Comprehensive Guide to Stihl MS 290 Repair Manual

In the world of outdoor tools, maintaining optimal performance is essential for longevity and reliability. Understanding the intricacies of these machines empowers users to tackle common issues effectively and keep their equipment in peak condition. This section serves as a comprehensive resource for those seeking to enhance their knowledge of chainsaw upkeep.

Regular attention to details such as assembly, disassembly, and troubleshooting can greatly improve the lifespan of your device. By familiarizing yourself with essential components and their functions, you can confidently address various challenges that may arise during operation. Knowledge is a powerful tool that enables enthusiasts and professionals alike to maximize the potential of their machinery.

Moreover, ensuring that every aspect of your chainsaw is in top shape not only enhances performance but also contributes to safety. Proper maintenance practices can prevent accidents and malfunctions, making your experience smoother and more enjoyable. Delving into the specifics of upkeep will prepare you for any eventuality and ensure that your equipment remains a trusted ally in your outdoor endeavors.

Understanding Stihl MS 290 Chainsaw

The understanding of a particular type of cutting tool involves recognizing its essential components, functions, and maintenance requirements. This powerful device is designed for a variety of tasks, including felling trees, pruning branches, and cutting firewood. Gaining insight into its mechanics can enhance performance and longevity, ensuring effective use for both professional and casual users.

Key Features

One notable aspect of this model is its robust engine, which provides sufficient power for demanding tasks. Additionally, the ergonomic design allows for comfortable handling, reducing fatigue during extended use. Safety features, such as chain brakes and throttle locks, contribute to a secure operation, making it suitable for users of different skill levels.

Maintenance Tips

Regular upkeep is crucial for optimal functionality. Checking the chain tension and sharpening the cutting edge are essential practices that can significantly impact performance. Furthermore, keeping the air filter clean and ensuring proper fuel mixture will help maintain efficiency and prolong the life of the device. Investing time in routine checks will yield rewarding results and minimize potential issues.

Common Issues with Stihl MS 290

This section explores frequent problems encountered with a popular chainsaw model, emphasizing typical challenges users may face during operation and maintenance.

- Starting Difficulties:

Many operators report trouble initiating the engine, which can stem from various factors such as:

- Fuel mixture issues

- Clogged air filter

- Defective spark plug

- Power Loss:

A reduction in cutting power can be frustrating. Common causes include:

- Worn chains

- Improper tensioning

- Fuel line blockages

- Excessive Vibration:

Increased vibration during use can indicate several underlying issues:

- Unbalanced chain

- Loose bolts or components

- Worn anti-vibration mounts

- Leaking Fuel:

Fuel leaks can pose safety hazards and are often caused by:

- Damaged fuel lines

- Faulty gaskets

- Loose connections

- Overheating:

When the equipment overheats, it may lead to significant damage. Potential causes include:

- Insufficient lubrication

- Blocked cooling fins

- Clogged exhaust port

phpCopy code

Addressing these common issues promptly can help maintain optimal performance and prolong the life of your equipment.

Essential Tools for Repairs

When it comes to maintaining and restoring equipment, having the right instruments is crucial for effective troubleshooting and enhancement. A well-equipped workspace not only facilitates smoother operations but also ensures safety and efficiency during the process. This section highlights the indispensable tools that every technician should have on hand to tackle various tasks with confidence.

Wrenches are fundamental for loosening or tightening bolts and nuts. A complete set, including adjustable and socket varieties, allows for versatility in handling different sizes and types of fasteners. Investing in high-quality wrenches can prevent stripping and ensure a secure fit.

Screwdrivers are another essential, with both flathead and Phillips options needed to address various components. A magnetic tip can enhance convenience, making it easier to retrieve screws from tight spaces.

Pliers serve multiple purposes, from gripping and twisting wires to cutting through tough materials. A good pair of needle-nose pliers is particularly useful for reaching into confined areas.

Safety gear should never be overlooked. Items such as gloves, goggles, and ear protection are vital to shield oneself from potential hazards while working. Ensuring personal safety allows for a more focused and effective repair experience.

Measuring tools, such as calipers and rulers, are important for precision. Accurate measurements can significantly affect the quality of the work, ensuring components fit perfectly and function as intended.

Lastly, a toolbox or organizer can keep all these instruments in one place, making them easily accessible and helping to maintain an orderly workspace. With the right collection of tools, any project can be approached with confidence and proficiency.

Step-by-Step Repair Instructions

This section provides a comprehensive guide for troubleshooting and fixing common issues that may arise with your equipment. By following these detailed steps, you can restore functionality and ensure optimal performance. Each stage is designed to be straightforward, making the process manageable for both novice and experienced users.

Tools and Materials Needed

- Wrench set

- Screwdrivers (flathead and Phillips)

- Replacement parts (if necessary)

- Cleaning supplies (brush, cloth, and solvent)

- Safety gear (gloves and goggles)

Procedure

- Preparation: Ensure the machine is powered off and disconnect the spark plug for safety.

- Inspection: Examine all components for signs of wear or damage.

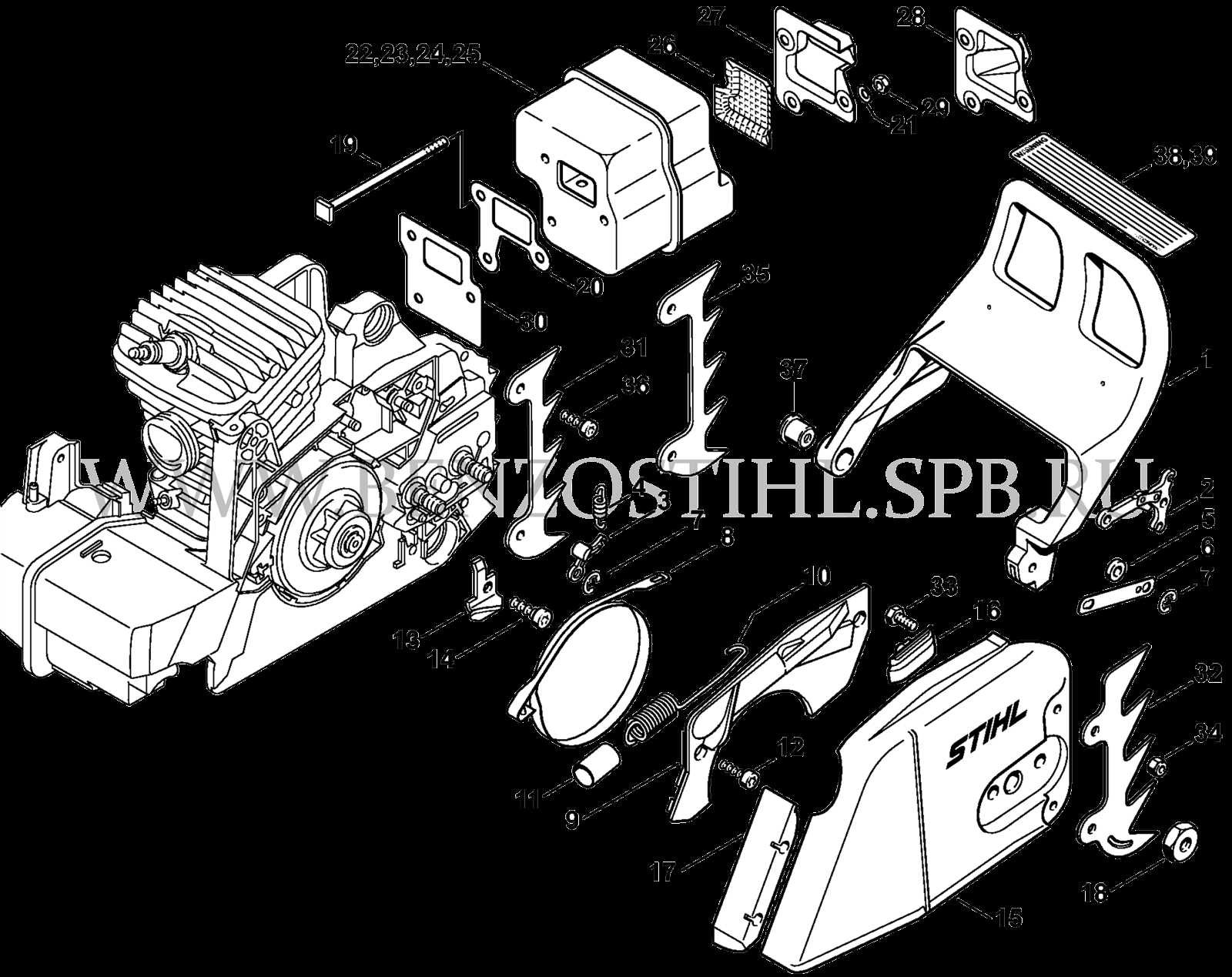

- Disassembly: Carefully remove screws and fasteners to access the internal parts. Keep track of all components for reassembly.

- Cleaning: Use appropriate cleaning supplies to remove dirt and debris from the parts.

- Replacement: If any parts are damaged, replace them with new ones. Follow specifications for compatibility.

- Reassembly: Reattach all components in reverse order, ensuring everything is secured tightly.

- Final Check: Reconnect the spark plug and conduct a final inspection to ensure everything is in place.

- Testing: Start the equipment to verify that the issues have been resolved and that it operates smoothly.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for extending the lifespan of your equipment. Adopting a consistent maintenance routine not only enhances performance but also prevents costly repairs and ensures reliable operation. Here are some key practices to consider for optimal functionality.

First, always keep the equipment clean. After each use, remove debris and dirt to prevent buildup that can lead to malfunctions. Regularly inspect filters and replace them as necessary to ensure efficient airflow and operation.

Next, check and sharpen the cutting tools frequently. Dull blades can strain the engine and reduce cutting efficiency, making the task more difficult and time-consuming. Keeping them sharp will also contribute to smoother operation and reduced wear on the machine.

Additionally, monitor and maintain the fuel system. Use fresh fuel and add appropriate oil to prevent residue buildup. Periodically check fuel lines for cracks or leaks and replace them as needed to avoid operational issues.

Lastly, store the equipment in a dry, sheltered area when not in use. Protecting it from extreme weather conditions will help prevent rust and degradation. Following these maintenance tips will ensure that your machinery remains in top condition for years to come.

Replacing the Fuel System Components

Maintaining optimal performance of your equipment often involves the replacement of essential components within the fuel delivery system. This section focuses on the necessary steps to ensure your machinery runs smoothly by addressing any issues related to fuel lines, filters, and pumps. A thorough understanding of these components is crucial for effective maintenance.

Step 1: Assessing the Fuel Lines

Begin by examining the fuel lines for any signs of wear, cracks, or blockages. Damaged lines can lead to leaks, affecting performance and safety. If any irregularities are found, it’s essential to replace the affected sections promptly. Ensure that the new lines are compatible with the existing fittings and securely attached.

Step 2: Changing the Fuel Filter

The fuel filter plays a critical role in preventing contaminants from entering the engine. A clogged filter can hinder fuel flow, leading to operational issues. To replace the filter, locate it within the system, disconnect the old filter, and install a new one according to the manufacturer’s specifications. Regular replacement is recommended to maintain efficiency.

Step 3: Inspecting the Fuel Pump

The fuel pump is vital for delivering fuel from the tank to the engine. If you notice a decrease in power or difficulty starting, the pump may be malfunctioning. Check for any leaks or unusual noises. If replacement is necessary, ensure you choose a pump that matches the specifications of your equipment for optimal performance.

Final Check and Testing

Once all components have been replaced, it’s important to conduct a thorough check for leaks and ensure all connections are secure. After confirming everything is properly installed, test the equipment to verify that it operates smoothly. Regular maintenance of the fuel system will help prolong the life of your machinery and improve its efficiency.

Troubleshooting Engine Performance Problems

Engine performance issues can arise from various factors, affecting overall functionality and efficiency. Identifying the root cause is crucial for restoring optimal operation. Below are common symptoms and their potential solutions to help you diagnose and address these challenges effectively.

- Symptoms of Poor Performance:

- Reduced power output

- Difficulty starting

- Irregular idling

- Excessive smoke emission

To troubleshoot these problems, follow these systematic steps:

- Inspect Fuel System:

- Check fuel quality; old or contaminated fuel can lead to performance issues.

- Examine fuel lines for cracks or blockages.

- Ensure the fuel filter is clean and unobstructed.

- Examine Air Intake:

- Inspect the air filter for dirt and debris, replacing it if necessary.

- Ensure that air intake passages are clear.

- Assess Ignition System:

- Check spark plug condition; replace if worn or fouled.

- Verify that ignition timing is set correctly.

- Evaluate Exhaust System:

- Look for blockages or restrictions in the exhaust pipe.

- Check for leaks that may affect engine performance.

By systematically evaluating these areas, you can pinpoint issues affecting engine performance and implement the necessary adjustments or repairs for improved functionality.

How to Replace the Chain and Bar

Changing the cutting chain and guide bar of your power saw is essential for maintaining optimal performance. Over time, these components can wear out or become damaged, affecting your tool’s efficiency. This guide outlines the steps needed to successfully perform this task, ensuring your equipment remains in peak condition.

Step 1: Safety First

Before beginning the replacement process, ensure your equipment is turned off and disconnected from any power source. Always wear protective gear, including gloves and safety glasses, to safeguard against potential injuries.

Step 2: Remove the Old Chain and Bar

Start by loosening the tensioning mechanism to relieve pressure on the chain. Next, locate the nuts or bolts securing the guide bar in place and remove them. Carefully slide off the old bar and chain, taking note of their orientation for proper installation of the new components.

Step 3: Install the New Chain and Bar

Position the new guide bar onto the mounting area and ensure it is aligned correctly. Place the new chain around the bar, making sure it fits into the groove properly. The cutting edges should face in the direction of the bar’s movement. Reattach the nuts or bolts, securing the bar in place.

Step 4: Adjust Chain Tension

Once the new components are installed, adjust the chain tension according to the manufacturer’s specifications. A properly tensioned chain will ensure efficient cutting and minimize wear on both the chain and bar.

Step 5: Final Checks

Before using your tool, double-check that all components are securely fastened and that the chain moves freely around the bar. This final inspection will help prevent accidents and ensure optimal performance during operation.

Electrical System Diagnostics and Repairs

This section focuses on troubleshooting and fixing issues related to the electrical components of outdoor power equipment. Understanding the intricacies of the electrical system is essential for ensuring optimal performance and longevity of the machine.

Common Electrical Issues

Several problems may arise within the electrical framework. Recognizing symptoms early can prevent more extensive damage.

| Issue | Symptoms | Potential Solutions |

|---|---|---|

| Faulty Spark Plug | Hard starting, misfires | Inspect and replace if necessary |

| Wiring Damage | Power loss, erratic performance | Check for frayed wires; repair or replace |

| Weak Battery | Slow cranking, dim lights | Test voltage; charge or replace |

Diagnostic Techniques

Using a multimeter can help identify electrical faults. Measuring voltage, continuity, and resistance allows for effective troubleshooting of the system.

Safety Precautions During Repairs

Ensuring safety is paramount when undertaking maintenance tasks on power tools. Adhering to proper guidelines not only protects the individual performing the work but also minimizes risks associated with the equipment. A careful approach to handling tools can prevent accidents and ensure a smooth process.

Personal Protective Equipment (PPE) is essential. Always wear appropriate gear, including safety goggles, gloves, and sturdy footwear. This gear helps shield against potential hazards such as flying debris or accidental contact with sharp components.

Before starting any task, it is crucial to disconnect the power source. This simple step prevents unintentional activation of the tool while maintenance is being performed. Additionally, keeping your workspace organized and free of clutter reduces the likelihood of mishaps.

Familiarize yourself with the specific features and mechanisms of the equipment. Understanding how various components work can significantly enhance safety and efficiency during the process. Always consult documentation or guidelines relevant to the tool.

Lastly, remain vigilant and focused while working. Distractions can lead to careless mistakes. Take breaks if needed to maintain concentration and ensure a safe working environment.

Where to Find Replacement Parts

Locating quality components for your equipment is essential for maintaining its performance and longevity. Various sources can provide the necessary parts to ensure your tools run smoothly. Understanding where to look will save time and ensure you find reliable replacements.

Authorized Dealers

One of the most dependable options is to visit authorized dealers. These retailers specialize in genuine parts and can offer expertise in selecting the right components. Benefits of choosing authorized dealers include:

- High-quality, original parts

- Expert assistance in part selection

- Warranty protection for your equipment

Online Marketplaces

The internet offers numerous platforms where you can purchase spare parts conveniently. When shopping online, consider the following:

- Check for reputable sellers with positive reviews.

- Look for clear return policies and customer support.

- Ensure compatibility with your equipment model.

By exploring both authorized dealers and online marketplaces, you can easily find the necessary components to keep your tools in top condition.