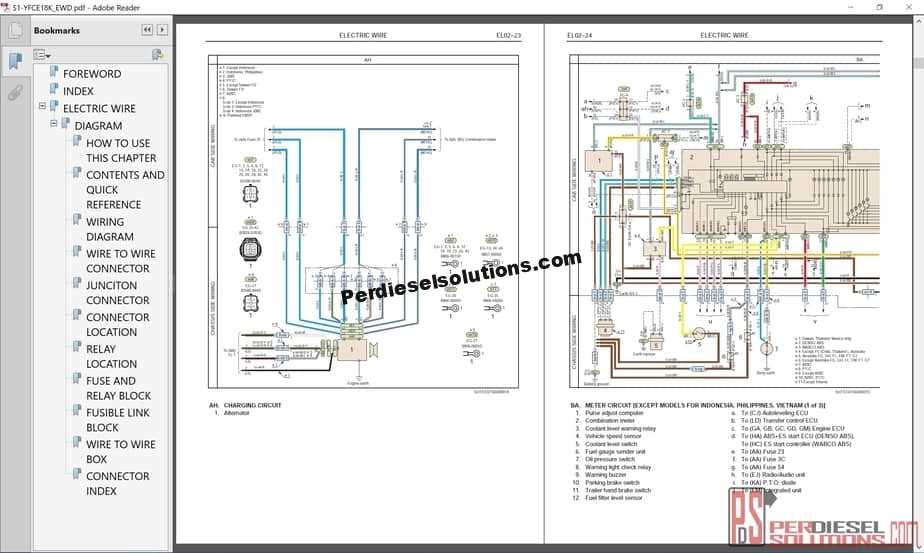

Troubleshooting Electrical Issues

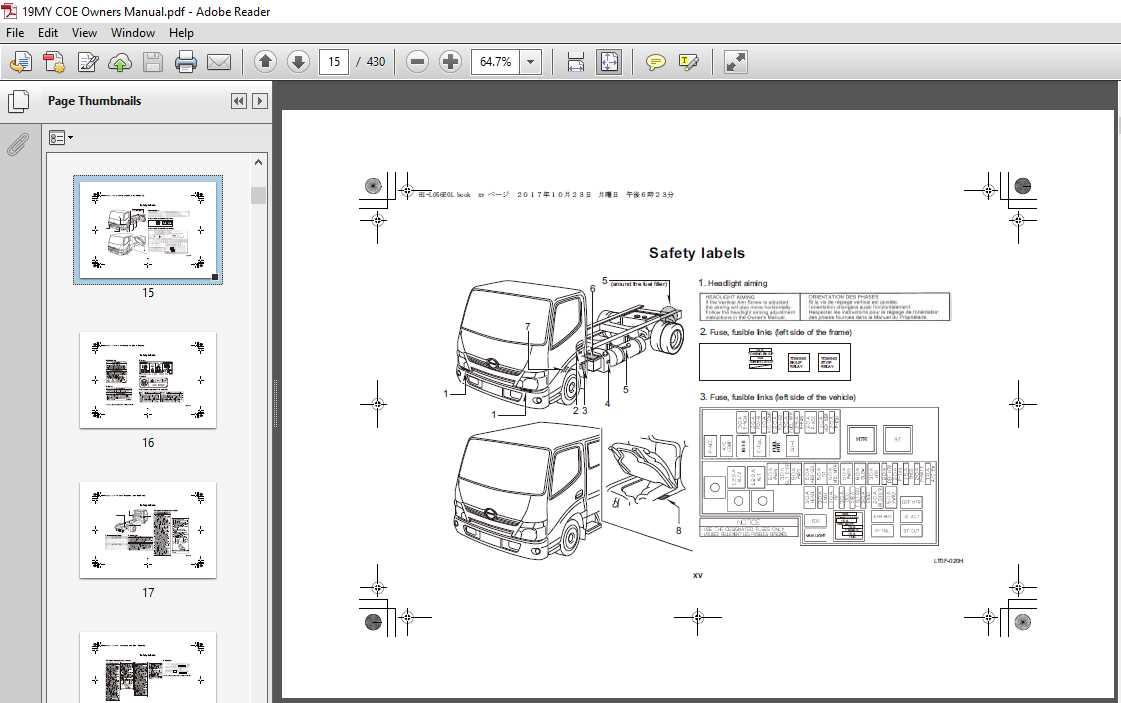

Electrical complications can often lead to operational disruptions in vehicles. Identifying and resolving these issues is essential for ensuring reliable performance. This section provides insights into common electrical challenges and effective methods for diagnosing them.

Begin by checking the battery, as a weak or dead power source can cause various malfunctions. Inspect the connections for corrosion or looseness, which may hinder electrical flow. A multimeter can be utilized to measure voltage and confirm the battery’s condition.

Next, examine the wiring throughout the system. Look for frayed or damaged insulation, as this can result in shorts or open circuits. Ensure that all connections are secure and free from debris. Regular maintenance can help prevent these issues from escalating.

Finally, consider the role of fuses and relays. A blown fuse may indicate an overload or a short circuit. Replacing a faulty fuse or relay can often restore functionality, but it’s crucial to investigate the underlying cause to prevent recurrence.

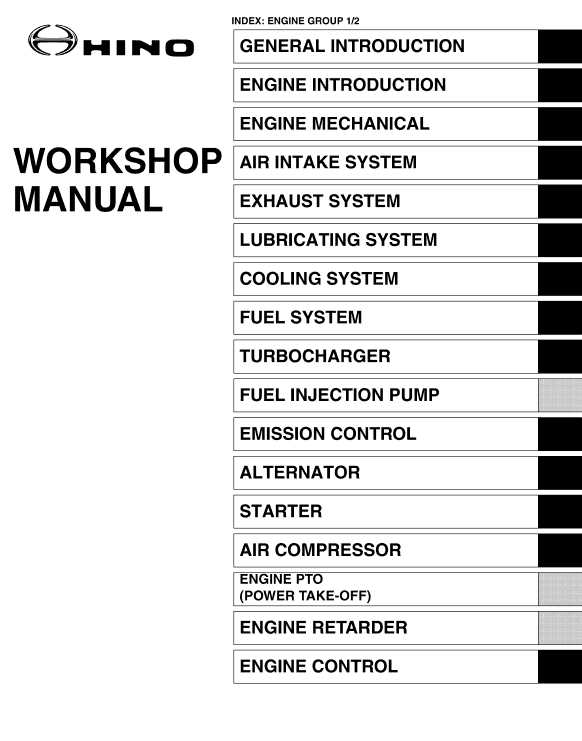

Engine Overhaul Techniques and Tips

Overhauling an engine involves a series of critical procedures aimed at restoring its performance and longevity. This process requires a systematic approach, focusing on precision and attention to detail. Understanding the various techniques and best practices can significantly enhance the efficiency of the overhaul.

Preparation is Key: Before starting the overhaul, ensure that all necessary tools and replacement parts are available. A well-organized workspace can streamline the process and reduce the likelihood of errors.

Disassembly Techniques: Carefully label and store components as they are removed. Utilizing a methodical approach to disassembly will facilitate reassembly and minimize confusion.

Inspection and Cleaning: Thoroughly inspect each part for wear and damage. Cleaning components with appropriate solvents is essential for removing debris and ensuring proper functionality. Pay special attention to critical areas that may affect performance.

Reassembly Tips: When reassembling, use new gaskets and seals to prevent leaks. Torque specifications must be adhered to meticulously, ensuring that each fastener is tightened to the manufacturer’s recommendations.

Final Checks: After reassembly, perform a comprehensive inspection to verify that all components are correctly installed. Conducting a pre-start checklist can help identify potential issues before the engine is turned on.

Transmission Servicing Best Practices

Maintaining the functionality of a vehicle’s gearbox is crucial for optimal performance. Adopting effective strategies for service can prolong the lifespan of the system and enhance overall efficiency.

- Regular fluid checks are essential. Ensure that the transmission fluid is at the correct level and in good condition.

- Change the fluid and filter periodically. This prevents contaminants from accumulating and damaging internal components.

- Inspect seals and gaskets for leaks. Addressing any issues promptly can prevent further damage and costly repairs.

- Monitor shifting performance. Any irregularities in shifting can indicate underlying problems that need attention.

- Keep an eye on temperature levels. Overheating can lead to significant damage, so ensure proper cooling mechanisms are functioning.

By implementing these best practices, one can ensure reliable operation and reduce the risk of future complications.

Suspension System Repairs Overview

The suspension framework plays a crucial role in maintaining vehicle stability and comfort. Addressing issues within this system is essential for ensuring optimal performance and safety during operation. This section outlines key considerations and procedures for effectively managing repairs related to the suspension setup.

Common problems can include wear on components, misalignment, or fluid leaks. Regular inspections and timely interventions can help extend the lifespan of the suspension and enhance overall vehicle functionality.

| Common Issues | Symptoms | Recommended Actions |

|---|---|---|

| Worn Shock Absorbers | Excessive bouncing, fluid leakage | Replace absorbers, check mounts |

| Broken Springs | Uneven ride height, noise during travel | Inspect and replace springs |

| Faulty Bushings | Increased vibrations, clunking sounds | Replace bushings, inspect surrounding components |

Brake System Maintenance Essentials

Ensuring the proper functioning of the braking mechanism is vital for the safety and performance of any vehicle. Regular attention to this crucial system helps prevent potential issues and guarantees reliable stopping power under various conditions.

Key maintenance tasks include inspecting brake components, checking fluid levels, and replacing worn parts. Following a systematic approach can enhance the longevity and effectiveness of the braking system.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Inspect Brake Pads | Every 10,000 miles | Check for wear and replace if necessary to ensure optimal performance. |

| Check Brake Fluid | Monthly | Verify fluid levels and quality; top off or change as needed to maintain effectiveness. |

| Examine Brake Lines | Every 6 months | Look for leaks or damage that could compromise braking efficiency. |

| Test Brake System | Annually | Conduct a full system test to ensure all components are functioning correctly. |

Identifying Common Fluid Leaks

Recognizing fluid leaks is essential for maintaining the functionality of any vehicle. Understanding the various types of fluids and their typical locations can help in quickly diagnosing issues that may arise during operation.

Types of Fluids and Their Indicators

Common fluids include engine oil, transmission fluid, coolant, and brake fluid. Each type has distinct characteristics. For instance, engine oil is usually dark brown or black and has a slick texture. In contrast, transmission fluid appears reddish or brown and has a thinner consistency. Coolant is often bright green, yellow, or orange, while brake fluid is typically clear or amber.

Locating the Source of Leaks

To effectively locate leaks, it is advisable to regularly inspect the ground where the vehicle is parked. Look for pooled liquid or stains, and trace any visible fluid lines. Additionally, check under the hood and around the engine bay for any signs of wetness or discoloration that could indicate a leak.

Tools Required for Repairs

When addressing maintenance and servicing tasks for vehicles, having the right equipment is essential. Various instruments facilitate efficient and effective handling of different issues that may arise during the process.

- Wrenches: Adjustable and fixed types are crucial for loosening and tightening various components.

- Screwdrivers: A set of flathead and Phillips screwdrivers is necessary for working with different types of fasteners.

- Pliers: These tools assist in gripping, twisting, and cutting materials, making them invaluable during various tasks.

- Jack and Stands: These are essential for lifting the vehicle safely to access the undercarriage.

- Diagnostic Tools: Electronic testers and scanners help identify issues and monitor system performance.

In addition to these fundamental tools, various specialized devices may be needed depending on the specific tasks at hand. Ensuring that all necessary equipment is available before starting any service work can significantly enhance productivity and safety.

Safety Protocols During Maintenance

Ensuring safety while conducting maintenance tasks is essential to protect both personnel and equipment. Proper precautions can significantly reduce the risk of accidents and injuries in the workplace. Adhering to established safety guidelines not only enhances the efficiency of operations but also promotes a culture of care among team members.

Before initiating any maintenance activities, it is vital to perform a thorough assessment of the work environment and the tools required. This includes identifying potential hazards and ensuring that appropriate safety gear is worn at all times. Key safety measures include:

| Safety Measure | Description |

|---|---|

| Personal Protective Equipment (PPE) | Wear safety goggles, gloves, and protective clothing to safeguard against injuries. |

| Proper Tool Usage | Utilize the correct tools for specific tasks to prevent accidents and equipment damage. |

| Work Area Organization | Keep the workspace tidy to minimize the risk of trips and falls. |

| Emergency Procedures | Familiarize all personnel with emergency protocols and first-aid measures. |

| Team Communication | Establish clear communication channels among team members to ensure safety during operations. |

Finding Genuine Hino Parts

Ensuring the longevity and optimal performance of your vehicle heavily relies on sourcing authentic components. Utilizing original parts not only enhances efficiency but also guarantees compatibility, thereby minimizing the risk of unforeseen issues.

Importance of Authentic Components

Utilizing genuine components is crucial for maintaining the integrity of your vehicle. These parts are designed to meet stringent quality standards, ensuring they function harmoniously with your system. Furthermore, they often come with warranties, providing peace of mind and protection against early failures.

Where to Purchase Authentic Components

Acquiring original components can be achieved through authorized dealerships and specialized suppliers. These sources ensure that the parts are certified and reliable. Additionally, online platforms may offer a selection, but it is vital to verify their authenticity before making a purchase.

Warranty and Service Information

This section provides essential details regarding the guarantees and maintenance support available for your vehicle. Understanding the terms of coverage and the procedures for service is crucial to ensuring optimal performance and longevity.

Key aspects to consider include:

- Coverage Duration: Information about the time frame during which your vehicle is protected under warranty.

- What is Covered: Details on components and services that are included in the warranty.

- Exclusions: Specific parts or situations that are not covered, ensuring clarity in your expectations.

Regular maintenance is essential for maximizing the benefits of your warranty. Adhering to scheduled service intervals can help prevent issues and maintain vehicle reliability.

To access service support, follow these steps:

- Locate your nearest authorized service center.

- Contact them to schedule an appointment.

- Have your vehicle’s identification information ready for reference.

Utilizing certified service professionals ensures that all maintenance and repairs are conducted according to the standards set forth, providing peace of mind and assurance in your vehicle’s performance.