Karcher K2 Repair Manual for Optimal Maintenance

In the realm of high-pressure cleaning devices, understanding their functionality and upkeep is essential for optimal performance. Proper care not only extends the lifespan of the equipment but also ensures efficient operation, making the cleaning process more effective. This section delves into the intricacies of maintaining these powerful machines, providing insights that can aid users in identifying and resolving common issues.

Equipping oneself with knowledge about the assembly and disassembly processes, along with troubleshooting techniques, can significantly enhance the user experience. With a focus on practical solutions, this guide serves as a valuable resource for both novice and experienced users alike. Emphasizing hands-on approaches, it empowers individuals to tackle challenges confidently.

By exploring various components and their functions, one can gain a deeper appreciation for the engineering behind these devices. Whether it’s dealing with minor malfunctions or conducting routine checks, understanding each part’s role is crucial. This comprehensive overview aims to demystify the complexities involved, enabling users to maintain their cleaning apparatus effectively.

Karcher K2 Repair Manual Overview

This section provides a comprehensive guide to understanding the maintenance and troubleshooting processes for a popular cleaning device. A well-structured resource can significantly enhance the user experience by detailing essential information needed to ensure optimal performance and longevity.

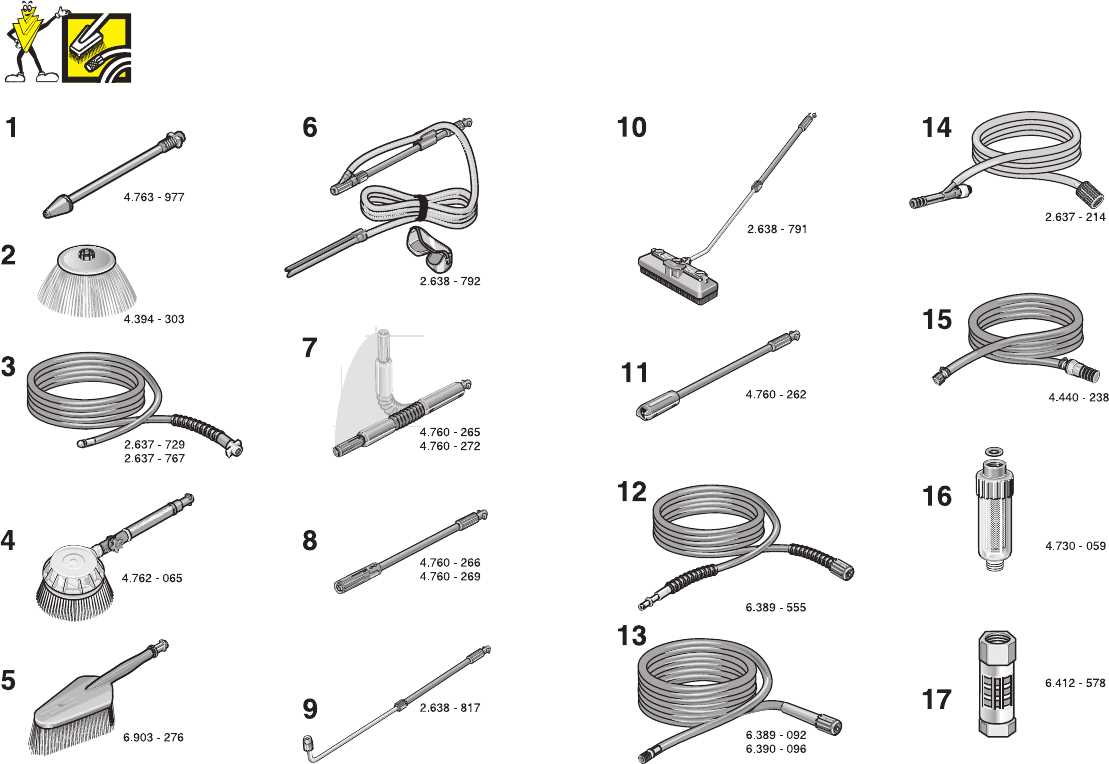

Essential Components: Familiarity with the key parts of the equipment is crucial. Users should be able to identify the main elements, as this knowledge aids in diagnosing issues effectively and facilitating smooth operation.

Troubleshooting Steps: Clear instructions on addressing common problems can empower users to resolve minor setbacks independently. By following systematic procedures, individuals can minimize downtime and maintain efficiency.

Maintenance Tips: Regular upkeep is vital for preserving functionality. Suggestions on cleaning, checking for wear, and replacing worn parts will help users keep their device in peak condition.

Safety Precautions: Awareness of safety guidelines is imperative when handling any equipment. Proper precautions can prevent accidents and ensure a secure environment during operation and maintenance activities.

Common Issues with Karcher K2

Pressure washers are invaluable tools for maintaining cleanliness and efficiency in various cleaning tasks. However, users may encounter several frequent challenges that can hinder performance. Understanding these common problems can help in identifying solutions and ensuring optimal operation.

- Insufficient Pressure: A lack of pressure can stem from various factors, including clogged nozzles or filters. Regular maintenance is essential to prevent this issue.

- Water Leakage: Leaks may occur at connection points or hoses, often due to wear and tear. Inspecting seals and fittings can help detect potential problems early.

- Engine Failures: Unusual noises or failure to start can indicate engine issues. Ensuring proper fuel and oil levels is crucial for reliable performance.

- Electrical Problems: Power interruptions or faulty connections can affect operation. Checking power sources and cords can help resolve these issues.

- Overheating: Extended use without breaks may cause overheating. It is important to allow the machine to cool down during prolonged cleaning sessions.

Addressing these issues promptly can enhance the lifespan and efficiency of the device, allowing users to enjoy uninterrupted cleaning tasks.

Essential Tools for Repairing Karcher K2

When maintaining or troubleshooting your pressure washer, having the right instruments at hand is crucial for effective and efficient service. Proper tools not only simplify the process but also ensure that you can address issues without causing further damage to the equipment.

Basic Hand Tools

Start with fundamental hand tools that are essential for most tasks. A set of screwdrivers, including both flathead and Phillips types, is vital for accessing various components. Additionally, a wrench set will allow you to tighten or loosen bolts and nuts as needed. Pliers can also be helpful for gripping and pulling parts during the maintenance process.

Specialized Equipment

Beyond standard tools, consider investing in specialized equipment tailored for pressure washer maintenance. A multimeter is indispensable for electrical diagnostics, while a manometer can help you measure pressure levels. Having a cleaning kit specifically designed for nozzles and hoses will also ensure optimal performance after service.

Step-by-Step Disassembly Guide

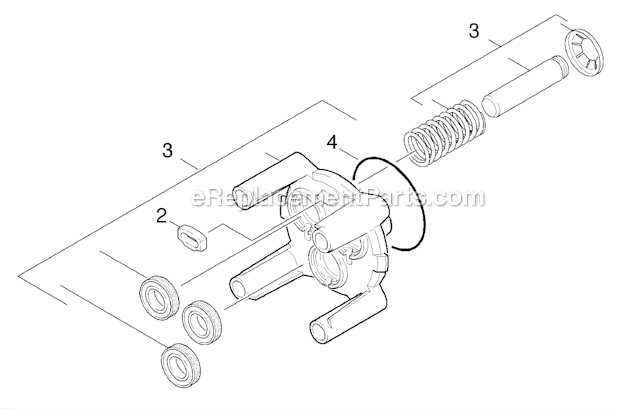

This section provides a comprehensive approach to carefully taking apart your pressure cleaning device. Following these steps will ensure that you can effectively access internal components for maintenance or troubleshooting, while minimizing the risk of damage.

Preparation for Disassembly

Before starting, gather the necessary tools such as screwdrivers, pliers, and a container for small parts. Make sure the device is unplugged and completely cooled down. Familiarize yourself with the outer casing and note any screws or fasteners that may need to be removed. Taking pictures during the process can help in reassembly.

Disassembly Steps

Begin by removing any accessories or attachments from the unit. Next, unscrew the outer casing carefully, keeping track of all screws. Once the casing is off, examine the internal components. Identify and detach any connectors or hoses before proceeding to take out the main components, such as the motor and pump. Handle each part gently and keep everything organized for a smooth reassembly.

Reassembling Your Karcher K2

When it comes to putting your high-pressure cleaner back together, attention to detail is crucial. This process not only ensures optimal performance but also extends the lifespan of the equipment. Following the right steps can help you avoid common pitfalls and ensure a smooth operation once reassembled.

Step 1: Gather Your Components

Before starting, make sure all parts are clean and accounted for. Lay them out systematically to facilitate easy access during reassembly. This includes the main unit, hose, trigger gun, and any other attachments you may have removed.

Step 2: Reattach the Main Unit

Begin by securing the main components. Align the body of the cleaner and ensure that any locking mechanisms are engaged properly. Pay attention to the orientation of the parts to prevent any misalignments that could lead to functional issues.

Step 3: Connect the Hose

Carefully attach the high-pressure hose to its designated inlet. Make sure it is tightened securely to prevent leaks. A proper connection will enhance the efficiency of your device during operation.

Step 4: Install the Trigger Gun

Next, insert the trigger gun into the appropriate outlet. Ensure that it clicks into place and is firmly secured. This step is vital for controlling the water flow effectively.

Step 5: Final Checks

Once all components are reattached, conduct a thorough inspection. Check for any loose fittings or misplaced parts. It’s advisable to perform a quick test run to ensure everything operates smoothly before resuming regular use.

By following these steps, you can confidently reassemble your device, ready for its next cleaning task.

Understanding the Pressure Washer Components

Pressure washers consist of several critical parts that work together to deliver high-pressure water for efficient cleaning. Familiarizing yourself with these components will enhance your understanding of the machine’s operation and maintenance requirements. Each element plays a unique role in generating and directing the water flow, ensuring optimal performance during use.

Main Components

- Motor/Engine: Provides the power necessary to operate the pump. It can be electric or gasoline-powered.

- Pump: Pressurizes the water, creating the high-pressure stream that is essential for cleaning.

- Nozzle: Controls the water flow and spray pattern, allowing users to adjust the pressure according to the cleaning task.

- Hose: Transports the pressurized water from the pump to the nozzle, often designed to withstand high pressure.

- Trigger Gun: Allows users to control water flow; squeezing activates the spray, while releasing it stops the flow.

Additional Features

- Wheels: Enable easy maneuverability across various surfaces.

- Detergent Tank: Stores cleaning solutions that can be mixed with water for enhanced cleaning capabilities.

- Pressure Gauge: Displays the pressure level, helping users monitor performance during operation.

Understanding these components will not only assist in troubleshooting issues but also ensure you utilize your cleaning equipment effectively, prolonging its lifespan and improving cleaning results.

How to Diagnose Electrical Problems

Identifying issues within electrical systems requires a systematic approach to ensure accurate assessments and effective solutions. Understanding the signs of malfunction can significantly aid in troubleshooting efforts and enhance overall performance.

Common Symptoms of Electrical Failures

Before delving into diagnostics, it’s crucial to recognize typical indicators of electrical faults. These may include unusual noises, flickering lights, or complete device failure. Observing these symptoms helps pinpoint potential areas of concern.

Step-by-Step Diagnostic Process

To effectively troubleshoot, begin by inspecting visible connections and components for any signs of damage or wear. Use a multimeter to measure voltage levels and continuity. Documenting findings throughout the process will provide a clearer picture of the underlying issues and guide you towards the ultimate resolution.

Fixing Water Leakage Issues

Addressing water leakage problems is crucial for maintaining the efficiency and longevity of your cleaning equipment. Such issues often stem from worn-out seals, loose connections, or damaged components. By identifying and rectifying these leaks, you can enhance performance and prevent further damage.

Identifying the Source of Leaks

To effectively tackle leaks, start by pinpointing their origin. Inspect hoses, connectors, and the body of the unit for visible signs of water escape. Common culprits include cracked hoses or loose fittings. It may be necessary to run the equipment briefly while monitoring for any water discharge, allowing for a clearer diagnosis.

Steps to Resolve Leakage Problems

Once you’ve identified the source, take action to fix it. For hose issues, replacing damaged sections or tightening connections can often resolve the problem. If seals are worn, consider applying appropriate sealants or replacing them altogether. Regular maintenance and checks can significantly reduce the likelihood of future leaks.

Replacing the Hose and Nozzles

Maintaining optimal performance in your pressure cleaning equipment often involves replacing worn-out components such as hoses and nozzles. These parts are crucial for ensuring efficient water flow and achieving the desired cleaning results. Regular inspection and timely replacement can prevent operational issues and enhance the longevity of the device.

Steps for Hose Replacement

To begin the process, first, ensure that the device is unplugged and all water connections are secure. Carefully detach the existing hose from both the machine and the spray gun. Examine the connection points for any damage or wear. Once removed, take the new hose and connect it firmly to both ends, ensuring a tight seal to prevent leaks. Finally, check the connections for stability before powering on the equipment.

Changing the Nozzles

Swapping out the nozzles is equally straightforward. Start by removing the current nozzle from the spray gun, which typically involves a simple twist or pull mechanism. Select the appropriate replacement nozzle based on the intended cleaning task. Attach the new nozzle securely, ensuring it clicks into place. Test the spray pattern to confirm that the new nozzle is functioning correctly and adjust as necessary for optimal performance.

Maintenance Tips for Longevity

Ensuring the extended life of your pressure cleaning equipment requires regular upkeep and attention. Implementing a few simple maintenance practices can significantly enhance performance and durability, saving you time and money in the long run.

Regular Cleaning

- After each use, wipe down the exterior to remove dirt and debris.

- Inspect and clean the nozzle to prevent clogging.

- Drain any remaining water from the unit to avoid internal corrosion.

Periodic Inspections

- Check hoses for signs of wear or damage.

- Examine the electrical connections for corrosion or loose fittings.

- Ensure the filters are clean and replace them if necessary.

By following these guidelines, you can ensure your equipment remains in optimal condition, ready for any task you undertake.

Upgrading Parts for Better Performance

Enhancing the functionality of your pressure cleaning equipment can significantly improve its efficiency and longevity. By upgrading certain components, you can achieve better results, reduce downtime, and extend the overall lifespan of the machine. This section discusses various modifications that can lead to noticeable performance improvements.

- High-Pressure Hose: Replacing the standard hose with a high-pressure variant can increase water flow and reduce pressure drops, leading to more effective cleaning.

- Nozzle Selection: Choosing specialized nozzles designed for different surfaces can optimize cleaning power. Consider options such as turbo or rotary nozzles for tough jobs.

- Water Filter: Installing a high-quality water filter prevents debris from entering the system, which can reduce wear on internal components and maintain performance.

- Upgraded Pump: Investing in a more robust pump can enhance pressure output and reliability, especially for heavy-duty tasks.

These enhancements not only improve cleaning capabilities but also provide a more enjoyable user experience. Prioritize quality parts to ensure compatibility and longevity with your equipment.

- Research available parts to find the best upgrades for your model.

- Consult user reviews and forums for insights on performance improvements.

- Follow installation instructions carefully to maximize the benefits of each upgrade.

By implementing these upgrades, you can transform your cleaning tasks and achieve professional-level results in your home or business.

Safety Precautions During Repairs

Ensuring a safe working environment is crucial when performing maintenance tasks on any equipment. Adhering to specific guidelines helps prevent accidents and injuries, allowing for a smoother process. By taking necessary precautions, one can protect both themselves and the tools involved.

Before starting any task, always disconnect the power source. This simple step can significantly reduce the risk of electrical shocks. Additionally, make sure to allow the device to cool down if it has been in use, as components may be hot and pose a burn hazard.

Wear appropriate personal protective equipment (PPE). This includes safety goggles to shield your eyes from debris, gloves to protect your hands, and sturdy footwear to prevent slips or injuries from falling objects. The right gear is essential for your safety during the process.

Work in a well-ventilated area. If you are using any chemicals or substances that emit fumes, ensure the workspace is properly ventilated to avoid inhalation of harmful vapors. Consider using a respirator if necessary, particularly when handling solvents or adhesives.

Keep your workspace organized and clutter-free. A tidy area reduces the risk of tripping hazards and allows you to easily access tools and parts. Always store tools in designated places after use to prevent accidents.

Follow manufacturer guidelines. Familiarizing yourself with the specifications and recommendations for the specific equipment will ensure that you perform tasks correctly and safely. Ignoring these can lead to further complications or damage.

By implementing these safety measures, you can create a secure environment that promotes efficient and effective maintenance. Prioritizing safety not only protects you but also extends the lifespan of your equipment.

Frequently Asked Questions About Repairs

This section addresses common inquiries regarding maintenance and troubleshooting of pressure devices. Understanding these issues can help users navigate potential challenges more effectively.

Common Issues

- Device not starting

- Loss of pressure

- Leaking water

- Strange noises during operation

Troubleshooting Steps

- Check power supply connections.

- Inspect hoses and fittings for damage.

- Clean filters and nozzles regularly.

- Ensure proper water supply and pressure settings.