Tecumseh LH195SP Repair Manual Guide

Engines are the heart of many machines, powering everything from lawn mowers to snow blowers. Proper understanding and upkeep of these mechanisms can significantly enhance their longevity and performance. In this section, we will delve into essential strategies for maintaining a specific type of engine, focusing on troubleshooting common issues and providing insights into effective solutions.

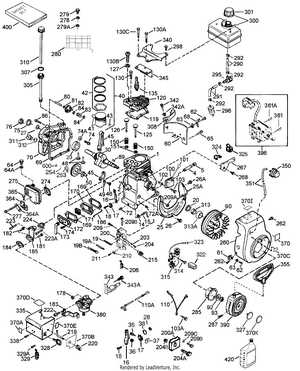

Understanding the Components is crucial for anyone looking to optimize the efficiency of their engine. Familiarity with the various parts and their functions not only aids in identifying problems but also empowers operators to perform routine checks and maintenance tasks. By mastering the intricacies of these systems, you can ensure smooth operation and minimize unexpected breakdowns.

In addition, proactive maintenance can save both time and money. Regular inspections and timely interventions can prevent minor issues from escalating into major repairs. This guide aims to equip you with the knowledge necessary to tackle common challenges, making the process of engine care more approachable and effective.

Tecumseh LH195SP Overview

This section provides a comprehensive understanding of a small engine that has gained recognition for its reliability and performance in various applications. Known for its efficient design and user-friendly features, this power unit is widely utilized in outdoor equipment and machinery, making it a popular choice among both professionals and hobbyists.

Key Features

The engine is equipped with several notable attributes that enhance its functionality and ease of use. These characteristics contribute to its effectiveness in powering different types of tools and devices.

| Feature | Description |

|---|---|

| Engine Type | Four-stroke, air-cooled design for efficient operation. |

| Power Output | Offers a reliable power output suitable for various applications. |

| Fuel System | Equipped with a simple carburetor for easy maintenance. |

| Starting Mechanism | Features a recoil starter for straightforward ignition. |

Applications

This engine is versatile and can be found in a variety of machines, from lawn mowers to generators. Its robust performance and durability make it an essential component in many outdoor tools, ensuring users can complete their tasks efficiently and effectively.

Common Issues with Tecumseh Engines

Small engines, often used in outdoor power equipment, can encounter a variety of challenges that may affect their performance. Understanding these common problems is essential for proper maintenance and ensuring longevity. This section explores frequent issues faced by users, along with their potential causes and solutions.

Starting Difficulties: One of the most prevalent issues is trouble starting the engine. This can stem from a drained battery, clogged fuel lines, or issues with the ignition system. Regular inspection of these components can help prevent starting failures.

Fuel System Problems: Another common concern involves the fuel system. Stale or contaminated fuel can lead to poor combustion, resulting in rough running or stalling. Keeping the fuel fresh and using the appropriate type can mitigate these problems.

Overheating: Engines may overheat due to insufficient airflow or a malfunctioning cooling system. Blocked air filters or dirty fins can restrict airflow, causing excessive heat buildup. Regular cleaning and maintenance of these parts are vital.

Oil Leaks: Leaking oil can indicate worn gaskets or seals. This not only affects performance but can also lead to further damage if not addressed. Regular checks and timely replacement of faulty components are recommended.

Noise Issues: Unusual noises, such as knocking or grinding, can signal internal wear or damage. Listening for these sounds during operation can help identify problems early, allowing for prompt action to prevent serious failures.

By being aware of these common challenges and performing regular maintenance, users can enhance the reliability and efficiency of their small engines, ensuring they run smoothly for years to come.

Tools Needed for Repairs

When embarking on a maintenance task, having the right equipment is essential for achieving optimal results. A well-equipped workspace can significantly streamline the process, making it easier to troubleshoot and fix various issues. Below is a list of indispensable tools that will aid in performing effective servicing.

Essential Hand Tools

- Socket set

- Wrenches (metric and imperial)

- Screwdrivers (flathead and Phillips)

- Pliers (needle-nose and standard)

- Torque wrench

Specialized Equipment

- Multimeter for electrical testing

- Compression gauge

- Fuel line wrench

- Feeler gauge for precise measurements

- Cleaning supplies (brushes, carburetor cleaner)

By ensuring you have these tools on hand, you can enhance your efficiency and accuracy during the service process, ultimately prolonging the life of the equipment.

Step-by-Step Repair Process

This section outlines a comprehensive approach to troubleshooting and restoring the functionality of small engines. Following a systematic procedure not only helps in identifying issues but also ensures that the necessary adjustments and replacements are carried out effectively.

Preparation

- Gather all necessary tools and replacement parts.

- Ensure the workspace is clean and well-lit.

- Review safety precautions to prevent accidents.

Diagnosis

- Inspect the engine for visible signs of wear or damage.

- Check the fuel system for blockages or leaks.

- Examine the ignition components for functionality.

- Test the compression to assess the internal condition.

- Document findings for reference during the repair process.

Following this structured method will facilitate a thorough evaluation and enhancement of the engine’s performance.

Maintaining Your Tecumseh Engine

Proper upkeep of your small engine is essential for ensuring its longevity and optimal performance. Regular maintenance tasks not only help prevent unexpected breakdowns but also enhance efficiency, allowing your equipment to run smoothly for years to come. Adhering to a consistent maintenance schedule can significantly reduce wear and tear, ultimately saving you time and money.

Start by regularly checking the oil level and changing it as needed. Clean oil is vital for the internal components, preventing sludge buildup and reducing friction. Additionally, inspect the air filter and replace it if it’s clogged or dirty; this ensures a steady flow of clean air, improving combustion efficiency.

Fuel quality also plays a crucial role in engine performance. Use fresh, high-quality fuel and consider adding a fuel stabilizer if the engine will be stored for an extended period. This helps prevent issues related to fuel degradation, which can affect starting and operation.

Don’t overlook the spark plug. A worn or fouled spark plug can lead to starting difficulties and poor performance. Regular inspection and replacement when necessary will keep your engine running reliably. Finally, keep the exterior clean and free of debris, as accumulated dirt can lead to overheating and other issues.

Understanding Engine Specifications

Comprehending the technical details of an engine is crucial for effective maintenance and optimal performance. These specifications provide essential information about the engine’s capabilities, including power output, displacement, and operational requirements. By familiarizing oneself with these characteristics, users can make informed decisions regarding care, troubleshooting, and performance enhancement.

Engine displacement, measured in cubic centimeters (cc) or liters, indicates the total volume of the engine’s cylinders. This measurement directly influences the engine’s power potential and efficiency. Additionally, the horsepower rating reveals the engine’s strength and ability to perform tasks, which is vital for selecting appropriate applications.

Other key specifications include torque ratings, which determine the force available for acceleration and load handling. Understanding fuel requirements, including type and octane rating, ensures compatibility and optimal functioning. Furthermore, details about lubrication systems and cooling mechanisms play a significant role in maintaining engine health over time.

By grasping these technical aspects, operators can better manage their equipment, leading to improved longevity and reliability. Engaging with the specifications not only empowers users but also enhances their ability to address any challenges that may arise during operation.

Replacement Parts Availability

Access to suitable components is crucial for maintaining optimal performance and longevity of small engines. Ensuring that you can find the necessary parts is essential for effective servicing and upkeep.

There are various sources to explore when searching for quality replacements:

- Authorized Dealers: These outlets often carry a comprehensive inventory of original parts, ensuring compatibility and reliability.

- Online Retailers: Websites dedicated to engine components provide a wide selection and often feature user reviews, aiding in the decision-making process.

- Local Hardware Stores: Many community stores stock essential parts and can offer valuable advice on installation and compatibility.

- Aftermarket Suppliers: Consider alternatives from reputable aftermarket manufacturers, which may offer cost-effective solutions.

When sourcing components, it is important to verify specifications to ensure proper fit and functionality. Additionally, keeping an inventory of frequently used parts can expedite maintenance tasks and minimize downtime.

Safety Tips for Engine Repairs

When working on machinery, prioritizing safety is crucial to prevent accidents and injuries. Proper precautions and awareness can significantly reduce risks while ensuring a smoother workflow. Understanding potential hazards and adopting best practices will help create a safe environment for any mechanical tasks.

Personal Protective Equipment

Always wear appropriate protective gear, such as gloves, safety goggles, and sturdy footwear. This equipment shields you from debris, chemical exposure, and other potential dangers. Additionally, consider using ear protection if you’re working with loud tools to prevent hearing damage.

Work Area Organization

Maintain a clean and organized workspace to minimize hazards. Ensure that tools are stored properly and that the area is free of clutter. Adequate lighting is also essential for visibility, helping you identify any issues and work more efficiently. Regularly check for spills and promptly clean them to prevent slips or falls.

Troubleshooting Engine Performance Problems

When dealing with performance issues in small engines, it’s essential to systematically identify and address potential causes. Many factors can contribute to reduced efficiency, such as fuel quality, air intake, ignition system, and overall maintenance. By following a structured approach, you can enhance engine performance and extend its lifespan.

Common Symptoms and Possible Causes

| Symptom | Possible Cause |

|---|---|

| Engine won’t start | Dead battery, faulty ignition, or fuel blockage |

| Engine runs rough | Clogged air filter or carburetor, poor fuel quality |

| Loss of power | Worn spark plug, low compression, or fuel starvation |

| Excessive smoke | Oil in the combustion chamber or incorrect fuel mixture |

Steps to Diagnose Issues

To effectively diagnose performance problems, start with a thorough inspection. Check the fuel system for any leaks or contamination, and ensure the air filter is clean and free of debris. Examine the spark plug for signs of wear or fouling. Additionally, monitor the engine’s exhaust for any unusual emissions that may indicate underlying issues.

Customer Support and Resources

This section is dedicated to assisting users in finding the help they need for their equipment. Whether you are facing challenges or simply seeking additional information, there are numerous avenues available to ensure you can effectively utilize your machinery.

Contacting Support: For immediate assistance, reaching out to customer service can be invaluable. Representatives are trained to provide guidance on troubleshooting, usage tips, and solutions to common issues. Be prepared to provide specific details about your product to expedite the process.

Online Resources: Many manufacturers offer a wealth of online materials, including instructional videos, FAQs, and forums where users can share experiences and advice. These resources can help enhance your understanding and provide step-by-step guidance on various topics.

User Communities: Engaging with fellow users through online platforms or social media groups can foster a sense of camaraderie. Sharing insights and learning from others who have faced similar situations can lead to effective solutions and new techniques.

Documentation: Always refer to the documentation that came with your product. This information is specifically tailored to help you understand the features and maintenance requirements, ensuring optimal performance and longevity.

By leveraging these resources, users can confidently navigate any challenges they may encounter, ensuring a smooth experience with their equipment.