Comprehensive Guide to Repairing the Brother SQ9185

Understanding the intricacies of machinery is crucial for any user aiming to enhance performance and longevity. A well-documented resource can serve as a vital tool for troubleshooting and ensuring the optimal functionality of your device. This guide provides insights into common challenges and effective solutions that can be applied to various models.

With a focus on practical techniques and easy-to-follow instructions, this resource aims to empower users by demystifying the maintenance process. Whether you’re encountering minor issues or more significant malfunctions, having a clear set of guidelines can make all the difference in restoring your equipment to peak condition.

By familiarizing yourself with the essential components and operational nuances, you can proactively address potential problems before they escalate. This approach not only saves time but also contributes to a more efficient and enjoyable experience with your machinery.

Overview of Brother SQ9185 Features

This section provides an insightful look into the various functionalities and characteristics of the sewing machine model in question. Designed for both novice and experienced users, it combines advanced technology with user-friendly features to enhance the sewing experience.

Key Functionalities

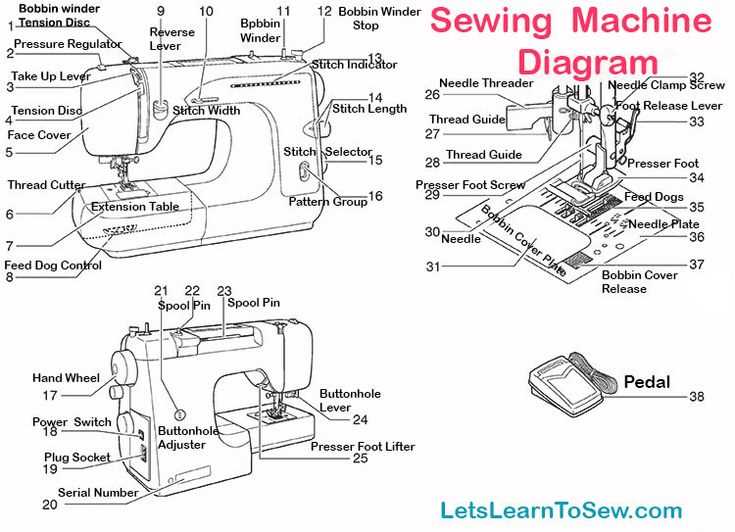

The sewing device is equipped with a multitude of features that cater to diverse sewing needs. From basic stitching to complex designs, it offers versatility and convenience. Key functionalities include automatic threading, multiple stitch options, and an intuitive control panel, making it accessible for everyone.

Technical Specifications

| Feature | Description |

|---|---|

| Stitch Options | Over 100 built-in stitches for various applications |

| Automatic Threading | Simplifies the threading process to save time |

| LCD Display | User-friendly interface for easy navigation |

| Free Arm Design | Allows for easy sewing of sleeves and pants |

| Foot Pedal Control | Provides hands-free operation for improved efficiency |

With its combination of practicality and innovation, this machine stands out as an ideal choice for various sewing projects, ensuring both quality and ease of use.

Common Issues with Brother SQ9185

Understanding the frequent challenges faced by users can significantly enhance the experience and performance of your stitching device. Many enthusiasts encounter similar problems, which can often be resolved with basic troubleshooting techniques. This section highlights typical malfunctions and provides insights into their possible causes and solutions.

Threading Problems

One of the most prevalent issues involves the threading mechanism. Incorrect threading can lead to jams or uneven stitching. Users should ensure that the upper and lower threads are properly threaded according to the guidelines provided in the instructions. Check for any tangles or knots that may be obstructing the thread path, and make sure that the tension settings are appropriately adjusted.

Needle Issues

Another common concern is related to the needle. A bent or dull needle can cause skipped stitches or fabric snags. It is advisable to regularly inspect and replace the needle as needed. Additionally, using the correct needle type for the specific fabric is crucial for optimal performance. If the device is making unusual noises, it may also indicate that the needle needs to be changed.

Tools Needed for Repairs

When addressing issues with your device, having the right instruments is essential for a successful troubleshooting process. This section outlines the necessary equipment to ensure you can effectively tackle any challenges that arise during maintenance.

Essential Instruments

First and foremost, a reliable set of screwdrivers is crucial. Different sizes and types, particularly Phillips and flathead, will allow you to access various components with ease. Additionally, a pair of pliers can assist in gripping and manipulating small parts, while tweezers can be invaluable for handling delicate components.

Additional Supplies

Incorporating a multimeter into your toolkit can help diagnose electrical issues, allowing for precise measurements of voltage and continuity. Furthermore, having a work mat will provide a safe and organized space to prevent any loss of small pieces during disassembly. Finally, consider using cleaning supplies such as lint-free cloths and isopropyl alcohol to maintain the integrity of sensitive surfaces.

Step-by-Step Repair Instructions

This section provides a detailed guide to assist you in troubleshooting and fixing common issues with your device. Following these structured steps will help ensure that you can efficiently address problems and restore functionality. Each phase is designed to be straightforward, allowing users of all skill levels to follow along with ease.

Step 1: Preparation

Before beginning, gather all necessary tools and materials. Ensure you have a clean workspace to avoid misplacing components. Disconnect the device from any power source to prevent accidents.

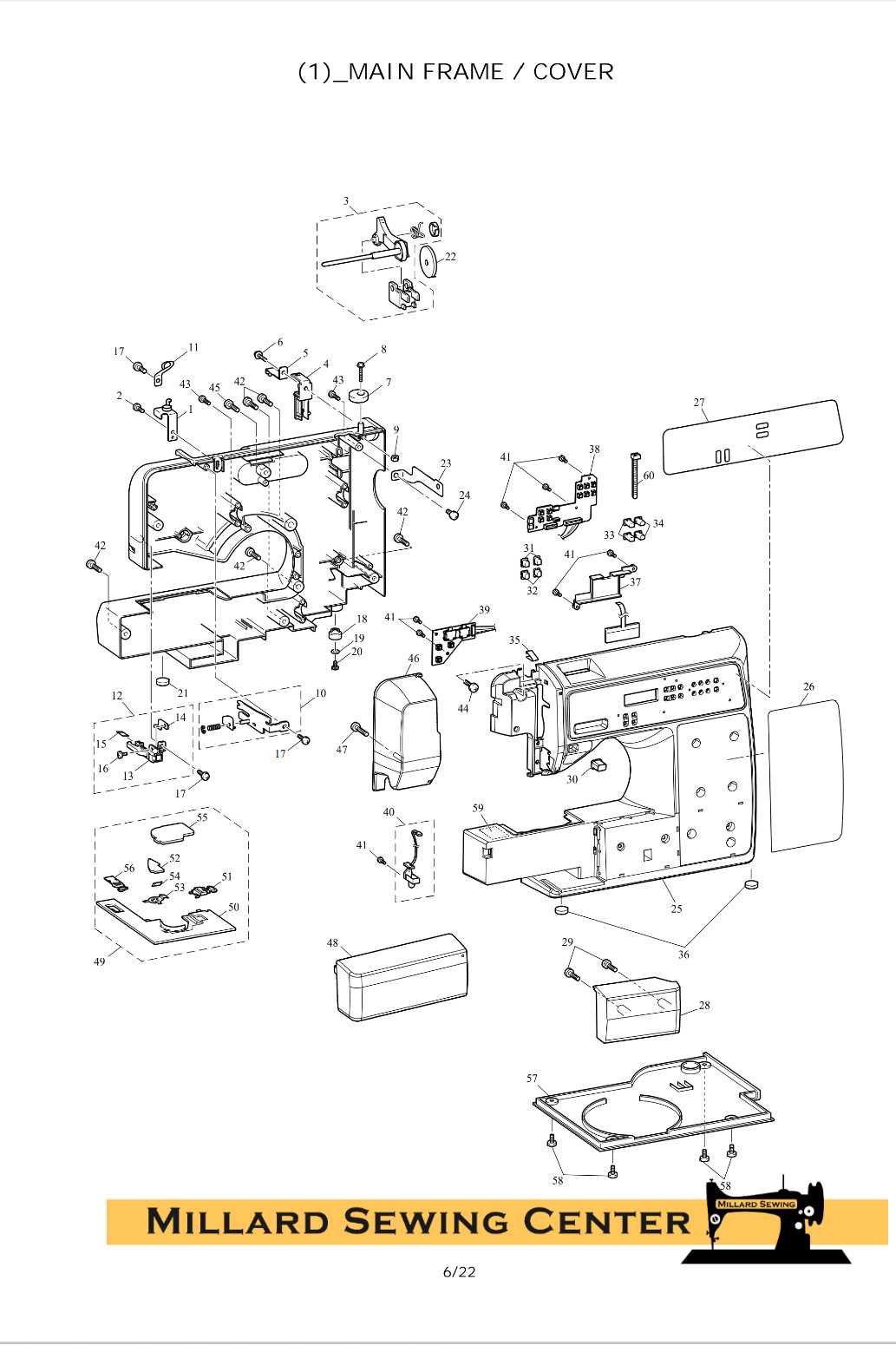

Step 2: Disassembly

Carefully open the casing, using appropriate tools to avoid damaging clips or screws. Take note of the location and type of fasteners for reassembly later. Keep small parts organized to simplify the process.

Step 3: Inspection

Examine internal components for any visible signs of wear or damage. Look for loose connections, frayed wires, or burnt elements. Document any irregularities you find to guide your repair efforts.

Step 4: Component Replacement

If a part needs to be swapped out, ensure you source a compatible replacement. Carefully remove the faulty component and install the new one, taking care to secure it properly. Double-check connections for a solid fit.

Step 5: Reassembly

Once all repairs are complete, carefully put the casing back together. Make sure to replace all screws and clips in their original positions. A thorough reassembly is crucial for the device’s longevity and performance.

Step 6: Testing

Reconnect the power source and test the device to confirm that issues have been resolved. Monitor its performance and ensure all functions operate as expected. If problems persist, revisit previous steps for further diagnosis.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for ensuring the prolonged functionality of your device. By following a few simple guidelines, you can significantly enhance its lifespan and performance, preventing unnecessary issues and costly replacements.

1. Regular Cleaning: Dust and debris can accumulate and interfere with performance. Periodically clean the exterior and interior components using a soft cloth and appropriate cleaning tools. Avoid using harsh chemicals that could damage surfaces.

2. Optimal Storage: When not in use, store the equipment in a dry, cool place to avoid exposure to moisture and extreme temperatures. Utilizing protective covers can also prevent dust buildup.

3. Routine Inspections: Schedule regular checks to identify wear and tear. Look for any loose parts or irregularities that may indicate underlying issues. Early detection can save you time and resources.

4. Use Compatible Accessories: Always opt for recommended attachments and consumables. Using incompatible parts can lead to malfunctions and reduce the overall efficiency of the device.

5. Follow Usage Guidelines: Adhere to the manufacturer’s instructions regarding operation and handling. Avoid overloading the device beyond its specified limits to prevent undue stress on its components.

Implementing these maintenance practices will not only ensure smooth operation but also prolong the life of your equipment, allowing you to maximize your investment.

Troubleshooting Error Messages

When operating a device, encountering error messages can be a common issue that disrupts functionality. Understanding these alerts is crucial for effective problem resolution. This section will guide you through interpreting various notifications and provide steps for troubleshooting to restore optimal performance.

Common Error Indicators

Error messages often display codes or brief descriptions that point to specific malfunctions. Recognizing these indicators is the first step in diagnosing the issue. Take note of any numerical codes or unique phrases, as they can significantly aid in pinpointing the problem.

Step-by-Step Troubleshooting

1. Identify the Error: Begin by noting the exact wording of the error message. Refer to your device’s documentation for insights into what the message signifies.

2. Perform Basic Checks: Ensure that all connections are secure and that the device is properly powered. Sometimes, a loose cable or insufficient power supply can trigger errors.

3. Reset the Device: Many issues can be resolved by performing a simple reset. Turn the device off, wait for a moment, and then power it back on.

4. Consult the Online Resources: If the error persists, explore online forums or support websites. Users often share their experiences and solutions, which can provide valuable insights.

When to Seek Professional Help

If troubleshooting steps do not resolve the error, it may be time to consult a professional. Persistent issues could indicate deeper mechanical or software problems that require expert attention.

How to Replace Key Components

When dealing with malfunctioning devices, knowing how to swap out essential parts can significantly enhance performance and longevity. This guide will help you navigate the process of replacing critical components, ensuring your equipment operates efficiently once again.

Identifying the Components

Before starting the replacement process, it’s vital to recognize which parts need attention. Common components that may require replacement include:

- Ink cartridges

- Drum units

- Fuser assemblies

- Print heads

Step-by-Step Replacement Process

Follow these steps to effectively replace the identified components:

- Turn off the device and unplug it from the power source.

- Carefully open the access panel to expose the internal parts.

- Remove the faulty component by following the manufacturer’s instructions.

- Insert the new part, ensuring it is securely fitted into place.

- Close the access panel and reconnect the power supply.

- Perform a test print to verify successful installation.

By following these guidelines, you can efficiently replace crucial parts and restore functionality to your equipment.

Cleaning Your Sewing Machine

Maintaining the cleanliness of your sewing device is essential for its optimal performance and longevity. Regular cleaning not only helps prevent dust and lint buildup but also ensures smooth operation and precision in your projects. A well-cared-for machine will produce better stitches and reduce the risk of malfunctions.

Step 1: Gather Your Supplies

Step 2: Disconnect and Access

Always unplug the machine before beginning any cleaning tasks. Remove the needle and presser foot, and then open the area where the bobbin and feed dogs are located. This access point is often where dust accumulates the most.

Step 3: Brush Away Debris

Using a soft brush, gently remove lint and threads from the bobbin area, feed dogs, and other accessible parts. Be careful not to damage any delicate components while doing this.

Step 4: Wipe and Oil

With a lint-free cloth, wipe down the exterior and accessible interior parts of the machine. After cleaning, apply a few drops of sewing machine oil to the designated spots as indicated in the user guide. This lubrication helps maintain smooth operation.

Step 5: Regular Maintenance

Incorporate cleaning into your routine, ideally after every few sewing projects. Regular maintenance will enhance performance and prolong the life of your machine, ensuring that it remains a reliable tool in your crafting endeavors.

Understanding the User Manual

Comprehending the documentation provided with your device is crucial for optimal usage and maintenance. This resource serves as a guide, offering insights into the functionalities, troubleshooting steps, and essential care procedures. By familiarizing yourself with this information, you can enhance your experience and extend the longevity of your equipment.

Key Sections of the Documentation

The content is typically divided into various sections, each addressing different aspects of the product. Operational instructions provide detailed information on how to effectively use the device, while maintenance guidelines outline procedures for regular upkeep to ensure it operates efficiently.

Navigating Troubleshooting Information

Encountering issues is a common part of any user experience. The troubleshooting section is invaluable, as it presents common problems and their corresponding solutions. Identifying symptoms and following the suggested steps can often resolve issues quickly, saving time and resources.

Where to Find Replacement Parts

Finding the right components for your device can be a straightforward process if you know where to look. Numerous resources are available to help you locate the necessary items to ensure your equipment operates efficiently.

- Official Retailers: Check authorized dealers or the manufacturer’s website for genuine parts. This ensures compatibility and reliability.

- Online Marketplaces: Websites like Amazon, eBay, and specialized electronic component sites often have a wide range of options. Read reviews to gauge quality.

- Local Repair Shops: Many repair centers keep a stock of common parts. Visiting them can provide access to components and professional advice.

- Surplus Stores: These shops can be treasure troves for hard-to-find items. Explore local options for unique finds.

- Community Forums: Online forums and groups dedicated to your specific device can offer insights on where to source parts. Members often share links and recommendations.

By utilizing these resources, you can efficiently locate the components you need to keep your device functioning optimally.

FAQs about Brother SQ9185 Repairs

This section addresses common inquiries regarding maintenance and troubleshooting for your sewing device. Whether you are facing minor issues or looking for guidance on more complex problems, these questions aim to provide clarity and support for users.

What should I do if my machine is not powering on?

First, check if the power cord is securely plugged into both the machine and the outlet. Ensure the outlet is functioning by testing it with another device. If everything seems fine but the machine still does not turn on, consider inspecting the power switch for any visible damage.

How can I fix threading problems?

If you are experiencing issues with the thread not feeding correctly, rethread the upper and bobbin threads. Refer to your device’s threading guide to ensure proper setup. Additionally, check for any obstructions in the thread path that may be causing the issue.

What maintenance tasks should I perform regularly?

Routine cleaning is essential. Remove lint from the feed dogs and bobbin area, and oil the machine as specified in the user guide. Regular maintenance helps prevent larger issues and keeps your device running smoothly.

How can I resolve tension problems?

Tension issues can often be adjusted using the tension dial. Experiment with different settings while testing on scrap fabric. If problems persist, inspect the thread quality and ensure it is appropriate for your projects.

When should I seek professional assistance?

If you encounter persistent issues that you cannot resolve through troubleshooting, it may be time to consult a qualified technician. Look for signs of mechanical failure or if you are unsure how to proceed with a specific problem.