Dewalt 735 Planer Repair Guide for Optimal Performance

Ensuring the longevity and efficiency of your woodworking equipment is crucial for achieving high-quality results in your projects. Over time, even the most reliable machines may encounter issues that require attention and care. Understanding the intricacies of your device can help you troubleshoot common problems and implement effective solutions.

This section is designed to provide you with comprehensive insights into maintaining and fixing your woodworking apparatus. By following the outlined procedures, you can enhance the performance of your tool and extend its lifespan. Knowledge of basic components and their functions will empower you to tackle minor setbacks without professional assistance.

Whether you are an experienced craftsman or a novice enthusiast, familiarity with the internal workings of your equipment will enhance your overall woodworking experience. With the right information at your fingertips, you can ensure that your machine remains in optimal condition, allowing you to focus on your creative endeavors.

Dewalt 735 Planer Overview

This section provides a comprehensive look at a powerful woodworking tool designed to enhance efficiency and precision in surface preparation. Its robust features cater to both professionals and hobbyists, making it a versatile addition to any workshop.

Engineered for optimal performance, this device boasts a high cutting speed and impressive material removal capabilities. The dual-blade system ensures a smooth finish, reducing the need for extensive sanding. Its compact design allows for easy maneuverability while maintaining stability during operation.

Equipped with advanced settings, users can effortlessly adjust thickness levels to suit a variety of projects. Additionally, the inclusion of a dust collection system helps maintain a clean workspace, minimizing cleanup time and enhancing safety.

Overall, this woodworking tool stands out for its reliability and user-friendly features, making it an essential asset for achieving professional-grade results in woodworking tasks.

Common Issues with Dewalt 735

When working with power tools designed for smoothing and leveling surfaces, users may encounter several recurring challenges. Understanding these common problems can help in diagnosing and resolving issues efficiently, ensuring optimal performance and longevity of the equipment.

One frequent concern is the inconsistency in the finish quality. This can result from dull blades, improper height adjustments, or accumulation of debris within the mechanism. Regular maintenance and blade replacement can significantly improve results.

Another issue often faced is the motor overheating. This usually occurs when the tool is subjected to excessive load or prolonged use without breaks. Ensuring adequate airflow and allowing the motor to cool down during operation can mitigate this problem.

Additionally, users may notice vibrations or unusual noises during operation. These symptoms might indicate loose components or misalignment within the system. Regular inspections and tightening of screws can help maintain stability and reduce such disturbances.

Lastly, power interruptions can lead to unexpected shutdowns. Checking the electrical connections and ensuring a stable power supply can prevent disruptions during work. Addressing these common issues promptly will enhance the tool’s efficiency and extend its lifespan.

Step-by-Step Repair Process

This section outlines a systematic approach to addressing common issues encountered with your equipment. Following these steps can help ensure effective troubleshooting and resolution of problems.

-

Identify the Problem: Begin by observing the symptoms. Is there an unusual noise? Is the tool not functioning at all? Take note of any specific issues.

-

Gather Tools and Materials: Before starting, collect the necessary tools. This may include:

- Screwdrivers

- Wrenches

- Replacement parts

- Cleaning supplies

-

Disassemble the Unit: Carefully take apart the components as needed. Keep track of screws and small parts to avoid losing them.

-

Inspect Components: Examine each part for wear and tear. Look for signs of damage or malfunction, such as cracks or corrosion.

-

Replace or Repair Parts: Depending on your findings, either replace damaged components or make necessary repairs. Ensure all replacements are compatible.

-

Reassemble the Equipment: Once repairs are made, carefully put the unit back together. Follow your disassembly steps in reverse order.

-

Test the Unit: After reassembly, conduct a test run to ensure everything operates smoothly. Monitor for any unusual behavior.

-

Document the Process: Take notes on what was done, any parts replaced, and observations during the testing phase. This will be helpful for future reference.

By following these steps, you can effectively troubleshoot and maintain your equipment, ensuring its longevity and performance.

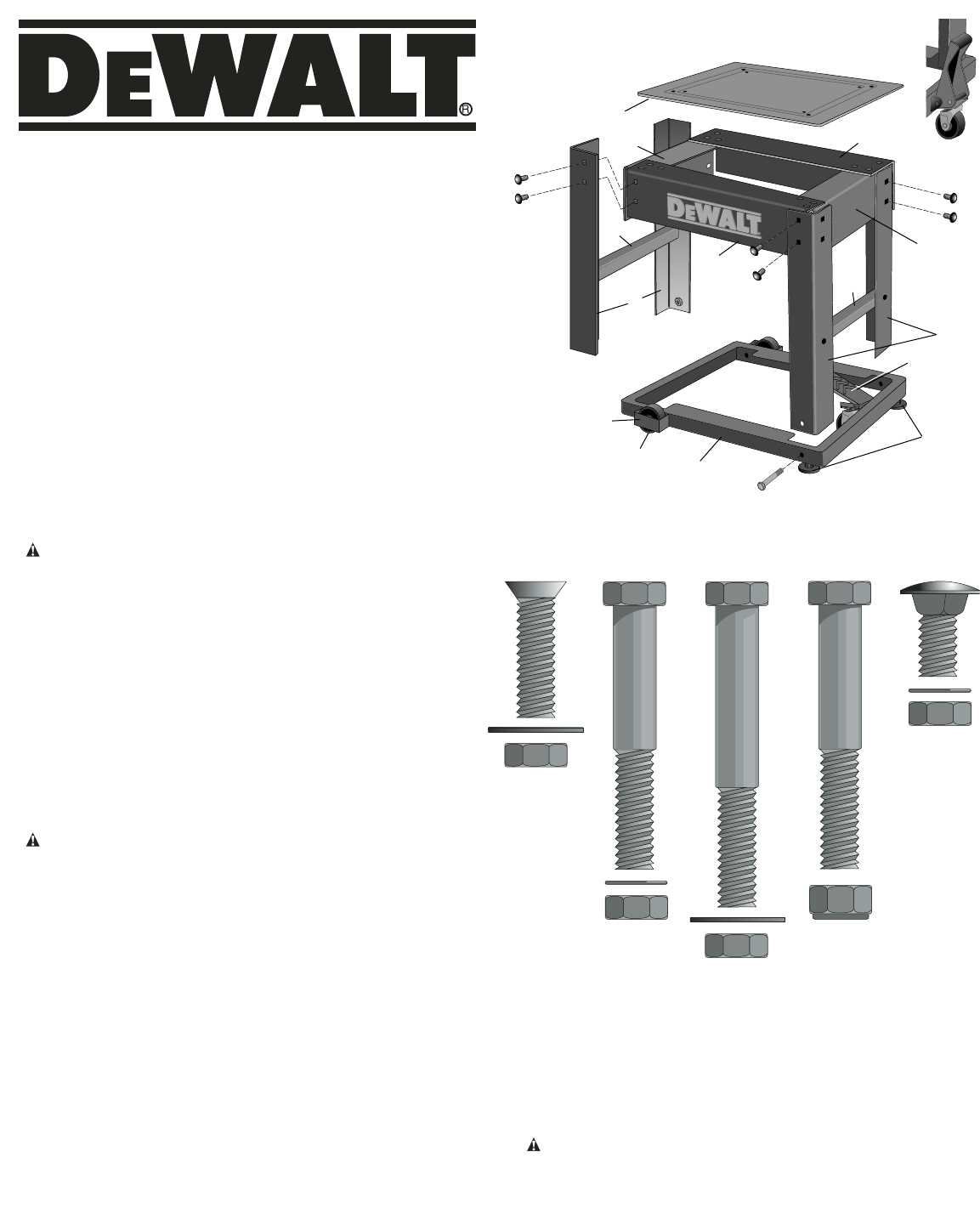

Tools Required for Repairs

When addressing maintenance issues, having the right tools is essential for effective resolution. The following equipment will facilitate the process and ensure optimal performance.

- Wrenches and Sockets

- Screwdrivers (Flathead and Phillips)

- Replacement Blades

- Calipers for Measuring

- Cleaning Brushes

- Lubricants and Oils

Organizing these instruments ahead of time will streamline your workflow and enhance efficiency during the procedure.

Replacing Blades on Dewalt 735

Proper maintenance of your woodworking tool is essential for achieving optimal results. One of the critical aspects of this upkeep is the replacement of cutting edges, which can significantly impact performance and finish quality. This section will guide you through the steps necessary for changing out the blades effectively.

Before starting the replacement process, ensure you have the following tools and materials ready:

- New cutting edges

- Screwdriver

- Wrench

- Safety gloves

- Clean cloth

Follow these steps to complete the blade replacement:

- Power Off: Disconnect the tool from the power source to prevent any accidents.

- Access the Blades: Remove the cover that protects the cutting edges, typically secured by screws.

- Remove Old Blades: Using the screwdriver and wrench, carefully take out the existing blades. Keep track of any screws or components removed.

- Clean the Area: Wipe down the blade housing with a clean cloth to remove any debris or dust.

- Install New Blades: Position the new cutting edges in place, ensuring they align correctly with the mounting points.

- Secure Everything: Reattach any screws or covers removed earlier, making sure everything is tightened appropriately.

- Power Up: Reconnect the tool to the power source and conduct a brief test to ensure proper operation.

Regularly changing the cutting edges will not only improve performance but also extend the lifespan of your equipment. Always consult the specific guidelines provided by the manufacturer for any additional tips or warnings related to your particular model.

Adjusting Cutting Depth Effectively

Achieving the desired finish on your woodworking projects hinges significantly on how well you can manage the cutting depth of your tool. Fine-tuning this setting not only enhances the quality of your cuts but also prolongs the life of the equipment. Proper adjustments allow for smoother surfaces and more accurate dimensions, ultimately leading to better results in your craftsmanship.

Steps to Adjust Cutting Depth

- Ensure the tool is unplugged for safety before making any adjustments.

- Locate the depth adjustment mechanism, typically found on the side or front of the unit.

- Turn the adjustment knob or lever to set the desired cutting depth. A smaller increment usually yields a finer finish.

- Double-check the setting against a reference piece of wood to ensure accuracy.

Tips for Optimal Results

- Start with a shallow depth and gradually increase until the desired finish is achieved.

- Always inspect the blades for sharpness; dull blades require deeper cuts and can lead to poor results.

- Adjust the depth based on the type of wood being used, as different materials respond differently to cutting.

- Make test cuts on scrap wood to evaluate the finish before proceeding with your main project.

Cleaning and Maintenance Tips

Proper upkeep of your woodworking equipment is essential for ensuring optimal performance and longevity. Regular cleaning and maintenance not only enhance the functionality of the device but also promote safety during use. Here are some valuable tips to keep your tools in excellent condition.

| Task | Frequency | Tips |

|---|---|---|

| Dust Removal | After each use | Use a soft brush or cloth to remove sawdust from all surfaces. |

| Blade Inspection | Monthly | Check for nicks or dullness; replace or sharpen as needed. |

| Lubrication | Every three months | Apply lubricant to moving parts to prevent rust and ensure smooth operation. |

| Electrical Check | Every six months | Inspect cords and plugs for wear; replace if damaged. |

| Storage Care | After each use | Store in a dry, clean environment to prevent moisture damage. |

By adhering to these guidelines, you can significantly extend the lifespan of your tools while maintaining their efficiency. Regular attention to maintenance tasks is key to a safe and productive woodworking experience.

Troubleshooting Electrical Problems

Addressing electrical issues can be a daunting task, but understanding the fundamentals can help simplify the process. This section outlines common electrical faults that may arise and provides guidance on identifying and resolving these challenges effectively.

Identifying Symptoms

Before diving into repairs, it’s crucial to observe the symptoms exhibited by the equipment. Common indicators of electrical malfunctions include irregular power supply, unusual noises, or failure to operate altogether. Documenting these signs will aid in pinpointing the underlying issue.

Basic Diagnostic Steps

Start by checking the power source and ensuring that all connections are secure. Inspecting the power cord for damage is also essential, as frayed wires can lead to malfunction. If everything appears intact, consider testing the internal components, such as switches and fuses, which may require replacement if faulty. Always prioritize safety by disconnecting the power before performing any inspections.

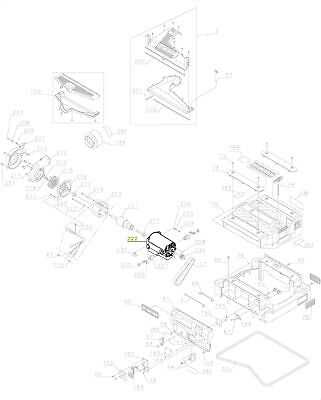

Parts List for Dewalt 735

This section provides a comprehensive overview of essential components necessary for the optimal functioning of your woodworking device. Understanding the various parts will aid in maintenance and troubleshooting, ensuring your equipment operates smoothly and efficiently.

1. Blades: High-quality cutting tools that are crucial for achieving precise finishes. Ensure you select the appropriate type based on your woodworking needs.

2. Rollers: These components assist in feeding the material through the machine. Regular inspection for wear is important to maintain performance.

3. Motor: The powerhouse of the equipment, providing the necessary energy to drive all operations. Pay attention to any unusual sounds or performance drops.

4. Housing: The outer shell that protects internal mechanisms. Look for any cracks or damage that could affect functionality.

5. Adjustment Handles: These allow for easy modification of settings to achieve desired results. Ensure they move freely and are not stripped.

6. Dust Collection Port: Essential for maintaining a clean workspace, this part connects to dust extraction systems to minimize debris.

7. Feet: Provide stability and support during operation. Check for wear to prevent any wobbling or misalignment.

By keeping track of these components and their conditions, users can ensure longevity and efficiency in their woodworking tasks.

Safety Precautions During Repairs

When undertaking maintenance on power tools, adhering to safety measures is essential to ensure both personal safety and the proper functioning of the equipment. Understanding potential hazards and following guidelines can prevent accidents and injuries.

Essential Safety Guidelines

- Always disconnect the power source before beginning any work.

- Wear appropriate personal protective equipment (PPE), such as goggles and gloves.

- Ensure your workspace is clean and well-lit to minimize distractions.

- Keep tools organized to avoid mishaps during the process.

Working with Sharp Components

- Handle blades and other sharp parts with care to avoid cuts.

- Use tools specifically designed for adjustments and maintenance.

- Store sharp components safely when not in use to prevent accidents.

By following these precautions, you can create a safer environment while ensuring that your equipment operates efficiently.

When to Seek Professional Help

Understanding the limits of your skills is crucial when tackling equipment issues. There are instances where attempting to fix a machine on your own could lead to further complications or even safety hazards. Recognizing these moments is essential to ensure both your well-being and the longevity of the tool.

Consider enlisting the expertise of a professional if you encounter persistent problems that do not resolve after basic troubleshooting. Strange noises, unusual vibrations, or inconsistent performance can signal underlying issues that require specialized knowledge. Additionally, if you find yourself needing to replace major components, seeking assistance might be the best course of action.

Another critical factor is your own comfort level with repairs. If the task seems daunting or if you lack the necessary tools, it may be wiser to consult a trained technician. Safety should always be a priority, and sometimes the best decision is to let a professional handle the intricacies of the repair process.