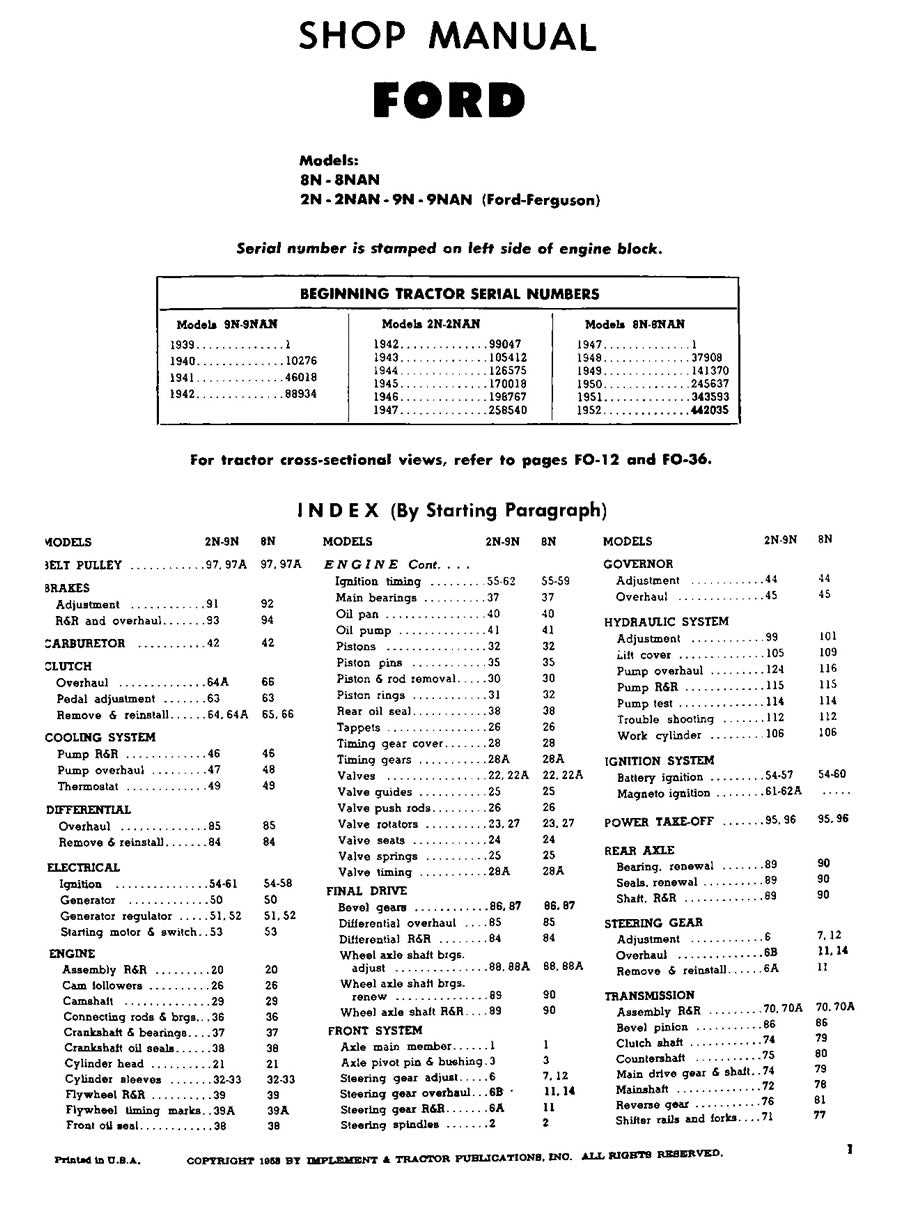

Comprehensive Guide to Ford 9N Repair Manual

When it comes to the upkeep of classic agricultural equipment, understanding the intricacies of the machinery is essential for longevity and optimal performance. This resource serves as a vital tool for enthusiasts and operators alike, providing detailed insights into maintaining these iconic machines. By delving into the various components and their functions, users can enhance their familiarity with the systems at play.

The essence of preserving such historic vehicles lies not only in knowing how to address common issues but also in appreciating the craftsmanship that went into their creation. This guide will illuminate the nuances of care and restoration, equipping owners with the knowledge necessary to tackle challenges effectively. With a focus on practical advice and troubleshooting techniques, individuals can ensure their machinery remains in peak condition.

Whether you are a seasoned mechanic or a passionate hobbyist, this compilation offers invaluable information to support your endeavors. From understanding engine dynamics to routine maintenance tips, every section is designed to foster confidence and skill in handling these remarkable pieces of history. Embrace the journey of restoration and upkeep, and keep the spirit of vintage machinery alive.

Overview of Ford 9N Tractor

The 9N model stands as a significant achievement in agricultural machinery, symbolizing innovation and practicality for farmers. This tractor was designed to enhance productivity on the field, providing robust performance and ease of use for various farming tasks.

Introduced in the early 1930s, this vehicle features a distinct design that combines functionality with reliable engineering. With its powerful engine and versatile capabilities, it became a favorite among those seeking efficiency and durability in their farming operations.

Equipped with advanced features for its time, the 9N revolutionized the way tasks were performed on the farm. Its adaptability allowed it to handle various implements, making it suitable for plowing, cultivating, and hauling, thereby increasing the overall output of agricultural activities.

Over the years, the 9N has garnered a loyal following, with enthusiasts appreciating its historical significance and lasting impact on the industry. The blend of classic design and functional prowess continues to resonate with both collectors and active users, ensuring its legacy endures in the world of machinery.

Common Issues and Solutions

This section addresses frequent problems encountered by users, providing effective strategies for resolution. Understanding these common difficulties can enhance the overall experience and ensure optimal performance of the machinery.

Engine Troubles

One of the most prevalent challenges is engine performance issues. These can stem from various factors, including fuel delivery problems or ignition system failures. Regular maintenance can help mitigate these concerns.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Poor Starting | Weak battery, faulty starter | Charge or replace battery, check starter connections |

| Overheating | Coolant leaks, blocked radiator | Inspect and repair leaks, flush radiator |

Transmission Concerns

Transmission issues can also arise, affecting the smooth operation of the equipment. Common symptoms include slipping gears and unusual noises, which may indicate the need for attention.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Slipping Gears | Low fluid levels, worn components | Check and refill fluid, inspect parts for wear |

| Unusual Noises | Improper alignment, lack of lubrication | Align components, ensure proper lubrication |

Essential Tools for Repairs

Having the right equipment is crucial when working on machinery. A well-stocked toolkit can make a significant difference in both efficiency and effectiveness during any maintenance task. Understanding which instruments are necessary allows one to tackle various challenges confidently.

Wrenches are fundamental for loosening and tightening bolts and nuts. A set of both standard and metric sizes is advisable to ensure compatibility with different components. Additionally, screwdrivers are indispensable for securing panels and accessing internal parts; having a variety of types–flathead and Phillips–will cover most needs.

Pliers serve multiple purposes, from gripping to cutting wires. Investing in a pair with a strong grip is essential for handling stubborn parts. Sockets and ratchets allow for more torque when dealing with larger fasteners, providing an advantage in situations where leverage is necessary.

Finally, safety gear, such as gloves and goggles, should never be overlooked. Protecting oneself while working not only enhances the experience but also prevents accidents, ensuring a productive environment. With these tools at hand, anyone can approach machinery tasks with greater assurance and competence.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring the longevity and optimal performance of your machinery. By following a structured routine, you can identify potential issues early and maintain efficiency. Regular upkeep is essential for any engine, and this guide outlines essential steps to keep it in top condition.

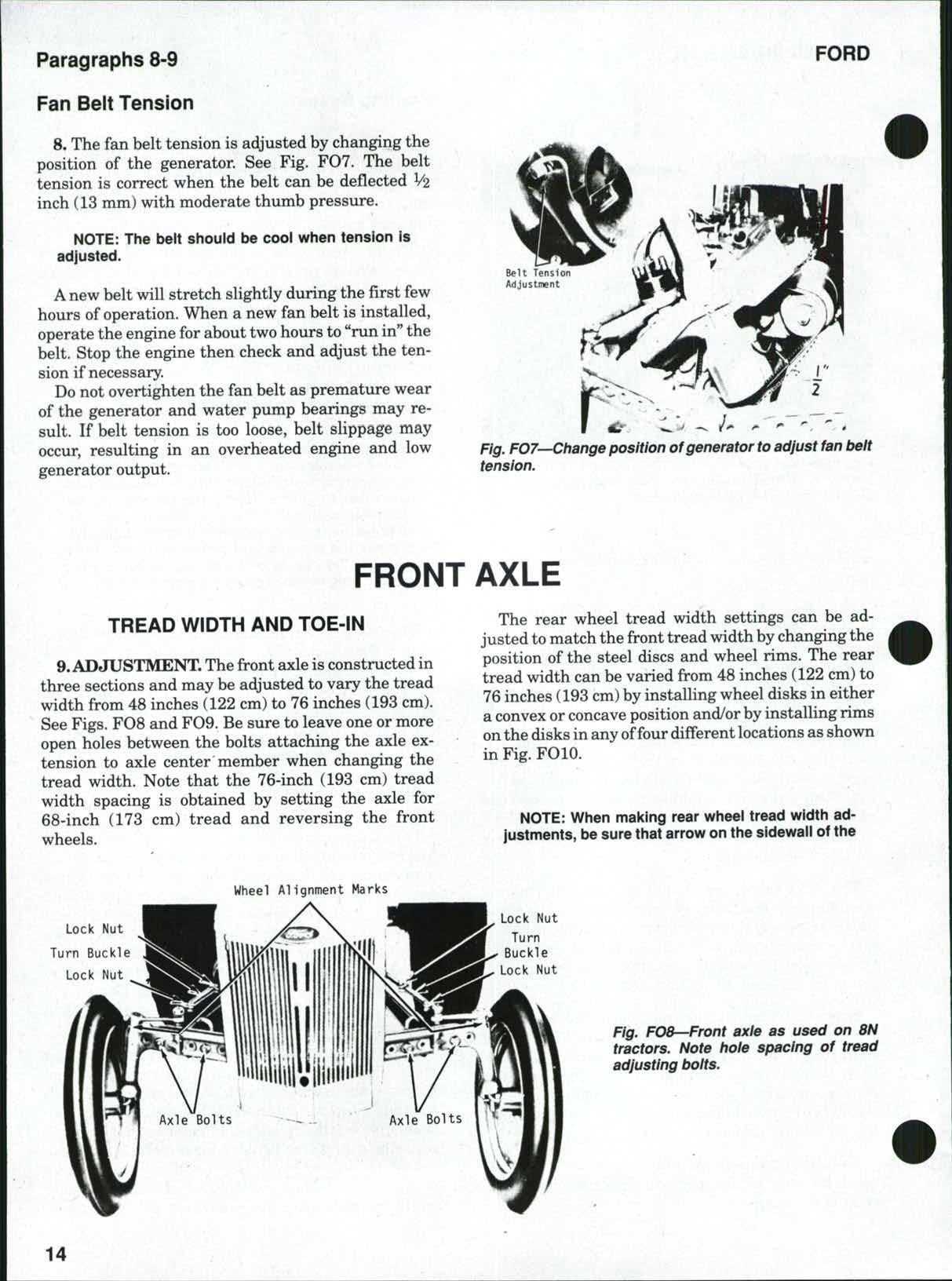

Regular Inspection

Conducting frequent checks is crucial. Follow these steps to perform thorough inspections:

- Check fluid levels, including oil, coolant, and transmission fluid.

- Inspect belts and hoses for signs of wear or damage.

- Examine the battery for corrosion and secure connections.

- Look for leaks around the engine and undercarriage.

Scheduled Maintenance Tasks

In addition to inspections, adhere to a routine maintenance schedule. Key tasks include:

- Change the oil and filter every 50 hours of operation.

- Replace the air filter at least once a year or as needed.

- Grease all fittings and joints according to the recommended intervals.

- Check tire pressure and tread condition regularly.

By following these steps diligently, you can enhance the performance and reliability of your equipment for years to come.

Engine Troubleshooting Tips

Maintaining optimal performance of your machinery often requires keen observation and systematic problem-solving. Identifying issues early can save time and resources while ensuring smooth operation. Here are some practical insights to help you diagnose engine-related challenges effectively.

Common Symptoms and Their Causes

When an engine exhibits unusual behavior, it is crucial to assess the symptoms thoroughly. For instance, if you notice a decrease in power, it may be linked to fuel supply issues or air intake blockages. Similarly, strange noises might indicate mechanical wear or loose components. Always pay attention to warning signs, as they can lead to more significant problems if left unaddressed.

Basic Diagnostic Steps

Start by checking fluid levels, including oil and coolant, as inadequate amounts can severely affect engine performance. Inspecting the ignition system is also vital; faulty spark plugs or wiring can prevent proper combustion. Additionally, examining filters for clogs can reveal underlying issues with airflow and fuel delivery. Documentation of findings during your inspections will assist in tracking recurring problems and determining the necessary corrective actions.

Transmission Repair Techniques

This section delves into various methods for addressing issues related to gear systems in agricultural machinery. Understanding these techniques can significantly enhance the functionality and longevity of the equipment.

Here are some effective approaches to consider:

- Inspection: Begin with a thorough examination of the transmission components. Look for signs of wear, leakage, or any unusual noises.

- Disassembly: Carefully dismantle the gear assembly, ensuring to document each step. This helps in reassembly and identifying problematic parts.

- Cleaning: Use appropriate solvents to remove dirt and grime from all components. This step is crucial for proper functioning.

- Component Replacement: Identify damaged parts and replace them with high-quality alternatives. Ensure compatibility with existing elements.

- Reassembly: Follow the documented steps to put everything back together. Double-check that all components fit correctly and securely.

- Fluid Change: Replace old lubricant with fresh fluid to maintain optimal performance and prevent future issues.

- Testing: Once reassembled, conduct tests to confirm that the system operates smoothly without any abnormal sounds or shifting problems.

By applying these techniques, users can effectively manage issues within the transmission system, promoting better performance and durability in their machinery.

Electrical System Diagnostics

Identifying and resolving issues within an electrical framework is crucial for optimal performance and reliability. This process involves a systematic approach to understanding the components, their interactions, and the potential points of failure. Proper diagnostics can prevent minor problems from escalating into significant malfunctions.

Common Symptoms of Electrical Issues

- Dim or flickering lights

- Inconsistent starting behavior

- Unresponsive electrical components

- Frequent blown fuses

Diagnostic Steps

- Inspect the battery condition and connections.

- Examine wiring for signs of wear or damage.

- Test the alternator output and voltage regulator.

- Utilize a multimeter to measure voltage across critical components.

- Check the grounding points for corrosion or looseness.

By following these steps, one can efficiently diagnose and address electrical concerns, ensuring a reliable operation for any equipment involved.

Hydraulic System Maintenance Essentials

Regular upkeep of the hydraulic system is crucial for ensuring optimal performance and longevity. Proper care can prevent costly repairs and maintain the efficiency of equipment. This section outlines the key practices necessary for the effective management of hydraulic systems.

Routine Inspections

Conducting frequent assessments helps identify potential issues before they escalate. Focus on the following:

- Check for leaks in hoses and connections.

- Inspect fluid levels and quality.

- Examine the condition of seals and gaskets.

Fluid Management

Maintaining the right fluid levels and quality is vital for the hydraulic system’s functionality. Key practices include:

- Regularly replace hydraulic fluid as recommended.

- Use the appropriate type of fluid for your system.

- Monitor for contamination and address any issues immediately.

Implementing these essential practices will contribute significantly to the reliability and efficiency of hydraulic operations.

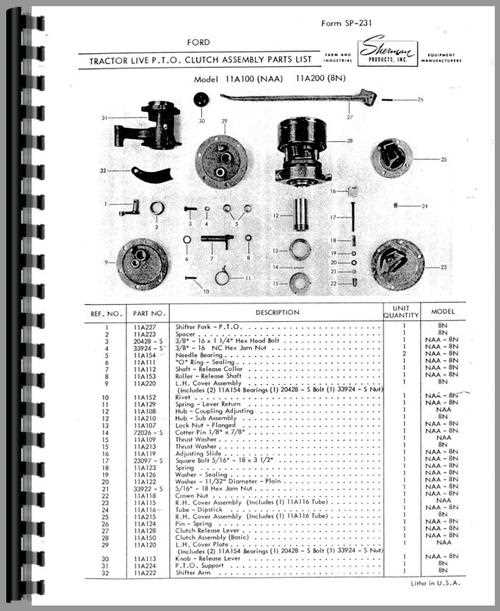

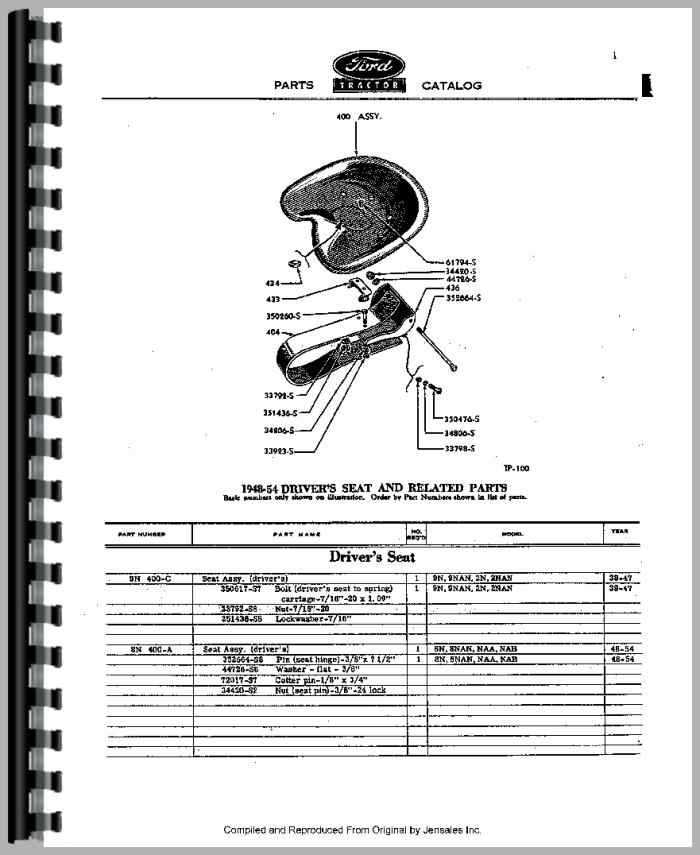

Parts Replacement Procedures

This section outlines the essential steps for effectively substituting components within the machinery. Proper execution of these procedures ensures optimal functionality and longevity of the equipment. Understanding each stage is crucial for achieving successful outcomes and maintaining performance standards.

Preparation and Safety Measures

Before initiating any component substitution, it’s vital to gather the necessary tools and materials. Ensure that the work area is clean and well-lit. Safety gear, such as gloves and goggles, should be worn to prevent injuries. Always consult the specifications for the parts involved to confirm compatibility and proper handling guidelines.

Step-by-Step Replacement Process

Begin by disconnecting any power sources to prevent accidental activation. Carefully remove the faulty part by loosening any fasteners or clamps. Take note of the orientation and connections to facilitate correct installation of the new component. Position the replacement part, ensuring it aligns with the assembly specifications, and secure it in place. Finally, recheck all connections and restore power to test the functionality of the newly installed part.

Safety Precautions While Repairing

When working on machinery, ensuring a secure environment is crucial to avoid accidents and injuries. Adopting safety measures not only protects the individual performing the tasks but also safeguards the equipment and surrounding area. It is essential to follow guidelines that promote a safe working atmosphere, enabling efficient and worry-free maintenance.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE). This includes gloves, safety goggles, and steel-toed boots. The right gear minimizes the risk of injury from sharp objects, chemical exposure, and falling debris. Additionally, consider using ear protection if operating loud machinery.

Work Environment Organization

Maintain a clean and organized workspace. Remove any unnecessary items that could create tripping hazards. Ensure that tools and equipment are stored properly and within reach. A well-structured environment reduces the likelihood of accidents and allows for a more focused approach to the task at hand.

Remember: Prioritizing safety is not just a guideline; it is an essential aspect of any maintenance process. Being proactive can prevent mishaps and promote a productive work atmosphere.

Restoration Projects and Upgrades

Revitalizing vintage machinery can be an incredibly rewarding endeavor, allowing enthusiasts to breathe new life into classic models while enhancing their functionality. This section explores various approaches to restoration and improvement, focusing on both aesthetic upgrades and performance enhancements.

Enhancing Performance

One of the primary goals during a restoration is to boost the overall efficiency and reliability of the equipment. Upgrading components such as the ignition system, fuel delivery, and exhaust can lead to significant improvements. Additionally, installing modern filtration systems can enhance longevity and maintain optimal performance, ensuring that the machinery operates smoothly for years to come.

Aesthetic Improvements

While functionality is crucial, the visual appeal of classic equipment should not be overlooked. Restoring the exterior with fresh paint, new decals, and polished finishes can transform the appearance dramatically. Moreover, upgrading seats or adding custom features can create a more comfortable experience for operators, making the machinery not only beautiful but also more enjoyable to use.

Ultimately, each project presents a unique opportunity to blend history with modern technology, creating a piece that is both a tribute to the past and a functional asset for the future.

Finding Genuine Parts and Resources

Locating authentic components and reliable information sources is essential for maintaining and enhancing the performance of your machinery. Ensuring that you have access to quality parts not only prolongs the life of your equipment but also helps in achieving optimal functionality.

Start by exploring official distributors and authorized dealers who specialize in equipment supplies. These sources typically offer original parts that match the specifications of your machinery, guaranteeing compatibility and durability. Additionally, visiting manufacturer websites can provide valuable insights into available components and recommended suppliers.

Online forums and communities dedicated to machinery enthusiasts are excellent platforms for exchanging knowledge and sourcing tips. Engaging with fellow users can lead to recommendations for trustworthy suppliers and hard-to-find parts. Furthermore, consider utilizing reputable marketplaces that focus on agricultural or industrial equipment, as they often feature a range of genuine components.

Lastly, do not overlook local salvage yards or specialty shops. These venues can be treasure troves for rare parts and often provide the opportunity to connect with knowledgeable individuals who understand the intricacies of the machinery. By tapping into these resources, you can ensure that your equipment remains in peak condition for years to come.