Suzuki GZ250 Comprehensive Repair Guide

When it comes to ensuring the longevity and performance of your two-wheeled companion, having a reliable source of information is crucial. A well-structured guide provides insights into the intricacies of upkeep, enabling enthusiasts and owners alike to address common issues effectively. Understanding the essential components and maintenance practices can transform your riding experience and extend the life of your vehicle.

Within this guide, you will discover detailed instructions on troubleshooting, part replacements, and preventative measures. Each section is crafted to demystify the technical aspects, making it accessible for both novice riders and seasoned mechanics. The emphasis on clear explanations and step-by-step processes will empower you to tackle repairs with confidence.

Equipped with the right knowledge, you can develop a deeper connection with your motorcycle. Regular maintenance not only enhances performance but also contributes to safety on the road. Embrace the art of motorcycle care, and unlock the full potential of your ride.

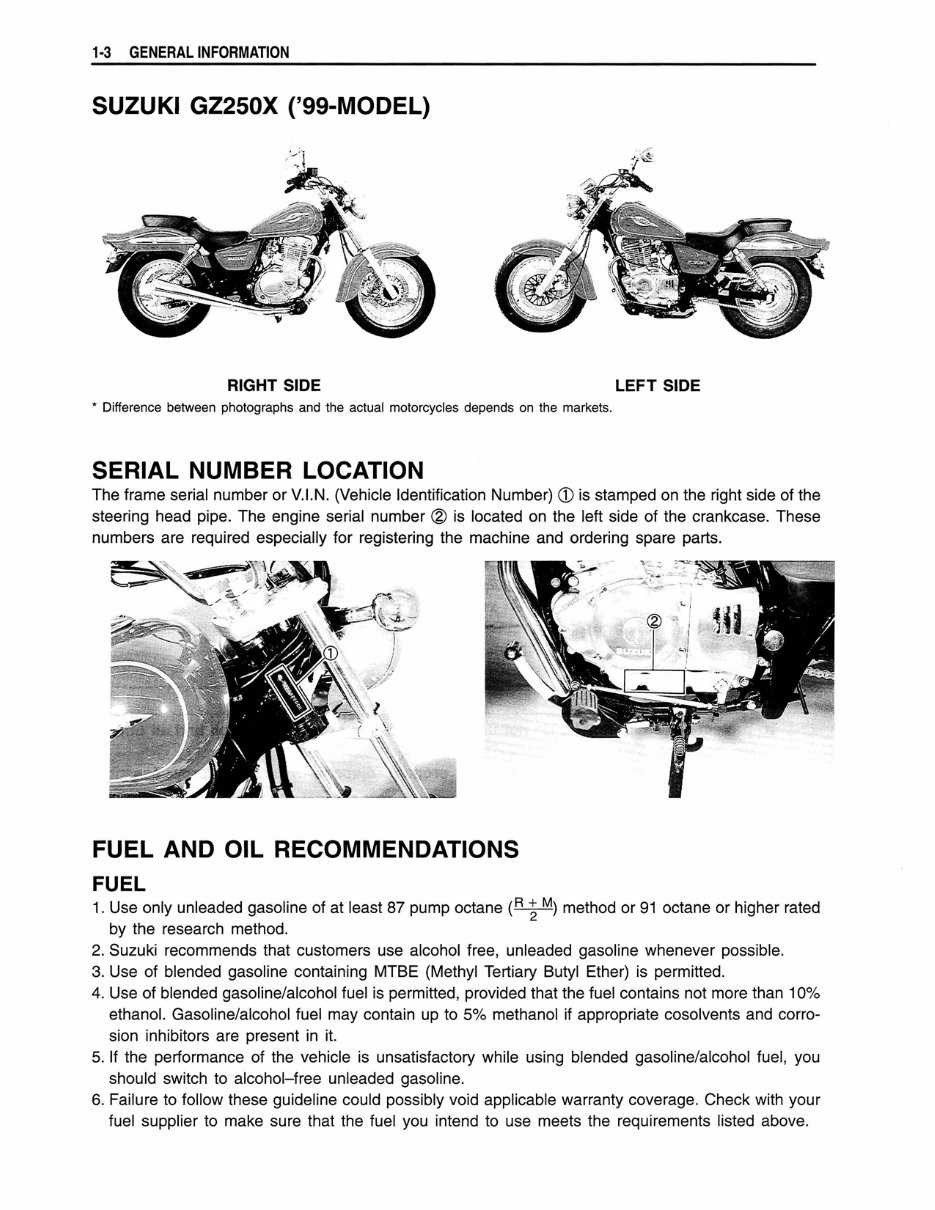

Overview of the Motorcycle

This section provides a comprehensive look at a popular entry-level motorcycle known for its balance of performance and ease of use. Ideal for both new riders and those seeking a reliable urban commuter, this model combines practicality with a classic aesthetic.

Key Features

- Lightweight frame for enhanced maneuverability

- Fuel-efficient engine designed for everyday use

- Comfortable seating position for long rides

- Classic styling that appeals to a wide audience

Performance Specifications

- Engine displacement: 250cc

- Transmission: 5-speed manual

- Fuel capacity: Approximately 13 liters

- Top speed: Around 130 km/h

Common Issues with the GZ250

This section addresses frequent challenges encountered by owners of this popular motorcycle model. Understanding these common problems can assist riders in maintaining their vehicles effectively and ensuring a smoother riding experience.

Engine Performance: One of the most common complaints involves engine sputtering or a lack of power during acceleration. This can often be attributed to issues such as a clogged air filter or fuel system problems.

Electrical Failures: Riders may experience electrical malfunctions, including problems with the battery or wiring. These issues can lead to difficulties starting the engine or problems with lighting systems.

Braking Concerns: Inconsistent braking performance is another frequent issue. Owners should check for worn brake pads and ensure that the fluid levels are adequate to maintain safety.

Chain and Sprocket Wear: Regular maintenance is essential for the chain and sprockets, which can wear out over time, leading to reduced efficiency and potential handling problems.

Suspension Issues: Problems with the suspension can also arise, affecting ride comfort and stability. Regular inspection and adjustment of the shock absorbers can help mitigate these concerns.

Essential Tools for Repairs

When it comes to maintaining and fixing your two-wheeled vehicle, having the right equipment is crucial. The correct set of tools not only simplifies the process but also ensures that every task is performed efficiently and safely. Investing in high-quality instruments can make a significant difference in your experience as a mechanic, whether you’re a novice or an expert.

Basic Tool Kit Components

A well-rounded toolkit should include a variety of essential items to tackle common maintenance and troubleshooting tasks. Below is a list of fundamental tools that every motorcycle enthusiast should have on hand:

| Tool | Purpose |

|---|---|

| Wrenches | For loosening and tightening bolts and nuts. |

| Screwdrivers | For fastening and removing screws of various sizes. |

| Socket Set | For accessing hard-to-reach fasteners with ease. |

| Torque Wrench | For applying a specific torque to fasteners. |

| Pliers | For gripping and bending materials or wires. |

| Allen Keys | For hexagonal bolts and screws commonly found in bikes. |

| Oil Filter Wrench | For removing and replacing oil filters. |

Advanced Tools for Specific Tasks

In addition to the basic tools, there are specialized instruments that can enhance your repair capabilities. These tools help you perform more intricate procedures, ensuring thorough and effective maintenance:

| Tool | Purpose |

|---|---|

| Diagnostic Scanner | For reading error codes and monitoring vehicle systems. |

| Compression Tester | For assessing engine health and performance. |

| Battery Tester | For checking battery voltage and condition. |

| Leak Down Tester | For diagnosing internal engine leaks. |

Step-by-Step Maintenance Procedures

This section outlines essential processes for keeping your two-wheeled vehicle in optimal condition. Regular upkeep not only enhances performance but also extends the lifespan of various components. Following a systematic approach ensures that all necessary tasks are performed effectively and efficiently.

Begin with an inspection of the fluid levels, including oil, coolant, and brake fluid. Ensure that each fluid is at the appropriate level and free from contaminants. If any fluid appears dirty or low, replace it according to the guidelines provided in your vehicle’s specifications.

Next, examine the tires for wear and proper inflation. Check the tread depth and look for any signs of damage or irregularities. Maintaining correct tire pressure is crucial for safe handling and performance.

Moving on, focus on the battery. Ensure that terminals are clean and free from corrosion. Check the charge level and connections to prevent electrical issues. If necessary, recharge or replace the battery to maintain reliable starting capabilities.

Inspect the braking system by checking the pads and discs for wear. Ensure that brake fluid levels are adequate, and test the brakes for responsiveness. Any unusual sounds or sensations during braking should be addressed immediately.

Lastly, clean and lubricate the chain and adjust its tension as needed. A well-maintained chain contributes to smoother operation and reduces strain on the engine. Follow the specific recommendations for lubrication intervals and products to use.

By adhering to these maintenance tasks regularly, you can ensure a safe and enjoyable riding experience, while also minimizing the risk of breakdowns and costly repairs.

Engine Troubleshooting Techniques

When it comes to diagnosing issues within the power unit of your vehicle, a systematic approach can make all the difference. Understanding how to identify and resolve common problems ensures optimal performance and longevity. This section outlines effective methods to troubleshoot engine-related concerns.

Identifying Symptoms

Begin by observing any irregularities in the engine’s operation. Common indicators such as unusual noises, vibrations, or performance drops can signal underlying issues. Pay attention to changes in starting behavior, idle stability, and overall responsiveness. Maintaining a log of these symptoms can assist in pinpointing the source of the problem.

Conducting Visual Inspections

A thorough visual examination is essential in the diagnostic process. Look for obvious signs of wear, such as leaks, cracks, or loose components. Check the condition of hoses, belts, and electrical connections, as deterioration in these areas can lead to significant malfunctions. Ensure that all fluids are at appropriate levels, and replace any worn or damaged parts as needed.

Utilizing these techniques not only aids in effective problem resolution but also enhances the understanding of your vehicle’s mechanics, ultimately leading to more informed maintenance decisions.

Electrical System Diagnostics

The functionality of the electrical system is crucial for the optimal performance of any two-wheeled vehicle. Diagnosing issues within this system requires a systematic approach to identify and resolve potential malfunctions. This section provides guidance on effective diagnostic techniques, ensuring reliability and safety.

Key components of the electrical system include the battery, wiring, fuses, and various electrical devices. Understanding how to test each of these elements is essential for pinpointing problems. Below is a basic diagnostic checklist to facilitate the process.

| Component | Common Issues | Diagnostic Method |

|---|---|---|

| Battery | Low charge, corrosion | Check voltage with a multimeter |

| Wiring | Fraying, shorts | Visual inspection and continuity test |

| Fuses | Blown fuses | Inspect for damage and continuity |

| Lights | Dim or non-functional | Check connections and bulb condition |

| Starter Motor | Failure to engage | Test with direct power supply |

By following this diagnostic framework, one can effectively troubleshoot and maintain the integrity of the electrical system, ensuring a smoother ride and enhancing overall vehicle performance.

Changing Oil and Filters

Regular maintenance of your vehicle’s lubrication system is essential for optimal performance and longevity. This process involves replacing both the oil and filters to ensure the engine runs smoothly and efficiently. Properly executing this task can significantly enhance the engine’s health, preventing potential issues down the line.

Preparation and Tools

Before starting, gather necessary tools such as a wrench, an oil catch pan, and a new filter. Ensure you have the correct type of lubricant recommended for your specific model. Wearing gloves is advisable to protect your hands from any contaminants.

Steps to Follow

Begin by warming up the engine slightly to thin the oil, making it easier to drain. Locate the oil drain plug and remove it, allowing the used oil to flow into the catch pan. Once fully drained, replace the plug and proceed to remove the old filter. Install the new filter, applying a thin layer of oil on its rubber gasket for a proper seal. Finally, refill the engine with fresh lubricant, checking the level to ensure it meets the required specifications.

Brake System Maintenance Tips

Maintaining a reliable stopping system is crucial for safe riding. Regular checks and proper care can enhance performance and longevity, ensuring you remain in control during your journeys. Here are essential guidelines to keep your braking components in optimal condition.

Inspecting Brake Components

Frequent examinations of the braking apparatus are necessary to identify wear and tear. Look for signs of damage on the brake pads, rotors, and calipers. If pads appear thin or unevenly worn, replace them promptly. Additionally, ensure rotors are not warped or excessively scored, as these issues can compromise stopping power.

Fluid Maintenance

The quality of hydraulic fluid is vital for effective brake operation. Regularly check the fluid level in the reservoir and top it up with the recommended type if it falls below the minimum mark. Flush the system periodically to remove any contaminants and air bubbles, which can diminish braking efficiency. A clean and well-maintained fluid system is essential for responsive braking.

Inspecting and Replacing Tires

Maintaining optimal tire condition is crucial for ensuring safety and performance. Regular inspection helps identify wear, damage, or other issues that may compromise handling and stability. Knowing when to replace tires can significantly impact overall riding experience and safety on the road.

During inspection, it is essential to check for signs of wear such as tread depth, cracks, or bulges. The following table outlines the key aspects to examine during the tire assessment process:

| Inspection Aspect | Description | Recommended Action |

|---|---|---|

| Tread Depth | Check if the tread is worn down to the minimum depth. | Replace tires if tread depth is below 1.6 mm (2/32 inches). |

| Cracks and Cuts | Look for visible cracks or cuts on the sidewall and tread. | Replace tires showing significant damage. |

| Bulges | Inspect for any bulging areas that indicate structural damage. | Replace tires with bulges immediately. |

| Uneven Wear | Check for uneven wear patterns that suggest alignment issues. | Realign the vehicle and consider tire replacement if necessary. |

| Pressure Levels | Ensure tires are inflated to the manufacturer’s recommended pressure. | Adjust tire pressure to recommended levels. |

When it comes time to replace tires, selecting the right type for your vehicle and riding style is vital. Consider factors such as weather conditions, riding frequency, and terrain to ensure optimal performance and safety. Always consult a professional if you are unsure about the condition of your tires or the replacement process.

Understanding the Fuel System

The fuel system is a vital component of any motorbike, ensuring that the engine receives the necessary energy to function effectively. This system involves a series of interconnected parts that work together to deliver fuel efficiently. A thorough comprehension of its operation and maintenance can significantly enhance performance and longevity.

Key Components

- Fuel Tank: Stores the fuel needed for the engine.

- Fuel Pump: Moves the fuel from the tank to the engine, maintaining proper pressure.

- Carburetor: Mixes the fuel with air for optimal combustion.

- Fuel Filter: Removes impurities from the fuel before it reaches the engine.

- Fuel Lines: Transport the fuel between components, ensuring a secure flow.

Common Issues

- Clogged Filter: Can restrict fuel flow, causing performance issues.

- Leaking Fuel Lines: May lead to fuel loss and potential hazards.

- Dirty Carburetor: Impacts the air-fuel mixture, resulting in poor engine performance.

- Weak Fuel Pump: Fails to supply adequate fuel pressure, affecting acceleration.

Regular inspection and maintenance of the fuel system are crucial for ensuring that your motorbike operates smoothly and efficiently. By understanding each component’s role and addressing potential issues promptly, you can avoid more significant problems down the line.

Adjusting the Clutch and Cables

Proper adjustment of the clutch and cables is essential for optimal performance and control of your motorcycle. This process ensures smooth operation and responsiveness, preventing potential issues that can arise from improper tension or misalignment.

To effectively adjust the clutch and cables, follow these steps:

- Start by locating the clutch lever and the adjustment points on the cable.

- Check the current cable tension. You should be able to pull the lever without excessive force.

- Determine the free play at the lever. Ideally, there should be about 2-3 mm of play before resistance is felt.

If adjustments are necessary, proceed as follows:

- Use the adjuster located at the lever to increase or decrease tension as needed.

- For finer adjustments, you can also modify the adjuster near the engine.

- Ensure that both adjustments result in the desired free play and smooth lever action.

Once adjustments are made, test the operation by pulling the lever and engaging the gears. Make further adjustments if necessary, ensuring that the clutch fully engages and disengages smoothly.

Regular maintenance of the clutch and cables not only prolongs their lifespan but also enhances your riding experience, allowing for greater confidence and control on the road.

Upgrading Components for Performance

Enhancing the capabilities of a motorcycle often involves optimizing various components to achieve better power delivery, handling, and overall ride quality. By focusing on critical areas such as the engine, exhaust system, and suspension, enthusiasts can significantly elevate the performance of their two-wheeled machines. This section explores essential upgrades that can transform a standard bike into a more dynamic and responsive ride.

Engine Modifications

One of the most impactful ways to boost performance is through engine enhancements. Upgrading the air intake system allows for improved airflow, which can increase combustion efficiency. Additionally, installing a performance exhaust can reduce back pressure, resulting in enhanced power output. Consideration should also be given to tuning the engine management system to ensure optimal fuel delivery and timing.

Suspension and Handling Improvements

Enhancing the suspension can lead to better stability and cornering capabilities. Upgrading to high-quality shock absorbers and fork springs can provide improved damping and responsiveness. Furthermore, adjustments to ride height and preload settings can help tailor the bike’s handling characteristics to suit individual riding styles. Such modifications not only improve performance but also enhance rider confidence on various terrains.

Safety Practices during Repairs

Ensuring safety while performing maintenance tasks is crucial to preventing accidents and injuries. Proper precautions and a systematic approach not only protect the individual working on the equipment but also contribute to the longevity and efficiency of the machine itself. Adhering to best practices can make the process smoother and safer for everyone involved.

Personal Protective Equipment

Utilizing appropriate personal protective equipment (PPE) is essential. Items such as gloves, goggles, and steel-toed boots can provide vital protection against potential hazards. Additionally, wearing a well-fitted mask can help guard against dust and fumes that may arise during the process. Ensuring that the work area is free from distractions also enhances focus and minimizes risks.

Workspace Organization

Maintaining an organized workspace is critical for safety. Keeping tools and materials neatly arranged reduces the likelihood of accidents caused by tripping or losing track of essential items. Moreover, ensuring that the area is well-lit and ventilated can significantly improve visibility and air quality, creating a safer environment for any task at hand.