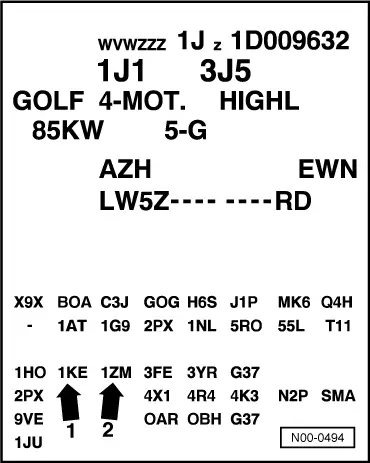

Comprehensive Guide to Golf MK4 Repairs

Ensuring the longevity and optimal performance of your automobile requires a comprehensive understanding of its various components. This section offers valuable insights into the essential practices that can help maintain your vehicle’s functionality and reliability.

From troubleshooting common issues to performing routine inspections, this guide serves as a useful resource for those looking to enhance their knowledge and skills. Emphasizing preventative measures, it aims to empower individuals to take control of their vehicle care.

Whether you are an experienced enthusiast or a newcomer, the information presented here is designed to provide clarity and support in navigating the complexities of automotive upkeep. Embrace the opportunity to cultivate a deeper connection with your automobile through informed maintenance choices.

Regular upkeep is vital for ensuring optimal performance and longevity of any vehicle. Understanding the key components that require attention can greatly enhance the driving experience. This section highlights essential practices for maintaining a specific automotive model, ensuring it remains in peak condition.

Key Maintenance Tasks

- Oil Changes

- Tire Inspections and Rotations

- Brake System Evaluations

- Fluid Checks

- Battery Maintenance

Seasonal Preparations

- Inspecting Wiper Blades for Visibility

- Checking Coolant Levels for Temperature Regulation

- Ensuring Lights Function Properly for Safety

Common Troubleshooting Tips

- Identifying Unusual Noises

- Monitoring Dashboard Indicators

- Understanding Fluid Leaks

Common Issues and Solutions

In the realm of automotive maintenance, several frequent challenges may arise, impacting the overall performance and reliability of vehicles. Understanding these typical problems, along with their corresponding solutions, is essential for effective troubleshooting and restoration.

| Issue | Description | Solution |

|---|---|---|

| Engine Performance | Loss of power or unusual noises from the engine. | Check spark plugs and fuel filters; replace if necessary. |

| Electrical System | Issues with lights or dashboard indicators not functioning. | Inspect fuses and wiring; replace damaged components. |

| Braking System | Unusual sounds or decreased responsiveness when braking. | Examine brake pads and fluid levels; service or replace as needed. |

| Transmission Problems | Difficulty shifting gears or slipping transmission. | Check fluid levels; consider professional servicing if issues persist. |

Engine Care and Troubleshooting

Proper maintenance of the power unit is essential for ensuring optimal performance and longevity. Regular checks and timely interventions can prevent minor issues from escalating into major concerns, ultimately leading to a smoother driving experience.

Routine Maintenance Tasks

- Regular oil changes to keep the engine lubricated.

- Checking coolant levels to prevent overheating.

- Inspecting belts and hoses for wear and tear.

- Replacing air filters to maintain airflow.

- Monitoring fuel quality to ensure efficient combustion.

Troubleshooting Common Issues

- Engine won’t start:

- Check the battery condition and connections.

- Inspect the fuel supply and pump functionality.

- Unusual noises:

- Identify the source; it may indicate wear in components.

- Ensure all fasteners are secure and not loose.

- Excessive smoke:

- Blue smoke may signal oil burning; check seals.

- Black smoke suggests too much fuel; examine the fuel system.

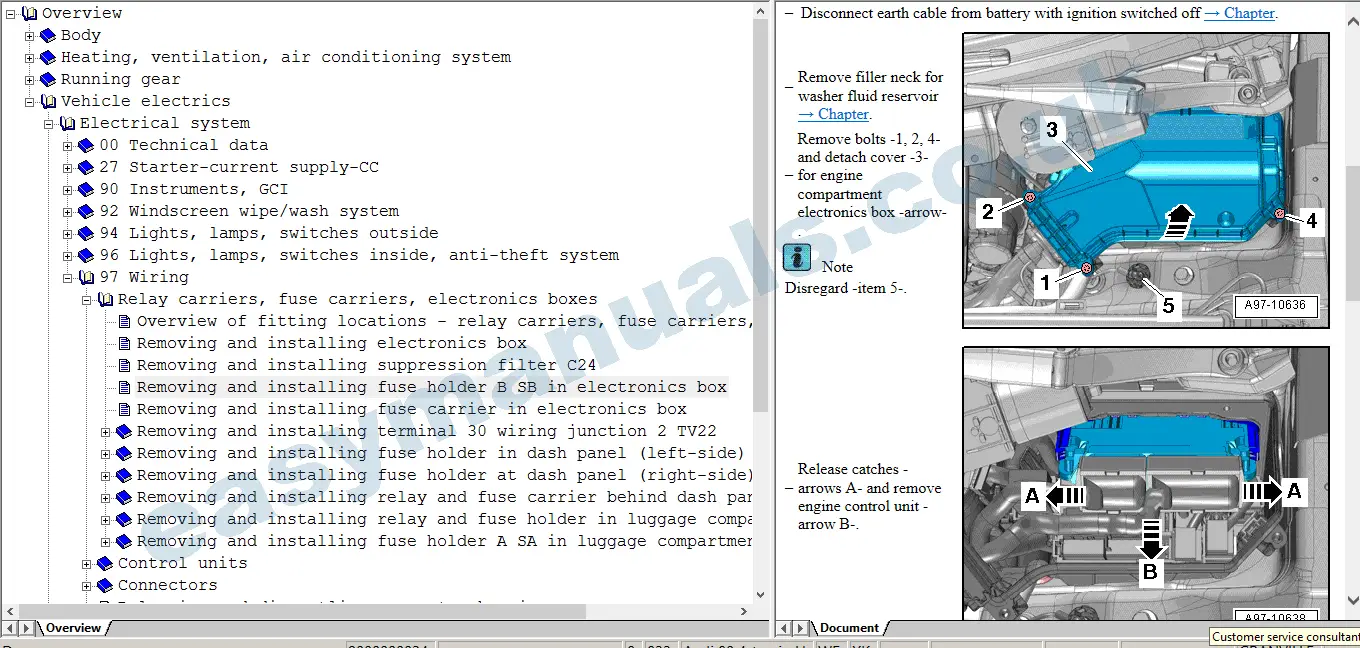

Electrical System Checks

Assessing the electrical system is crucial for ensuring optimal performance and reliability of the vehicle. A thorough examination helps identify potential issues that could lead to malfunctions or failures in various components. This process typically involves testing circuits, connections, and individual parts to maintain efficiency.

Key Areas of Focus

When inspecting the electrical components, pay close attention to the following areas:

- Battery condition and connections

- Fuses and relays functionality

- Wiring harness integrity

- Grounding points

- Switches and sensors

Testing Procedures

Utilize the following table as a guide for systematic testing:

| Component | Test Method | Expected Outcome |

|---|---|---|

| Battery | Voltage test | 12.6V or higher |

| Fuses | Continuity test | No breaks |

| Wiring | Visual inspection | No frays or corrosion |

| Grounds | Resistance test | Low resistance |

| Switches | Functionality test | Correct operation |

Regular checks of the electrical system can prevent future complications and enhance the overall performance of the vehicle.

Braking System Overview

The braking system is a crucial component of any vehicle, ensuring safe stopping and control during operation. Understanding its functionality and parts can significantly enhance maintenance and performance. This section delves into the various elements that contribute to effective deceleration and the mechanisms that support driver safety.

Components of the Braking System

The primary elements include the brake pedal, master cylinder, brake lines, and the actual braking units. Each part works harmoniously to convert the force applied by the driver into stopping power. Regular inspection of these components is essential to maintain optimal functionality and prevent potential failures.

Maintenance and Safety Considerations

Routine checks and timely replacements of worn-out parts can extend the lifespan of the braking system. It’s vital to monitor brake fluid levels and listen for unusual noises during braking, as these may indicate underlying issues. Ensuring all components are in good condition not only enhances performance but also safeguards occupants.

Suspension and Steering Insights

This section delves into the intricacies of the vehicle’s suspension and steering systems, which play a crucial role in ensuring optimal handling, comfort, and overall driving experience. Understanding these components helps in maintaining the vehicle’s stability and responsiveness on various terrains.

Key Components of Suspension

The suspension system comprises several essential elements, including springs, shock absorbers, and control arms. These parts work in unison to absorb road imperfections, thereby enhancing ride quality. Regular inspection of these components can prevent issues such as uneven tire wear and poor handling.

Steering Mechanism Overview

The steering system is responsible for directing the vehicle’s movement. It typically includes components like the steering rack, tie rods, and the steering wheel. A well-maintained steering mechanism ensures precise maneuverability and feedback, allowing for a safer driving experience. Keeping an eye on these components can help identify potential problems early, leading to more efficient maintenance.

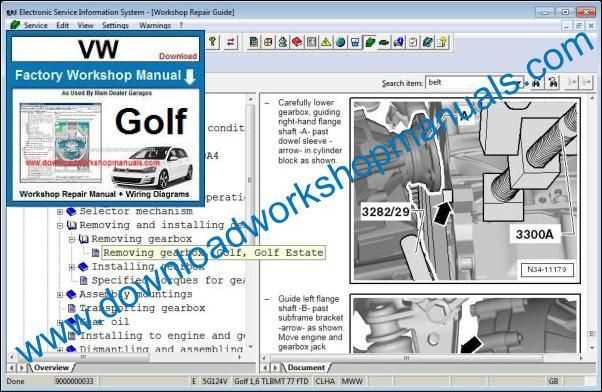

Transmission and Gearbox Tips

Understanding the intricacies of transmission and gearbox systems is essential for optimal vehicle performance. This section provides insights and practical advice for maintaining and troubleshooting these vital components, ensuring longevity and efficiency.

Regular Maintenance Practices

Consistent upkeep is crucial for preserving functionality. Here are key practices to consider:

- Check fluid levels regularly to prevent overheating.

- Replace transmission fluid at recommended intervals to maintain optimal lubrication.

- Inspect seals and gaskets for leaks to avoid fluid loss.

Troubleshooting Common Issues

Identifying problems early can save time and money. Consider these common symptoms and solutions:

- Slipping Gears: May indicate low fluid or worn components. Check fluid levels first.

- Unusual Noises: Grinding or whining sounds can signal internal damage. Inspect the system promptly.

- Delayed Engagement: If there’s a lag when shifting, it might be due to low fluid or a faulty solenoid. Investigate the fluid condition and electrical components.

Cooling System Maintenance

Proper upkeep of the cooling mechanism is essential for the longevity and efficiency of the vehicle. This system plays a crucial role in regulating engine temperature, preventing overheating and ensuring optimal performance. Regular inspections and maintenance can help identify potential issues before they escalate.

Regular Inspections

Routine checks should include examining hoses and connections for any signs of wear or leaks. Additionally, monitoring the coolant level and quality is vital, as degraded coolant can lead to inefficient cooling and corrosion within the system. If any components show signs of damage, timely replacement is advisable to maintain system integrity.

Fluid Replacement

It is important to replace the coolant at specified intervals to ensure effective thermal regulation. The type of coolant used should align with the manufacturer’s recommendations, as different formulations can affect performance. Flushing the system periodically also helps eliminate contaminants and build-up, promoting optimal functionality.

Exhaust System Considerations

The exhaust assembly plays a crucial role in managing emissions and optimizing performance. Proper maintenance and understanding of this system can enhance the overall efficiency of the vehicle while contributing to a healthier environment.

When evaluating the exhaust setup, several factors come into play:

| Aspect | Description |

|---|---|

| Components | Includes the manifold, catalytic converter, muffler, and tailpipe, each serving distinct functions. |

| Inspection | Regular checks for leaks, corrosion, or damage are essential to ensure optimal performance. |

| Upgrades | Performance enhancements, such as aftermarket parts, can improve flow and sound but should be compatible with local regulations. |

| Environmental Impact | Compliance with emissions standards is vital; an efficient system reduces harmful pollutants. |

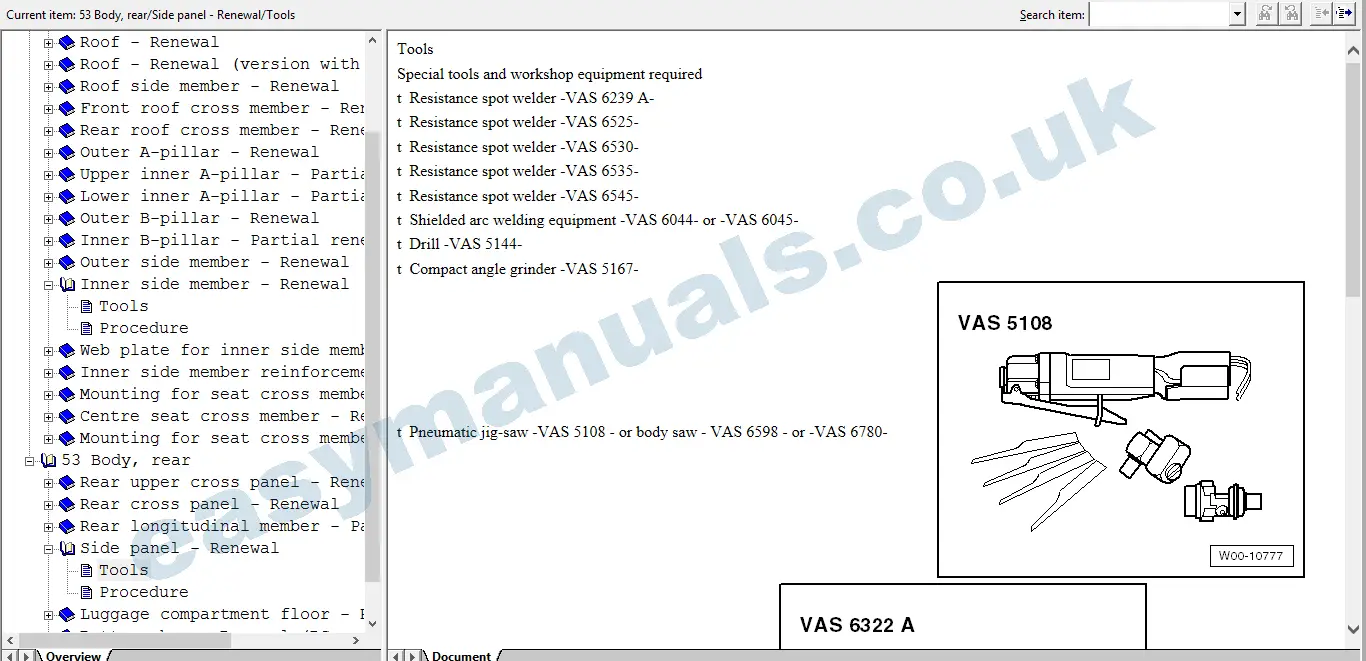

Bodywork Repair Techniques

This section explores various methods for restoring the exterior of vehicles, focusing on both aesthetic and structural integrity. Understanding these techniques is essential for achieving a polished finish while ensuring durability.

Common Approaches: Techniques such as dent removal and panel replacement are fundamental. Each method varies in complexity and tools required, emphasizing the importance of selecting the right approach for the damage type.

Tools and Materials: Utilizing appropriate instruments like hammers, pullers, and fillers is crucial. Selecting high-quality materials ensures that repairs withstand wear and environmental factors.

Finishing Touches: After addressing the primary issues, refinishing the surface with paint or protective coatings is vital. This not only enhances appearance but also safeguards against future damage.

Interior Upkeep and Repairs

Maintaining and restoring the interior of your vehicle is essential for both comfort and aesthetics. Regular attention to various components can enhance the driving experience and prolong the lifespan of materials. This section outlines key practices to ensure that the cabin remains inviting and functional.

Routine Cleaning and Maintenance

Regular cleaning is crucial to prevent the buildup of dirt and grime. Utilize appropriate cleaning solutions for different surfaces, such as upholstery, leather, and plastics. A vacuum cleaner with suitable attachments can help reach difficult spots, while microfiber cloths are ideal for a streak-free finish on windows and dashboards. Additionally, consider applying protectants to surfaces to guard against wear and UV damage.

Addressing Common Issues

Over time, various issues may arise, including worn-out fabrics, fading colors, or minor scratches. For fabric seats, using a steam cleaner can effectively remove stains, while touch-up kits are available for scratches on plastic or painted surfaces. If you encounter more significant damage, such as tears or burns, consider consulting a professional service for repairs or replacement parts. Staying proactive with these concerns will maintain the overall appeal of the cabin.

Diagnostic Tools and Equipment

Accurate assessments of vehicle issues rely on a variety of specialized instruments and apparatus designed to facilitate thorough evaluations. These resources enable technicians to identify faults effectively, ensuring timely and efficient repairs.

Among the essential devices are electronic diagnostic scanners, which interface with the vehicle’s onboard systems. These tools retrieve error codes, providing insights into potential malfunctions and assisting in pinpointing areas that require attention. In addition, multimeters and oscilloscopes play a crucial role in examining electrical components, allowing for precise measurements and waveform analysis.

Moreover, mechanical tools such as compression testers and leak-down testers are vital for evaluating engine performance and ensuring optimal operation. Together, these implements form a comprehensive toolkit that empowers technicians to deliver effective solutions.