1987 Toyota Supra Repair Manual Guide and Tips

The allure of classic sports cars lies in their unique blend of power and vintage charm. These high-performance vehicles demand careful attention and periodic care to keep them running smoothly on the road. Understanding the specific systems and components, from engine mechanics to electronic configurations, ensures that every element functions harmoniously, preserving both longevity and efficiency.

For enthusiasts and owners, maintaining these iconic vehicles offers not only the satisfaction of hands-on experience but also the confidence of knowing every detail within the car. Whether you’re tuning the engine, adjusting the suspension, or handling detailed wiring tasks, each step brings you closer to a fully optimized driving machine. This guide will walk through essential upkeep practices, tips for efficient servicing, and common troubleshooting solutions tailored to maximize the vehicle’s performance and reliability.

Equipped with insights into various subsystems and functional details, you can tackle each maintenance step with clarity and precision. From standard procedures to advanced restoration tasks, this resource is designed to support every aspect of your vehicle’s upkeep journey. Embrace the process and elevate the legacy of a true automotive icon.

1987 Toyota Supra Repair Guide

This guide provides essential insights into maintaining and servicing your classic vehicle. The focus is on ensuring long-term reliability, addressing common mechanical challenges, and enhancing overall performance with a series of practical steps.

Engine Maintenance and Tune-Up

Regular engine care is crucial for keeping the vehicle in top shape. From fuel system checks to ignition components, attention to detail helps avoid future complications. Here are key tasks:

- Inspect and replace spark plugs periodically for optimal combustion.

- Ensure proper timing adjustment to maintain smooth engine operation.

- Check the air filter and fuel injectors for any blockages or wear.

Transmission and Drivetrain Adjustments

For smooth power transfer and better driving experience, servicing the transmission and drivetrain can make a difference. Follow these guidelines:

- Monitor fluid levels to prevent overheating and wear.

- Regularly inspect and tighten driveshaft and differential components.

- Address any unusual sounds promptly to prevent extensive repairs.

Engine Diagnostics and Troubleshooting

Effective engine diagnostics requires understanding common indicators of potential issues and accurately interpreting signals from the vehicle’s performance. This process helps in identifying specific engine problems before they escalate, ensuring timely maintenance and avoiding more extensive repairs.

During an assessment, focus on monitoring vital elements such as ignition, fuel delivery, and exhaust systems. Observing unusual sounds, vibrations, or changes in responsiveness can also provide essential clues for identifying mechanical or electrical faults.

Key Diagnostic Steps: To begin, assess the functionality of the ignition system, fuel injectors, and air intake. Check for possible clogging, wear, or malfunction in essential components. Use appropriate diagnostic tools to evaluate voltage levels, fuel pressure, and emission standards, as these metrics often reveal underlying problems.

Engine troubleshooting benefits significantly from methodical inspection. Verify connections, test sensors, and inspect wiring for any signs of wear or damage. By carefully examining these areas, it becomes easier to pinpoint causes behind unexpected engine behavior, thereby enhancing vehicle reliability and performance.

Transmission Maintenance and Adjustment Tips

Maintaining and fine-tuning the transmission is crucial for a vehicle’s performance and longevity. Proper upkeep helps prevent unnecessary wear and ensures smooth transitions during gear shifts. This section outlines essential maintenance steps and adjustments to enhance transmission efficiency and extend its lifespan.

Routine Maintenance Essentials

- Check Fluid Levels: Regularly monitor transmission fluid levels and quality. Clean, full fluid prevents overheating and ensures proper lubrication.

- Inspect for Leaks: Look for any leaks under the vehicle that may indicate worn seals or gaskets. Early detection helps prevent significant fluid loss and further complications.

- Replace Fluid Periodically: Schedule fluid changes based on your vehicle’s usage. Fresh fluid removes contaminants and maintains the optimal viscosity needed for smooth operation.

Adjustment Tips for Smooth Shifting

- Adjust Linkages: Worn or misaligned linkages can cause shifting issues. Ensure all connections are secure and aligned to avoid slippage or difficult gear engagement.

- Inspect Cables: Over time, cables may stretch or wear. Adjust or replace them as needed to maintain precise control over shifting mechanisms.

- Calibrate Clutch Components: For manual transmissions, regularly check the clutch pedal free play. Adjust as needed to ensure comfortable and accurate clutch engagement.

Consistent attention to transmission maintenance and periodic adjustments can significantly enhance performance, reducing the risk of breakdowns and ensuring a smoother driving experience.

Brake System Inspection Procedures

The braking mechanism is a crucial part of vehicle safety, and routine checks are essential to ensure it operates effectively. This section outlines essential steps to assess the condition and performance of the braking components, helping prevent wear-related issues and ensure optimal safety and control on the road.

Inspecting Brake Pads and Rotors

Begin by examining the brake pads and rotors for signs of wear or damage. Brake pads should have a substantial thickness; if the material appears thin or uneven, replacement is likely necessary. Rotors should be inspected for grooves, cracks, or excessive wear, which can compromise braking efficiency and may indicate the need for resurfacing or replacement.

Evaluating Brake Fluid and Lines

Check the brake fluid level and quality, as well as the condition of the brake lines. Ensure that the brake fluid is clear and at the recommended level; dark or contaminated fluid should be replaced. Examine the brake lines for any signs of leaks, cracks, or damage that could lead to fluid loss and reduced braking power.

Regularly inspecting these elements of the brake system contributes significantly to the safe operation of the vehicle, minimizing the risks of brake failure and enhancing overall driving safety.

Electrical System Overview and Common Issues

The vehicle’s electrical system is a crucial network that powers essential functions, from lighting and climate controls to ignition and engine management. This interconnected system relies on various components to operate seamlessly, ensuring efficient energy distribution and communication between subsystems.

Battery and Alternator: The power flow begins with the battery, responsible for storing energy and supplying it to start the engine. The alternator takes over to maintain a steady charge and support ongoing electrical needs. Common problems in these areas include weak battery life and alternator failure, often indicated by dimming lights or issues with starting.

Wiring and Connectors: Worn or corroded wiring and loose connectors are frequent sources of electrical interruptions. These issues can lead to sporadic outages in lighting, dashboard displays, and accessory systems. Regular inspections and proper insulation help prevent such malfunctions.

Fuses and Relays: Fuses and relays act as protective components, preventing electrical overloads. Blown fuses can cause specific functions to fail, while faulty relays may lead to intermittent operation of key systems. Routine checks and timely replacements are essential to maintain reliability.

Identifying and addressing these common electrical issues can improve system performance and reduce the likelihood of unexpected breakdowns.

Cooling System Repair and Maintenance

The efficient functioning of an engine’s temperature regulation system is crucial for optimal performance and longevity. Regular upkeep and timely interventions can prevent overheating and associated damages. Understanding the components involved and their maintenance needs will help ensure a reliable operation.

Inspection of Components: Periodically examine the radiator, hoses, and water pump for any signs of wear or leaks. Look for cracks in hoses and corrosion on metal surfaces. Early detection of such issues can save considerable effort and expense later.

Fluid Replacement: It’s essential to replace the coolant at regular intervals as specified by the manufacturer. Old fluid may lose its effectiveness, leading to overheating. Make sure to use the recommended type of coolant to ensure compatibility with the system.

Flushing the System: Flushing the cooling system helps remove contaminants and deposits that can hinder performance. This process involves draining the old coolant, rinsing the system with water, and refilling it with fresh coolant. Consider doing this annually or as advised by a professional.

Thermostat Functionality: The thermostat regulates the flow of coolant and ensures the engine reaches its optimal operating temperature. If overheating occurs, testing the thermostat for proper operation is crucial, as a malfunction can disrupt the entire cooling process.

Regular Monitoring: Always keep an eye on temperature gauges while driving. Unusual readings can indicate issues within the cooling system. Addressing any irregularities immediately can prevent more severe problems down the line.

Suspension Tuning and Component Replacement

Tuning the suspension system is crucial for enhancing the vehicle’s handling and overall performance. Proper adjustments can significantly improve ride quality and stability, allowing for a more responsive driving experience. This section focuses on various aspects of suspension tuning and the replacement of critical components to ensure optimal functionality.

Key Components of Suspension System

Understanding the primary components of the suspension system is essential for effective tuning and replacement. Below is a table summarizing the key elements along with their functions:

| Component | Function |

|---|---|

| Shock Absorbers | Dampen oscillations and improve stability during driving. |

| Springs | Support vehicle weight and absorb bumps from the road. |

| Control Arms | Connect the suspension to the vehicle frame and allow for controlled movement. |

| Sway Bars | Reduce body roll during cornering, enhancing stability. |

Tips for Effective Tuning

When tuning the suspension system, consider the following tips to achieve desired performance:

- Adjust shock absorber settings to suit driving conditions.

- Choose spring rates that balance comfort and handling.

- Regularly inspect and replace worn components to maintain efficiency.

- Experiment with different alignment settings for improved cornering grip.

Bodywork Restoration and Care Techniques

Restoring and maintaining the exterior of a vehicle is essential for preserving its aesthetics and structural integrity. Effective techniques not only enhance appearance but also protect against environmental elements that can lead to deterioration over time. This section explores various methods and practices to ensure the longevity and visual appeal of the bodywork.

Assessment and Preparation: Before embarking on restoration, a thorough inspection of the vehicle’s exterior is crucial. Look for signs of rust, dents, and scratches. Addressing these issues promptly can prevent further damage. Once identified, prepare the surfaces by cleaning them to remove any dirt, grease, or old paint. This preparation sets the foundation for effective restoration.

Repair Techniques: For minor dents and scratches, techniques such as paintless dent removal or the use of filler compounds can be employed. These methods restore the original shape without compromising the integrity of the surface. When dealing with rust, it’s vital to sand down affected areas, treat the metal with rust inhibitors, and apply appropriate primers and paints to create a protective barrier.

Protection and Maintenance: To maintain the restored appearance, regular washing and waxing are essential. Utilizing high-quality wax provides a protective layer against UV rays and contaminants. Additionally, consider using sealants or ceramic coatings that offer long-lasting protection and enhance the shine of the exterior. Regular inspections and prompt touch-ups of any minor damages will keep the bodywork in excellent condition.

Final Touches: Once the restoration is complete, polishing the surface can enhance the overall finish. This final step not only improves the look but also adds an extra layer of protection. By following these techniques, you can ensure that the bodywork remains in pristine condition, reflecting the care and attention invested in its upkeep.

Interior Features and Component Repairs

The interior of a vehicle plays a crucial role in ensuring comfort and functionality for both the driver and passengers. Various elements contribute to the overall experience, from the dashboard to the seating arrangements. Maintaining and addressing issues with these components is essential for optimal performance and longevity.

Dashboard and Instrument Panel: The dashboard houses vital instruments and controls that provide essential information to the driver. Regular inspection and cleaning are necessary to prevent dust accumulation and ensure all gauges function correctly. If any lights or displays malfunction, it’s important to diagnose the issue promptly, as this could indicate a deeper electrical problem.

Seats and Upholstery: Comfortable seating is key to an enjoyable driving experience. Over time, wear and tear can lead to cracks, tears, or stains on the upholstery. Repairing or reupholstering seats may be required to restore their appearance and functionality. Consider using protective covers to prevent future damage.

Audio System and Controls: An effective audio system enhances the driving experience. If speakers produce poor sound quality or controls become unresponsive, troubleshooting these components can restore functionality. Checking wiring connections and replacing faulty units may be necessary for optimal performance.

Climate Control: Maintaining a comfortable temperature inside the vehicle is vital. Ensure that the heating and cooling systems are operational. If any issues arise, such as strange noises or insufficient airflow, investigating the ductwork and controls will be essential for effective climate management.

Addressing the various components within the interior space not only enhances comfort but also promotes safety. Regular maintenance and timely repairs will ensure a pleasant and functional driving environment.

Exhaust System Service and Replacement

The exhaust assembly plays a crucial role in directing harmful gases away from the engine and reducing noise. Regular maintenance and timely replacement of components within this system are essential for optimal vehicle performance and environmental compliance. This section will provide guidance on inspecting, servicing, and replacing various parts of the exhaust system.

Begin by examining the exhaust components for any signs of wear or damage, such as rust, cracks, or loose connections. It is vital to address these issues promptly to prevent further complications that may lead to reduced efficiency or increased emissions. When a section of the exhaust system needs replacing, ensure to choose high-quality parts that meet the necessary specifications.

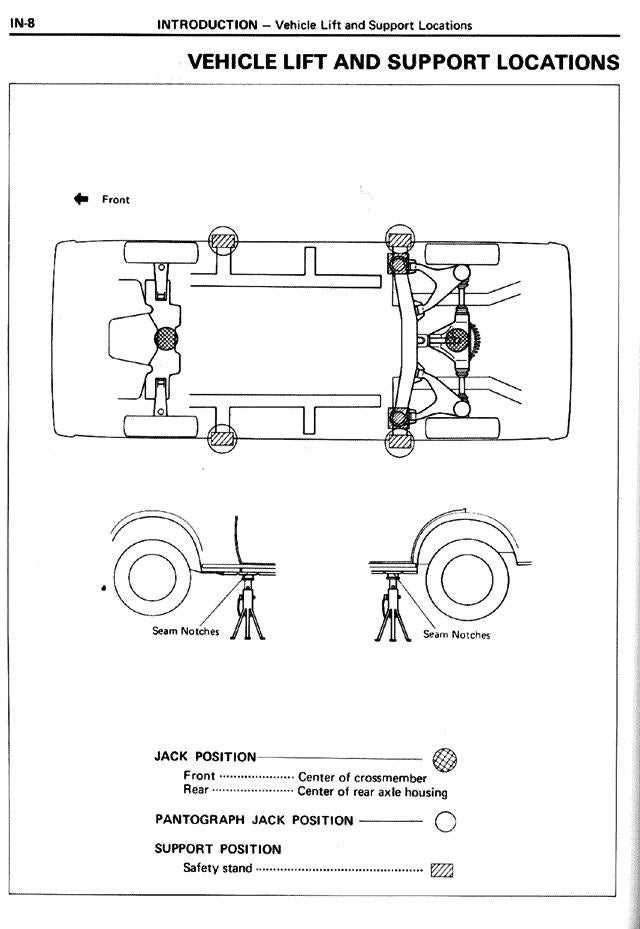

To replace a damaged part, start by safely lifting the vehicle and securely supporting it. Remove the old component carefully, taking note of the installation method and any specific fittings used. When installing the new piece, ensure a proper seal and secure all connections tightly to avoid leaks. Finally, conduct a thorough inspection and test the system to confirm that it operates correctly.

Fuel System Cleaning and Repair Tips

Maintaining the cleanliness and functionality of the fuel system is crucial for optimal engine performance. A well-kept fuel delivery mechanism ensures that the combustion process operates efficiently, resulting in improved power output and fuel economy. Regular maintenance can help prevent costly repairs and prolong the lifespan of various components.

Cleaning Procedures

Cleaning the fuel system involves several steps to ensure that all contaminants are removed, allowing for smooth fuel flow. Here are some effective methods:

| Procedure | Description |

|---|---|

| Fuel Injector Cleaning | Utilize a specialized cleaning kit or ultrasonic cleaner to remove deposits from injectors. |

| Fuel Filter Replacement | Change the fuel filter regularly to prevent blockages and ensure clean fuel reaches the injectors. |

| Fuel Tank Cleaning | Inspect and clean the fuel tank to remove rust and sediment that may affect fuel quality. |

Repair Tips

In case of damage or malfunction, certain repair strategies can be employed to restore system integrity. Consider the following recommendations:

| Component | Repair Tip |

|---|---|

| Fuel Pump | Check electrical connections and replace the pump if it shows signs of failure or unusual noise. |

| Fuel Lines | Inspect for leaks or cracks; replace any damaged sections promptly to prevent fuel loss. |

| Injectors | If injectors are clogged, they may need to be serviced or replaced for optimal performance. |