Troy-Bilt Self Propelled Lawn Mower Repair Guide

Taking care of your outdoor tools is essential for achieving a beautifully manicured yard. Whether you’re dealing with a device designed for cutting grass or another type of landscape equipment, knowing how to troubleshoot common issues can save you time and money. This section will provide you with the knowledge you need to keep your machinery running smoothly.

Understanding the inner workings of your equipment allows you to address potential problems before they escalate. Regular maintenance not only extends the lifespan of your tools but also ensures optimal performance during use. In the following paragraphs, you will discover practical tips and insights tailored to help you navigate various challenges and enhance your gardening experience.

From simple adjustments to more intricate fixes, mastering these techniques can empower you to take control of your outdoor maintenance tasks. By following the guidelines presented here, you can confidently approach any situation that may arise, ensuring your gardening efforts are both efficient and effective.

Troy-Bilt Lawn Mower Overview

This section provides a comprehensive look at a well-regarded brand in the garden equipment market, known for its reliability and innovation. The products from this manufacturer cater to various needs, ensuring that homeowners can maintain their green spaces with ease and efficiency.

The machines are designed with user-friendly features, focusing on performance and durability. With a variety of models available, they accommodate both small yards and larger properties, allowing users to choose the best fit for their gardening requirements.

| Feature | Description |

|---|---|

| Engine Power | Robust engines provide ample power for effective cutting. |

| Cutting Width | Various sizes available to suit different yard dimensions. |

| Adjustable Height | Easy height adjustments for customized grass length. |

| Fuel Type | Compatible with standard gasoline for convenience. |

| Weight | Lightweight designs for easy maneuverability. |

With a focus on innovation, the brand integrates features that enhance user experience, including ergonomic handles and simple starting mechanisms. These aspects ensure that anyone, regardless of experience, can operate the equipment efficiently and with confidence.

Common Issues with Self-Propelled Models

When operating powered yard equipment, users may encounter various challenges that can affect performance and efficiency. Understanding these common problems is essential for maintaining optimal functionality and ensuring a smooth experience.

1. Difficulty in Movement: One of the most frequent complaints is related to mobility. Machines may struggle to move forward or backward due to issues with the drive system or wheel assembly. This can result from worn-out belts or a malfunctioning transmission.

2. Uneven Cutting: Users may notice that the cutting performance is inconsistent. This can be attributed to dull blades, improper height settings, or an unbalanced deck. Regular maintenance and adjustments can help mitigate this issue.

3. Engine Starting Problems: A common frustration is the inability to start the engine. This may stem from fuel issues, spark plug malfunctions, or battery problems in electric models. Ensuring proper fuel levels and checking electrical connections can often resolve these concerns.

4. Excessive Vibration: If the equipment vibrates excessively during operation, it could indicate loose components or misaligned parts. Tightening bolts and ensuring everything is properly secured can alleviate this problem.

5. Stalling: Unexpected stalling can disrupt yard work significantly. This issue can arise from a clogged air filter, fuel line blockages, or overheating. Regularly inspecting these components can prevent stalling and enhance overall performance.

By recognizing these prevalent issues and addressing them promptly, users can prolong the lifespan of their equipment and enjoy a more efficient working experience.

Tools Needed for Repairs

When it comes to maintaining outdoor equipment, having the right instruments at hand is essential for efficient and effective troubleshooting. Proper tools not only facilitate the process but also ensure safety and precision during work. Below is a comprehensive list of essential instruments that will aid in handling various tasks related to upkeep and adjustments.

A basic toolkit should include a set of screwdrivers–both flathead and Phillips–to manage different types of screws. Pliers are crucial for gripping and twisting components, while a socket set will allow for tightening and loosening nuts and bolts with ease. Additionally, a torque wrench can help ensure that fasteners are tightened to the manufacturer’s specifications.

Having a multimeter is beneficial for diagnosing electrical issues, providing insights into voltage and continuity. A spark plug socket will be indispensable for changing or inspecting ignition components. Furthermore, a good set of wrenches in various sizes will assist in accessing hard-to-reach areas.

Don’t overlook the importance of safety gear. Gloves protect your hands from sharp edges and grime, while safety glasses shield your eyes from debris. With these tools and safety measures, you’ll be well-equipped to tackle maintenance tasks effectively.

Step-by-Step Repair Guide

This guide provides a systematic approach to diagnosing and fixing common issues encountered with garden equipment. By following these steps, you can effectively troubleshoot problems and restore functionality without needing professional assistance.

-

Identify the Issue:

- Observe any unusual sounds or behavior during operation.

- Check for visible damage or wear on key components.

- Make note of any error codes or warning lights, if applicable.

-

Gather Necessary Tools:

- Wrenches and screwdrivers

- Replacement parts

- Cleaning supplies

- Safety equipment (gloves, goggles)

-

Perform Initial Cleaning:

- Remove debris and grass clippings from the exterior.

- Inspect and clean air filters, if accessible.

- Ensure that the blades are sharp and free of obstructions.

-

Check Fuel and Oil Levels:

- Ensure there is sufficient fuel in the tank.

- Check oil quality and levels, topping up or changing as needed.

-

Inspect Electrical Components:

- Check battery connections and charge level.

- Inspect wiring for any frayed or damaged areas.

-

Test Functionality:

- Attempt to start the equipment after performing checks and maintenance.

- Listen for any abnormal sounds and assess performance.

By following these detailed steps, you can effectively troubleshoot and address issues, ensuring your equipment operates efficiently for all your gardening needs.

Engine Troubleshooting Techniques

When dealing with engine performance issues, it’s essential to systematically identify the root causes of malfunctions. Employing effective diagnostic methods can streamline the process of finding and resolving problems, ensuring optimal functionality.

Common Symptoms and Initial Checks

Start by observing any noticeable symptoms. Here are key indicators to consider:

- Unusual noises during operation

- Difficulty starting the engine

- Inconsistent power output

- Excessive vibration

Before delving deeper, perform these initial checks:

- Examine fuel levels and quality.

- Inspect air filters for dirt and blockages.

- Check spark plugs for wear or fouling.

Systematic Troubleshooting Steps

Once initial checks are complete, follow these systematic troubleshooting steps:

- Ensure all connections are secure, including wiring and hoses.

- Test battery voltage and condition.

- Run a compression test to assess engine health.

- Inspect the carburetor for clogs or improper settings.

By applying these techniques, you can effectively diagnose and resolve various engine issues, leading to improved performance and reliability.

Adjusting Self-Propel Mechanism

Properly tuning the drive system is essential for achieving optimal performance and ease of use. Adjustments may be required to ensure that the equipment moves smoothly and responds accurately to the operator’s inputs. This guide outlines the steps necessary to achieve a well-functioning drive mechanism.

Before beginning the adjustment process, it’s important to gather the required tools and ensure safety precautions are in place. This will help facilitate a smooth operation and prevent any accidents.

| Tools Needed | Description |

|---|---|

| Wrench | For loosening and tightening bolts. |

| Screwdriver | For adjusting tension and settings. |

| Measuring tape | To ensure accurate distance settings. |

| Safety gloves | To protect your hands during the process. |

Follow these steps to adjust the mechanism:

- Inspect the drive components for any wear or damage. Replace any parts if necessary.

- Loosen the tension adjustment bolts slightly to allow for movement.

- Adjust the tension according to the manufacturer’s specifications to ensure proper engagement.

- Tighten the bolts securely once adjustments are made.

- Test the equipment in a safe area to ensure the adjustments were successful.

Regular maintenance and adjustments will not only prolong the life of the machinery but also enhance its performance. Keep a log of any changes made for future reference and troubleshooting.

Maintaining Blade Sharpness

Keeping the cutting edge of your equipment in optimal condition is essential for achieving a clean and efficient cut. A sharp blade enhances performance, reduces strain on the engine, and promotes healthier growth in the grass by providing a clean cut rather than tearing. Regular maintenance is crucial to ensure longevity and effectiveness.

Signs of Dull Blades

Recognizing when your cutting edge is losing its sharpness can save you time and effort. Here are some indicators to look for:

| Indicator | Description |

|---|---|

| Uneven Cuts | Grass appears unevenly trimmed, leading to an unkempt appearance. |

| Brown Tips | Grass blades show signs of browning at the tips due to tearing. |

| Excessive Clumping | Clumps of grass accumulate instead of being evenly dispersed. |

Sharpening Techniques

There are several effective methods for restoring the sharpness of your cutting edge. The choice of technique may depend on personal preference and available tools:

- File Sharpening: Using a metal file to manually sharpen the edge is a traditional and effective method.

- Angle Grinder: A power tool can provide a quick and precise edge, but care must be taken to avoid overheating.

- Sharpening Stone: A whetstone allows for a fine finish and can help maintain the blade’s integrity.

Changing the Oil Safely

Regular maintenance is essential for the longevity of your outdoor equipment, and one of the key tasks is the replacement of lubricating fluid. Ensuring this process is done correctly and safely can help prevent damage and enhance performance. This section provides guidance on how to execute this task efficiently while minimizing risks.

Preparation Steps

Before starting, gather all necessary tools and materials, including a suitable container for used fluid, a wrench, and a funnel. Ensure the device is on a flat surface and powered down. Allow the engine to cool for a few minutes to avoid burns, then carefully locate the drain plug and any access points for the new fluid. Wearing gloves and goggles is recommended to protect yourself from spills and splashes.

Draining and Refilling

Once prepared, begin by removing the drain plug to allow the old liquid to flow into your container. Be cautious, as it may still be warm. After all fluid has been drained, replace the plug securely. Next, use the funnel to pour in the new lubricant, ensuring you follow the manufacturer’s recommended type and quantity. Check the level with the dipstick, and add more if necessary. Dispose of the used fluid responsibly at a designated recycling location.

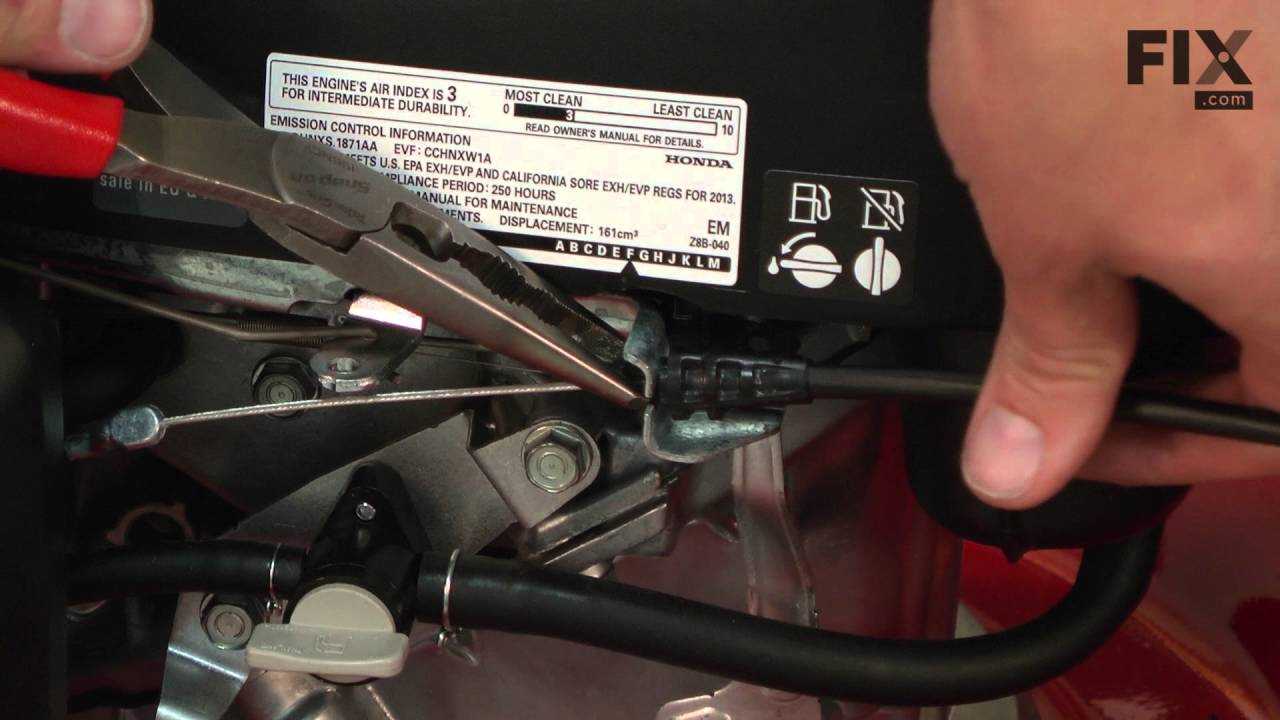

Replacing Spark Plugs Efficiently

Changing ignition components can significantly improve engine performance. This process, though simple, requires attention to detail and a few essential tools. By following a structured approach, you can ensure a smooth replacement, enhancing the overall efficiency of your equipment.

Tools Required

To effectively complete this task, gather the following items:

| Tool | Purpose |

|---|---|

| Socket Wrench | For loosening and tightening the spark plug |

| Gap Gauge | To check and adjust the spark plug gap |

| Torque Wrench | To ensure proper tightness |

| Clean Cloth | To wipe any debris |

Step-by-Step Process

Start by disconnecting the power source to prevent any accidental starts. Remove the old component using the socket wrench, being careful not to damage surrounding parts. Inspect the new item for any defects before installation. Use the gap gauge to ensure it meets the manufacturer’s specifications. Once everything is aligned, carefully tighten it using the torque wrench to avoid over-tightening.

Cleaning Air Filters Regularly

Maintaining optimal performance of outdoor equipment requires attention to various components, and air filters play a crucial role in this process. Regular cleaning of these filters ensures that the engine receives adequate airflow, promoting efficiency and longevity. Neglecting this task can lead to reduced performance and potential damage over time.

To keep the air filters in top condition, follow these simple steps:

| Step | Description |

|---|---|

| 1 | Locate the air filter according to the manufacturer’s guidelines. |

| 2 | Remove the filter carefully, taking care not to damage any surrounding components. |

| 3 | Use a soft brush or compressed air to remove dirt and debris from the filter. |

| 4 | If the filter is heavily soiled, consider washing it with mild soap and water. |

| 5 | Allow the filter to dry completely before reinstalling it. |

| 6 | Reattach the filter securely and ensure all components are in place. |

By adhering to this maintenance routine, users can enhance the functionality and lifespan of their equipment, leading to a more effective and enjoyable experience.

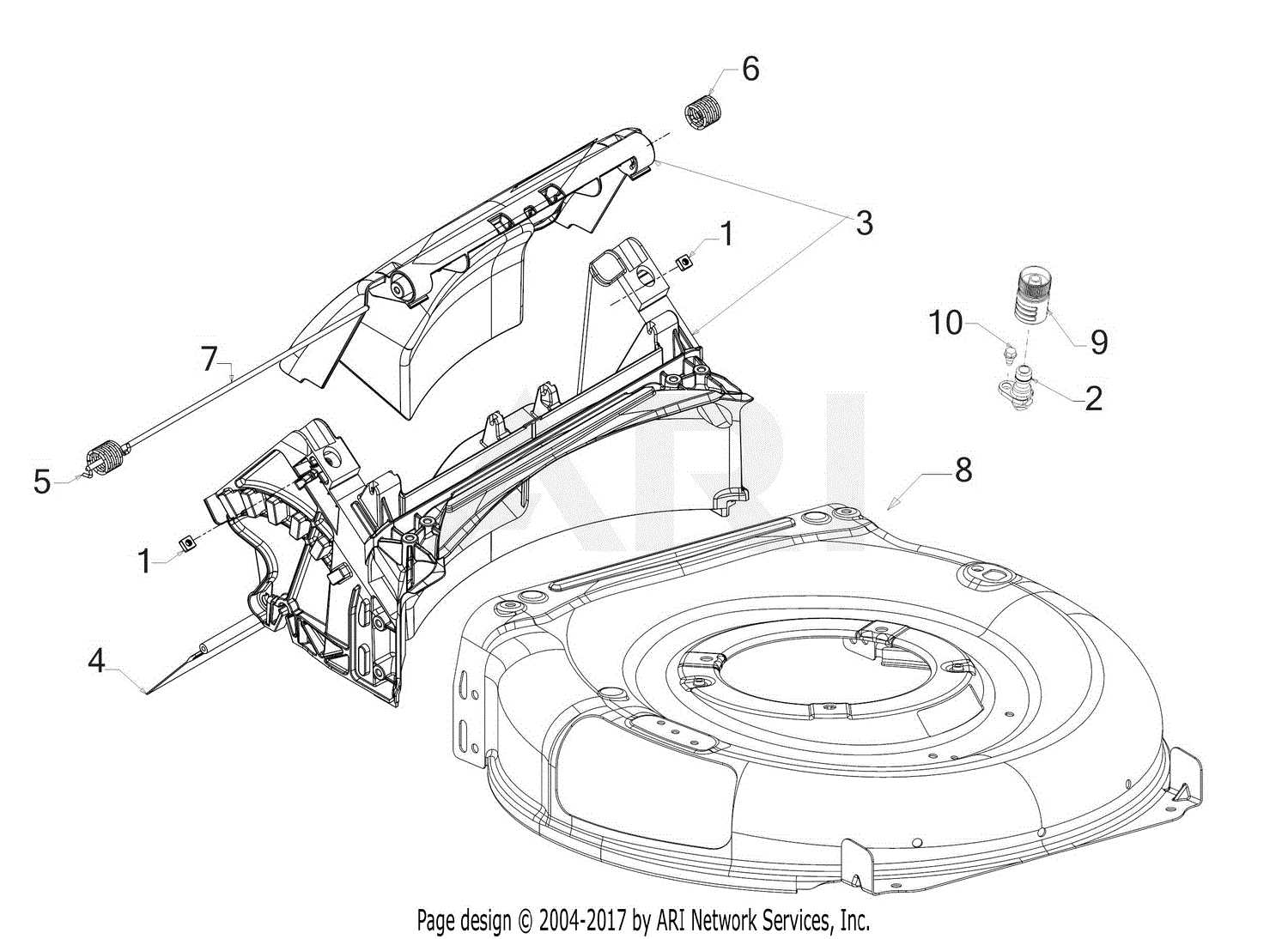

Inspecting and Replacing Cables

Ensuring the proper functionality of your equipment involves a thorough examination of the cables that connect various components. These cables are essential for transmitting power and signals, and any wear or damage can significantly affect performance. Regular inspections can help identify issues early, allowing for timely replacements and minimizing the risk of further complications.

Steps for Inspection

Begin by visually examining all cables for signs of fraying, cuts, or corrosion. Pay close attention to connections, as these areas are often prone to wear. If you notice any abnormalities, it’s crucial to test the cables for continuity using a multimeter.

| Condition | Action Required |

|---|---|

| Frayed Cables | Replace immediately to prevent malfunction. |

| Corroded Connectors | Clean with a suitable solvent; replace if heavily damaged. |

| No Continuity | Inspect for breaks; replace if necessary. |

Replacement Procedure

To replace a damaged cable, first disconnect the power source to ensure safety. Carefully remove the old cable, taking note of how it is routed. Install the new cable in the same manner, ensuring secure connections and proper routing to avoid interference with moving parts. Finally, reconnect the power source and perform a functionality test to confirm the repair.

Winterizing Your Lawn Mower

Preparing your outdoor equipment for the colder months is essential for ensuring its longevity and optimal performance. Proper maintenance can prevent damage caused by frost and corrosion, making springtime startup much smoother.

Steps to Prepare

- Clean the exterior thoroughly to remove dirt and debris.

- Drain the fuel tank to prevent stale gasoline from causing issues.

- Change the oil to keep the engine in good condition.

- Inspect and sharpen the blades for efficient cutting next season.

Storage Tips

- Store in a dry, sheltered location to avoid moisture exposure.

- Cover with a tarp or cloth for added protection.

- Check regularly for any signs of wear or pests during the off-season.

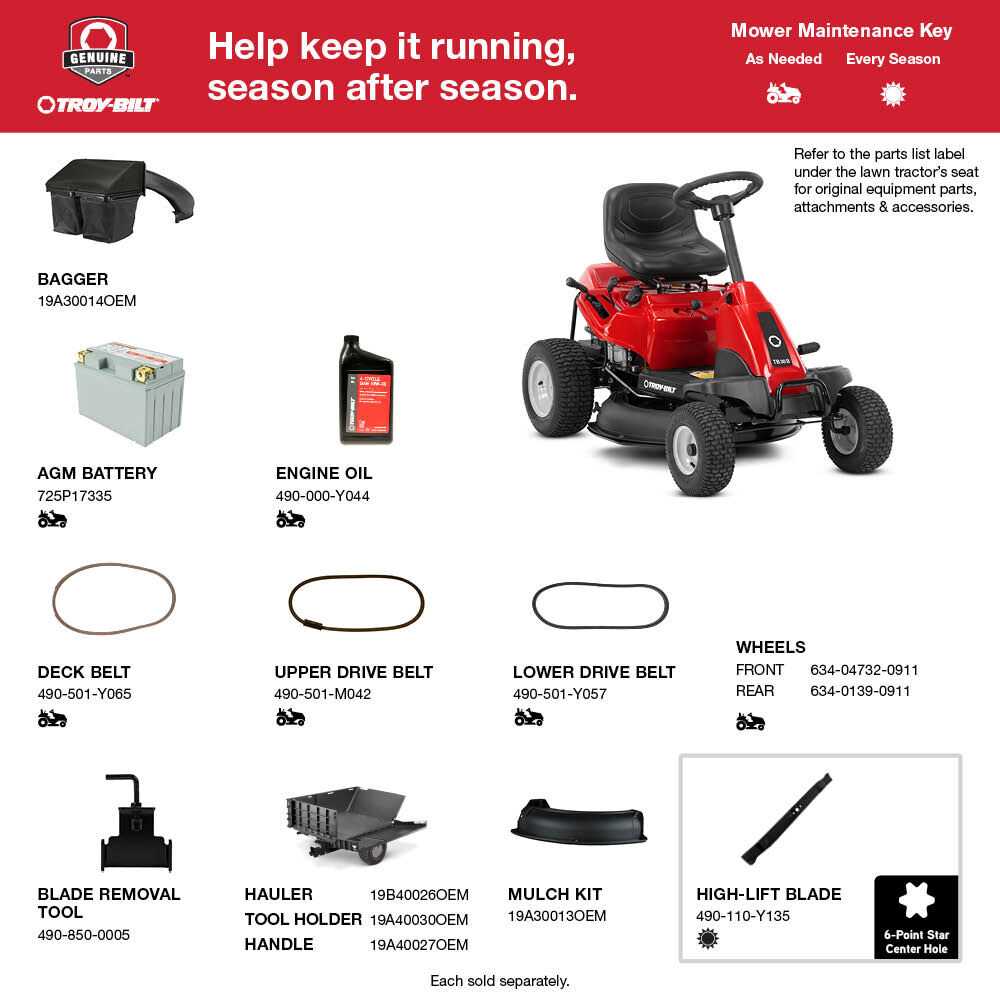

Finding Replacement Parts Online

Locating components for your equipment can be a straightforward process if you know where to look. The internet offers a variety of platforms and resources that cater to your needs, ensuring you find the right pieces to keep your machine running smoothly.

Utilizing Manufacturer Websites

One of the best starting points is the official website of the brand. Most manufacturers provide detailed catalogs of parts, allowing you to search by model number or specific features. This method guarantees authenticity and compatibility, ensuring that you receive high-quality components.

Exploring Third-Party Retailers

In addition to official sites, numerous third-party retailers specialize in offering a wide range of components. Websites such as Amazon or eBay can be invaluable, providing options for new, used, or aftermarket parts. Always check customer reviews and ratings to ensure reliability before making a purchase.

When searching for components online, consider using specific keywords related to the part you need. This will refine your search results and help you locate the exact item faster. Take your time to compare prices and shipping options to find the best deal.