Singer 4423 Repair Manual Guide

Understanding the intricacies of your stitching device can greatly enhance your sewing experience. Proper upkeep ensures longevity and consistent performance, allowing you to focus on your creative projects without unnecessary interruptions. This section will provide valuable insights into maintaining your equipment effectively.

Whether you are facing minor issues or need to address more significant concerns, having a comprehensive approach is essential. Familiarizing yourself with various components and their functions will empower you to troubleshoot problems with confidence. Emphasizing routine checks and preventative measures can help avoid complications in the future.

Equipped with the right knowledge, you can tackle maintenance tasks with ease. This guide aims to simplify the process, offering step-by-step instructions and helpful tips. Embrace the art of caring for your device, ensuring it remains a reliable companion in your sewing journey.

Troubleshooting Guide

This section provides guidance on addressing common issues encountered with your sewing machine. Understanding the potential problems and their solutions can enhance your sewing experience and help maintain optimal performance.

Common Issues and Solutions

Machines may face various challenges, such as thread jamming, inconsistent stitching, or unusual noises. For thread jams, ensure the bobbin is correctly threaded and that the upper thread tension is appropriately adjusted. Inconsistent stitching often results from incorrect needle selection or dull blades. Regular maintenance can prevent these issues and prolong the life of the equipment.

When to Seek Professional Help

If you encounter persistent problems that do not resolve with basic troubleshooting, it may be time to consult a professional. Signs that professional assistance is needed include failure to start, electrical issues, or significant mechanical malfunctions. Addressing these concerns promptly can prevent further damage and ensure your machine remains in good working condition.

Common Issues and Solutions

This section addresses frequent challenges encountered with sewing devices and offers practical solutions to enhance their performance and longevity.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Skipped Stitches | Incorrect needle type, dull needle, or improper threading | Change to the correct needle, replace dull needles, and ensure proper threading |

| Tension Problems | Incorrect tension settings or dirty tension discs | Adjust the tension settings and clean the tension discs |

| Thread Bunching | Incorrect bobbin winding or improper threading | Ensure the bobbin is wound correctly and rethread the machine |

| Machine Not Starting | Power supply issues or worn-out components | Check power connections and inspect for worn parts |

Understanding Machine Components

To effectively utilize a sewing device, it is essential to comprehend its various elements and how they function together. Each component plays a crucial role in ensuring smooth operation and achieving the desired results in sewing projects.

Key Components

- Needle: This element pierces the fabric to create stitches, and its size and type can affect the stitching quality.

- Bobbin: The bobbin holds the lower thread and works in conjunction with the needle to form stitches.

- Presser Foot: This component holds the fabric in place while sewing, allowing for even and consistent stitching.

- Feed Dogs: These are the metal teeth that move the fabric under the needle during sewing.

- Tension Control: This mechanism adjusts the tightness of the thread, which is critical for achieving balanced stitches.

Importance of Understanding Components

Familiarity with these parts enables users to troubleshoot issues effectively and perform basic maintenance. Recognizing how each element interacts fosters a more intuitive approach to using the device, ultimately leading to improved results in sewing tasks.

Parts Identification and Functions

This section aims to provide a comprehensive overview of various components within the device and their specific roles. Understanding these elements is essential for effective operation and maintenance, allowing users to troubleshoot issues and ensure optimal performance.

Key Components

Several critical parts contribute to the overall functionality. The needle is fundamental for stitching, while the bobbin stores the thread that forms the stitch. The presser foot holds the fabric in place during the sewing process, ensuring accuracy and stability.

Supporting Mechanisms

In addition to primary elements, various supporting mechanisms enhance usability. The foot pedal allows for speed control, providing users with the flexibility to adjust their pace. The stitch selector enables users to choose different sewing patterns, broadening the range of projects that can be tackled.

Maintenance Tips for Longevity

Proper care is essential for ensuring the durability and efficiency of your sewing equipment. Regular maintenance not only enhances performance but also extends the lifespan of your machine, allowing you to enjoy seamless stitching for years to come.

- Regular Cleaning: Dust and lint can accumulate, affecting the functionality. Clean the machine after every few projects to maintain optimal performance.

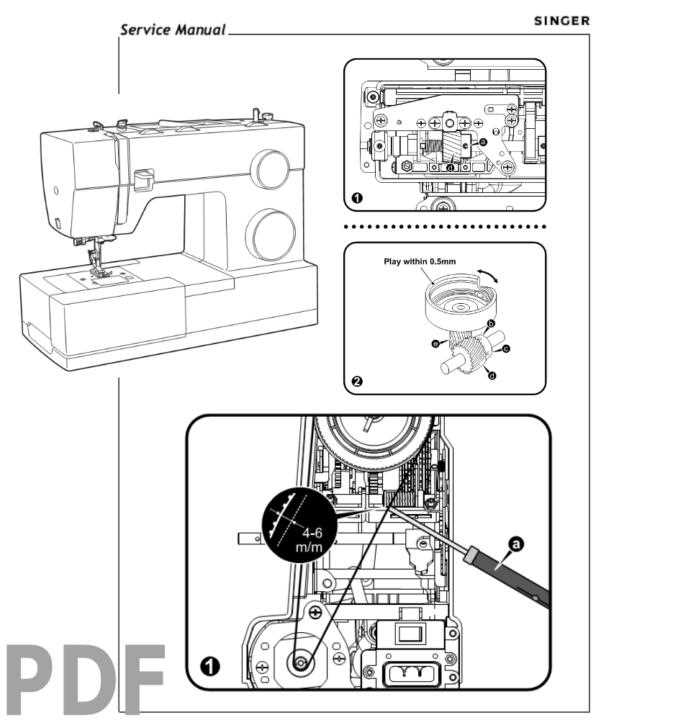

- Oil the Moving Parts: Lubrication is crucial. Refer to the manufacturer’s instructions for the correct oil and application points to keep the machine running smoothly.

- Check the Needle: A dull or damaged needle can cause issues. Replace the needle regularly to avoid fabric snags and ensure clean stitches.

- Use the Correct Thread: Different projects require specific threads. Using the right type reduces strain on the machine and prevents breakage.

- Store Properly: When not in use, cover the equipment to protect it from dust and moisture. Avoid placing heavy objects on top of it to prevent damage.

By following these simple guidelines, you can significantly enhance the longevity of your sewing equipment and maintain its performance over time.

Best Practices for Care

Maintaining your sewing machine is essential for ensuring its longevity and optimal performance. By following some simple yet effective practices, you can keep your device in excellent condition and avoid unnecessary issues.

Regular Cleaning

Dust and lint can accumulate over time, impacting the functionality of your equipment. It’s important to clean the machine regularly. Use a soft brush or a cloth to wipe down the exterior, and ensure the interior components are free from debris. This will help prevent jams and maintain smooth operation.

Proper Lubrication

Lubrication is crucial for the moving parts of your device. Applying the appropriate oil at recommended intervals helps reduce friction and wear. Always refer to the specific guidelines for the type of oil suitable for your model, and avoid over-lubricating, which can attract more dirt.

How to Change the Needle

Replacing the sewing implement is a straightforward process that can significantly enhance your stitching results. Over time, needles may become dull or damaged, impacting performance and fabric quality. Ensuring you have a fresh needle is essential for achieving clean and precise seams.

Begin by turning off the machine and unplugging it for safety. Next, raise the needle to its highest position using the handwheel. Locate the needle clamp, typically found on the right side of the needle. Loosen the clamp screw with a small screwdriver, allowing the old needle to slide out easily.

Take your new sewing implement and insert it into the clamp, ensuring the flat side aligns correctly with the guide. Once positioned, tighten the clamp screw securely to hold the needle in place. Finally, check that the needle is straight and properly seated before plugging in the machine and performing a test stitch to confirm the change was successful.

Step-by-Step Instructions

This section provides a comprehensive guide to effectively troubleshoot and maintain your sewing device. Following these organized steps will help ensure optimal performance and longevity of your equipment.

Step 1: Begin by gathering all necessary tools and materials required for the task. This preparation will streamline the process and reduce interruptions.

Step 2: Carefully examine the machine for any visible issues. Look for signs of wear, loose parts, or misalignments that may affect functionality.

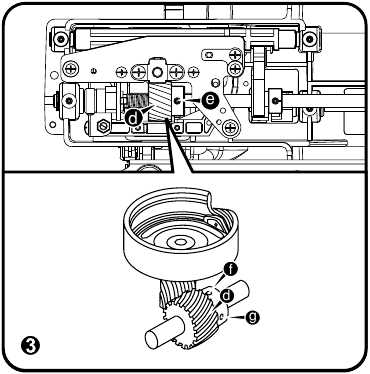

Step 3: Follow the specific procedures for disassembling components as outlined in your reference document. Ensure that you keep track of all screws and parts to facilitate reassembly.

Step 4: Clean all accessible areas, removing dust and debris that may hinder operation. Use appropriate cleaning solutions and tools for best results.

Step 5: Reassemble the components in the reverse order of disassembly, ensuring that everything is securely fitted. Double-check for any missed steps.

Step 6: Conduct a test run to verify that the device operates smoothly. Pay attention to any unusual noises or performance issues that may indicate further adjustments are needed.

Step 7: If problems persist, consult additional resources or seek assistance from a professional technician to address more complex issues.

Threading the Machine Correctly

Properly setting up the thread in your sewing device is essential for achieving smooth operation and quality stitches. This process ensures that the fabric is fed correctly and that the threads intertwine as intended, preventing issues such as tangling or skipped stitches.

Step-by-Step Threading Guide

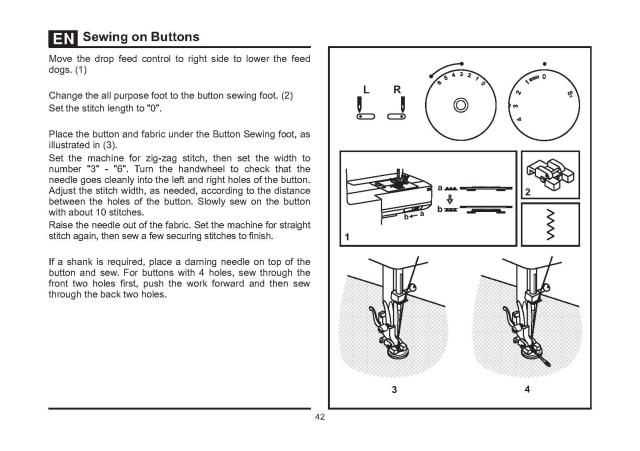

Begin by placing the spool of thread on the spindle, ensuring it unwinds smoothly. Guide the thread through the tension mechanism, following the designated path, and ensure it is seated correctly to maintain consistent tension. Once this is done, lead the thread through the needle from the front to the back.

Troubleshooting Common Issues

If you encounter problems such as uneven stitches or thread breakage, recheck the threading process. Confirm that the thread is positioned correctly in all guides and that it is not tangled or caught in any components. Adjusting the tension settings may also help resolve any inconsistencies.

Ensuring Proper Setup

Achieving optimal performance from your sewing machine requires careful attention to its configuration. A well-established setup not only enhances functionality but also prolongs the life of the device. It is essential to ensure that all components are correctly positioned and that the environment is conducive to smooth operation.

Check the Machine Alignment

Begin by verifying that the needle is correctly installed and aligned. An improperly positioned needle can lead to various issues, including skipped stitches and uneven tension. Additionally, ensure that the presser foot is securely attached and functioning as intended.

Maintain a Clean Workspace

Creating an organized and clutter-free workspace can significantly impact your sewing experience. Ensure that the area around the machine is tidy and free from distractions. Regularly clean the machine to remove dust and debris, which can affect performance and result in complications during use.

Cleaning Your Singer 4423

Maintaining the cleanliness of your sewing machine is essential for optimal performance and longevity. Regular upkeep helps prevent issues that can arise from lint and debris accumulation, ensuring smooth operation and beautiful stitching.

Supplies Needed

- Soft, lint-free cloth

- Small brush or toothbrush

- Vacuum with a brush attachment

- Isopropyl alcohol or sewing machine oil

Steps to Clean

- Unplug the machine to ensure safety during cleaning.

- Remove the needle and presser foot for easier access.

- Use the brush to gently sweep away lint and dust from the feed dogs and surrounding areas.

- Carefully vacuum the machine to remove any loose particles.

- Dampen a cloth with isopropyl alcohol and wipe the exterior surfaces, avoiding any electrical components.

- Apply a few drops of oil to the designated lubrication points as indicated in the guidelines.

- Reassemble the components and plug the machine back in.

Regularly cleaning your sewing companion will enhance its functionality and prolong its lifespan, allowing for countless creative projects to come to life.

Effective Cleaning Techniques

Maintaining your sewing machine’s optimal performance requires regular upkeep, particularly cleaning. By implementing effective cleaning methods, you can extend the lifespan of your device and ensure smooth operation.

Regular Dusting: Frequent dust accumulation can interfere with the functionality of your machine. Use a soft brush or a lint-free cloth to gently remove debris from the exterior and surrounding areas.

Deep Cleaning: Every few months, a more thorough cleaning is beneficial. Open the access panels and carefully remove any accumulated thread or lint. Utilize a vacuum attachment designed for delicate tasks to reach hard-to-access spots.

Oiling: After cleaning, apply a few drops of appropriate lubricant to the moving parts as specified in your device’s guidelines. This will keep the mechanisms running smoothly and reduce wear over time.

Surface Care: Wipe the surface of your machine with a damp cloth to remove stains and maintain its appearance. Avoid harsh chemicals that could damage the finish.

By following these straightforward techniques, you can keep your sewing apparatus in top condition, enhancing both its performance and your sewing experience.

Adjusting Tension Settings

Properly configuring the tension of your sewing machine is essential for achieving optimal stitch quality. An appropriate tension setting ensures that the thread is pulled evenly, preventing issues such as thread breakage or fabric puckering. Understanding how to adjust these settings can greatly enhance your sewing experience.

Identifying the Right Tension

To determine if the tension is correctly set, examine your stitches on the fabric. If the stitches appear loose or are not uniform, adjustments are necessary. Conversely, if the stitches are too tight, they may cause the fabric to gather. Aim for a balanced look where the stitches lie flat on both sides of the material.

Making Adjustments

Most machines have a tension dial that allows for easy modifications. Start with the recommended setting, typically found in the device’s guidelines. Gradually turn the dial clockwise for tighter tension and counterclockwise for looser tension. Always test on a scrap piece of fabric to ensure the adjustments meet your needs before working on your main project.