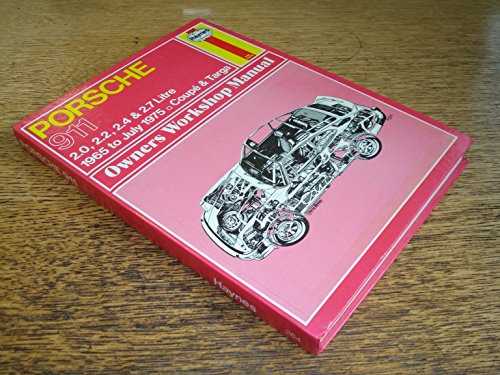

Porsche 911 Comprehensive Automotive Repair Guide

This section provides essential insights into the upkeep and troubleshooting of a specific sports vehicle renowned for its performance and engineering excellence. Understanding the intricacies of this high-performance machine is vital for enthusiasts and owners who seek to preserve its exceptional qualities over time.

By delving into the details of its functionality and mechanisms, individuals can enhance their knowledge of maintenance practices that contribute to the longevity and reliability of the vehicle. Comprehensive guidance covers various aspects, from routine checks to more advanced techniques, ensuring that every driver can engage with their vehicle confidently.

Furthermore, familiarizing oneself with the intricacies of this extraordinary car allows for a more profound appreciation of its design and capabilities. This knowledge not only empowers owners to maintain their vehicle effectively but also fosters a deeper connection to the craftsmanship and innovation that define this iconic model.

Repair Overview

This section provides a comprehensive outline for maintaining and servicing a high-performance vehicle. It emphasizes the importance of understanding the intricacies involved in the upkeep of such an iconic automobile. Each component plays a crucial role, and attention to detail can significantly enhance the longevity and efficiency of the machine.

Essential Maintenance Practices

Regular upkeep practices are vital to ensuring optimal performance. Routine inspections, fluid checks, and timely replacements of worn parts contribute to the vehicle’s reliability. Owners are encouraged to follow a structured schedule that aligns with the manufacturer’s guidelines to maximize the lifespan of key components.

Common Issues and Solutions

Understanding frequent challenges faced by owners is essential for effective troubleshooting. Some typical concerns may include issues with the electrical system, braking performance, or engine functionality. Identifying symptoms early can lead to straightforward solutions, often preventing more extensive damage and costly repairs.

Essential Tools for Maintenance

Proper upkeep of a high-performance vehicle requires a specific set of implements to ensure efficiency and longevity. Having the right tools not only simplifies tasks but also enhances the overall experience of caring for your vehicle. Below are some fundamental items every enthusiast should have in their toolkit.

Basic Hand Tools

Every maintenance routine begins with essential hand tools. A quality set of wrenches and screwdrivers is crucial for tackling various components. Ensure you have a mix of sizes to accommodate different fasteners. Torque wrenches are particularly important for achieving the correct tension on bolts, preventing over-tightening or damage to critical parts.

Diagnostic Equipment

In addition to basic tools, diagnostic devices play a vital role in vehicle maintenance. An OBD-II scanner allows for quick identification of issues by reading error codes from the engine control unit. This tool provides insight into performance and helps in making informed decisions regarding repairs and adjustments.

Understanding Engine Components

The engine is a complex assembly of parts that work together to convert fuel into mechanical energy. Each component plays a vital role in the overall functionality, contributing to efficiency and performance. By examining these elements, one can gain insight into how they operate and their importance in the system.

Key Elements of the Engine

Among the essential components are the cylinders, where the fuel-air mixture is ignited. The pistons move up and down within these cylinders, converting the energy from combustion into motion. Additionally, the crankshaft transforms this linear motion into rotational force, which ultimately powers the vehicle.

Supporting Systems

Beyond the primary components, various supporting systems, such as the cooling and lubrication systems, are crucial for maintaining optimal operating temperatures and reducing friction. These systems ensure that the engine runs smoothly and extends its lifespan.

Transmission Troubleshooting Tips

Addressing issues with the gear system can be crucial for maintaining the performance and longevity of your vehicle. Recognizing early signs of trouble can help prevent further complications and costly repairs. This section offers guidance on common problems and solutions related to the transmission, ensuring a smoother driving experience.

Common Symptoms

- Slipping gears during acceleration

- Unusual noises while shifting

- Delayed engagement when shifting from park to drive

- Fluid leaks under the vehicle

- Warning lights on the dashboard

Troubleshooting Steps

- Check Fluid Levels: Ensure that the transmission fluid is at the appropriate level. Low fluid can lead to various shifting problems.

- Inspect for Leaks: Look for signs of fluid leaks around the transmission pan and hoses. If leaks are found, address them promptly.

- Listen for Sounds: Pay attention to any unusual sounds such as grinding or whining when shifting. These could indicate underlying issues.

- Test Shifting: Conduct a test drive to assess shifting smoothness. If there is hesitation or harshness, further investigation may be needed.

- Consult the Guide: Refer to the technical documentation for specific troubleshooting methods relevant to your vehicle’s transmission system.

Brake System Diagnostics Guide

This section aims to provide essential insights into the evaluation and troubleshooting of the braking mechanism in vehicles. A well-functioning brake system is crucial for safe driving, and recognizing potential issues early can prevent serious accidents and costly repairs. The following guidelines outline common symptoms and diagnostic procedures to assess the condition of the braking system effectively.

Common Symptoms of Brake Issues

Drivers may encounter various warning signs indicating that the braking system requires attention. Here are some typical symptoms:

| Symptom | Possible Cause |

|---|---|

| Squeaking or grinding noises | Worn brake pads or damaged rotors |

| Soft or spongy brake pedal | Air in the brake lines or brake fluid leaks |

| Pulling to one side when braking | Uneven brake pad wear or malfunctioning caliper |

| Vibration during braking | Warped rotors or uneven brake pad wear |

Diagnostic Procedures

Conducting thorough diagnostic checks is vital for identifying brake system issues. Follow these steps for effective evaluation:

- Inspect brake fluid levels and condition.

- Examine the brake pads and rotors for signs of wear.

- Check for fluid leaks around calipers and hoses.

- Test brake response and pedal feel during operation.

Suspension and Steering Adjustments

Proper alignment and calibration of the suspension and steering systems are vital for achieving optimal vehicle performance and handling. This section outlines the essential adjustments required to enhance ride quality and ensure accurate steering response, contributing to a smoother and safer driving experience.

Importance of Suspension Calibration

Calibrating the suspension system involves fine-tuning various components to achieve the desired balance between comfort and stability. This process can include adjusting shock absorbers, springs, and bushings to manage the vehicle’s weight distribution and improve its overall dynamics. Regular checks and adjustments can help prevent uneven tire wear and maintain control during maneuvers.

Steering System Alignment

Accurate alignment of the steering system is crucial for ensuring responsive handling. Misalignment can lead to drifting, uneven tire wear, and compromised safety. This section highlights the procedures for checking and adjusting the toe, camber, and caster angles, which play significant roles in steering precision and vehicle stability. Routine inspections and adjustments will contribute to a more enjoyable and controlled driving experience.

Electrical System Maintenance Procedures

The upkeep of an electrical system is crucial for the optimal performance of any vehicle. Regular attention ensures reliable operation and can prevent unexpected failures. This section outlines essential practices to maintain and troubleshoot the electrical components effectively.

Here are key procedures to follow:

- Visual Inspection:

Conduct regular visual checks for any signs of wear or damage to wiring and connectors. Look for:

- Frayed or exposed wires

- Corrosion on terminals

- Loose connections

- Battery Care:

Maintain the battery to ensure it operates efficiently:

- Clean battery terminals and ensure a secure connection.

- Check the electrolyte levels and top up if necessary.

- Test the battery’s voltage regularly to detect potential issues.

- Fuse Inspection:

Fuses protect the electrical system from overloads:

- Inspect fuses for continuity and replace any that are blown.

- Ensure that the fuse ratings match the specifications to avoid damage.

- Wiring and Connections:

Keep wiring and connections in top condition:

- Secure all connections to prevent shorts or interruptions.

- Use appropriate connectors for repairs to maintain integrity.

- Avoid using tape as a long-term solution for frayed wires.

By adhering to these procedures, you can significantly enhance the reliability and longevity of the vehicle’s electrical system.

Bodywork Repair Techniques

This section focuses on various methods and practices aimed at restoring the exterior structure of vehicles. Understanding these techniques is crucial for achieving a seamless finish and maintaining the integrity of the chassis.

Key approaches to enhancing bodywork include:

- Panel Beating: This method involves manipulating the metal panels back to their original shape using specialized tools. Care must be taken to avoid damaging the surrounding areas.

- Welding: When sections of the body are too damaged, welding new pieces is essential. This process requires skill to ensure a strong bond and a clean appearance.

- Filling: For minor imperfections, fillers can be applied to smooth out dents and scratches. Once dried, the surface can be sanded to create a flawless finish.

- Painting: After all repairs are completed, the final step is to repaint the affected areas. Matching the original color and applying a clear coat are vital for a professional look.

Each technique requires attention to detail and proper execution to ensure the longevity and aesthetic appeal of the vehicle’s exterior.

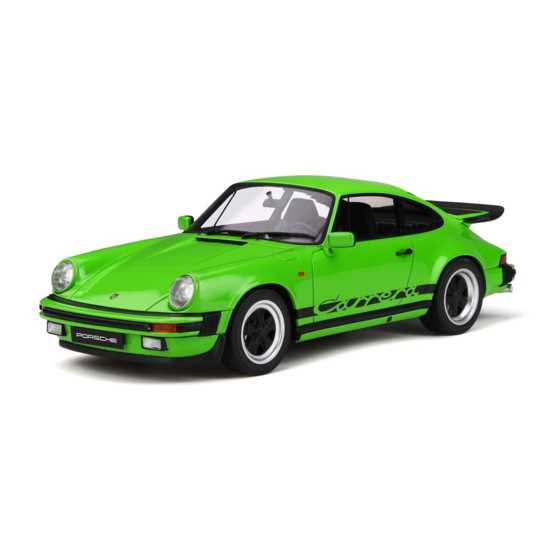

Performance Upgrade Options

Enhancing the capabilities of a high-performance vehicle can significantly elevate its driving experience. Numerous modifications can be implemented to boost speed, handling, and overall efficiency. This section explores various enhancement possibilities that cater to enthusiasts seeking improved dynamics and responsiveness from their machines.

Engine Modifications: Upgrading the engine components can lead to substantial performance gains. Options include installing a high-flow intake system, upgrading the exhaust for better airflow, and implementing tuning software to optimize engine mapping. These changes can result in increased horsepower and torque, providing a more exhilarating ride.

Suspension Enhancements: Improving the suspension system is crucial for enhancing handling and stability. Upgrading to performance shocks and struts, along with adjustable coilovers, allows for precise tuning of ride height and stiffness. These upgrades can significantly improve cornering capabilities and overall road feel.

Brake System Upgrades: To match the increased power, enhancing the braking system is essential. Installing larger rotors, high-performance calipers, and upgraded brake pads ensures better stopping power and reduced fade during intense driving conditions. This is vital for maintaining control and safety.

Tire and Wheel Choices: The right set of tires and wheels can dramatically affect traction and handling. Opting for lightweight alloys can reduce unsprung weight, while performance tires provide enhanced grip and responsiveness. These choices contribute to a more engaging and controlled driving experience.

Ultimately, selecting the right combination of upgrades depends on individual driving preferences and intended use. Careful consideration of each component’s impact on performance can lead to a truly remarkable transformation.

Routine Maintenance Checklists

Regular upkeep is essential for ensuring optimal performance and longevity of your vehicle. By following a systematic approach, owners can identify potential issues before they escalate, thereby enhancing safety and reliability. This section outlines comprehensive checklists that should be adhered to during routine inspections.

Engine Checks: Ensure that the engine oil level is adequate and replace the oil filter as needed. Inspect belts and hoses for wear or leaks. Regularly check coolant levels and assess the condition of the radiator.

Tire Maintenance: Monitor tire pressure and tread depth. Rotate tires periodically to promote even wear. Inspect for any signs of damage or punctures that may require attention.

Brake System Inspection: Examine brake pads and rotors for signs of wear. Check brake fluid levels and ensure that there are no leaks in the system. Test the functionality of the handbrake and foot brake for proper operation.

Battery Care: Inspect battery terminals for corrosion and ensure connections are tight. Check the battery charge level and clean any debris that may have accumulated around it.

Lighting and Electrical Systems: Verify that all exterior lights, including headlights, taillights, and indicators, are functioning correctly. Inspect fuses and replace any that are blown.

By adhering to these checklists, owners can maintain their vehicles in peak condition, thereby prolonging their lifespan and enhancing the overall driving experience.

Common Issues and Solutions

This section addresses typical challenges encountered in high-performance vehicles and offers practical solutions to ensure optimal functionality. Understanding these common problems can significantly enhance the driving experience and prolong the life of the vehicle.

Engine Performance Problems

One frequent issue is the decline in engine efficiency, often indicated by reduced power output or increased fuel consumption. This may stem from factors such as clogged air filters or faulty sensors. Regular maintenance, including timely replacement of filters and thorough diagnostic checks, can effectively mitigate these concerns.

Electrical System Malfunctions

Electrical issues, such as malfunctioning lights or erratic dashboard displays, can be a source of frustration. These problems often arise from loose connections or worn-out components. Conducting periodic inspections of the electrical system and replacing damaged wiring can help restore functionality and reliability.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is paramount. Following specific guidelines can prevent accidents and injuries, promoting a secure environment for both the individual performing the tasks and any nearby personnel. Adopting these measures will help in maintaining focus and effectiveness throughout the process.

Essential Safety Measures

- Always wear appropriate protective gear, including gloves and goggles.

- Utilize tools correctly and ensure they are in good condition before use.

- Keep the workspace organized and free of unnecessary clutter.

- Ensure proper ventilation when working with chemicals or fumes.

- Disconnect the power source before starting any work on electrical components.

Emergency Preparedness

- Familiarize yourself with the location of first aid kits and fire extinguishers.

- Have an emergency plan in place in case of serious incidents.

- Know how to shut off utilities in case of a hazardous situation.

- Maintain clear communication with others in the vicinity.