Mi-T-M Pressure Washer Repair Guide

Understanding the inner workings and key maintenance practices for high-efficiency cleaning devices can significantly extend their lifespan and improve their overall performance. Regular upkeep and timely adjustments help ensure that these machines operate smoothly, preventing any unexpected issues that may hinder functionality. This guide delves into the essentials of keeping these machines in optimal condition and provides practical tips for troubleshooting common operational issues.

In the following sections, you’ll discover expert-recommended steps for identifying and resolving performance challenges that may arise over time. Through a combination of preventive care and targeted fixes, you can maintain the equipment’s operational standards and address potential malfunctions promptly. This information is designed to help users handle the equipment confidently and maintain its reliability through proactive attention to detail.

Ensuring longevity and effective function of such cleaning tools doesn’t require advanced expertise but rather a structured approach to care and upkeep. Following these recommended practices, users can minimize potential issues and sustain high standards

Understanding Mi-T-M Pressure Washer Components

This section provides an overview of key components in these cleaning systems, giving insight into how each part contributes to efficient functionality. Knowing these elements can simplify maintenance, enhance performance, and assist in troubleshooting common issues.

- Engine or Motor: The power source, either electric or gasoline-powered, which drives the system’s operations. Regular maintenance of this part is crucial for ensuring consistent power output.

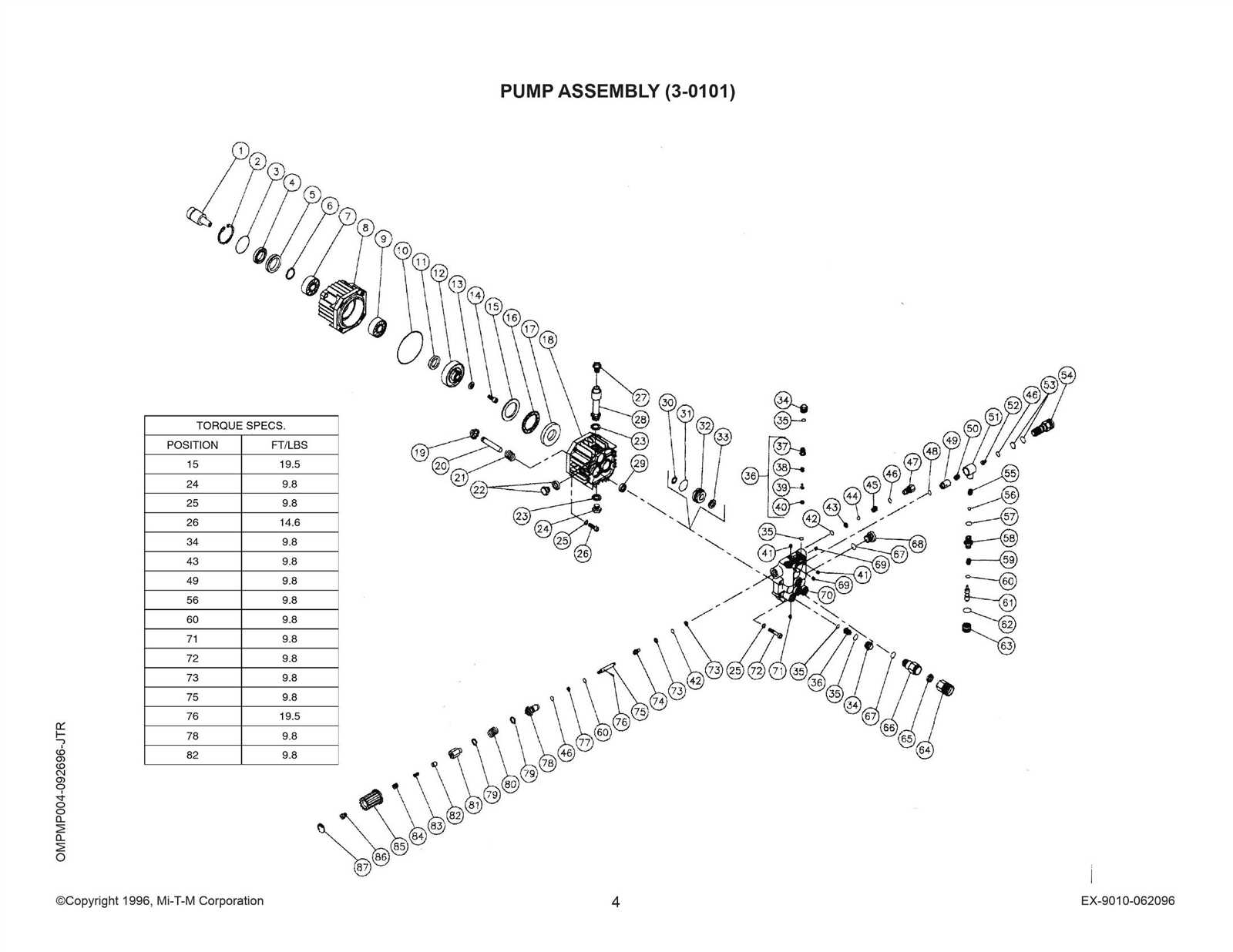

- Pump: Responsible for generating the necessary force to deliver water effectively. It typically requires regular checks for seal integrity and proper lubrication.

- Hose and Connections: High-strength hoses and secure connections carry the water flow, allowing seamless operation. Inspecting for wear, leaks, or damage is essential to prevent pressure loss and maintain efficiency.

- Nozzle Tips: Available in various designs, these tips adjust the spray pattern and intensity. Understanding which tip to use helps achieve optimal results for different cleaning tasks.

- Common Issues in Mi-T-M Pressure Washers

High-performance cleaning equipment can sometimes encounter a range of challenges due to prolonged use, exposure to various elements, or component wear. Understanding these common issues can aid in diagnosing problems early, ensuring better functionality and longevity.

Difficulty Starting

One frequent problem that users may experience is the machine not starting properly. This can be caused by a variety of factors, including issues with the fuel system, spark plug faults, or air filter clogging. Regular checks and basic maintenance of these parts can often resolve such starting difficulties.Low Water Flow

Reduced flow or lack of adequate water pressure during use can result from a clogged nozzle, restricted hose, or leaks in the water supply system. Ensuring aEssential Tools for Pressure Washer Repair

Maintaining and troubleshooting high-power cleaning equipment requires a set of reliable tools to ensure efficiency and safety. Having a well-prepared toolkit can simplify diagnosing issues and streamline the maintenance process, helping avoid unnecessary delays.

One critical tool is a sturdy adjustable wrench, ideal for loosening or securing various fasteners and fittings on components. Additionally, a socket set with both metric and standard sizes enables precise handling of bolts and nuts found in different sections of the equipment.

A multimeter is essential for checking electrical connections, as it allows you to safely verify circuit integrity and power flow. This tool is invaluable for pinpointing any electrical issues that may arise.

To address potential clogging or buildup in narrow passageways, a selection of nozzle cleaning needles or fine wire brushes will help clear debris and keep flow channels clear. Proper cleaning tools enhance performance and extend the lifespan of critical parts.

Lastly, a durable pair of gloves and safety goggles ensure safe handling of parts and fluids, reducing the risk of accid

Diagnosing Power Problems in Mi-T-M Models

Understanding power-related issues in specific models can help ensure smoother operation and prevent potential downtimes. This section offers essential insights into identifying the root causes of these issues, allowing users to efficiently troubleshoot and maintain the equipment.

Common Causes of Power Failures

Power failures may arise from various factors, ranging from electrical faults to component wear. The table below outlines typical causes along with recommended solutions, which can aid in restoring full functionality and extending the equipment’s lifespan.

Problem Possible Cause Solution Unit fails to start Tripped circuit breaker or blown fuse Check and reset the breaker, replace fuse if needed Unit Replacing Worn-Out Pressure Washer Parts

With consistent use, various components in a cleaning unit can gradually wear out, leading to reduced performance and potential breakdowns. Regular inspection and timely replacement of these parts can ensure your equipment remains efficient and functional over the long term. This guide will walk you through recognizing signs of wear and the steps to change essential elements safely.

Identifying Key Components That May Need Replacement

Several parts in a high-performance cleaning unit are more prone to wear. Knowing which ones require regular checks can help prevent interruptions and ensure consistent function:

- Pump and Seals: Frequent use can wear down pump seals, causing leaks and reducing efficiency.

- Nozzles: Over time, nozzles can become clogged or worn, affecting spray pattern and cleaning power.

- Hoses: Constant water flow and pressure can lead to cracks or leaks in hoses, requiring timely replacement.

- Filters: Dirty or clogged filters can strain the unit’s m

Maintaining High Pressure Output Effectively

Ensuring optimal performance of your cleaning equipment is essential for achieving desired results during operation. Regular attention to specific components and practices can significantly enhance the efficiency and effectiveness of your machine. This section outlines key strategies to help maintain robust output levels consistently.

Regular Inspection and Maintenance

Frequent checks on various parts can prevent minor issues from escalating into major problems. Focus on the following areas:

- Inspect hoses and fittings for wear or damage.

- Check the connections for leaks.

- Ensure that the filter is clean and free from blockages.

- Examine the nozzle for clogs or damage.

Proper Use of Equipment

Correct handling and usage techniques contribute to maintaining high output. Consider the following tips:

- Utilize the recommended nozzle for specific tasks.

- Avoid using excessive force when connecting or disconnecting components.

- Follow manufacturer guidelines for operating temperatures and pressures.

- Store the equipment in a clean, dry area to prevent rust and corrosion.

Troubleshooting Nozzle and Spray Issues

When encountering difficulties with nozzle performance or spray patterns, it’s essential to identify the underlying problems effectively. Various factors can contribute to improper operation, including clogs, incorrect settings, or equipment malfunctions. This section will guide you through diagnosing and resolving these common challenges to ensure optimal functionality.

Common Symptoms and Their Causes

- Uneven Spray Pattern:

- Clogged nozzle openings.

- Incorrect nozzle selection for the intended task.

- Worn or damaged nozzle components.

- Low Pressure:

- Insufficient water supply.

- Blocked hoses or filters.

- Faulty pump or pressure regulator.

- Excessive Spray Mist:

- Improper nozzle angle or distance from the surface.

- Inadequate fluid viscosity or mixing issues.

- Worn seals or connections.

Steps to Resolve Issues

- Check for any visible blockages in the nozzle and clean if necessary.

- Ensure the correct nozzle type is being used for your specific application.

- Inspect hoses for kinks or damage that may restrict water flow.

- Verify that the water supply is sufficient and at the appropriate temperature.

- Examine all fittings and seals for wear and replace if needed.

- Test the unit after each adjustment to determine if the issue persists.

Cleaning and Storing Your Pressure Washer

Proper maintenance and storage are crucial for ensuring the longevity and efficiency of your cleaning equipment. By implementing a few simple practices, you can enhance performance and minimize the risk of damage during periods of inactivity.

Cleaning your equipment after each use is essential. Begin by disconnecting the water supply and removing any attached nozzles. Use a damp cloth to wipe down the exterior surfaces, ensuring that dirt and grime do not accumulate. Pay special attention to the inlet filters and hoses, as debris can obstruct flow and lead to inefficiency. If necessary, a gentle brush can help dislodge stubborn particles.

Once cleaned, it is important to store the unit in a suitable environment. Keep it in a cool, dry place, protected from extreme temperatures and direct sunlight. If possible, cover the equipment with a breathable tarp to shield it from dust and moisture. Additionally, consider coiling hoses neatly and securing them to avoid kinks and wear. For those living in colder climates, draining any remaining fluid from the system is vital to prevent freezing and potential damage.

By following these guidelines, you can ensure your cleaning tool remains in excellent condition, ready for its next task.

How to Fix Fuel Line Leaks

Addressing leaks in the fuel delivery system is crucial for maintaining optimal performance and safety. This section provides a step-by-step approach to identify and resolve such issues effectively.

Identifying the Leak

Before attempting any repairs, it is essential to determine the source of the leak. Here are some common signs to look for:

- Fuel odor around the equipment.

- Visible fuel stains on the ground or surfaces.

- Unexpected drops in fuel levels.

Steps to Repair

- Gather Necessary Tools: Ensure you have the right tools on hand, including wrenches, screwdrivers, and replacement tubing.

- Disconnect Fuel Supply: Turn off the fuel supply and disconnect any lines to prevent spills during repairs.

- Inspect Connections: Check all fittings and connections for wear or damage. Tighten loose connections as needed.

- Replace Damaged Lines: If any hoses are cracked or frayed, cut them to the appropriate length and replace them with new fuel lines.

- Test the System: Reconnect the fuel supply and start the equipment to check for any remaining leaks. Monitor for any signs of fuel escaping.

By following these steps, you can effectively manage leaks and ensure a reliable fuel system.

Best Practices for Regular Maintenance

Maintaining your cleaning equipment is essential to ensure its longevity and optimal performance. Implementing routine care not only prevents potential breakdowns but also enhances efficiency, making your tasks easier and more effective.

Begin by regularly inspecting all components for wear and tear. Check hoses, connectors, and nozzles for any signs of damage or blockages. Addressing these issues promptly can prevent more serious complications down the line.

Keep the machinery clean by removing dirt and debris after each use. This simple act helps maintain functionality and prevents buildup that could hinder operation. Additionally, follow the manufacturer’s recommendations for lubricating moving parts to ensure smooth performance.

Monitoring fluid levels is crucial. Regularly check oil and fuel levels, ensuring they are at recommended levels to avoid operational issues. If your equipment uses filters, replace them as needed to maintain optimal performance.

Lastly, store your machinery in a dry and secure location when not in use. Proper storage protects it from environmental factors that could lead to damage. Following these practices will help extend the lifespan of your equipment while ensuring it operates at its best.