Toro Lawn Mower Repair Guide

When it comes to maintaining outdoor machinery, having a comprehensive resource is essential. Whether you’re a seasoned user or new to handling such tools, understanding their functionality and upkeep can greatly enhance their performance and longevity.

Essential knowledge about troubleshooting common issues and performing routine care can save time and resources. By familiarizing yourself with the various components and operations of these devices, you’ll be better equipped to tackle any challenges that arise.

In this section, we will delve into best practices, tips, and detailed procedures that will assist you in effectively managing your equipment. From regular inspections to step-by-step guidance on handling typical problems, this resource aims to empower you in your maintenance journey.

When it comes to maintaining grass-cutting equipment, several typical problems can arise, impacting performance and efficiency. Understanding these challenges can help owners troubleshoot effectively and ensure their machinery operates smoothly.

Engine Troubles

One of the most frequent complications involves the engine. Issues may stem from various factors, including:

- Insufficient fuel supply

- Clogged air filters

- Old or contaminated oil

- Defective spark plugs

Cutting Mechanism Failures

The cutting system is vital for optimal performance. Common failures include:

- Dull or damaged blades

- Incorrect blade height adjustment

- Debris buildup around the cutting area

- Drive belt issues

Regular inspections and proper maintenance can help mitigate these issues, ensuring efficient operation and longevity of the equipment.

Essential Tools for Repairing

Having the right instruments at your disposal can significantly enhance the efficiency of any maintenance task. Whether you are tackling minor adjustments or major fixes, equipping yourself with the necessary tools is crucial for success.

Here are some fundamental instruments you should consider:

- Socket Wrench Set: Versatile for loosening and tightening bolts.

- Screwdriver Set: A variety of types and sizes ensures you can handle different fasteners.

- Plier Set: Useful for gripping, twisting, and cutting wires or small components.

- Torque Wrench: Ensures fasteners are tightened to the manufacturer’s specifications.

- Multimeter: Essential for diagnosing electrical issues and testing circuits.

- Oil Can: For applying lubricants to moving parts to prevent wear and tear.

- Safety Goggles: Protects your eyes from debris while working.

- Gloves: Keeps hands safe and clean during the process.

Utilizing these essential tools will facilitate efficient handling of various tasks and promote longevity in the equipment’s performance. Proper preparation and the right equipment can make all the difference in achieving effective outcomes.

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. Following systematic procedures can help you maintain optimal performance and prevent potential issues. This section outlines key tasks that should be performed periodically to keep your machine running smoothly.

1. Cleaning the Exterior: Begin by clearing any debris and dirt from the surface. Use a soft brush or cloth to wipe down components, ensuring that air vents remain unobstructed. Regular cleaning not only improves appearance but also enhances functionality.

2. Checking and Replacing the Blades: Inspect the cutting edges for signs of wear or damage. Dull blades can lead to poor performance and uneven cutting. If necessary, sharpen or replace them according to the manufacturer’s recommendations.

3. Changing the Oil: Periodic oil changes are crucial for maintaining engine health. Drain the old oil and replace it with fresh lubricant, following the specified grade. Regular changes help prevent engine wear and ensure efficient operation.

4. Inspecting the Fuel System: Examine fuel lines for leaks or cracks. Replace any damaged components and ensure that the fuel filter is clean. Fresh fuel should be used, as stale fuel can cause starting issues and performance problems.

5. Air Filter Maintenance: Regularly check the air filter for dirt and debris. A clean filter is vital for proper airflow and engine performance. If the filter appears clogged, replace it to maintain optimal efficiency.

By adhering to these maintenance steps, you can significantly extend the life of your equipment and ensure reliable operation throughout its use.

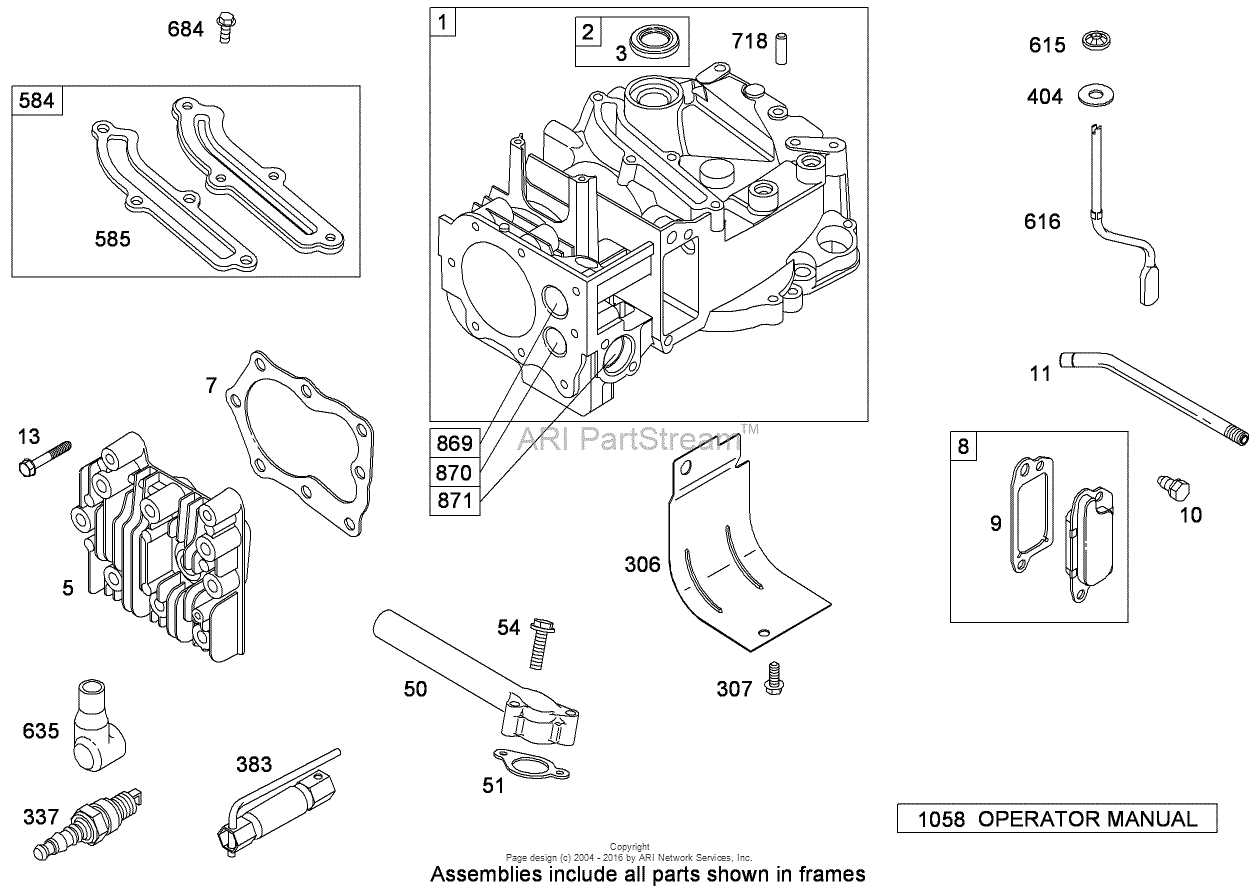

Identifying Engine Problems

Diagnosing issues within a power unit requires careful observation and systematic evaluation. Common signs of malfunction may manifest as unusual sounds, performance dips, or difficulty in starting. Recognizing these indicators early can prevent further complications and ensure efficient operation.

One key symptom to watch for is excessive noise, which may indicate wear or damage within internal components. Additionally, irregular vibrations can suggest misalignment or other mechanical issues. If the engine struggles to start or runs inconsistently, it may point to fuel delivery problems, ignition failures, or air intake obstructions.

Conducting a thorough inspection of the spark plug, fuel filter, and air cleaner can reveal crucial information about the overall health of the unit. Ensuring these elements are clean and functioning properly is essential for optimal performance. Regular maintenance and timely troubleshooting will help maintain the longevity of the power unit.

Blade Sharpening Techniques

Maintaining cutting tools is essential for optimal performance and longevity. Properly sharpened edges not only enhance efficiency but also reduce the strain on the equipment during use. This section covers effective methods for honing and maintaining the sharpness of cutting implements.

Tools Required

- File or sharpening stone

- Bench grinder

- Protective gloves

- Safety goggles

- Clamping tool

Sharpening Steps

- Ensure safety by wearing gloves and goggles.

- Secure the blade using a clamping tool to prevent movement.

- Using a file or sharpening stone, begin at the base of the edge, applying consistent pressure.

- Maintain the original angle of the blade while sharpening to avoid altering its profile.

- Inspect the edge periodically to assess sharpness and adjust your technique as needed.

- After achieving the desired sharpness, clean the blade to remove any metal shavings.

Regular maintenance of cutting edges through these techniques will result in improved cutting performance and extend the lifespan of the equipment.

Fuel System Troubleshooting

Diagnosing issues within the fuel delivery mechanism is essential for ensuring optimal performance. A malfunctioning system can lead to poor operation, difficulty in starting, or complete failure. Understanding the components involved and common problems can aid in effective resolution.

Common Issues

- Clogged Fuel Filter: Blockages can restrict fuel flow, causing the engine to stall.

- Faulty Fuel Pump: A malfunctioning pump may fail to deliver the required fuel pressure.

- Contaminated Fuel: Impurities can lead to operational inefficiencies and engine wear.

- Leaky Fuel Lines: Cracks or breaks can result in loss of pressure and fuel leaks.

Troubleshooting Steps

- Inspect the fuel filter for clogs and replace if necessary.

- Check the fuel pump for proper operation and pressure.

- Examine the fuel for any signs of contamination, replacing it if needed.

- Inspect fuel lines for leaks or damage, repairing or replacing as required.

Electrical System Diagnostics

Understanding the intricacies of an engine’s electrical framework is crucial for effective troubleshooting. This section delves into methods for assessing and diagnosing potential issues within the system, ensuring optimal functionality.

To begin the diagnostic process, follow these steps:

- Check the battery condition:

- Inspect for corrosion on terminals.

- Test the voltage with a multimeter.

- Look for frayed or damaged cables.

- Ensure connections are secure and free of debris.

- Inspect spark plugs for wear.

- Test the ignition coil for functionality.

By systematically evaluating these elements, one can effectively identify and rectify issues within the electrical system, enhancing overall performance.

Replacing Key Components

Maintaining optimal performance in your equipment often requires the replacement of essential parts. Understanding the procedures for swapping out these elements is crucial for ensuring longevity and functionality. This section will guide you through the process of identifying and replacing critical components effectively.

Identifying Components for Replacement

Before proceeding, it’s vital to recognize which parts may need attention. Commonly replaced components include:

- Air filters

- Blades

- Fuel filters

- Belts

- Battery

Steps for Replacement

Follow these steps to replace key parts safely and efficiently:

- Disconnect the power source to prevent accidents.

- Remove any protective coverings to access the components.

- Carefully detach the worn or damaged parts.

- Install the new components, ensuring they are secured properly.

- Replace any coverings and reconnect the power source.

By adhering to these guidelines, you can enhance the performance and reliability of your equipment, ensuring it operates smoothly for years to come.

Safety Precautions for Repairs

When undertaking maintenance tasks on outdoor equipment, it is essential to prioritize safety. Proper precautions can prevent accidents and ensure a smooth process. Understanding the necessary steps to protect yourself is vital before starting any service work.

Below are important guidelines to follow:

| Precaution | Description |

|---|---|

| Personal Protective Equipment (PPE) | Always wear appropriate gear, such as gloves, goggles, and sturdy footwear, to minimize the risk of injury. |

| Work Area | Ensure that the workspace is clean and free of hazards. A clutter-free environment reduces the chance of accidents. |

| Power Source | Disconnect the equipment from any power source before beginning any tasks. This helps prevent unintended activation. |

| Tool Check | Inspect tools before use to ensure they are in good condition. Damaged tools can lead to injuries or equipment damage. |

| Follow Guidelines | Refer to the manufacturer’s guidelines for specific safety instructions related to the equipment being serviced. |

Seasonal Maintenance Tips

Proper upkeep is essential for ensuring optimal performance and longevity of your outdoor equipment. Adopting a seasonal approach to maintenance not only enhances efficiency but also helps in identifying potential issues before they escalate.

Spring Preparation

As the growing season begins, it’s crucial to check all components thoroughly. Start by inspecting the blades for sharpness and any signs of wear. Cleaning the air filter and replacing it if necessary can improve airflow and overall performance. Additionally, ensure that the fuel system is free from contaminants to prevent starting issues.

Fall Shutdown

Before storing your equipment for the winter months, take the time to conduct a comprehensive check-up. Drain any residual fuel to avoid gum buildup in the system. Consider lubricating moving parts to protect against corrosion. Finally, clean the exterior and store it in a dry, protected area to prevent damage from harsh weather conditions.

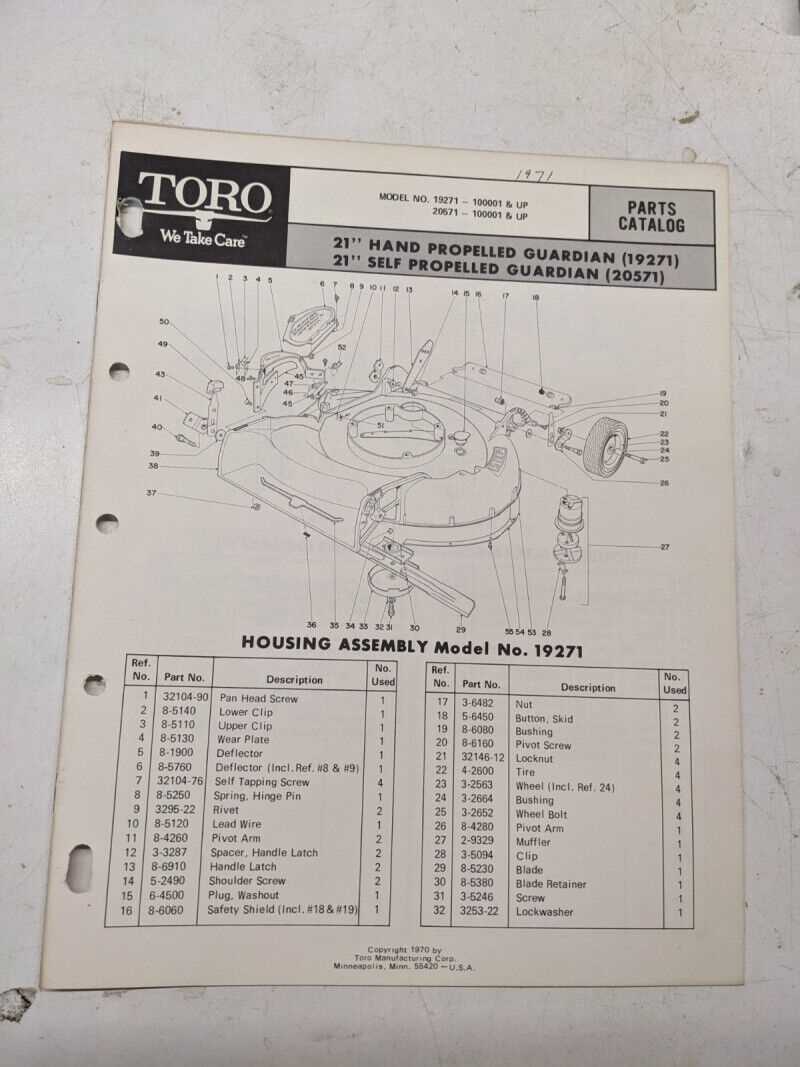

Finding Replacement Parts

Locating suitable components for your equipment is essential to ensure optimal performance and longevity. The process of sourcing these items involves understanding various options available, whether through local retailers or online platforms.

Start by identifying the specific parts needed, which can be achieved by consulting diagrams or specifications associated with your device. This clarity will streamline your search and help in verifying compatibility.

Additionally, consider exploring multiple vendors to compare prices and availability. Many specialized retailers offer a wide range of components, often including original and aftermarket alternatives. This variety allows for more flexibility in budget and quality.

Lastly, take advantage of online resources, such as forums and dedicated websites, where fellow users share insights and recommendations regarding reliable sources for obtaining the necessary parts. These platforms can provide valuable information and support throughout the process.