Comprehensive Guide to Automotive Motors Repair Manuals

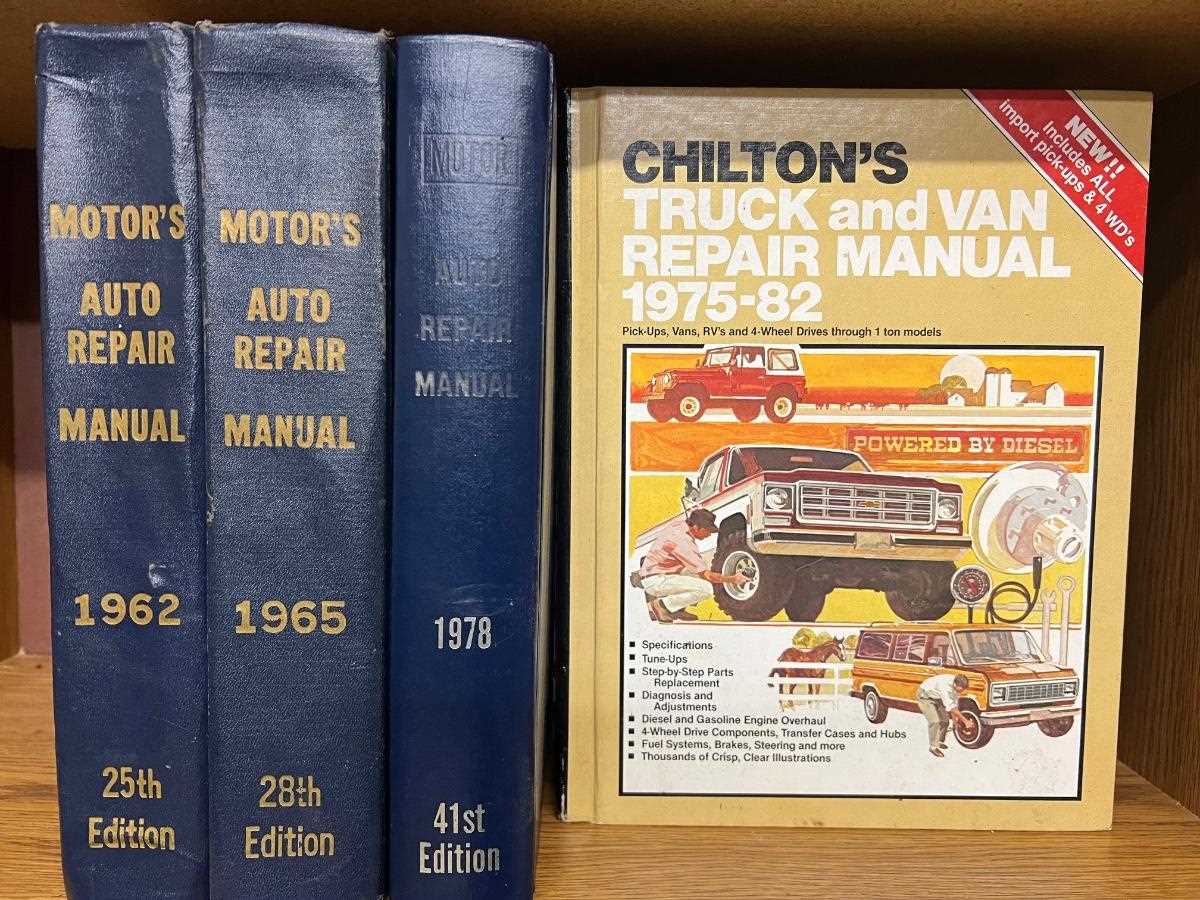

In the world of vehicle upkeep, having access to comprehensive resources is crucial for enthusiasts and professionals alike. These resources provide essential insights and step-by-step instructions that empower individuals to tackle various tasks effectively. Understanding the intricate workings of vehicles can greatly enhance one’s ability to ensure optimal performance and longevity.

With a wealth of information at one’s fingertips, individuals can dive deep into the intricacies of vehicle systems. From troubleshooting issues to performing routine tasks, these guides serve as invaluable references. Whether one is looking to improve their knowledge or solve specific problems, such resources are designed to cater to a diverse audience.

Furthermore, the availability of detailed information allows for greater independence and confidence in handling vehicle challenges. Equipped with the right tools and knowledge, anyone can transform their understanding into practical skills, fostering a deeper connection with their vehicles. This journey not only enhances proficiency but also nurtures a sense of accomplishment and satisfaction.

Understanding Common Motor Issues

Recognizing the typical problems encountered with engines can significantly enhance maintenance efforts and extend the lifespan of your vehicle. Various symptoms may indicate underlying complications, often requiring attention to ensure optimal performance and reliability.

Identifying Symptoms

Common indicators of malfunction may include unusual noises, reduced power output, or inconsistent operation. These signs often serve as warnings that further investigation is necessary to determine the root cause of the issue.

Causes of Malfunctions

Several factors can contribute to engine difficulties, such as wear and tear, overheating, or electrical failures. Addressing these issues promptly can prevent more extensive damage and costly repairs down the line.

Diagnostic Tools for Engine Repairs

Effective troubleshooting is essential for restoring vehicle functionality. A variety of specialized instruments aid in identifying issues within the power unit, allowing technicians to pinpoint malfunctions with precision.

OBD-II Scanners are invaluable for accessing onboard diagnostics, providing error codes that highlight specific problems. These devices facilitate swift assessments, enabling mechanics to address issues efficiently.

Another critical tool is the multimeter, which measures electrical parameters. This instrument assists in verifying voltage, current, and resistance levels, ensuring all electrical connections operate correctly.

Additionally, compression testers evaluate the health of engine cylinders. By measuring pressure levels, these devices indicate potential leaks or wear, guiding further examination and repairs.

Incorporating these tools into diagnostic procedures enhances accuracy and speeds up the troubleshooting process, ultimately leading to successful vehicle restoration.

Step-by-Step Motor Disassembly Guide

This section provides a comprehensive approach to the intricate process of taking apart an engine unit. Understanding each phase is crucial for effective maintenance and subsequent reassembly. Follow these detailed instructions to ensure a successful disassembly.

- Preparation

- Gather necessary tools: wrenches, screwdrivers, and pliers.

- Ensure a clean workspace to prevent loss of parts.

- Review the specific layout of the engine for reference.

- Detach any accessories such as alternators and belts.

- Remove the intake and exhaust manifolds carefully.

- Label all components and screws for easier reassembly.

- Unscrew and take off the cylinder head using a torque wrench.

- Remove the piston assembly from the block, taking note of the orientation.

- Carefully extract the crankshaft, ensuring no damage to bearings.

- Examine all parts for wear or damage.

- Clean components using appropriate solvents.

- Document any findings for future reference.

Following this structured approach allows for thorough analysis and effective reassembly of the engine unit, ensuring optimal performance in the future.

Essential Safety Precautions in Repairs

When undertaking any form of mechanical work, ensuring a safe environment is paramount. Adopting necessary precautions not only protects the individual performing the tasks but also safeguards the equipment and surroundings. Awareness of potential hazards can significantly reduce the risk of accidents and injuries.

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and steel-toed boots.

- Ensure the workspace is well-ventilated to prevent the accumulation of harmful fumes.

- Disconnect power sources before beginning any disassembly or maintenance work.

- Utilize tools that are in good condition and suitable for the specific task at hand.

- Keep a first aid kit accessible and familiarize yourself with its contents and usage.

Maintaining a clean and organized workspace is essential. Clutter can lead to mistakes and accidents, so it’s advisable to keep tools and materials properly stored when not in use. Regularly check for spills or debris that could pose a slip hazard.

- Establish a clear plan before starting any task, outlining steps and expected outcomes.

- Communicate effectively with any team members involved to ensure everyone is aware of the procedures being followed.

- Take breaks as needed to avoid fatigue, which can impair focus and increase the likelihood of errors.

By adhering to these fundamental safety practices, individuals can foster a more secure atmosphere, minimizing risks and enhancing the efficiency of mechanical tasks.

Reassembling Motors: Best Practices

Reassembling complex machinery requires meticulous attention to detail and adherence to proven techniques. Proper assembly ensures optimal performance and longevity of the device. Following established guidelines can help prevent common pitfalls and ensure a successful reconstruction process.

- Organize Components: Before beginning, sort all parts and fasteners. Use labeled containers to keep similar items together, reducing the chance of misplacing critical elements.

- Refer to Documentation: Utilize schematics or diagrams that outline the assembly process. This reference will serve as a roadmap, ensuring each component is correctly positioned.

- Clean Surfaces: Ensure all surfaces are free of debris, oil, or rust. Cleanliness is crucial for achieving proper fit and function.

- Use Proper Tools: Employ the appropriate tools for each task. Using the right equipment minimizes the risk of damage and promotes efficiency.

Following these best practices can enhance the effectiveness of the assembly process, leading to a reliable and high-performing result.

Types of Motor Lubricants Explained

Understanding the various substances used for lubrication is crucial for optimal performance and longevity of engines. These fluids play a vital role in reducing friction, minimizing wear, and ensuring smooth operation of components. Different formulations cater to specific requirements, making it essential to choose the right type for various applications.

| Type of Lubricant | Description | Common Uses |

|---|---|---|

| Synthetic Oils | Man-made fluids designed to provide superior protection and performance in extreme conditions. | High-performance engines, racing vehicles |

| Mineral Oils | Derived from refining crude oil, these are the most traditional lubricants with reliable performance. | Standard vehicles, older models |

| High Mileage Oils | Formulated with additives to restore and maintain the functionality of older engines. | Vehicles with over 75,000 miles |

| Bio-based Oils | Environmentally friendly options derived from renewable resources, offering a sustainable alternative. | Eco-conscious consumers, hybrid vehicles |

Identifying Electrical Problems in Motors

Understanding the complexities of electrical issues in mechanical devices is essential for effective diagnostics and resolution. These challenges often manifest as performance inconsistencies, unusual noises, or complete failures. By recognizing the signs early, one can prevent further damage and ensure reliable operation.

Common Symptoms of Electrical Failures

Typical indicators of electrical malfunctions include erratic functioning, unexpected shutdowns, and overheating. Monitoring the performance can help in pinpointing the root cause. In many instances, an inspection of wiring, connectors, and circuitry is necessary to identify underlying faults.

Diagnostic Techniques

Employing a systematic approach to troubleshooting can yield better results. Using multimeters to measure voltage and resistance is crucial for assessing the integrity of electrical components. Additionally, visual inspections of connections and circuit boards can reveal wear and corrosion that contribute to operational issues. Regular maintenance can significantly reduce the occurrence of such problems, ensuring longevity and efficiency.

Common Tools for Automotive Repair

In the realm of vehicle maintenance, having the right equipment is essential for achieving optimal results. A well-equipped workspace can greatly enhance efficiency and accuracy when working on various components. Different tasks require specific instruments, and understanding which tools are necessary can make the process smoother and more effective.

One of the most fundamental instruments is the socket set, which allows for the loosening and tightening of bolts and nuts. Accompanied by a ratchet, these sets provide versatility for various fastening applications. Another essential item is the torque wrench, which ensures that fasteners are tightened to the manufacturer’s specifications, preventing damage and ensuring safety.

Hand tools such as pliers, wrenches, and screwdrivers are indispensable for performing a wide array of tasks. Pliers can grip and manipulate wires or small parts, while a range of wrenches is necessary for different sizes of fasteners. Screwdrivers, available in various head types, are crucial for accessing and securing components within the vehicle.

For those delving deeper into the intricacies of vehicle systems, diagnostic tools such as code readers and multimeters are invaluable. These devices help identify issues within the electronic systems, facilitating troubleshooting and repair. Additionally, a hydraulic jack or lift allows for easy access to the undercarriage, making it simpler to work on suspension or exhaust components.

Overall, a comprehensive collection of these tools not only enhances the quality of work but also contributes to a safer and more efficient environment for vehicle maintenance. Mastery of these instruments is essential for anyone looking to effectively manage vehicle upkeep.

How to Maintain Engine Performance

Ensuring optimal performance of a vehicle’s power source involves regular attention and a systematic approach. Various factors contribute to the overall efficiency and longevity of the engine, and understanding these can significantly enhance its functionality.

Regular Inspections

Frequent checks can identify potential issues before they escalate. Key areas to focus on include:

- Fluid levels: Monitor oil, coolant, and transmission fluids to prevent overheating and friction.

- Filters: Change air and fuel filters regularly to ensure clean airflow and fuel supply.

- Belt and hoses: Inspect for wear and tear, as damaged components can lead to serious failures.

Proper Maintenance Practices

Adopting sound habits can greatly influence performance. Consider the following practices:

- Scheduled oil changes: Regularly replace engine oil to keep moving parts lubricated.

- Use quality fuel: Choose fuels with the appropriate octane rating to prevent knocking.

- Monitor driving habits: Gentle acceleration and avoiding sudden stops can reduce wear.

Cost-Effective Repair Solutions for Motors

Finding economical methods to address mechanical issues can significantly enhance the longevity and performance of your vehicle’s components. Implementing smart strategies not only saves money but also ensures that your equipment functions optimally.

Prioritize Routine Maintenance: Regular upkeep is essential for preventing major problems. Simple tasks like cleaning, lubricating, and inspecting parts can avert costly breakdowns and extend the lifespan of your machinery.

Utilize Quality Aftermarket Parts: Opting for aftermarket components can be a budget-friendly alternative to OEM parts. Ensure that these replacements are reliable and compatible with your system to maintain performance without overspending.

Learn Basic Troubleshooting: Familiarizing yourself with common issues and their solutions empowers you to handle minor faults independently. This knowledge can lead to significant savings by reducing reliance on professional services.

Engage in Community Resources: Joining local forums or workshops can provide valuable insights and shared experiences. Accessing community knowledge can help you discover cost-effective techniques and suppliers for your projects.