Comprehensive Guide to Chrysler Outboard Motor Repairs

Understanding the intricacies of propulsion systems is essential for any marine enthusiast. Proper upkeep not only enhances performance but also extends the lifespan of the equipment. This section delves into the essential practices and techniques required to ensure optimal functionality.

Regular maintenance is crucial for preventing common issues that can arise during usage. By familiarizing oneself with various components and their functions, users can effectively troubleshoot and address potential problems before they escalate. This proactive approach fosters a deeper connection with the equipment and promotes a smoother sailing experience.

Furthermore, having access to detailed resources empowers individuals to make informed decisions regarding servicing and upgrades. Whether you are a novice or an experienced user, comprehensive guidance can illuminate the path toward achieving peak performance in your aquatic adventures.

Understanding Outboard Motor Components

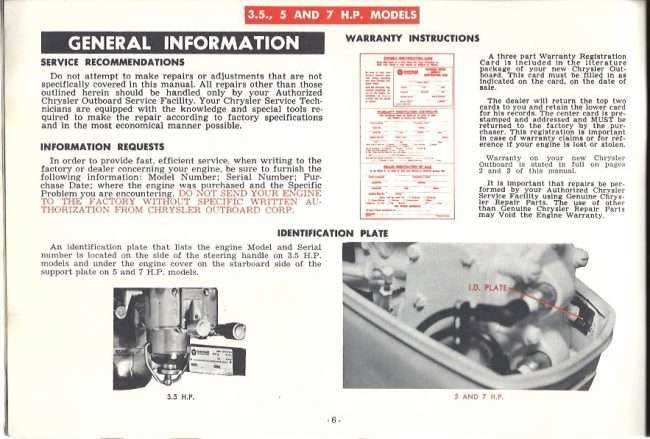

The functioning of a marine propulsion device relies on a variety of essential parts, each playing a pivotal role in ensuring optimal performance. Gaining insight into these components is crucial for effective management and troubleshooting, leading to enhanced reliability and longevity of the apparatus.

Key Elements of Marine Propulsion Systems

Among the primary elements are the power unit, which generates thrust, and the gear system that transmits this power to the propeller. Additionally, the cooling and fuel systems are integral, maintaining the efficiency and stability of operation. Recognizing how these components interact can significantly impact overall functionality.

Maintenance and Functionality

Regular examination and maintenance of these parts are vital for preventing malfunctions. Understanding their specific roles and the signs of wear can aid in timely interventions, ensuring smooth operation during use. Awareness of each component’s condition not only enhances performance but also contributes to a safer experience on the water.

Common Issues and Troubleshooting Steps

Understanding frequent complications and their solutions is essential for maintaining optimal performance. This section highlights typical challenges encountered during usage, along with effective methods to address them.

Engine Performance Problems

One common issue is inadequate performance, which may manifest as poor acceleration or reduced power. This can often be traced back to fuel supply concerns, such as clogged filters or incorrect fuel types. Regular checks and cleanings can enhance functionality.

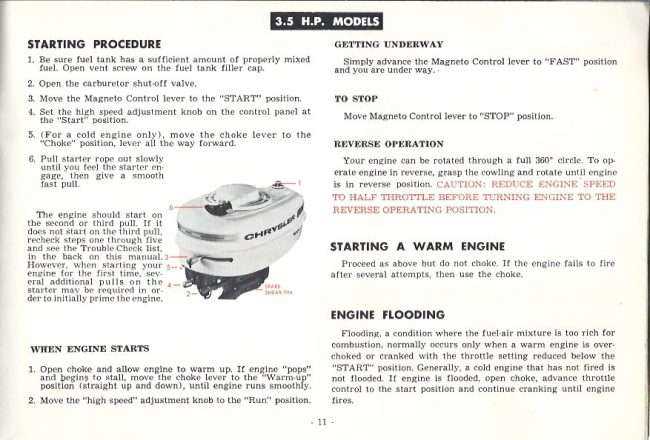

Starting Difficulties

Another prevalent challenge is difficulty starting. This may result from electrical system failures or battery issues. It’s advisable to inspect connections and ensure the battery is fully charged. A thorough examination of ignition components can also reveal underlying problems.

Essential Tools for Repairs

When tackling maintenance tasks for aquatic propulsion devices, having the right instruments at your disposal is crucial for achieving optimal results. A well-equipped toolkit not only enhances efficiency but also ensures safety and precision during the process.

Basic Hand Tools

Fundamental implements such as wrenches, screwdrivers, and pliers form the backbone of any toolkit. These essentials allow for easy disassembly and assembly, making them indispensable for any maintenance task. Additionally, selecting high-quality tools can greatly improve durability and performance.

Specialized Equipment

Incorporating specialized gear, like torque wrenches and multimeters, can significantly streamline troubleshooting and adjustments. Utilizing these advanced tools enables technicians to achieve precise calibrations and diagnostics, leading to enhanced performance and longevity of the equipment.

Step-by-Step Maintenance Procedures

This section provides a comprehensive guide to performing essential upkeep on your marine engine. Following these systematic procedures will help ensure optimal performance and longevity, while also preventing common issues that may arise from neglect.

Begin by gathering the necessary tools and materials, ensuring everything is within reach for a smooth workflow. Start with a thorough inspection of the exterior components, checking for signs of wear or damage. Address any visible issues before proceeding to the internal systems.

Next, focus on fluid levels, including fuel and lubrication. Replace old fluids with fresh supplies as needed, following manufacturer specifications. Regularly changing these fluids is crucial for maintaining efficiency and preventing engine wear.

Afterward, inspect the electrical systems, including connections and battery health. Clean any corroded terminals and ensure a secure connection to avoid electrical failures during operation.

Lastly, conclude with a comprehensive cleaning of all accessible areas. Removing debris and contaminants not only enhances the appearance but also promotes better functionality. Following these steps regularly will contribute to a reliable and efficient engine experience.

Diagnosing Electrical Problems

Identifying issues within electrical systems requires a systematic approach to ensure proper functionality. Understanding the components involved and employing effective troubleshooting techniques can greatly enhance the diagnostic process. This section outlines key strategies for addressing electrical malfunctions, emphasizing the importance of careful analysis.

Common Symptoms of Electrical Issues

Recognizing the signs of electrical problems is crucial for timely intervention. Users may experience various symptoms that indicate potential faults, including:

| Symptom | Possible Cause |

|---|---|

| Failure to Start | Weak battery or corroded connections |

| Inconsistent Performance | Faulty wiring or loose terminals |

| Unusual Noises | Electrical shorts or component failure |

Steps for Effective Diagnosis

To efficiently diagnose electrical issues, follow these essential steps:

- Inspect all connections for tightness and corrosion.

- Test the battery voltage and charge levels.

- Utilize a multimeter to check continuity across circuits.

Fuel System Maintenance Tips

Ensuring the longevity and efficiency of your fuel delivery system is essential for optimal performance. Regular upkeep not only enhances functionality but also prevents potential issues that may arise from neglect. Following a few straightforward guidelines can significantly improve the reliability of the system.

Regular Inspection and Cleaning

Periodic examination of fuel lines and filters is crucial. Check for any signs of wear, leaks, or blockages. Cleaning or replacing filters regularly will help maintain a steady flow of fuel, ensuring the engine operates smoothly. Additionally, inspect all connections to prevent any air leaks that could hinder performance.

Quality of Fuel

Using high-quality fuel can make a substantial difference in the system’s efficiency. Ensure that the fuel is fresh and free from contaminants. Consider adding fuel stabilizers if the fuel will sit for an extended period. This practice helps prevent degradation and maintains the integrity of the system.

Preventive Measures for Longevity

Ensuring the extended life of your aquatic engine involves implementing consistent and effective strategies. By adhering to a routine of care and attention, you can significantly reduce the likelihood of issues arising over time.

Regular Maintenance is crucial; routinely inspecting components helps identify potential problems before they escalate. This includes checking fluid levels, examining electrical connections, and ensuring all parts are functioning properly.

Storage Practices also play a vital role. Properly storing your equipment when not in use protects it from environmental factors that may cause damage. Using protective covers and keeping the unit in a dry, temperature-controlled environment can prevent unnecessary wear and tear.

Additionally, using quality materials for replacements and upgrades ensures durability. Investing in reliable parts may cost more initially but pays off in the long run by minimizing repairs and enhancing performance.

Lastly, following manufacturer recommendations for service intervals and using the correct fuel and lubricants will help maintain optimal functionality and extend the lifespan of your device.

Guidelines for Proper Storage

Ensuring the longevity and functionality of aquatic engines necessitates appropriate storage practices. Proper safeguarding can prevent damage from environmental factors and enhance the overall lifespan of the equipment.

Preparation Steps

- Clean the equipment thoroughly to remove dirt, salt, and debris.

- Drain any remaining fluids to prevent contamination and leaks.

- Inspect all components for signs of wear or damage before storing.

Optimal Storage Conditions

- Store in a cool, dry place to avoid moisture buildup.

- Avoid direct sunlight to prevent fading and deterioration of materials.

- Utilize a protective cover to shield against dust and pests.

By following these guidelines, you can ensure that your aquatic equipment remains in excellent condition for future use.

Safety Precautions During Repairs

When engaging in maintenance tasks on aquatic propulsion devices, adhering to safety protocols is essential to ensure personal well-being and protect the equipment. Understanding the potential hazards and implementing preventive measures can significantly reduce the risk of accidents and injuries.

General Safety Guidelines

Prior to initiating any service, it is crucial to familiarize oneself with the operational environment and the tools required. Always don appropriate protective gear such as gloves and goggles to shield against unexpected splashes or sharp components. Ensure the workspace is well-ventilated to avoid inhaling harmful fumes.

Equipment Handling

Proper handling of tools and components is vital for a secure working atmosphere. Organize tools systematically to prevent misplacement and accidental injuries. Additionally, maintain a clear workspace free from clutter to facilitate safe movement around the device.

| Precaution | Description |

|---|---|

| Personal Protective Equipment | Use gloves, goggles, and appropriate clothing. |

| Tool Organization | Keep tools organized and easily accessible. |

| Ventilation | Ensure adequate airflow to minimize inhalation risks. |

Resources for Further Learning

Expanding your knowledge on the maintenance and troubleshooting of marine equipment can greatly enhance your understanding and skills. Various resources are available to support enthusiasts and professionals alike in their quest for expertise.

Online Courses and Tutorials

Numerous platforms offer structured learning through online courses and tutorials. These resources often include videos, quizzes, and practical assignments to help reinforce concepts. Engaging with these materials can provide a comprehensive foundation in handling various types of marine devices.

Books and Guides

Consider exploring published books and guides focused on marine technology. These texts typically cover a wide range of topics, from basic principles to advanced techniques. Reference materials can serve as valuable tools for both beginners and seasoned individuals looking to deepen their comprehension. Additionally, community forums often recommend specific titles based on practical experiences.