Delco Remy Starter Repair Guide

This section serves as a comprehensive overview for those seeking to enhance their knowledge and skills in restoring vital components of automotive machinery. The focus will be on the intricate workings of a specific type of device essential for initiating engine operation, emphasizing methods and techniques to extend its lifespan and improve functionality.

With a wealth of information on diagnostics and servicing, readers will gain insights into common issues faced by these systems and effective solutions. Detailed instructions will provide clarity on the step-by-step processes involved in rejuvenating these critical elements, ensuring they perform at their best.

By understanding the components and mechanics involved, enthusiasts and professionals alike can approach their projects with confidence. Whether for personal use or professional applications, mastering the intricacies of these mechanisms can lead to successful outcomes and greater efficiency in automotive maintenance.

Understanding Delco Remy Starters

This section explores the mechanisms and functionality of a well-known ignition component used in various vehicles. Understanding its operation is essential for anyone looking to maintain or troubleshoot issues effectively. This unit plays a crucial role in initiating the engine, converting electrical energy into mechanical force to ensure seamless vehicle operation.

Components and Functionality

The unit comprises several vital elements, each contributing to its overall performance. A key part is the electric motor, which engages upon activation. This motor spins the flywheel, initiating the engine’s combustion process. Additionally, a solenoid acts as a switch, controlling the flow of electricity. Proper functioning of these components is critical for reliable performance.

Troubleshooting Common Issues

When experiencing difficulties, various symptoms may indicate underlying problems. Unusual noises, failure to engage, or intermittent performance can signal the need for closer examination. Addressing these issues often involves checking connections, inspecting the solenoid, and assessing the motor’s condition. Regular maintenance can prevent many common complications, ensuring longevity and efficiency.

Common Issues and Symptoms

Understanding the frequent challenges encountered with ignition systems is essential for effective troubleshooting. Identifying these problems can prevent further complications and ensure efficient operation.

1. Difficulty Starting: One of the most prevalent signs is when the engine struggles to crank or makes a clicking noise. This often indicates a malfunction in the initiating mechanism or insufficient voltage supply.

2. Unusual Noises: Strange sounds, such as grinding or whining, may suggest improper alignment or worn components. Addressing these noises promptly can prevent extensive damage.

3. Intermittent Operation: An erratic performance, where the system occasionally fails to engage, may point to electrical issues or faulty connections. Consistent checks can help isolate the cause.

4. Smoke or Burning Smell: The presence of smoke or a burning odor is a serious indicator of overheating or electrical failure. Immediate attention is crucial to avoid fire hazards.

5. Warning Lights: Dashboard indicators that illuminate unexpectedly can signify underlying issues. Consulting diagnostic tools can provide insights into the specific faults present.

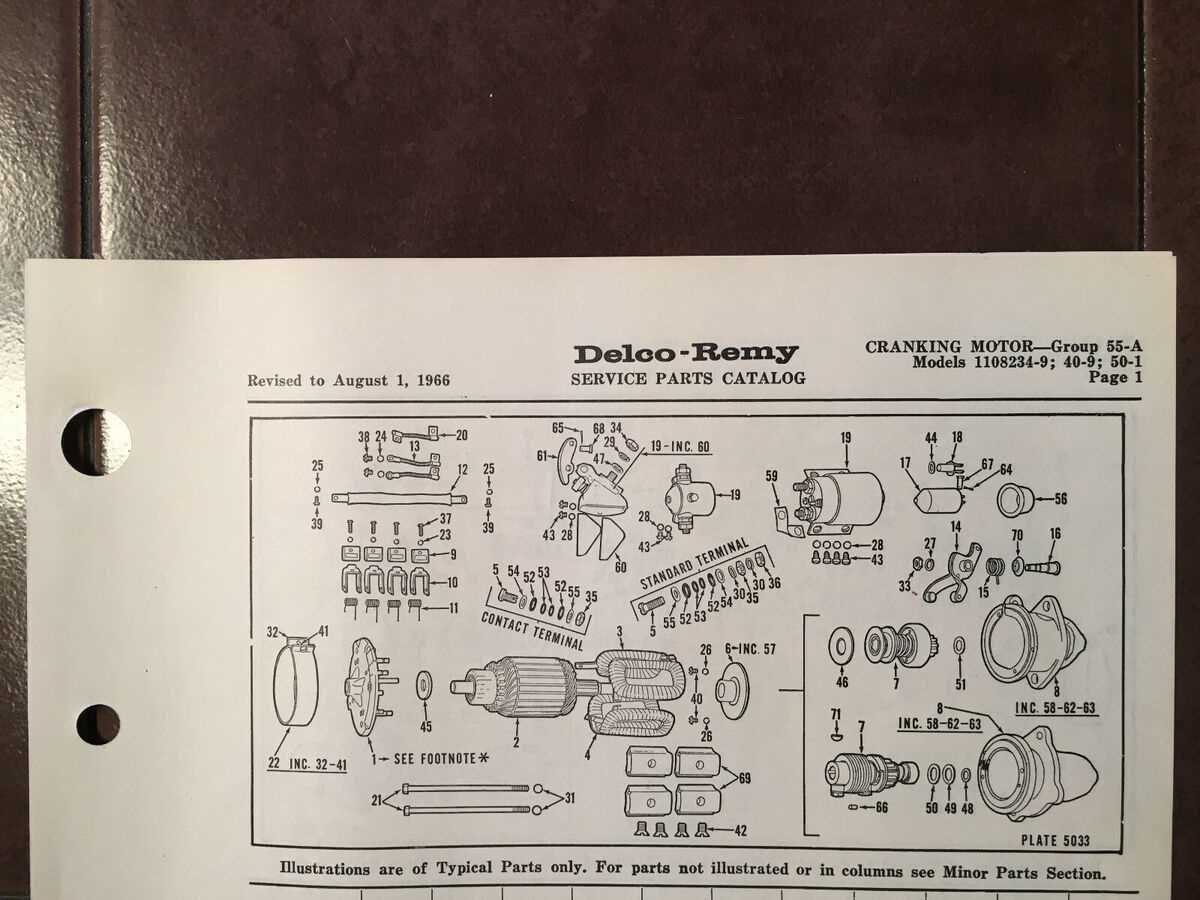

Disassembly Process Explained

This section outlines the steps involved in taking apart a specific mechanical component for servicing or maintenance. Understanding the sequence and techniques required ensures a thorough approach, ultimately leading to successful reassembly and optimal performance.

Essential Tools and Preparation

Before beginning the disassembly, gather the necessary tools and prepare the workspace:

- Wrenches and sockets

- Screwdrivers (flat and Phillips)

- Pliers and wire cutters

- Cleaning materials (rags, solvents)

- Protective gear (gloves, goggles)

Step-by-Step Disassembly

- Ensure the unit is disconnected from any power source.

- Remove any external covers or casings to expose internal components.

- Carefully disconnect electrical connections, noting their arrangement for later reference.

- Unscrew and remove fasteners holding critical parts together.

- Gently separate components, taking care to avoid damaging delicate elements.

- Organize disassembled parts systematically for easy reassembly.

Following these guidelines will facilitate a smooth disassembly process, making the subsequent maintenance tasks more manageable.

Essential Tools for Repair

When undertaking the task of restoring automotive ignition systems, having the right instruments is crucial. Proper tools not only streamline the process but also ensure precision and safety during operations. A well-equipped workspace enhances efficiency and contributes to a successful outcome.

Key implements include wrenches, which facilitate the loosening and tightening of various components. Additionally, screwdrivers in multiple sizes are vital for accessing intricate areas. Socket sets allow for the removal of bolts in tight spaces, while pliers are useful for gripping and manipulating small parts.

Moreover, testing equipment, such as multimeters, assists in diagnosing electrical issues, ensuring that all systems function correctly. An organized toolbox will not only keep these essentials handy but also promote a smoother workflow. Investing in high-quality tools is a fundamental step towards achieving lasting results.

Testing Electrical Components

Evaluating the functionality of various electrical elements is crucial for ensuring optimal performance and longevity of any machinery. This process involves assessing the integrity and responsiveness of circuits and devices, which can help identify underlying issues and facilitate efficient troubleshooting.

Common methods for testing include using a multimeter, which allows for measuring voltage, resistance, and current across components. Understanding the specifications and requirements of each part can guide the evaluation process effectively.

| Component | Testing Method | Expected Values |

|---|---|---|

| Batteries | Voltage Test | 12.6V (fully charged) |

| Solenoids | Resistance Test | 5-10 Ohms |

| Relays | Continuity Test | Close circuit when activated |

| Wiring | Insulation Test | Resistance > 1 Megaohm |

By systematically testing these components, one can ensure that each element functions correctly, which contributes to the overall efficiency and reliability of the system.

Replacing Worn-Out Parts

Over time, components within a mechanical assembly may deteriorate, leading to decreased performance and reliability. Addressing these issues promptly is essential to ensure optimal functionality and longevity of the system. Understanding which elements are prone to wear and how to effectively substitute them can significantly enhance overall operation.

When assessing which parts require replacement, focus on those that exhibit visible signs of damage, such as fraying, cracking, or unusual wear patterns. Common candidates for replacement include bearings, brushes, and electrical contacts. Each of these elements plays a critical role in the overall efficiency of the mechanism, and neglecting them can result in further complications.

Before commencing the replacement process, ensure that the correct specifications for the new components are obtained. Using parts that meet or exceed the original standards will guarantee compatibility and performance. Once replacements are acquired, carefully follow the assembly guidelines to install them, paying close attention to torque specifications and alignment to prevent future issues.

Regular maintenance and timely substitution of damaged components not only extend the lifespan of the system but also improve its overall efficiency. Keeping a log of replacements can also aid in predicting future maintenance needs, ensuring that the mechanism remains in peak condition.

Reassembly Tips and Techniques

Properly putting components back together after maintenance is crucial for optimal functionality and longevity. Attention to detail during this process can prevent future issues and ensure everything operates smoothly. Below are some essential strategies to guide you through the reassembly stage.

Step-by-Step Approach

Adopting a systematic method is beneficial. Begin by organizing all parts and ensuring that each one is clean and free of debris. Refer to documentation for guidance on the order of assembly, as following the original sequence can simplify the process. Taking notes or photographs during disassembly can serve as a useful reference when reassembling.

Securing Connections

Ensuring tight and secure connections is paramount. Utilize the appropriate tools to achieve the correct torque specifications, preventing any components from becoming loose during operation. It is also advisable to double-check all connections before completing the assembly. A thorough inspection can save time and effort later by identifying potential issues upfront.

Maintenance Practices for Longevity

Ensuring the durability and efficient operation of automotive components requires regular attention and appropriate care. Implementing systematic maintenance routines can significantly extend the lifespan of these critical systems, enhancing their performance and reliability over time.

Regular Inspections

Conducting frequent checks is essential for identifying wear and tear before it escalates into serious issues. Look for signs of corrosion, loose connections, and other anomalies that may compromise functionality. Early detection allows for timely intervention, reducing the risk of unexpected failures.

Proper Cleaning Techniques

Maintaining cleanliness is vital for optimal performance. Accumulated dirt and grime can interfere with the operation of components. Use suitable cleaning agents and techniques to remove contaminants without causing damage. Regular cleaning promotes better efficiency and helps prevent potential malfunctions.

Diagnosing Performance Problems

Identifying issues related to functionality is crucial for maintaining efficiency in any mechanical system. This section focuses on the common signs that indicate a need for attention, along with systematic approaches to pinpoint the underlying causes.

Common Symptoms

When performance declines, several indicators may manifest. These can include unusual noises, failure to engage properly, or erratic behavior during operation. Recognizing these symptoms early can prevent further complications and ensure timely intervention.

Systematic Approach

To effectively diagnose these challenges, a methodical evaluation is essential. Start by inspecting all connections and components for signs of wear or damage. Utilize diagnostic tools to assess voltage and current levels, ensuring they meet specified standards. This structured approach will help in isolating the problem and determining the necessary corrective actions.

FAQs About Starter Repair

This section addresses common inquiries related to the maintenance and servicing of ignition devices. Understanding these aspects can greatly enhance the longevity and functionality of your equipment.

What signs indicate that servicing may be necessary?

Frequent clicking sounds, intermittent failures to engage, or unusual noises during operation can signal the need for attention.

Can I perform maintenance myself?

While some tasks can be handled by a knowledgeable individual, complex issues often require professional assistance to ensure safety and effectiveness.

How often should maintenance be performed?

Regular inspections are recommended, ideally during routine vehicle servicing or whenever you notice irregular behavior.

What tools are essential for maintenance?

A basic toolkit including wrenches, screwdrivers, and a multimeter is typically sufficient for most tasks related to these systems.

Are there specific products that should be used?

Utilizing high-quality components and lubricants designed for ignition devices can significantly improve performance and reliability.