Motor Auto Repair Manual from 1935

In this section, we explore essential instructions aimed at enhancing the longevity and functionality of vintage vehicles. Whether you are a seasoned enthusiast or a newcomer, understanding the fundamental aspects of upkeep is crucial for ensuring optimal performance.

The preservation of these timeless machines requires careful attention to various elements, from mechanical systems to aesthetic features. By delving into practical suggestions, you can foster a deeper connection with your vehicle while ensuring it remains in excellent condition.

With a focus on thorough techniques and best practices, this guide serves as a valuable resource for those who cherish the art of maintaining classic transportation. Embracing this knowledge not only benefits your vehicle but also enriches your overall experience as an owner.

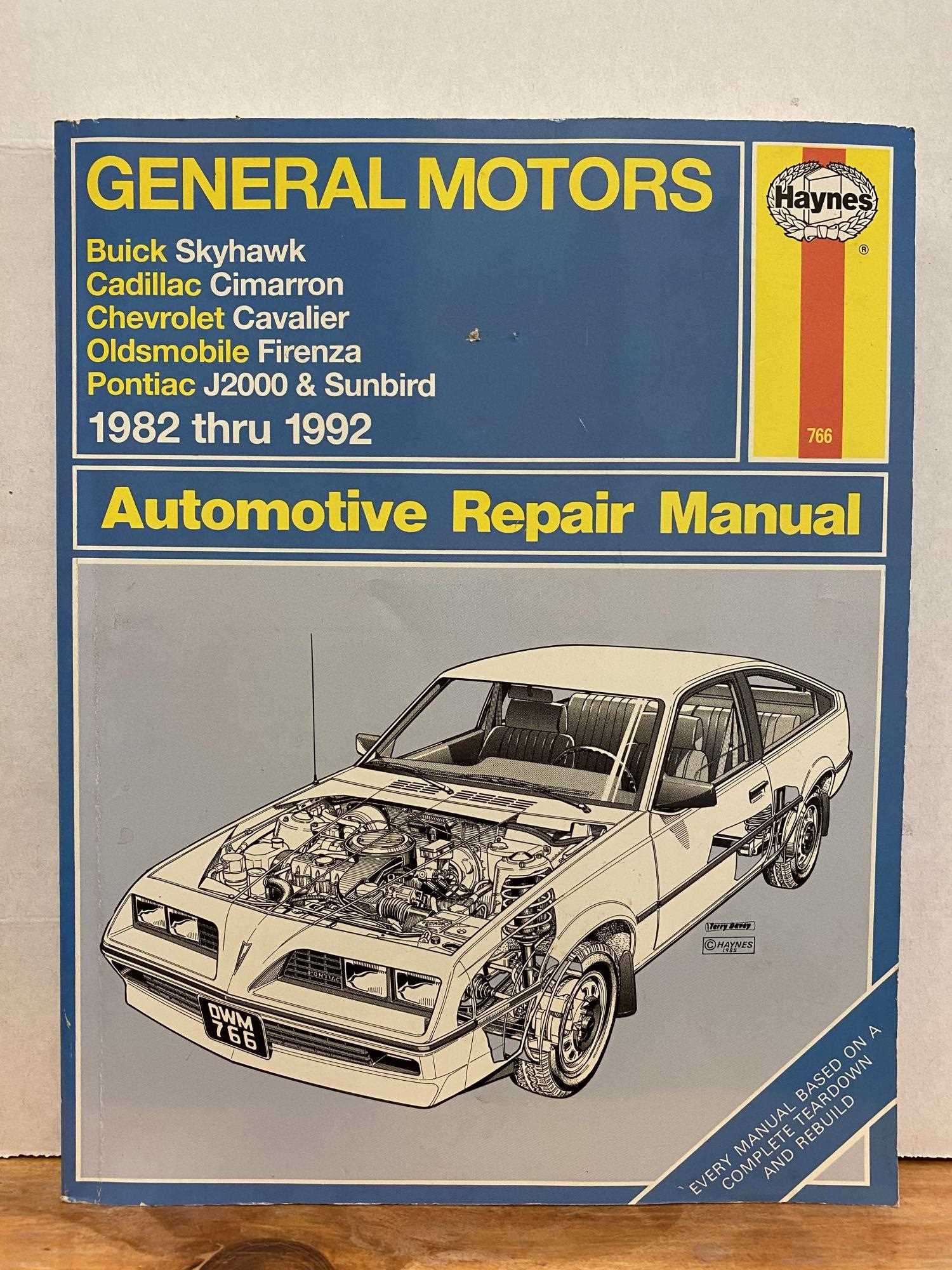

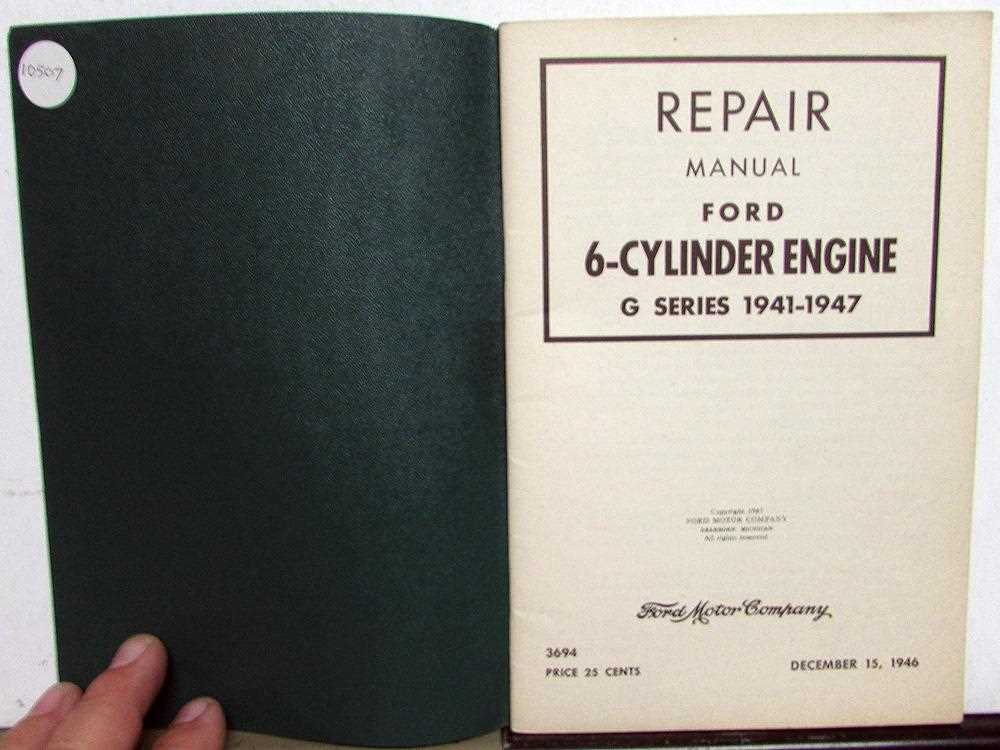

This section explores the evolution of vehicle maintenance practices during a significant year in automotive history. Understanding the methodologies and innovations of that time provides insight into the foundations of contemporary vehicle servicing.

| Key Developments | Description |

|---|---|

| Standardization of Techniques | Introduction of consistent procedures for various types of machinery, enhancing efficiency and reliability. |

| Emergence of Professional Workshops | Growth of specialized facilities aimed at providing expert assistance, fostering a community of skilled technicians. |

| Innovative Tools and Equipment | Adoption of new instruments that streamlined maintenance tasks, improving the overall effectiveness of services. |

Essential Tools for Maintenance

Maintaining a vehicle requires a selection of indispensable instruments that ensure efficiency and effectiveness. Proper tools not only facilitate routine checks but also contribute to the longevity of the machinery. This section highlights the key items every enthusiast should have in their collection for optimal upkeep.

Basic Hand Tools

- Wrenches: Adjustable wrenches and socket sets are crucial for tightening and loosening various fasteners.

- Screwdrivers: A variety of flathead and Phillips screwdrivers is essential for accessing different components.

- Pliers: Needle-nose and slip-joint pliers aid in gripping, twisting, and cutting tasks.

Specialized Equipment

- Jack: A hydraulic jack or floor jack is necessary for lifting the vehicle safely.

- Oil Filter Wrench: This tool simplifies the process of changing oil filters, ensuring a clean and efficient change.

- Multimeter: Essential for diagnosing electrical issues, a multimeter helps in measuring voltage and continuity.

Common Issues in Vintage Vehicles

Classic automobiles often present unique challenges due to their age and the materials used in their construction. Enthusiasts and owners should be aware of frequent complications that can arise, as these vehicles may not have the same durability or technological advancements as modern models.

Mechanical Problems

One of the most common concerns with older vehicles is mechanical failure. Components such as the engine, transmission, and brakes can experience wear and tear, leading to performance issues. Regular maintenance and inspections are essential to mitigate these risks.

Electrical System Failures

Electrical issues can also be prevalent in vintage models. Aging wiring, outdated electrical components, and deteriorating connections may result in malfunctions or complete failures. Upgrading certain elements while preserving the original aesthetic can improve reliability.

| Issue | Description | Solution |

|---|---|---|

| Engine Overheating | Can occur due to worn-out cooling systems. | Regularly check coolant levels and inspect hoses. |

| Transmission Slippage | May indicate worn components or fluid leaks. | Routine fluid changes and inspections. |

| Brake Failure | Due to aging brake lines and pads. | Replace worn parts and check the entire system. |

Step-by-Step Repair Techniques

This section outlines effective methods for addressing various issues related to vehicles, focusing on a structured approach to facilitate successful outcomes. By following these techniques, enthusiasts and professionals alike can ensure a thorough understanding of the processes involved in restoring functionality.

Essential Tools and Preparation

Before commencing any work, it’s crucial to gather the necessary tools and materials. Here are some key items to consider:

- Wrenches and sockets

- Screwdrivers of various types

- Diagnostic equipment

- Lubricants and cleaners

- Protective gear

Additionally, ensuring a clean and organized workspace will enhance efficiency and safety throughout the procedure.

Process Overview

The following steps provide a framework for effective intervention:

- Assessment: Examine the issue thoroughly to identify the root cause.

- Disassembly: Carefully take apart the necessary components, ensuring to keep track of all parts.

- Inspection: Check each piece for wear or damage, making notes of any that require replacement.

- Cleaning: Remove any dirt or debris from the components to ensure proper functioning.

- Reassembly: Put the pieces back together in reverse order, ensuring all fasteners are secure.

- Testing: Conduct a thorough test to confirm that the issue has been resolved.

By adhering to this structured approach, individuals can enhance their skills and achieve better results in their vehicular projects.

Understanding Engine Components

Grasping the intricacies of a powertrain is essential for anyone involved in vehicle maintenance and enhancement. The assembly consists of various elements that work harmoniously to ensure optimal performance and efficiency.

Key Parts of this system include the cylinder block, where combustion occurs, and the crankshaft, which converts linear motion into rotational energy. Each element plays a pivotal role in the overall functionality of the system.

Moreover, understanding the significance of components like the camshaft and valves helps in comprehending how air and fuel mixtures are managed within the structure. This knowledge can lead to more informed decisions regarding upgrades and diagnostics.

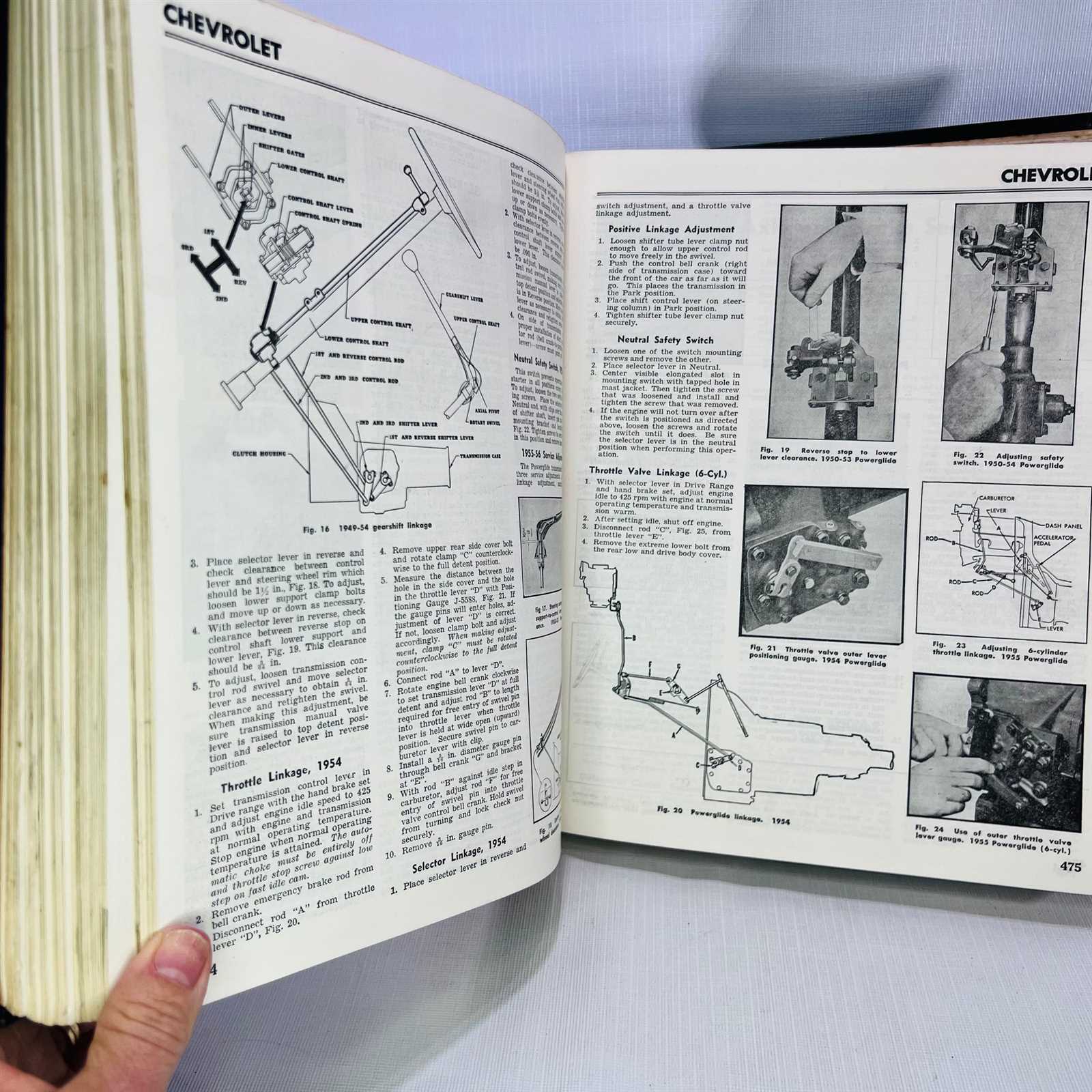

Transmission Repair and Troubleshooting

This section focuses on identifying and resolving common issues related to vehicle gear systems. Understanding the inner workings of these components is crucial for effective maintenance and ensuring optimal performance.

Common Issues and Symptoms

Various complications can arise in the gear system, leading to performance declines. Recognizing these symptoms early can prevent further damage and costly interventions.

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Slipping gears | Worn clutch or low fluid | Inspect and replace fluid or adjust the clutch |

| Noisy operation | Worn bearings or gears | Inspect and replace affected components |

| Fluid leaks | Deteriorated seals or gaskets | Replace seals and gaskets as needed |

Maintenance Tips

Regular checks and maintenance can significantly enhance the lifespan of the gear system. Following recommended procedures and schedules will help avoid unforeseen complications.

Brake System Maintenance Essentials

Ensuring the longevity and functionality of a vehicle’s stopping mechanism is crucial for safe operation. Regular upkeep not only enhances performance but also promotes safety for both the driver and other road users. Understanding the key components and their care is essential for any responsible vehicle owner.

Key Components of the Stopping Mechanism

The stopping mechanism comprises several vital elements that work together to bring the vehicle to a halt effectively. Familiarity with these parts aids in recognizing signs of wear or malfunction, which can significantly impact safety.

| Component | Function |

|---|---|

| Brake Pads | Friction material that presses against the rotor to slow down the vehicle. |

| Rotors | Metal discs that work with brake pads to create stopping power. |

| Calipers | Holds the brake pads and applies pressure to the rotors. |

| Brake Lines | Transfer hydraulic fluid from the master cylinder to the calipers. |

Maintenance Tips

Regular inspections and timely replacements of worn parts are vital for maintaining optimal performance. Keep an eye on brake fluid levels and inspect the system for leaks or corrosion. Addressing issues promptly will ensure reliable braking capabilities and enhance overall safety.

Electrical Systems: Wiring and Fuses

This section delves into the intricate components that power the electrical functionalities of vehicles. Understanding the layout and connections of wiring, along with the crucial role of fuses, is essential for ensuring proper operation and safety.

Wiring Overview

The wiring system serves as the backbone of electrical distribution, connecting various elements such as lights, ignition, and other accessories. Key aspects include:

- Conductors: Wires that carry electric current throughout the system.

- Connectors: Junctions that link different wiring sections.

- Insulation: Material that protects wires from damage and prevents short circuits.

Fuses and Their Importance

Fuses act as safety devices designed to protect the electrical system from overloads. When excess current flows, the fuse melts, breaking the circuit. Consider the following points:

- Types of Fuses: Various kinds are available, including blade, glass, and ceramic fuses.

- Fuse Ratings: Each fuse has a specified amperage rating, essential for selecting the right one for specific circuits.

- Regular Checks: Periodic inspection of fuses is necessary to ensure they are functioning correctly and to replace any that have blown.

Bodywork Repair and Restoration

The process of addressing exterior damage and renewing surfaces is essential for maintaining the overall aesthetics and functionality of a vehicle. This section delves into techniques and considerations that are crucial for achieving a high-quality finish and longevity in bodywork projects.

Assessment and Preparation are the first steps in any successful restoration. A thorough evaluation of the affected areas allows for identifying the extent of damage and the materials needed for the task. Preparing the surface by cleaning and removing old paint ensures proper adhesion of new coatings.

Once preparation is complete, Techniques for Repair come into play. Utilizing methods such as welding, filling, and smoothing can restore original contours and integrity. Each approach requires skill and the right tools to achieve the desired results.

Finally, Finishing Touches involve painting and protecting the newly repaired surfaces. Selecting appropriate coatings and applying them correctly ensures that the restoration not only looks good but also withstands the elements, providing long-lasting beauty and durability.

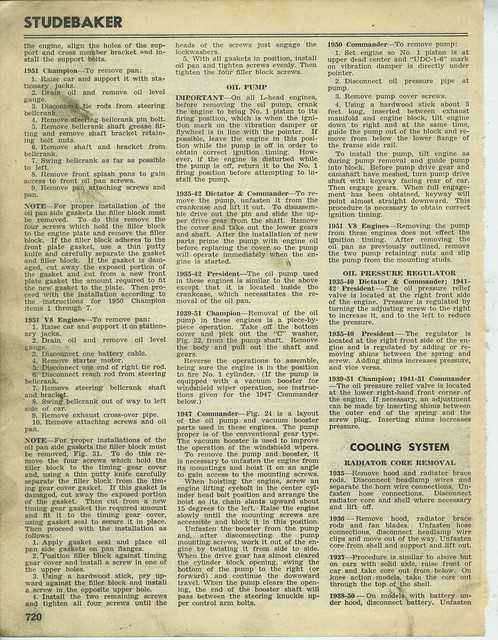

Cooling System Functionality Explained

The cooling system is a crucial component designed to regulate the temperature within an engine. By efficiently managing heat, it prevents overheating and ensures optimal performance during operation. Understanding its functionality helps in maintaining the longevity of the machinery.

Components of the Cooling System

This system typically consists of various elements, including a radiator, water pump, and thermostat. Each part plays a vital role in circulating coolant and dissipating heat effectively. The radiator, for instance, cools the liquid before it re-enters the engine, while the water pump ensures continuous flow throughout the system.

Importance of Regular Maintenance

Routine checks and maintenance are essential to ensure that the cooling system operates efficiently. Neglecting this aspect can lead to significant issues, such as engine damage due to excessive heat. Regular inspection of coolant levels and the integrity of hoses can prevent potential failures and promote reliability.

Fuel System Management Practices

Effective oversight of the fuel mechanism is crucial for maintaining optimal performance and efficiency in vintage vehicles. Proper techniques and practices ensure the system operates smoothly, minimizing issues related to fuel delivery and combustion.

One essential aspect of managing the fuel system involves regular inspections to identify potential leaks, blockages, or wear. Maintaining clean fuel lines and filters helps prevent impurities from entering the engine, enhancing overall reliability.

| Practice | Description |

|---|---|

| Inspection | Routine checks for leaks or damage in fuel lines and connections. |

| Cleaning | Periodic cleaning of fuel filters and lines to ensure unobstructed flow. |

| Calibration | Adjusting the fuel delivery system to maintain optimal fuel-air mixtures. |

| Testing | Regular testing of fuel quality to avoid degradation and contamination. |

By implementing these practices, enthusiasts can ensure longevity and performance in their classic machines, creating a more enjoyable driving experience.

Suspension and Steering Systems Overview

The suspension and steering mechanisms are vital components that significantly influence vehicle dynamics and comfort. These systems work in harmony to ensure a smooth ride and precise handling, allowing drivers to navigate various terrains effectively.

The suspension system is designed to absorb shocks from the road, maintaining stability and enhancing passenger comfort. It consists of various parts, including springs, shock absorbers, and linkages, which collectively manage the vehicle’s weight distribution and response to road conditions.

On the other hand, the steering system is responsible for directing the vehicle’s path. It enables the driver to control the direction by translating input from the steering wheel into movement of the wheels. Key elements of this system include the steering gear, linkages, and the wheel assembly, all working together to provide accurate maneuverability.

Understanding the functions and interactions of these systems is essential for maintaining optimal performance and ensuring safety on the road.

Safety Precautions for Mechanics

Ensuring a secure environment during maintenance tasks is crucial for preventing accidents and injuries. Understanding the fundamental safety measures helps create a workspace that minimizes risks associated with mechanical work.

Proper Attire and Gear

Wearing appropriate clothing is essential. Mechanics should don protective gear such as gloves and goggles to shield against potential hazards. Additionally, sturdy footwear with slip-resistant soles can prevent slips and falls in the workshop.

Workspace Organization

A well-organized workspace promotes safety. Keeping tools and equipment neatly arranged reduces the chance of accidents. Regularly inspecting the area for spills or obstructions is vital in maintaining a safe environment. Furthermore, always ensuring proper ventilation when working with hazardous materials is crucial for personal safety.