Essential Guide to Free Singer Sewing Machine Repair Manuals

Understanding the intricacies of your crafting apparatus can significantly enhance its longevity and performance. This section aims to equip you with essential knowledge and techniques necessary for effective upkeep of your favorite tools. By familiarizing yourself with common issues and their solutions, you can ensure seamless operation and extend the life of your gear.

Regular maintenance is crucial for optimal functionality. Often, simple adjustments or cleanings can resolve minor complications that may arise during use. Learning to identify these problems early can save both time and resources, allowing you to focus on what you love most–creating.

In this informative resource, you’ll find a wealth of insights and step-by-step instructions tailored to various models. With a little patience and dedication, you’ll soon be able to tackle typical challenges with confidence. Embrace the journey of becoming a skilled caretaker of your tools and elevate your crafting experience to new heights.

Understanding Free Singer Sewing Machines

Exploring the intricacies of vintage stitching devices reveals a rich tapestry of innovation and craftsmanship. These remarkable tools have a storied history, captivating enthusiasts and hobbyists alike. Their design not only showcases functionality but also reflects the artistry involved in creating garments and crafts.

Historical Significance

The origins of these devices trace back to a time when home textile creation became accessible to many. The evolution of these tools marked a shift in domestic life, empowering individuals to express their creativity through fabric manipulation. Collectors often seek out these models, appreciating their engineering and the nostalgia they evoke.

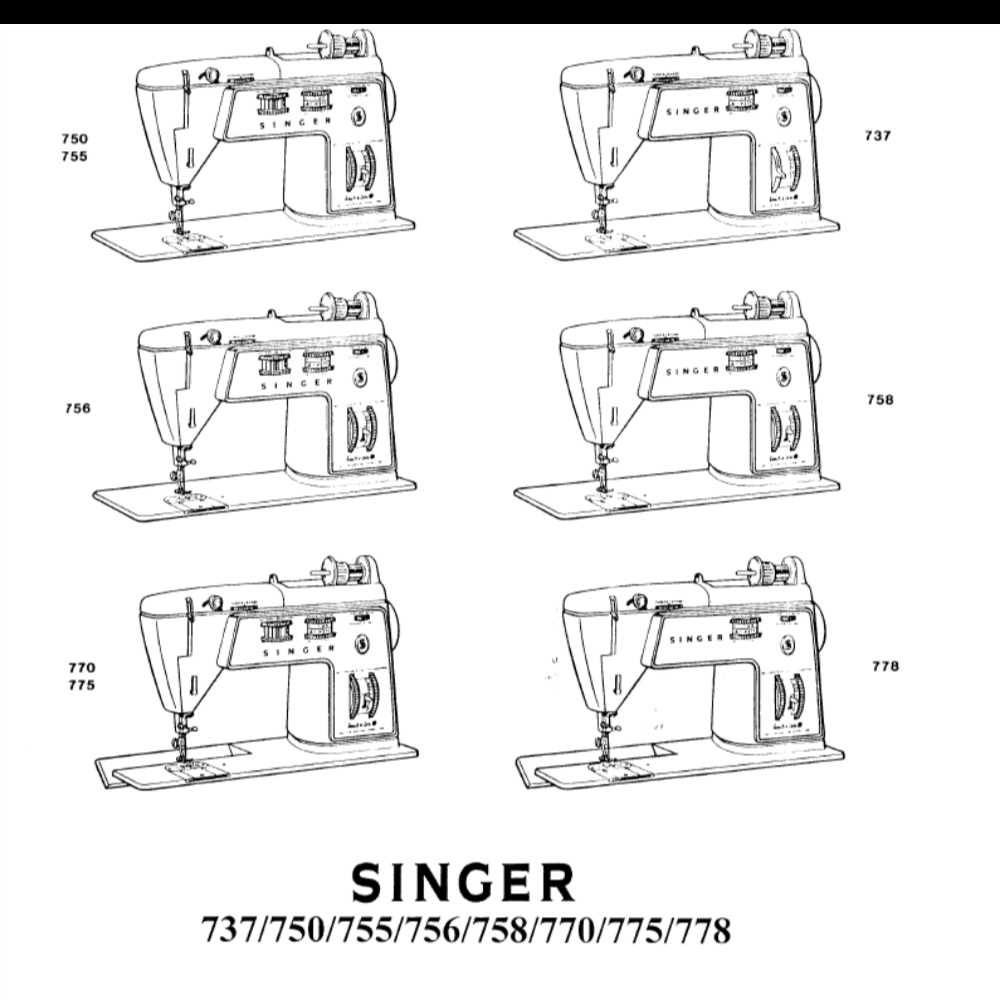

Common Features

Many of these appliances boast unique characteristics that set them apart from modern counterparts. Notable elements include robust construction, straightforward operation, and various stitch options that cater to different needs. Understanding these features can enhance the user experience, making it easier to appreciate the beauty of craftsmanship involved.

In summary, a deeper understanding of these devices illuminates not just their mechanical functions but also their role in cultural history and personal expression. Engaging with such tools offers a journey through time, revealing the artistry behind everyday practices.

Common Issues with Singer Machines

Many individuals encounter various challenges when working with their fabric crafting tools. Understanding these common problems can help users troubleshoot effectively and maintain optimal performance.

Frequent Challenges

- Thread Bunching: This often occurs when the threading is incorrect or the tension is not properly adjusted.

- Skipping Stitches: A common issue that may arise due to a dull needle, incorrect needle type, or tension misconfiguration.

- Fabric Jamming: This can happen when the material is too thick or improperly fed, causing interruptions in the workflow.

- Unusual Noises: Grinding or squeaking sounds can indicate a need for lubrication or potential mechanical issues.

- Bobbin Problems: Issues with winding or inserting the bobbin can lead to inconsistent stitching results.

Prevention and Solutions

- Regular Maintenance: Keep the equipment clean and lubricated to ensure smooth operation.

- Use the Right Needle: Always select a needle that suits the fabric type to prevent skipping.

- Check Thread Quality: Ensure high-quality thread to minimize tangling and breakage.

- Adjust Tension: Experiment with tension settings to achieve the desired stitch quality.

- Follow the User Guide: Consult the instruction booklet for specific guidance and troubleshooting tips.

Tools Needed for Repairing Machines

Successful restoration of any mechanical device requires a set of essential instruments that facilitate the process. These tools not only ensure efficiency but also help in achieving precision during various tasks. Understanding which items are crucial can significantly enhance the overall experience of maintaining and bringing life back to your equipment.

Basic Hand Tools: A reliable set of screwdrivers, pliers, and wrenches are indispensable for opening panels and adjusting components. Each tool should be well-sized to fit the screws and nuts of the device, ensuring a secure grip without causing damage.

Measuring Instruments: To achieve accuracy in repairs, measuring devices such as calipers and rulers are vital. These help in assessing dimensions and ensuring that parts are correctly aligned, which is critical for optimal performance.

Lubricants and Cleaning Supplies: Proper maintenance often involves cleaning and lubrication. Having appropriate oils and cleaners can prevent wear and tear, extending the life of the equipment. Always choose products that are specifically designed for the type of device you are working with.

Safety Gear: Don’t overlook personal safety when engaging in maintenance tasks. Protective eyewear and gloves can shield you from potential hazards, making the work environment safer and more comfortable.

Equipped with these fundamental tools, you can approach any task with confidence, ensuring that the restoration process is smooth and effective.

Step-by-Step Repair Procedures

This section provides a comprehensive guide to troubleshooting and fixing common issues that can arise with your equipment. By following a systematic approach, you can effectively address problems and restore functionality. Each step is designed to be clear and concise, ensuring that even those with minimal experience can successfully navigate the process.

1. Identify the Problem: Begin by observing the symptoms. Is there unusual noise, skipping stitches, or inconsistent performance? Take note of any specific behaviors that can help pinpoint the issue.

2. Gather Necessary Tools: Before starting any work, collect the tools required for the task. Common items may include screwdrivers, pliers, and cleaning supplies. Having everything at hand will streamline the process.

3. Disassemble the Unit: Carefully remove any panels or covers to access the internal components. Ensure you keep track of screws and parts to avoid confusion during reassembly.

4. Clean Components: Dust and debris can hinder performance. Use a soft brush or cloth to clean moving parts, ensuring that lubricants and oils are also reapplied where needed.

5. Inspect for Damage: Look for any signs of wear, such as frayed wires or broken parts. If damage is found, determine if it can be repaired or if a replacement is necessary.

6. Reassemble and Test: Once all repairs and cleaning are complete, carefully reassemble the unit. Power it on and conduct a test to ensure that everything is functioning as expected.

7. Document Findings: Keep a record of the issues encountered and the steps taken to resolve them. This information can be invaluable for future reference or for others facing similar challenges.

Following these procedures will not only enhance your understanding of the equipment but also empower you to tackle issues confidently. Remember, patience and attention to detail are key to successful maintenance.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment involves regular attention and care. Implementing simple practices can significantly extend the lifespan of your tool, enhancing its efficiency and reliability. Below are essential suggestions to keep your device in top condition.

Regular Cleaning

Dust and debris can accumulate over time, affecting the performance of your apparatus. Establish a routine for cleaning, which includes wiping down surfaces and removing any lint or residue. Use a soft brush or cloth to access hard-to-reach areas, ensuring that all components remain unobstructed and functional.

Proper Lubrication

Maintaining adequate lubrication is vital for smooth operation. Utilize high-quality oil specifically designed for your type of equipment. Apply it sparingly to moving parts, following the manufacturer’s guidelines. This practice not only prevents wear and tear but also enhances overall efficiency, allowing for seamless performance.

Where to Find Repair Manuals

Locating guides for fixing various devices can be essential for maintaining their functionality. Several resources exist that cater to individuals seeking detailed instructions and troubleshooting tips for their equipment. By exploring both online and offline avenues, users can access a wealth of information to assist them in their repair endeavors.

| Source | Description |

|---|---|

| Manufacturer Websites | Many brands offer downloadable resources directly on their sites, ensuring you have access to the most accurate information. |

| Online Forums | Communities dedicated to specific brands or types of devices often share valuable insights and links to documentation. |

| YouTube | Video tutorials provide step-by-step guidance, often accompanied by visuals that make the process easier to follow. |

| Local Libraries | Many libraries have physical copies of instructional literature or can help you find relevant resources through interlibrary loans. |

| Retailers | Some stores that sell these devices also carry manuals and offer advice on repairs, either in-person or through their websites. |

Online Resources for Troubleshooting

In today’s digital age, a wealth of information is readily available online for addressing various issues that may arise with your equipment. Whether you’re dealing with performance hiccups or seeking general advice, numerous platforms offer valuable insights and solutions. Accessing these resources can empower users to resolve problems efficiently and enhance their understanding of their tools.

Video Tutorials

One of the most effective ways to learn about troubleshooting is through visual aids. Numerous websites host video guides that demonstrate common issues and their solutions in real-time. These resources can provide step-by-step instructions, making it easier to follow along and implement fixes.

Community Forums

Online forums serve as a hub for enthusiasts and professionals alike, allowing users to share experiences and advice. Participating in these communities can help you find answers to specific questions or connect with others who have encountered similar challenges. You can often find unique tips and tricks that are not covered in official documentation.

| Resource Type | Description | Example Platforms |

|---|---|---|

| Video Tutorials | Step-by-step guides demonstrating solutions | YouTube, Vimeo |

| Community Forums | Discussion platforms for advice and tips | Reddit, specialized forums |

| Blogs and Articles | Written guides and troubleshooting tips | Personal blogs, DIY websites |

| Official Websites | Manufacturer resources and documentation | Brand websites |

Community Forums for Sewing Enthusiasts

Online platforms dedicated to enthusiasts of needlework provide a vibrant space for sharing experiences, tips, and advice. These forums foster a sense of community where individuals can connect, exchange knowledge, and support one another in their crafting journeys. Whether you are a novice or an experienced artisan, these resources can be invaluable for enhancing your skills and expanding your creative horizons.

Participating in discussions can lead to discovering innovative techniques and troubleshooting common challenges. Many forums also feature sections for showcasing personal projects, which can inspire others and provide constructive feedback.

| Forum Name | Description | Website Link |

|---|---|---|

| The Craft Forum | A community for various crafting enthusiasts to share ideas and resources. | Visit |

| Creative Corner | A space for creators to discuss techniques and showcase their latest projects. | Visit |

| Stitch Talk | A platform dedicated to discussions around various stitching methods and tips. | Visit |

Engaging in these discussions not only enhances your expertise but also builds lasting connections within the crafting community. Whether seeking advice or offering your own insights, these platforms are essential for anyone passionate about their craft.

Importance of Regular Servicing

Consistent maintenance is crucial for the longevity and optimal performance of any intricate device. Without regular attention, even the most reliable equipment can suffer from decreased efficiency, leading to potential breakdowns and costly repairs. Ensuring that a thorough check-up is part of your routine can prevent minor issues from escalating into major problems.

Benefits of Routine Maintenance

Engaging in regular upkeep offers numerous advantages, including enhanced performance, extended lifespan, and improved reliability. It not only allows users to maintain their equipment in top condition but also provides peace of mind knowing that everything is functioning as it should.

Key Maintenance Practices

| Practice | Frequency | Benefits |

|---|---|---|

| Cleaning | After every use | Prevents dust accumulation and ensures smooth operation |

| Lubrication | Monthly | Reduces friction and wear on moving parts |

| Inspection | Quarterly | Identifies potential issues before they become serious |

Incorporating these practices into your schedule can lead to a significant improvement in your device’s performance, ensuring it continues to serve you well for years to come.

Upgrading Parts for Better Performance

Enhancing the functionality of your device can lead to significant improvements in efficiency and output quality. By selecting and replacing certain components with superior alternatives, you can achieve a smoother operation and extended lifespan. This process not only boosts performance but also helps in maintaining consistent results over time.

| Component | Benefits of Upgrading | Recommended Upgrade Options |

|---|---|---|

| Needle | Improved precision and reduced fabric damage | High-quality titanium or specialty needles |

| Foot | Better fabric handling and versatility | Walking foot, zipper foot, or specialty feet |

| Bobbin | Enhanced thread tension and fewer jams | Metal or larger capacity bobbins |

| Motor | Increased speed and reliability | High-torque or upgraded motors |

| Belts | Smoother operation and reduced noise | Durable, high-performance belts |

By investing in these upgrades, users can experience a marked difference in their device’s performance, leading to more enjoyable and efficient outcomes in their projects.

Safety Precautions During Repairs

Ensuring personal safety and preventing damage while working on devices is crucial for any enthusiast or technician. Adopting the right precautions can significantly reduce the risk of accidents and enhance the overall experience of maintenance tasks. This section outlines essential safety measures to consider before and during the servicing process.

Essential Safety Measures

| Precaution | Description |

|---|---|

| Unplug the Device | Always disconnect the power source before starting any work to prevent electrical shocks. |

| Wear Protective Gear | Use gloves and safety goggles to protect against sharp edges and debris. |

| Organize Your Workspace | A tidy area reduces the chance of accidents and helps you find tools easily. |

| Follow Instructions | Adhere to guidelines and procedures specific to the device for safe handling. |

| Handle Tools Carefully | Use tools appropriately to avoid injuries and damage to components. |

Post-Repair Checklist

After completing the maintenance, take a moment to review your work. Ensure that all components are properly reassembled and that there are no tools left behind. Double-check that the device is safe to use by verifying that all connections are secure and the area is clean. Following these steps helps guarantee a safe and efficient operation once the device is powered back on.