Comprehensive Repair Guide for Singer Stylist 457

In the world of textile arts, understanding the intricacies of your crafting equipment is crucial for achieving optimal results. Proper maintenance not only enhances performance but also extends the lifespan of your machine, allowing you to create with confidence. This guide aims to equip you with the knowledge necessary for keeping your sewing apparatus in top condition, ensuring that it continues to meet your creative needs.

By delving into the specifics of upkeep and troubleshooting, you can avoid common pitfalls that might hinder your projects. From routine cleaning to addressing minor issues, having a comprehensive resource at your fingertips empowers you to take control of your sewing experience. Whether you are a seasoned artisan or a budding enthusiast, this information will serve as a valuable asset in your creative toolkit.

Join us as we explore the essential steps and techniques that will help you maintain the functionality and efficiency of your sewing machine. With a little care and attention, you can ensure that your device remains a reliable partner in all your crafting endeavors.

Understanding the Singer Stylist 457

The machine in question represents a blend of functionality and ease of use, designed for a variety of sewing enthusiasts. Its user-friendly features make it accessible to both novices and experienced crafters alike. With a focus on versatility, this model accommodates a wide range of projects, ensuring that creativity can flourish without technical limitations.

Key Features: The device offers an array of stitch options, allowing users to explore different techniques and styles. Its robust construction guarantees longevity, making it a reliable companion for various fabric types. Additionally, intuitive controls simplify the sewing process, enhancing the overall experience.

Maintenance Tips: To ensure optimal performance, regular upkeep is essential. Users should familiarize themselves with routine cleaning and lubrication, which are crucial for smooth operation. Understanding the components and their functions can significantly contribute to the machine’s lifespan and efficiency.

In conclusion, this sewing apparatus stands out for its adaptability and ease of use, making it a valuable asset for anyone looking to enhance their sewing skills. Embracing its features and maintaining it properly can lead to countless creative possibilities.

Common Issues with Singer Stylist 457

Many users encounter various challenges when operating their sewing machines. Understanding these common problems can help in troubleshooting and maintaining optimal performance. Below are some frequent concerns that may arise, along with potential solutions.

Thread Jamming: One of the most prevalent issues is the thread getting caught in the bobbin area. This can occur due to incorrect threading or using incompatible thread types. Ensuring that the machine is threaded properly and using the recommended materials can often resolve this problem.

Skipped Stitches: Skipped stitches can be frustrating and may result from several factors, including needle selection, thread tension, or fabric type. It is essential to check that the needle is appropriate for the fabric being used and that the tension settings are correctly adjusted.

Tension Problems: Inconsistent stitching can indicate tension issues. If stitches are too loose or too tight, users should review the tension settings and adjust them accordingly. Sometimes, cleaning the machine can also improve tension performance.

Machine Not Powering On: If the device fails to turn on, it could be due to electrical issues, such as a faulty power cord or pedal. Checking these components for damage and ensuring a proper connection can help diagnose the problem.

Noise and Vibration: Unusual sounds during operation may signal that parts are misaligned or need lubrication. Regular maintenance, including oiling the moving parts and checking for loose screws, can mitigate this issue.

By addressing these common concerns, users can enhance their sewing experience and extend the life of their equipment. Regular maintenance and mindful usage are key to preventing many of these problems.

Basic Tools for Repairs

Having the right equipment is essential for any restoration task. The tools not only facilitate the process but also ensure that each adjustment is performed accurately and efficiently. A well-equipped toolkit can make all the difference in achieving optimal results.

Essential items include various types of screwdrivers, pliers, and wrenches, each serving distinct purposes. Additionally, a reliable set of scissors or snips can assist with cutting threads or fabric. Measuring tools are also crucial, as precise measurements lead to successful modifications.

Furthermore, consider including a seam ripper for quick fixes and a set of replacement needles to accommodate different fabrics. A sturdy toolbox will help keep everything organized, ensuring that you can easily find what you need when it’s time to tackle a project.

Step-by-Step Repair Guide

This section provides a comprehensive approach to troubleshooting and fixing common issues with your sewing machine. Whether you’re dealing with thread jams, inconsistent stitching, or mechanical malfunctions, following these detailed instructions will help you restore your device to optimal working condition.

Identifying Common Issues

Begin by observing the symptoms your machine is exhibiting. Common problems include:

- Thread Bunching: Often caused by incorrect threading or tension settings.

- Skipped Stitches: Can result from a dull needle or incorrect needle size.

- No Power: Usually indicates an electrical issue or a faulty power cord.

Understanding these issues is crucial for effective troubleshooting.

Troubleshooting Steps

Follow these steps to address the identified problems:

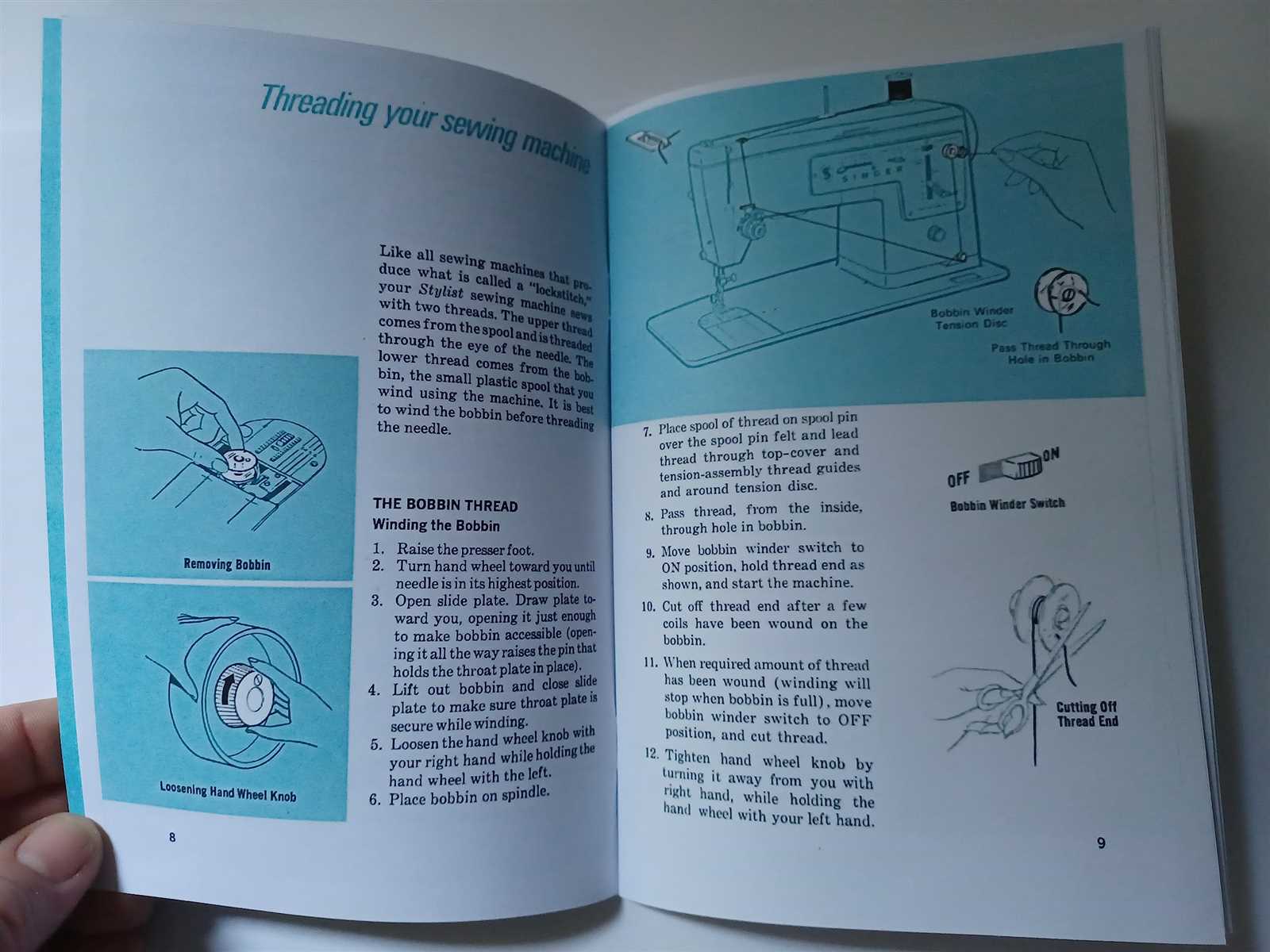

- Check Threading: Ensure that the upper and lower threads are threaded correctly, referring to the threading diagram if necessary.

- Adjust Tension: Use the tension dial to make small adjustments. Test the stitch on a scrap fabric until the tension is balanced.

- Inspect the Needle: Replace any dull or bent needles with a new one, ensuring the correct type is used for your fabric.

- Clean the Machine: Remove lint and debris from the bobbin area and feed dogs using a small brush or cloth.

- Check Power Supply: Ensure the machine is plugged in and the power switch is on. Test the outlet with another device if necessary.

By systematically addressing these areas, you can often resolve many common difficulties and enhance your machine’s performance.

Maintenance Tips for Longevity

Ensuring the enduring performance of your sewing machine requires regular attention and care. Proper maintenance not only enhances functionality but also extends the life of the equipment, preventing common issues that arise from neglect.

1. Regular Cleaning: Dust and debris can accumulate in the machine, affecting its operation. Make it a habit to clean the interior and exterior frequently, using a soft brush and lint cloth to remove any particles.

2. Lubrication: Keeping moving parts well-lubricated is essential for smooth functioning. Use appropriate oil, as recommended, to avoid friction and wear, paying particular attention to areas that experience frequent movement.

3. Needle Replacement: A dull or damaged needle can lead to subpar stitching and potential harm to the machine. Regularly check and replace needles to maintain optimal performance.

4. Tension Adjustment: Proper tension settings are crucial for achieving quality stitches. Periodically check and adjust the tension according to the fabric and thread you are using to ensure consistent results.

5. Storage Conditions: Keep the machine in a dry, cool place, away from direct sunlight and humidity. Using a cover can also protect it from dust and other environmental factors when not in use.

6. Professional Servicing: Schedule regular check-ups with a qualified technician. Professional maintenance can catch potential issues early and ensure all components are functioning as intended.

By incorporating these practices into your routine, you can enjoy a reliable and efficient sewing experience for years to come.

Troubleshooting Common Problems

Addressing issues with your sewing machine can enhance your sewing experience and ensure that projects are completed smoothly. Below are some typical challenges you may encounter, along with effective solutions to resolve them.

- Thread Bunching:

- Check if the upper thread is threaded correctly through the tension discs.

- Ensure the bobbin is wound evenly and inserted properly.

- Adjust the tension settings on the machine.

- Skipped Stitches:

- Examine the needle for damage or wear; replace if necessary.

- Confirm the needle is suitable for the fabric being used.

- Check the threading path to ensure it is correct.

- Machine Not Sewing:

- Ensure the machine is plugged in and powered on.

- Check if the foot pedal is functioning properly.

- Verify that the needle is not bent or improperly installed.

- Tension Issues:

- Adjust the upper and lower tension settings gradually to find the right balance.

- Replace the thread if it appears frayed or damaged.

- Clean any lint buildup around the tension discs.

By following these troubleshooting steps, you can effectively address common challenges and maintain optimal performance of your sewing machine.

Replacing Key Components Explained

Understanding the process of substituting essential parts in a sewing machine can greatly enhance its functionality and longevity. This section will delve into the critical components that may require replacement over time, ensuring optimal performance and efficiency. Whether due to wear and tear or a need for improvement, knowing how to address these elements is crucial for any user.

One of the most frequently replaced items is the needle, which directly impacts the quality of stitching. A dull or damaged needle can lead to skipped stitches and fabric snagging. Regularly checking and replacing the needle according to the type of fabric being used is vital for maintaining a smooth sewing experience.

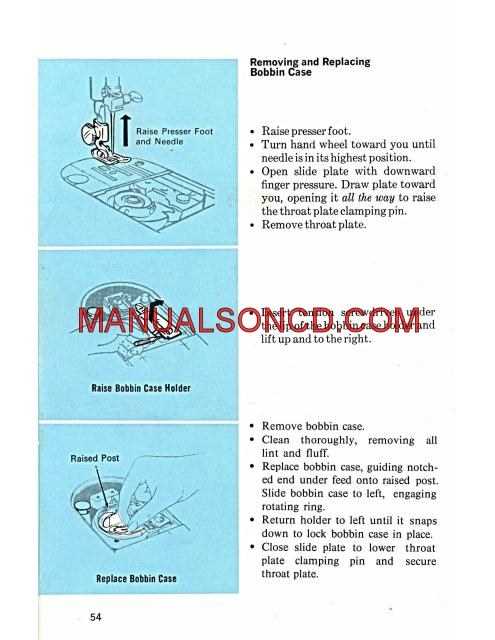

Another key component is the bobbin case, which can become misaligned or worn out. Ensuring that this part is in good condition is essential for proper thread tension and stitch formation. Users should periodically inspect and clean the bobbin area to prevent any build-up of lint or debris that could affect operation.

Additionally, the motor and belt are integral to the machine’s functionality. Over time, the belt may stretch or wear down, leading to reduced power transfer. Replacing these components can restore the machine’s original speed and reliability, allowing for efficient sewing tasks.

Finally, keeping an eye on the presser foot and its mechanism is important. This part controls the fabric feed and should be adjusted or replaced if any issues arise. A well-functioning presser foot ensures even fabric handling, preventing uneven stitching.

By familiarizing yourself with these essential components and understanding when and how to replace them, you can maintain the performance of your sewing machine and enjoy a seamless crafting experience.

Cleaning and Lubrication Techniques

Maintaining the functionality of your sewing machine is essential for optimal performance and longevity. Regular cleaning and appropriate lubrication can prevent wear and tear, ensuring smooth operation and minimizing potential issues.

Cleaning involves removing dust, lint, and debris that can accumulate in various parts of the device. Begin by unplugging the machine and accessing the areas that are prone to buildup, such as the bobbin case and feed dogs. Use a soft brush or a vacuum attachment to gently eliminate any particles without damaging delicate components. It’s advisable to wipe down the exterior with a damp cloth to keep the surface free from grime.

Lubrication is equally important in maintaining the efficiency of moving parts. Identify the lubrication points as indicated in your user guide. Use a high-quality oil designed specifically for sewing machines. Apply a small amount to the designated areas, ensuring not to over-lubricate, as excess oil can attract more dust and dirt. Operate the machine briefly after lubrication to distribute the oil evenly throughout the mechanisms.

Incorporating these practices into your regular maintenance routine will help enhance performance, reduce noise, and extend the life of your equipment.

Upgrading Your Sewing Machine

Enhancing your sewing device can significantly elevate your crafting experience. By implementing various improvements, you can achieve better performance, efficiency, and versatility, allowing you to explore new creative avenues.

Here are several effective ways to upgrade your sewing equipment:

- Foot Attachments: Invest in additional presser feet designed for specific tasks such as quilting, embroidery, or zipper insertion.

- Needle Selection: Experiment with different needle types and sizes to accommodate various fabrics and techniques.

- Thread Quality: Use high-quality threads that suit your projects to ensure smooth stitching and durability.

Consider the following enhancements to improve your sewing experience:

- Lighting: Upgrade your workspace with bright, adjustable lighting to better see your fabric and details.

- Extension Tables: Add an extension table for larger projects, providing more support and stability while sewing.

- Bobbin System: Opt for a more efficient bobbin system to reduce time spent on re-threading and maintenance.

Investing in these upgrades not only enhances the functionality of your sewing machine but also makes your projects more enjoyable and efficient. Explore these options to find the perfect combination that suits your crafting needs.

When to Seek Professional Help

Understanding when to turn to an expert can save time, resources, and frustration. Certain issues may seem manageable at first glance, but they can quickly escalate without the right knowledge or tools. Here are some key indicators that it might be time to call in a professional:

- Persistent Problems: If issues recur despite your attempts to resolve them, it may indicate a deeper underlying issue.

- Lack of Progress: When DIY efforts fail to yield positive results, professional assistance may be necessary to avoid further complications.

- Complex Repairs: For intricate malfunctions or damage, an expert’s experience can ensure proper handling and restoration.

- Safety Concerns: If a task involves potential hazards or complex electrical components, prioritizing safety with professional help is wise.

- Limited Knowledge: If you’re unsure about the troubleshooting process or lack specific skills, seeking expert guidance is recommended.

Recognizing these signs early can help maintain the longevity and functionality of your equipment while ensuring your safety and satisfaction.