Repairing Goodrich De-Ice Boots

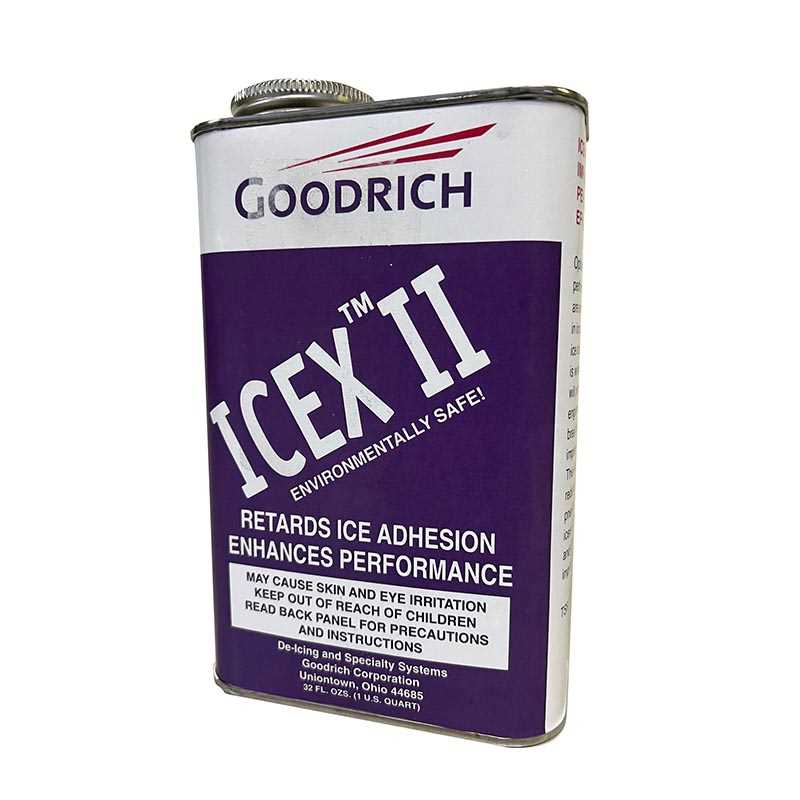

Maintaining the integrity of aircraft surfaces is crucial for ensuring optimal performance and safety during flight operations. Various protective elements are employed to prevent the buildup of ice and other contaminants, which can significantly impact aerodynamic efficiency. Understanding the methodologies behind these preservation techniques is essential for effective maintenance and operation.

Proper care and management of these components can extend their lifespan and enhance overall aircraft functionality. This section delves into essential practices, highlighting common issues and solutions associated with the maintenance of these protective systems. Emphasizing the importance of thorough inspections and timely interventions will enable operators to safeguard their equipment effectively.

By familiarizing oneself with the intricacies of these preservation techniques, personnel can better respond to challenges that arise in the field. This knowledge not only aids in the prevention of potential failures but also promotes adherence to safety protocols and regulatory requirements. Ultimately, a proactive approach to surface protection ensures that aircraft remain in peak operational condition, ready to face the demands of flight.

Common Issues with De-Icing Boots

In the realm of aviation, challenges related to ice protection systems can significantly impact performance and safety. Understanding the common complications associated with these essential components is crucial for maintaining aircraft functionality in adverse weather conditions.

Material Fatigue and Cracking

One frequent problem arises from material degradation over time. Exposure to harsh environmental factors can lead to brittleness and cracking, reducing the effectiveness of the ice protection system. Regular inspections and timely replacement of affected sections can mitigate this issue.

Improper Installation and Sealing

Another critical concern is the improper application of these systems. Inadequate sealing during installation may result in air leaks, diminishing the overall efficiency. Ensuring correct installation techniques and performing routine maintenance checks can help identify and rectify these issues early.

Materials Needed for Repairs

Effective restoration requires a specific set of resources to ensure successful outcomes. Utilizing the right components and tools can significantly enhance the efficiency and quality of the work being undertaken.

Below is a list of essential items to consider when preparing for the task:

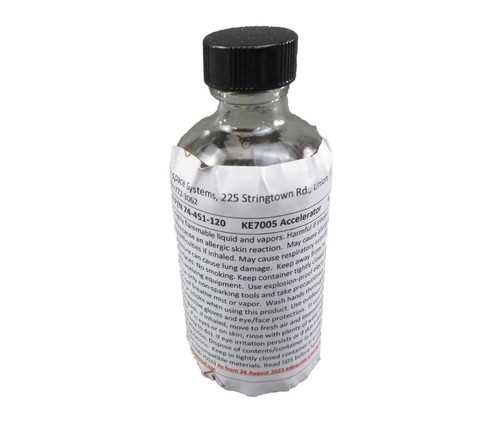

- Adhesives: Strong bonding agents suitable for the materials in use.

- Sealing agents: To prevent moisture ingress and ensure longevity.

- Protective gear: Gloves, masks, and goggles to ensure safety during the process.

- Cleaning supplies: Solvents and cloths for surface preparation and maintenance.

- Cutting tools: Scissors or knives designed for precision and control.

- Measuring instruments: Rulers and calipers to ensure accurate sizing of components.

- Application tools: Brushes or rollers for even distribution of adhesives and coatings.

Gathering these materials in advance will streamline the procedure and contribute to a more effective outcome.

Step-by-Step Repair Process

This section outlines a comprehensive approach to addressing issues with ice-prevention coverings. Following a systematic method ensures effectiveness and longevity of the solution.

Preparation

- Gather all necessary tools and materials, including adhesives, cleaning supplies, and protective gear.

- Inspect the surface for any visible damage or wear that needs attention.

- Ensure the working area is clean and free of any distractions.

Application of Adhesives

- Begin by thoroughly cleaning the affected area to remove any dirt or residues.

- Apply the adhesive evenly across the designated surface.

- Press the new material firmly against the surface, ensuring proper contact.

- Allow adequate time for curing, following manufacturer recommendations.

Once completed, double-check the integrity of the application before returning the component to service. Regular maintenance checks will help extend the lifespan of the treatment.

Safety Precautions During Repairs

Ensuring a secure working environment is essential when undertaking maintenance tasks. Adhering to safety guidelines not only protects the technician but also preserves the integrity of the equipment being serviced. Proper precautions help mitigate risks associated with various tools and materials involved in the process.

Personal Protective Equipment

Using appropriate personal protective gear is crucial. This includes gloves, goggles, and masks to safeguard against potential hazards. Selecting the right equipment based on the specific tasks at hand enhances overall safety and minimizes the likelihood of accidents.

Workspace Organization

Maintaining a tidy and organized workspace significantly reduces risks. Ensure that all tools and materials are stored properly to avoid tripping hazards or unintended injuries. Clear labeling and proper storage of components can streamline the maintenance process while promoting a safer environment.

Testing Boot Effectiveness Post-Repair

Evaluating the performance of a protective covering after maintenance is crucial to ensure optimal functionality. This assessment helps in identifying any lingering issues and confirms that the restoration process has been successful.

To carry out an effective evaluation, consider the following steps:

- Visual Inspection: Examine the surface for any signs of damage or irregularities.

- Pressure Testing: Apply controlled pressure to check for leaks or weaknesses.

- Temperature Assessment: Monitor the thermal response under simulated operational conditions.

- Functional Testing: Operate the system to observe performance under normal conditions.

Documentation of findings during these evaluations is essential for future reference and can aid in ongoing maintenance efforts. Address any identified issues promptly to ensure longevity and reliability of the covering.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your equipment. By following a few straightforward practices, you can ensure optimal performance and minimize the risk of issues over time.

- Regularly inspect components for signs of wear or damage. Early detection can prevent more serious problems later.

- Clean surfaces frequently to remove dirt and debris that could hinder functionality.

- Apply appropriate lubricants to moving parts to reduce friction and prevent premature wear.

- Store equipment in a controlled environment to protect against extreme temperatures and humidity.

- Follow the manufacturer’s guidelines for maintenance schedules and procedures to ensure compliance and efficiency.

By implementing these practices, you can significantly enhance the durability and reliability of your system, leading to better performance and reduced maintenance costs over time.

Frequently Asked Questions

This section addresses common questions regarding the maintenance and upkeep of specialized protective equipment. By exploring these answers, users can better understand the general practices, materials, and techniques involved, helping them to maintain the reliability of essential components.

What are the recommended steps for routine maintenance?

Regular inspections are crucial. Examine the surface for any signs of wear, abrasions, or foreign particles. Cleaning with approved, non-abrasive solutions can help prevent material breakdown. Adhere to recommended schedules for optimal performance.

How should I handle minor surface damage?

For minor scratches or scuffs, follow guidelines for light repairs using appropriate materials. Make sure to assess

Best Practices for Installation

Ensuring a seamless installation process requires attention to detail, adherence to guidelines, and a commitment to quality. By following well-established methods, technicians can achieve reliable results and extend the service life of the protective components. This section outlines essential practices for achieving effective and lasting installation.

Preparing the Surface

Before applying any materials, it’s crucial to thoroughly clean and prepare the surface area. Remove any debris, oils, or contaminants, as these can interfere with adhesion and compromise durability. A proper cleaning solution should be chosen based on compatibility with the surface, ensuring it does not leave behind residues that may affect bonding.

Applying Materials with Precision

Precision during the application phase is vital to prevent bubbles or misalignment. Techniques such as smooth layering and consistent pressure help main

Identifying Damage and Wear

Effective maintenance relies on recognizing early signs of deterioration in flexible components. Subtle imperfections, if unnoticed, may lead to more extensive issues, impacting overall performance. A careful inspection routine helps to catch these indicators promptly, ensuring lasting reliability.

Common Signs of Deterioration

Surface cracks, fading, and structural weakness are key signs that can indicate compromised integrity. Additionally, any visible fraying along edges or loss of material texture often suggests gradual wear. Identifying these elements during routine checks can prevent further damage.

Inspection Checklist

| Indicator | Description |

|---|