Comprehensive Guide to John Deere 2305 Repair Manual

In the world of compact agricultural machinery, understanding the intricacies of maintenance is essential for optimal performance. Proper guidance ensures that operators can address issues efficiently, enhancing both the lifespan of the equipment and the quality of work achieved. This resource serves as a vital tool for anyone looking to delve into the specifics of upkeep and problem resolution.

Having access to detailed instructions and insights can make a significant difference when facing mechanical challenges. Whether you are a seasoned professional or a novice user, knowing how to navigate common difficulties can lead to smoother operations and increased productivity. The following sections provide a wealth of knowledge designed to empower you in handling various tasks related to your machinery.

Equipping yourself with the right information can transform potential setbacks into manageable tasks. From routine maintenance checks to diagnosing unusual symptoms, this guide will walk you through essential procedures, enabling you to maintain peak performance effectively. Embrace the opportunity to enhance your skills and ensure your equipment operates at its best.

Overview of John Deere 2305

This section provides a comprehensive understanding of a popular compact utility vehicle known for its versatility and efficiency. Designed to handle various agricultural tasks, it combines robust features with user-friendly operation, making it a preferred choice among both hobbyists and professionals.

Key Features

- Powerful engine for enhanced performance

- Compact size for easy maneuverability in tight spaces

- Hydraulic system that supports a wide range of attachments

- Comfortable operator station with ergonomic controls

Applications

- Landscaping and garden maintenance

- Snow removal and winter services

- Agricultural operations and tillage

- Construction and light-duty excavation tasks

Overall, this machine stands out in the market due to its combination of power, efficiency, and adaptability, making it an essential tool for various outdoor projects.

Common Issues and Solutions

Understanding typical challenges and their resolutions can significantly enhance the maintenance and functionality of compact utility machinery. Below are several frequently encountered problems along with effective solutions.

-

Engine Starting Difficulties:

If the engine struggles to start, consider the following steps:

- Check the fuel level and quality.

- Inspect the battery for proper charge and connections.

- Examine the ignition system, including spark plugs.

-

Poor Performance:

When experiencing reduced power or efficiency, try these solutions:

- Clean or replace the air filter.

- Ensure the fuel system is free from blockages.

- Adjust the throttle linkages if necessary.

-

Hydraulic Issues:

For problems related to hydraulic systems, follow these troubleshooting tips:

- Check hydraulic fluid levels and quality.

- Inspect hoses and fittings for leaks.

- Test the hydraulic pump operation.

-

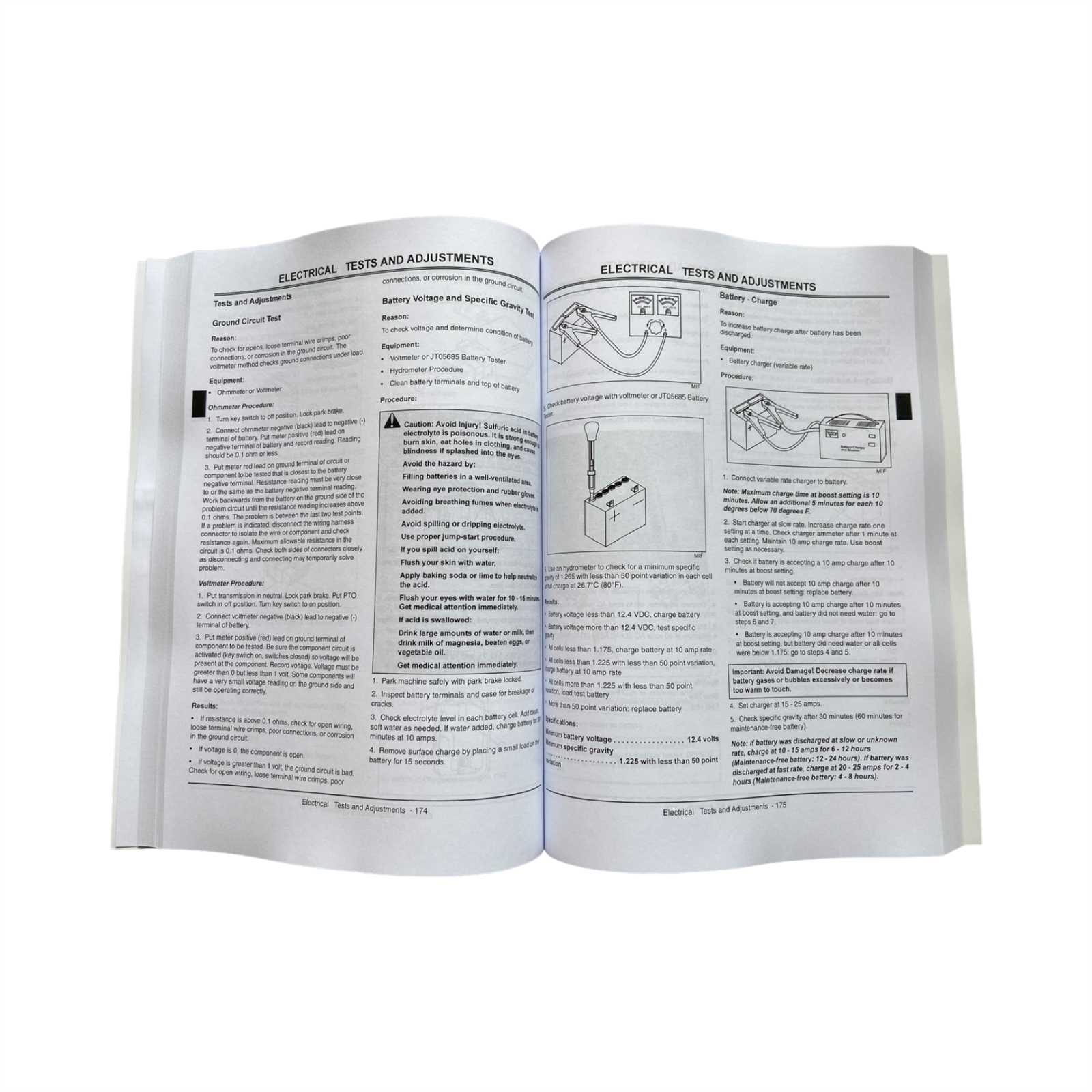

Electrical Problems:

If electrical components are malfunctioning, consider the following:

- Inspect all fuses and relays for integrity.

- Check wiring connections for corrosion or damage.

- Test switches and sensors for proper function.

By addressing these common issues with the suggested solutions, users can improve the reliability and lifespan of their machinery.

Importance of a Repair Manual

A comprehensive guide for maintenance and troubleshooting is essential for anyone looking to keep their machinery in optimal condition. Such resources provide invaluable insights that can enhance the longevity and performance of equipment, ensuring it runs smoothly and efficiently.

Having access to a detailed reference can help users quickly identify issues and implement solutions without unnecessary delays. This not only saves time but also reduces costs associated with professional repairs.

| Benefits | Description |

|---|---|

| Cost-Effective | Allows owners to perform tasks independently, minimizing expenses on professional services. |

| Increased Knowledge | Enhances understanding of machinery operation and maintenance, empowering users to make informed decisions. |

| Time Efficiency | Facilitates quicker diagnosis and resolution of problems, reducing downtime. |

| Safety | Promotes safe handling and operation practices, minimizing the risk of accidents. |

In summary, a well-structured reference guide is a vital asset for anyone invested in maintaining their machinery effectively. It ensures that equipment remains reliable and functional for years to come.

Key Components to Inspect Regularly

Regular examination of essential parts is crucial for maintaining optimal performance and longevity of your equipment. By focusing on specific areas, you can prevent minor issues from escalating into significant problems, ensuring reliable operation throughout its lifespan.

Start with the engine, as it is the heart of the machinery. Check fluid levels, inspect belts for wear, and ensure proper air filtration. Next, pay attention to the hydraulic system; look for leaks, monitor fluid levels, and test the functionality of the hydraulic components.

The electrical system is another vital area. Examine wiring for signs of damage, ensure connections are secure, and test the battery to guarantee it holds a charge. Don’t forget the tires; inspect tread depth, check for proper inflation, and look for any signs of wear or damage.

Finally, regularly inspect the frame and chassis for cracks or corrosion, which can compromise structural integrity. By systematically assessing these components, you can enhance the durability and efficiency of your machinery.

Step-by-Step Repair Instructions

This section provides a detailed guide to effectively troubleshoot and address common issues with your equipment. By following these organized steps, you can ensure that your machinery operates smoothly and efficiently. The process outlined here emphasizes clarity and systematic action to facilitate successful outcomes.

Preparation

Before diving into the troubleshooting process, it’s essential to gather the necessary tools and materials. Here’s what you will need:

- Basic tool set (wrenches, screwdrivers, pliers)

- Diagnostic equipment (if applicable)

- Replacement parts (check compatibility)

- Safety gear (gloves, goggles)

Troubleshooting Steps

- Begin by identifying the symptoms. Observe any unusual noises, vibrations, or performance issues.

- Check fluid levels and connections. Low fluids or loose connections can lead to performance failures.

- Inspect electrical components. Look for frayed wires, blown fuses, or loose terminals.

- Test critical systems individually. Focus on hydraulic, electrical, and mechanical parts.

- Replace any worn or damaged components. Ensure you use parts that meet the manufacturer’s specifications.

- After making adjustments, run the equipment under normal conditions to verify that issues are resolved.

By adhering to these outlined procedures, you can maintain the efficiency and longevity of your machinery, minimizing downtime and ensuring reliable operation.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires consistent attention and care. By following a series of maintenance practices, you can extend the life of your machinery and enhance its efficiency.

- Regular Inspections: Conduct routine checks for any signs of wear or damage. Early detection of issues can prevent more significant problems later.

- Fluid Changes: Regularly replace essential fluids, such as engine oil, coolant, and hydraulic fluid, to ensure smooth operation and reduce friction.

- Filter Maintenance: Keep air, fuel, and oil filters clean and replace them as needed to maintain optimal performance.

- Tire Care: Check tire pressure frequently and inspect for any signs of wear. Properly inflated tires improve fuel efficiency and handling.

By adhering to these guidelines, you can significantly enhance the lifespan of your equipment and ensure it operates at its best. Prioritize these practices to enjoy reliable performance for years to come.

Tools Required for Repairs

When undertaking maintenance tasks on machinery, having the right instruments at hand is crucial for efficiency and safety. Proper tools not only facilitate the process but also ensure that the job is completed to a high standard, minimizing the risk of damage or malfunction. This section outlines the essential equipment needed to address common issues effectively.

Basic Hand Tools

Essential hand tools include wrenches, screwdrivers, pliers, and hammers. These items form the foundation of any repair toolkit, allowing for basic assembly and disassembly. It is advisable to have a variety of sizes and types to accommodate different fasteners and components.

Specialized Equipment

In addition to standard tools, certain specialized instruments may be necessary for more complex tasks. These can include torque wrenches, diagnostic scanners, and hydraulic jacks. Investing in quality equipment ensures durability and accuracy, which are vital for successful maintenance operations.

Safety Precautions During Repairs

When undertaking maintenance tasks on machinery, it is essential to prioritize safety to prevent accidents and injuries. Adhering to proper protocols not only protects the individual performing the work but also ensures that the equipment remains in optimal condition throughout the process.

Proper Personal Protective Equipment

Before starting any maintenance work, always wear the appropriate personal protective equipment (PPE). This includes gloves, safety glasses, and sturdy footwear. Using PPE can significantly reduce the risk of injuries from sharp objects, chemicals, or heavy components. Additionally, ensure that long hair is tied back and loose clothing is secured to prevent entanglement in moving parts.

Work Environment Considerations

Creating a safe workspace is crucial. Ensure that the area is well-lit and free from clutter to minimize tripping hazards. Always work on a flat, stable surface, and utilize proper lifting techniques or equipment when handling heavy components. Regularly inspect tools for wear and tear, and never use damaged tools, as they can lead to accidents during the maintenance process.

Where to Find Official Manuals

Accessing reliable documentation is crucial for maintenance and troubleshooting. Official resources ensure that users receive accurate and comprehensive information for their equipment. Below are some trusted sources where you can obtain these important guides.

- Manufacturer’s Website: Most companies provide downloadable documents on their official sites. Look for a dedicated section for customer support or resources.

- Authorized Dealers: Local dealerships often have physical copies or can order specific guides for you. They may also offer additional assistance in understanding the material.

- Online Forums: Community forums can be valuable resources. Experienced users often share links to official documents or their personal insights on where to find them.

- Library Archives: Some public libraries maintain archives of agricultural equipment resources. Check with your local library for access to physical or digital versions.

- Social Media Groups: Many social media platforms host groups focused on specific machinery. Members may share direct links to official documentation or provide recommendations.

Utilizing these sources can significantly enhance your ability to maintain your equipment effectively and efficiently.

Cost-Effective DIY Repair Strategies

Engaging in do-it-yourself maintenance can significantly reduce expenses while ensuring your machinery remains in top condition. By adopting a few practical approaches, you can tackle issues efficiently without relying on professional services. Here are some strategies to help you save money and time.

- Assessing Problems Early: Regular inspections can help you identify minor issues before they escalate into major repairs. This proactive approach saves both time and resources.

- Utilizing Online Resources: Leverage forums, videos, and guides available online. These resources often provide step-by-step instructions tailored for various tasks.

- Investing in Basic Tools: A set of essential tools can empower you to perform most tasks. Focus on quality over quantity to ensure durability.

- Joining Local Workshops: Participate in community workshops or classes. Learning from experienced individuals can enhance your skills and confidence.

- Documenting Repairs: Keep a log of maintenance tasks and repairs. This record helps you track what works, and it can assist you in diagnosing future issues more effectively.

Implementing these strategies will not only enhance your mechanical skills but also contribute to long-term savings. Embracing the DIY spirit can lead to a greater understanding of your equipment and increased self-sufficiency.