Guide to Automatic Gearbox Repairs

Understanding the intricacies of modern vehicle systems is essential for any automotive enthusiast or professional. This section delves into the complexities of a specific type of mechanical system that plays a critical role in vehicle performance. Proper handling and upkeep of this component can significantly enhance driving experience and prolong the lifespan of the vehicle.

In this guide, we will explore various procedures and techniques necessary for ensuring optimal functionality. From troubleshooting common issues to implementing preventive measures, the information provided aims to equip readers with the knowledge needed to effectively manage this essential aspect of automotive engineering.

Whether you’re looking to enhance your skills or seeking solutions to persistent challenges, this comprehensive resource offers insights into the best practices for maintaining this crucial system. By following the outlined steps, you can foster a deeper understanding of its operation and ensure your vehicle runs smoothly.

Common Issues with Automatic Transmissions

Vehicles equipped with advanced shifting systems often encounter a range of typical problems that can affect performance and drivability. Understanding these issues can help in early detection and maintenance, ensuring smoother operation over time.

Frequent Problems Encountered

- Slipping: This occurs when the vehicle unexpectedly changes gears or loses power during acceleration.

- Delayed Engagement: Drivers may notice a lag when shifting from park to drive, indicating potential underlying issues.

- Fluid Leaks: Low fluid levels can lead to overheating and increased wear on components.

- Unusual Noises: Grinding, clunking, or whining sounds can signal mechanical failures or wear.

Signs of Malfunction

- Warning Lights: Dashboard indicators may illuminate, signaling the need for inspection.

- Poor Fuel Efficiency: Increased consumption can be a symptom of an inefficient system.

- Erratic Shifting: Inconsistent or harsh transitions between gears can indicate a malfunction.

- Burning Smell: A burnt odor may suggest overheating fluids or failing components.

Tools Needed for Gearbox Repairs

When it comes to fixing transmission issues, having the right instruments at hand is essential for a successful outcome. This section will outline the necessary equipment that every mechanic should consider when tackling such projects, ensuring efficiency and precision throughout the process.

Basic Tools

To start, a set of basic hand tools is vital. Wrenches, screwdrivers, and pliers are fundamental for disassembly and reassembly tasks. Additionally, a torque wrench is crucial for applying the correct force to fasteners, preventing damage or malfunction.

Specialized Equipment

In addition to standard tools, specialized equipment enhances the repair process. A diagnostic scanner can help identify issues accurately, while a hydraulic jack or transmission stand provides the necessary support for safe handling of heavy components. These tools contribute significantly to achieving optimal results in maintenance and troubleshooting.

Step-by-Step Disassembly Process

This section outlines a comprehensive guide for carefully dismantling a specific transmission unit. Understanding each stage is essential for ensuring a successful reassembly and maintaining the functionality of the components.

To begin, ensure that you have all the necessary tools at your disposal, such as wrenches, screwdrivers, and any specialized equipment required for this task. It is vital to work in a clean and organized environment to avoid misplacing any parts.

1. Initial Assessment: Before proceeding, examine the outer casing for any visible damage. This will help determine if further inspection is necessary.

2. Remove the Cover: Carefully detach the outer cover by loosening the screws or bolts. Use a gentle prying motion if needed, taking care not to damage the housing.

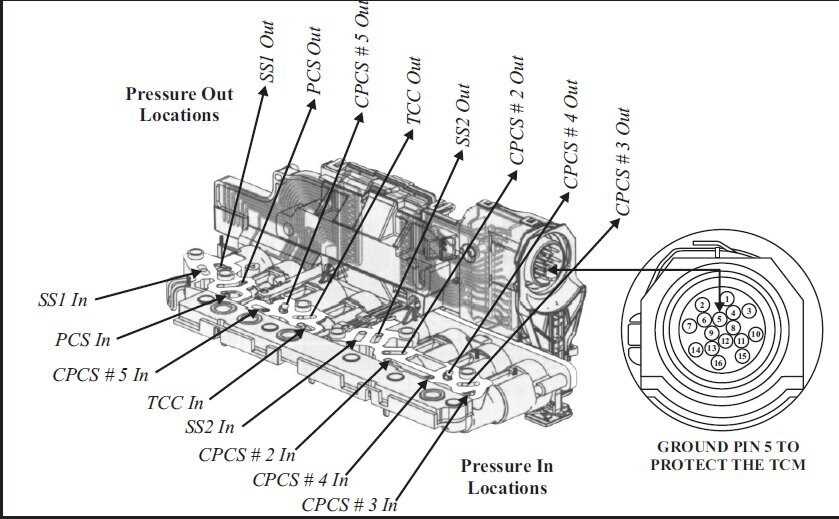

3. Disconnect Electrical Connections: Identify and unplug any electrical connectors attached to the unit. Ensure that you label them for easier reinstallation later.

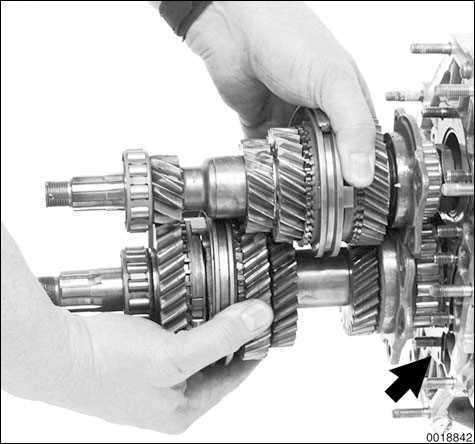

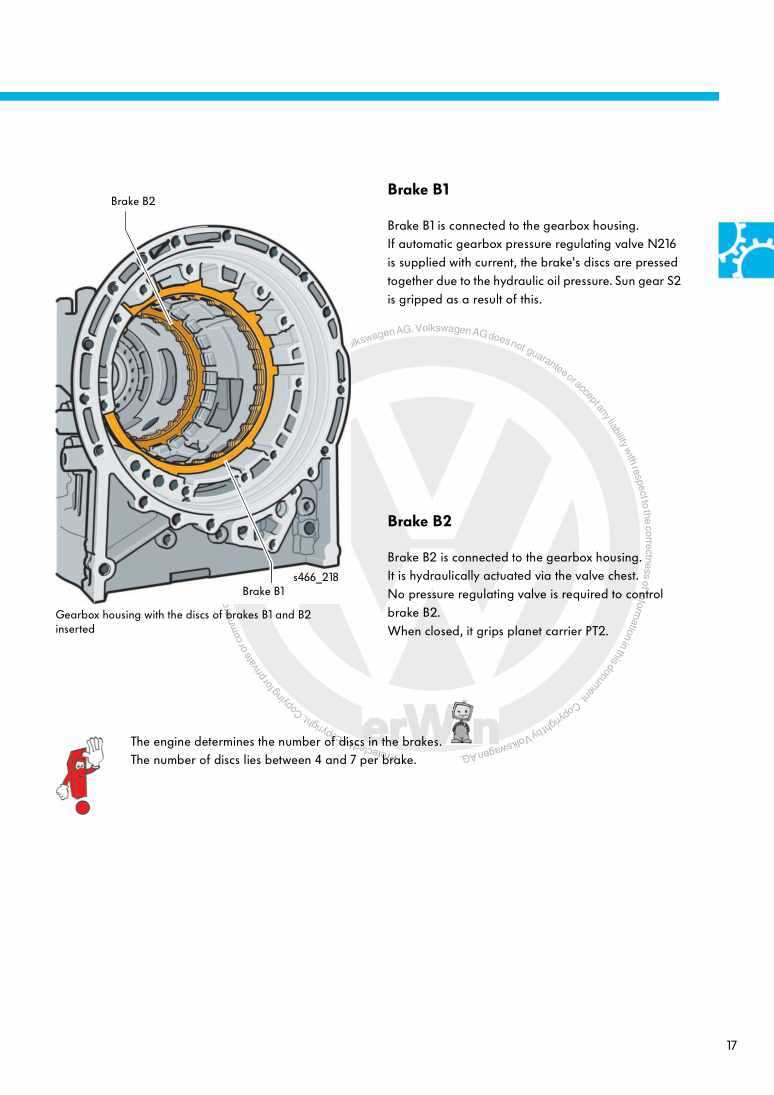

4. Take Off Internal Components: Systematically remove the internal parts, starting with the smaller elements. Keep track of the order in which you remove them, as this will facilitate reassembly.

5. Final Inspection: After all components are removed, inspect them for wear and tear. This will inform any decisions regarding replacements or repairs needed during reassembly.

By following these steps methodically, you will ensure a thorough dismantling process that lays the groundwork for effective maintenance and reassembly.

Diagnosing Transmission Fluid Problems

Identifying issues with the fluid used in your vehicle’s shifting system is crucial for maintaining optimal performance. Various symptoms can indicate potential problems, and recognizing them early can prevent further complications.

Common signs of fluid-related issues include unusual noises, erratic shifting behavior, and fluid leaks. Monitoring these symptoms can help pinpoint the root cause of the problem.

| Symptoms | Possible Causes |

|---|---|

| Unusual noises during shifting | Low fluid levels or contamination |

| Delayed or rough shifting | Fluid breakdown or incorrect type |

| Fluid leaks | Damaged seals or gaskets |

| Overheating | Insufficient fluid or debris buildup |

Regular checks of the fluid condition and level are essential practices for any vehicle owner. These actions can aid in preventing serious malfunctions and extend the lifespan of the system.

Inspecting Gears for Wear and Tear

Regular examination of mechanical components is crucial for ensuring optimal performance and longevity. Identifying signs of deterioration early can prevent more significant issues down the line. This section focuses on the essential steps involved in assessing the condition of various parts responsible for transmitting power.

Start by gathering the necessary tools and safety equipment:

- Protective gloves

- Magnifying glass

- Measuring tools

- Cleaning supplies

Follow these steps to thoroughly inspect the components:

- Visual Inspection: Examine the surface for cracks, chips, or discoloration. Pay attention to any irregularities that could indicate excessive wear.

- Measurement: Use measuring tools to check dimensions against manufacturer specifications. Look for any deviations that could affect functionality.

- Rotation Test: Manually rotate the components to feel for any unusual resistance or grinding noises. Smooth movement is a positive indicator.

- Surface Cleaning: Remove any dirt or debris that could obscure your assessment. Clean surfaces will reveal hidden flaws.

By following these guidelines, you can ensure that all essential elements are in good condition, thus maintaining reliable operation.

Replacing Worn-Out Components Effectively

When dealing with the replacement of deteriorated parts, it’s essential to approach the task methodically to ensure optimal performance and longevity. Understanding the signs of wear and having a clear plan can significantly enhance the process.

Identifying Signs of Wear

- Unusual noises during operation

- Inconsistent performance or responsiveness

- Visible damage or excessive play in components

Steps for Replacement

- Gather the necessary tools and replacement parts.

- Carefully disassemble the affected unit, taking note of the arrangement of components.

- Inspect surrounding areas for any additional damage.

- Install the new parts, ensuring proper alignment and fit.

- Reassemble the unit, double-checking for any loose connections.

- Conduct a thorough test to confirm that the issues have been resolved.

Reassembly Techniques for Automatic Gearboxes

Reassembling complex transmission systems requires careful attention to detail and a methodical approach. Following systematic procedures ensures that each component fits perfectly and functions optimally, contributing to the overall performance of the vehicle.

Key techniques to consider during the reassembly process include:

- Component Inspection: Thoroughly check all parts for wear and damage before reassembly.

- Cleanliness: Ensure all components are clean to prevent contamination that can lead to failures.

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction and wear.

- Torque Specifications: Follow manufacturer specifications for tightening bolts and fasteners.

By adhering to these principles, you can enhance the reliability and longevity of the transmission assembly.

Testing the Gearbox After Repair

After completing the restoration process, it is crucial to assess the functionality of the transmission system. This step ensures that all components operate smoothly and effectively, preventing future issues and guaranteeing optimal performance.

Begin the evaluation by performing a visual inspection of the system for any signs of leakage or misalignment. Once this is complete, proceed to engage the transmission in various drive modes to observe its responsiveness. Pay attention to the shifting patterns, ensuring that transitions are seamless and without hesitation.

Additionally, conduct a road test to simulate real-world conditions. Monitor the system’s performance during acceleration and deceleration, noting any unusual noises or vibrations. This practical assessment will provide valuable insights into the overall condition and reliability of the transmission.

Finally, compile the results of your tests to determine if any adjustments or further actions are necessary. A thorough evaluation is essential for ensuring the longevity and efficiency of the system after restoration.

Maintaining Your Gearbox for Longevity

Ensuring the durability of your vehicle’s transmission system is essential for optimal performance. Regular maintenance not only enhances functionality but also extends the lifespan of this crucial component. Understanding the key practices involved in care can prevent costly issues and improve overall efficiency.

Regular Fluid Checks: One of the most critical aspects of upkeep is monitoring fluid levels. Maintaining the right amount of lubricant helps reduce friction and wear, which can lead to smoother operation. Always refer to the specifications outlined by the manufacturer for fluid type and change intervals.

Scheduled Inspections: Routine inspections allow you to identify potential issues before they escalate. Look for signs of leaks or unusual noises during operation. Early detection can save time and resources, ensuring that your vehicle runs reliably.

Professional Servicing: Periodically, it’s advisable to consult with a skilled technician who can conduct a thorough examination. Professionals can diagnose problems that may not be visible and recommend necessary adjustments or replacements to keep the system functioning optimally.

By following these guidelines, you can significantly enhance the longevity of your transmission system, ensuring a smooth driving experience for years to come.

Common Myths About Gearbox Repairs

Many misconceptions surround the maintenance and troubleshooting of transmission systems. These beliefs can lead to confusion and poor decision-making among vehicle owners. It is essential to clarify these myths to ensure proper understanding and care for these critical components.

Myth 1: All issues require complete replacement. Many believe that any malfunction means the entire system must be replaced. However, many problems can be resolved through adjustments or partial repairs, saving time and money.

Myth 2: Fluid changes are unnecessary. Some think that the fluid within the transmission is a lifetime product. In reality, regular fluid changes are vital for optimal performance and longevity, preventing buildup and potential failures.

Myth 3: Warning signs are always obvious. There is a perception that issues will always manifest through noticeable symptoms. In truth, many problems develop subtly, making regular maintenance and inspections critical to catch potential failures early.

Myth 4: Repairs are always expensive. A common belief is that addressing issues with transmission systems is prohibitively costly. While some repairs can be expensive, many solutions are quite affordable and can help avoid larger expenses down the road.

Understanding these misconceptions helps vehicle owners make informed choices and promotes better care of their transmission systems.

When to Seek Professional Help

Recognizing the right moment to consult an expert is crucial for maintaining the functionality of your vehicle’s transmission system. Certain signs indicate that intervention by a trained technician is necessary to prevent further complications.

Common indicators that professional assistance may be needed include:

- Unusual noises during operation, such as grinding or clunking.

- Inconsistent shifting patterns or difficulty in changing gears.

- Warning lights on the dashboard indicating system malfunctions.

- Fluid leaks beneath the vehicle, which may suggest internal issues.

- Overheating of the system, often noticeable through changes in performance.

Addressing these symptoms promptly can save time and money, ensuring your vehicle operates smoothly and safely.