Exmark Lazer Z Repair Manual Guide

This section offers a comprehensive overview of essential practices for ensuring the longevity and optimal performance of your lawn care machinery. By understanding the fundamental aspects of upkeep, users can maintain their equipment effectively, preventing common issues and enhancing operational efficiency.

Routine maintenance is crucial for preserving the functionality of your machinery. Regular checks and timely interventions can significantly reduce the risk of unexpected breakdowns, saving both time and resources. Moreover, familiarizing oneself with the operational aspects and components will empower users to address minor issues independently.

In this guide, you will find valuable insights and step-by-step instructions tailored to assist in maintaining various aspects of your lawn care equipment. Whether you’re looking to troubleshoot common problems or enhance performance, this resource aims to provide clear and actionable advice for all users.

Exmark Lazer Z Overview

This section provides an insight into a renowned zero-turn mower, highlighting its design, capabilities, and performance features. These machines are engineered for efficiency and precision, making them a preferred choice among landscaping professionals.

The key characteristics of this model include:

- Powerful Engine: Equipped with robust engines that deliver exceptional performance in various mowing conditions.

- Advanced Maneuverability: Designed for tight turns and agility, allowing for quick navigation around obstacles.

- Durable Construction: Built with high-quality materials to ensure longevity and withstand tough environments.

- Comfort Features: Includes ergonomic seating and controls for enhanced operator comfort during prolonged use.

Overall, this mower is ideal for both residential and commercial applications, providing users with the reliability and efficiency needed for effective lawn care.

Common Issues and Solutions

This section addresses frequently encountered challenges and their corresponding remedies related to lawn care equipment. Understanding these common problems can help users maintain optimal performance and extend the lifespan of their machines.

Engine Performance Problems

One of the most prevalent issues involves engine performance. If the engine struggles to start or runs unevenly, it may indicate fuel system issues or air filter blockages. Regularly checking the fuel filter and ensuring it is clean can enhance performance. Additionally, replacing the air filter as recommended can prevent airflow restrictions, ensuring smooth operation.

Cutting Deck Malfunctions

Another common concern is associated with the cutting deck. If the blades are dull or not spinning correctly, it may result in uneven grass cutting. Ensuring blades are sharpened regularly and properly aligned can significantly improve cutting efficiency. Moreover, inspecting the belt tension and replacing any worn components can prevent further complications.

Maintenance Tips for Longevity

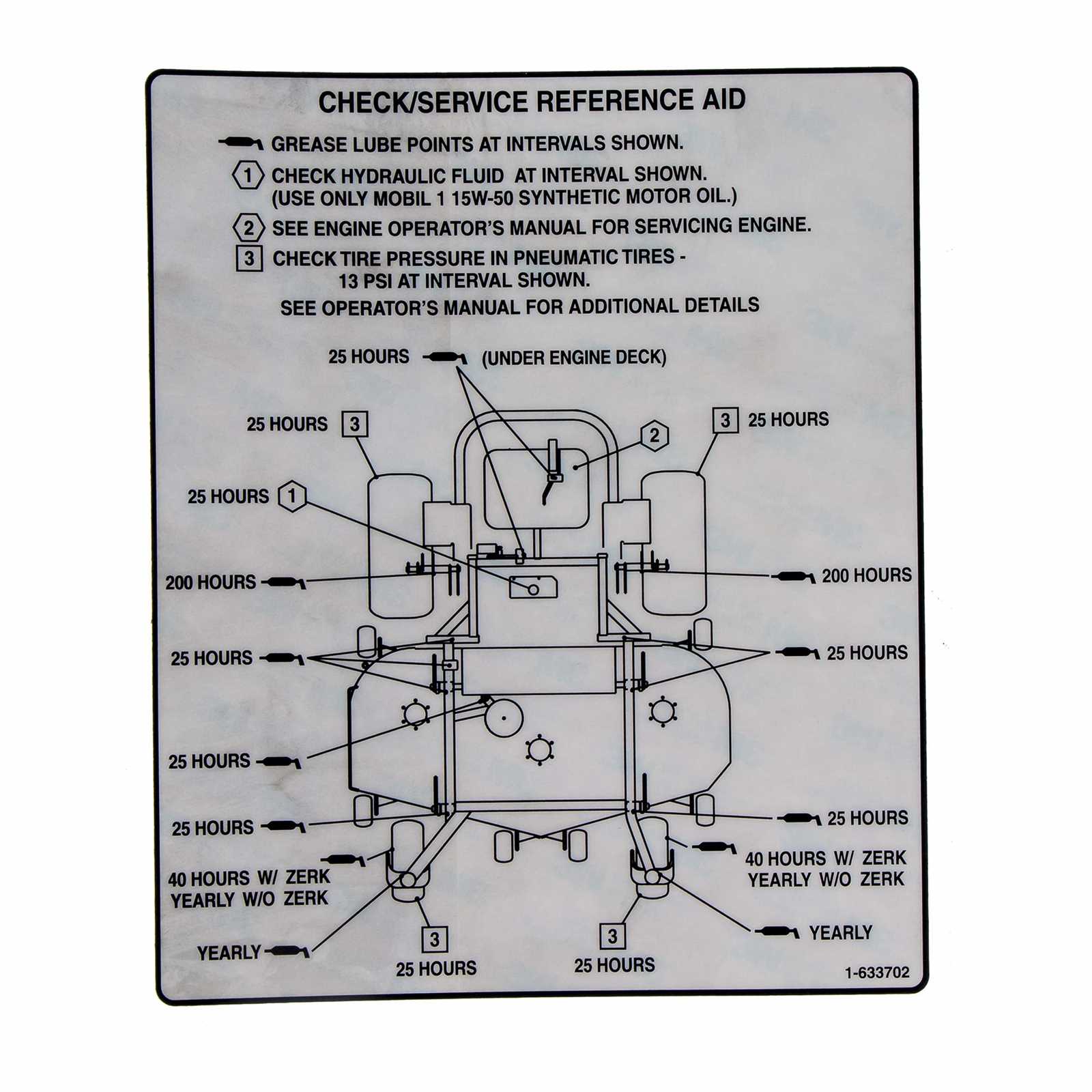

Ensuring the long-term performance of your machinery requires regular care and attention. Implementing a consistent maintenance routine can significantly extend the lifespan of your equipment, enhancing its reliability and efficiency.

Regular Cleaning

Keeping your equipment clean is essential for optimal performance. Debris and dirt can accumulate, causing unnecessary strain on components. Follow these cleaning tips:

- Remove grass clippings and dirt after each use.

- Check and clean air filters regularly to ensure proper airflow.

- Inspect and wash undercarriages to prevent buildup.

Routine Inspections

Regular inspections help identify potential issues before they become major problems. Schedule the following checks:

- Examine belts and hoses for signs of wear or damage.

- Check fluid levels, including oil, coolant, and fuel.

- Ensure blades are sharp and properly adjusted for efficient cutting.

By adhering to these maintenance practices, you can help ensure that your machinery remains in excellent working condition for years to come.

Tools Required for Repairs

Ensuring that your equipment is in optimal condition often requires a variety of tools to address different issues effectively. Understanding which instruments to have on hand can greatly simplify the maintenance process and enhance the longevity of your machinery.

Essential Hand Tools

- Wrenches (various sizes)

- Screwdrivers (flathead and Phillips)

- Pliers (needle-nose and standard)

- Socket set

- Adjustable wrench

Specialized Equipment

- Torque wrench

- Diagnostic tools

- Fuel line wrenches

- Multimeter for electrical testing

- Cleaning brushes for maintenance

Having the right tools ready not only makes the task at hand easier but also helps ensure that the job is completed accurately and safely. Regularly inspecting and organizing your toolkit can prevent delays when addressing any issues that arise.

Step-by-Step Repair Instructions

This section provides a comprehensive guide to addressing common issues encountered with your equipment. Following these detailed steps will help ensure proper functionality and longevity.

1. Gather Necessary Tools

Before starting the process, collect all required tools and replacement parts. Having everything at hand will streamline the task and minimize interruptions.

2. Safety First

Ensure the machine is turned off and disconnected from any power source. Wearing appropriate safety gear, such as gloves and goggles, is essential to protect yourself during the process.

3. Accessing the Components

Begin by removing any covers or shields that obstruct access to the internal parts. Carefully follow the manufacturer’s guidelines to avoid damaging any components during this step.

4. Identifying the Problem

Examine the parts closely for wear, damage, or misalignment. Take note of any irregularities that may indicate the root cause of the malfunction.

5. Performing the Fix

Once the issue is identified, follow the specific steps to address it. This may involve tightening loose connections, replacing worn components, or recalibrating settings to restore optimal performance.

6. Reassemble the Equipment

After completing the necessary adjustments, carefully reassemble the machine. Ensure all screws and fasteners are securely tightened to prevent future issues.

7. Testing the Equipment

Finally, reconnect the power source and test the equipment to ensure it operates smoothly. Monitor its performance to confirm that the issue has been resolved effectively.

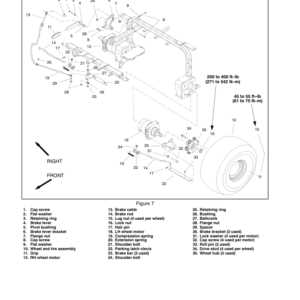

Parts Identification and Replacement

This section focuses on recognizing and substituting various components of your equipment to ensure optimal performance and longevity. Understanding the specific elements within your machine is crucial for efficient maintenance and timely replacements.

Identification of Key Components: Familiarize yourself with the essential parts, including the engine, transmission, and cutting system. Each element plays a significant role in the overall functionality, and knowing their locations will assist in troubleshooting and repairs.

Common Replacement Parts: Regular wear and tear can necessitate the replacement of certain items. Commonly replaced parts include belts, blades, filters, and spark plugs. Having these components on hand can streamline the maintenance process.

Substituting Components: When replacing parts, ensure compatibility with your specific model. Refer to the manufacturer’s specifications for guidance on part numbers and installation procedures. Proper installation is key to maintaining performance and preventing damage.

Maintenance Tips: Regular inspections and timely replacements can prevent unexpected breakdowns. Develop a maintenance schedule that includes checking for wear, replacing filters, and sharpening blades to enhance the efficiency and lifespan of your equipment.

Safety Precautions During Repairs

Ensuring a safe working environment is crucial when performing maintenance on machinery. By following specific guidelines, individuals can protect themselves from potential hazards and ensure efficient workflow. Awareness of surroundings, proper use of tools, and adherence to safety protocols are vital for preventing accidents.

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use gloves, goggles, and other protective equipment to shield against injuries. |

| Keep Workspace Clean | A tidy area reduces the risk of slips, trips, and falls, allowing for better focus on tasks. |

| Disconnect Power Sources | Ensure all power sources are disconnected before starting any work to avoid electrical hazards. |

| Use Tools Properly | Employ the right tools for the job and maintain them in good condition to minimize risks. |

| Follow Manufacturer Guidelines | Refer to instructions provided by the manufacturer to ensure correct procedures are followed. |

Troubleshooting Electrical Problems

When encountering issues related to the electrical system of your equipment, it’s essential to follow a systematic approach to identify and resolve the underlying causes. Understanding the common symptoms and employing effective diagnostic techniques can significantly streamline the troubleshooting process.

Start by inspecting the battery, as it is often the primary source of power for many components. Ensure that the terminals are clean and securely connected. If the battery shows signs of damage or is not holding a charge, it may need replacement.

Next, examine the wiring and connections throughout the system. Look for any frayed or broken wires that could disrupt the flow of electricity. Pay special attention to connectors, as corrosion can lead to poor contact, resulting in intermittent issues.

Testing individual components is another critical step. Utilize a multimeter to check the functionality of fuses, relays, and switches. If a component does not operate as expected, it may require repair or replacement.

Finally, consult the schematics for your equipment to ensure all parts are functioning harmoniously. Understanding the electrical layout can help pinpoint problems that may not be immediately visible. By methodically addressing each aspect of the electrical system, you can effectively troubleshoot and restore functionality.

Engine Care and Maintenance

Proper care and maintenance of your engine are essential for ensuring optimal performance and longevity. Regular attention to key components not only enhances efficiency but also prevents potential issues that could lead to costly repairs.

Regular Maintenance Tasks

- Check and replace the oil as needed to ensure smooth operation.

- Inspect air filters regularly; replace them if they are dirty or clogged.

- Monitor fuel levels and use fresh fuel to prevent deterioration.

- Keep the cooling system clean and free from debris to maintain temperature control.

Signs of Potential Problems

Being aware of signs that indicate potential engine trouble can save you time and money. Look out for:

- Unusual noises during operation, such as knocking or grinding.

- Excessive smoke from the exhaust, indicating possible combustion issues.

- Reduced power or sluggish acceleration, which may suggest fuel delivery problems.

- Overheating, which could lead to severe engine damage if not addressed promptly.

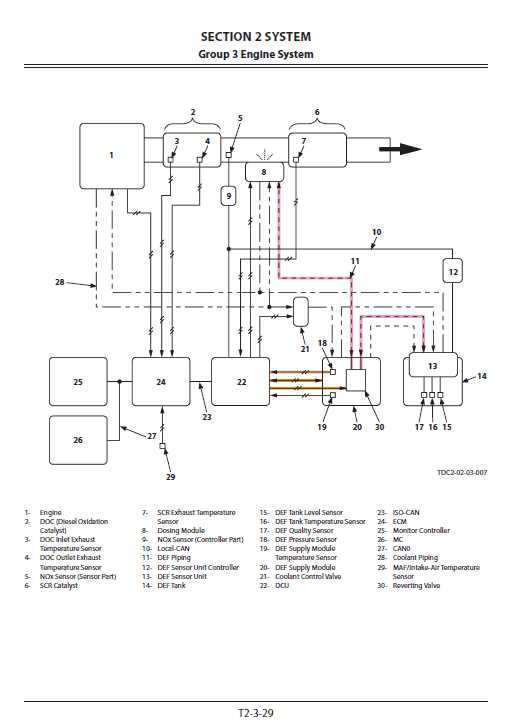

Hydraulic System Overview

The hydraulic system plays a crucial role in the overall functionality of the equipment, providing the necessary force to operate various components. This system utilizes fluid power to facilitate movement and perform tasks effectively, ensuring optimal performance during operation.

Components of the Hydraulic System

The hydraulic system is composed of several key elements that work together to generate and transmit hydraulic pressure. Understanding these components is essential for proper maintenance and troubleshooting.

| Component | Function |

|---|---|

| Pump | Generates hydraulic fluid flow, creating pressure for operation. |

| Actuator | Converts hydraulic energy into mechanical movement. |

| Hoses and Fittings | Transport hydraulic fluid between components, maintaining system integrity. |

| Reservoir | Stores hydraulic fluid, allowing for cooling and separation of contaminants. |

Importance of Regular Maintenance

Deck and Blade Adjustments

Proper maintenance of the cutting system is essential for achieving optimal performance and longevity. Regular adjustments ensure that the mower operates efficiently, providing a clean and even cut across various types of terrain. This section focuses on the key aspects of fine-tuning the deck and blades to enhance the overall mowing experience.

Importance of Deck Leveling

Ensuring that the deck is level is critical for effective grass cutting. An uneven deck can lead to inconsistent cutting heights and may cause scalping in some areas. To achieve the correct level, it is advisable to measure the height from the ground to the blade tips on both sides of the deck, making necessary adjustments to achieve a uniform height.

Blade Sharpening and Maintenance

Keeping the blades sharp is vital for clean cuts and promoting healthy grass growth. Dull blades can tear the grass rather than cut it, leading to a ragged appearance and increased susceptibility to disease. Regularly inspect the blades for wear and sharpen them as needed. When replacing blades, ensure they are securely fastened and properly aligned to maximize cutting efficiency.

Warranty Information and Support

This section provides essential details regarding coverage and assistance for your equipment. Understanding the terms and conditions of your warranty is crucial for maintaining the longevity and performance of your machine. Here, you will find information about what is included in your warranty, how to access support services, and guidelines for claims.

Coverage Details

The warranty typically covers defects in materials and workmanship under normal use. It’s important to familiarize yourself with the specific duration of the coverage and any exclusions that may apply. Regular maintenance is often required to keep the warranty valid, so be sure to adhere to the recommended service intervals.

Accessing Support

If you encounter issues, support is available through various channels. Whether through phone, email, or online resources, trained professionals are ready to assist you. Always have your model information and warranty details on hand when seeking help to expedite the process.