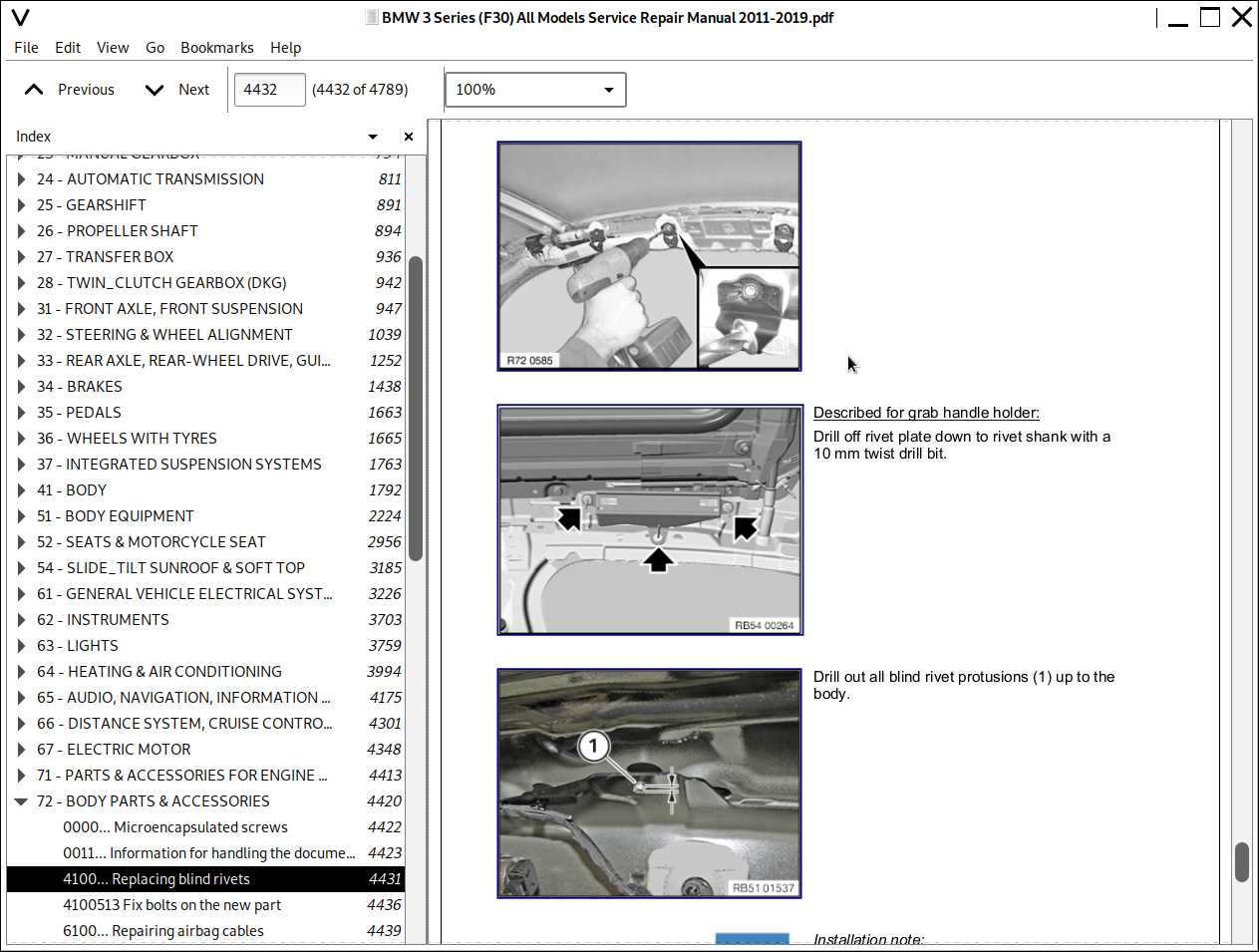

Comprehensive Guide for BMW 335i Repairs

Ensuring the optimal performance of your automobile involves understanding its components and systems. This guide aims to provide essential insights into the various procedures necessary for maintaining your vehicle effectively. By following these guidelines, you can enhance the longevity and reliability of your transportation.

From routine inspections to troubleshooting techniques, this resource covers a wide range of topics relevant to vehicle upkeep. You will find valuable information on how to address common issues, perform necessary adjustments, and maintain key systems. Understanding these elements can empower you to take control of your vehicle’s health.

Whether you are a seasoned enthusiast or a novice owner, having access to clear, detailed instructions can make a significant difference in your maintenance routine. This guide serves as a practical reference, enabling you to confidently navigate the complexities of your automobile’s care.

This section provides a comprehensive look at the notable attributes and capabilities of a high-performance vehicle. Understanding these characteristics is essential for appreciating its design and functionality, as well as for guiding maintenance and care practices.

- Engine Performance: Explore the powertrain specifications and the influence of engine size on acceleration and efficiency.

- Handling Dynamics: Discuss the suspension setup and its role in providing a responsive driving experience.

- Interior Comfort: Highlight the materials and layout that contribute to an enjoyable driving environment.

- Technological Features: Review the advanced systems available for entertainment and navigation purposes.

- Safety Systems: Examine the various safety features that enhance occupant protection.

- Fuel Efficiency: Analyze consumption rates and the impact of driving habits on overall efficiency.

- Customization Options: Discuss the different configurations and accessories that allow personalization of the vehicle.

- Exterior Design: Describe the aesthetics and engineering behind the vehicle’s exterior features.

- Maintenance Recommendations: Provide insights on routine checks and servicing to ensure longevity.

- Common Issues: Identify typical problems that may arise and how to address them.

- Performance Upgrades: Discuss potential modifications that can enhance driving experience and power.

- Market Comparison: Compare attributes with similar models in the same class to highlight unique selling points.

Common Issues with BMW 335i

Vehicles of this category often encounter a range of challenges that can affect their performance and reliability. Understanding these frequent problems is essential for owners to maintain optimal functionality and ensure a smooth driving experience.

One notable issue involves the engine’s power delivery, where owners may experience a noticeable drop in acceleration or unusual vibrations during operation. This can often be linked to complications with the fuel system or ignition components, necessitating careful inspection.

Another common concern is related to the cooling system, where overheating can occur due to a malfunctioning thermostat or a leak in the radiator. Such issues not only diminish efficiency but also pose a risk of severe engine damage if left unaddressed.

Additionally, electrical system glitches, such as erratic dashboard warnings or malfunctioning features, frequently arise. These problems may stem from faulty sensors or wiring connections, requiring thorough diagnostics to resolve.

Lastly, the suspension components may wear down, leading to a less comfortable ride and potential handling issues. Regular maintenance checks can help identify and rectify these concerns before they escalate.

Maintenance Schedule for BMW 335i

Regular upkeep is essential for ensuring the longevity and performance of your vehicle. Establishing a systematic schedule for inspections and service can help identify potential issues before they escalate. This proactive approach not only enhances reliability but also optimizes driving experience.

Every 5,000 miles or 6 months: It is advisable to check the engine oil level and condition, replacing it if necessary. Additionally, inspect the air filter and replace it if it appears dirty or clogged. This routine maintenance contributes to better engine efficiency.

Every 10,000 miles: Inspect brake pads and rotors for wear. Ensure that fluid levels for brakes, coolant, and windshield washer are topped up. Attention to these components can prevent more significant repairs in the future.

Every 15,000 miles: Perform a more comprehensive inspection, including tire rotation and balancing, as well as checking the condition of belts and hoses. Replacing worn components at this stage can avoid unexpected breakdowns.

Every 30,000 miles: Replace the cabin air filter and conduct a thorough inspection of the exhaust system. This ensures that the vehicle remains comfortable and operates efficiently.

Every 60,000 miles: Consider replacing the spark plugs and inspecting the fuel system. These actions can significantly improve performance and fuel efficiency, keeping the vehicle in optimal condition.

Tools Required for Repairs

When undertaking maintenance or fixing issues, having the right instruments is crucial for efficient and safe work. A well-equipped toolkit ensures that tasks can be performed effectively, minimizing the risk of damage and facilitating smooth procedures. Below is a list of essential items that should be included in any automotive toolkit.

| Tool Type | Description |

|---|---|

| Wrenches | Essential for loosening or tightening nuts and bolts in various applications. |

| Screwdrivers | Used for driving screws, available in various sizes and types for different head shapes. |

| Socket Set | Provides versatility in accessing fasteners in tight spaces, commonly includes a ratchet. |

| Pliers | Useful for gripping, twisting, and cutting wires or other materials. |

| Torque Wrench | Ensures that fasteners are tightened to the manufacturer’s specified settings. |

| Diagnostic Tools | Helps in identifying issues by reading fault codes and monitoring systems. |

Engine Components and Functionality

The engine is the heart of any vehicle, comprising various elements that work in harmony to convert fuel into motion. Understanding these components is essential for anyone looking to grasp how power is generated and delivered to the wheels. Each part plays a specific role, contributing to overall efficiency and performance.

Key Components

Among the critical parts are the cylinder block, pistons, and crankshaft. The cylinder block houses the cylinders where combustion occurs, while pistons move up and down, creating the necessary force. The crankshaft then converts this linear motion into rotational energy, enabling the vehicle to move.

Functionality Overview

The seamless operation of these components is vital. Fuel enters the cylinders, mixes with air, and ignites to produce energy. This energy pushes the pistons, which drive the crankshaft, ultimately powering the vehicle. Regular maintenance and understanding of these functions can enhance performance and longevity.

Understanding the Electrical System

The electrical framework of a vehicle is crucial for its overall functionality, providing power to various components and ensuring seamless operation. This system encompasses a variety of elements, from batteries and alternators to wiring harnesses and control modules, all working in harmony to maintain performance and safety.

Key Components

At the heart of the electrical architecture lies the battery, responsible for storing energy and supplying it to the vehicle’s electrical circuits. The alternator plays a vital role in recharging the battery while the engine is running, ensuring a consistent power supply. Additionally, fuses and relays protect the system from overloads, safeguarding sensitive components.

Troubleshooting Common Issues

Diagnosing problems within the electrical system often involves checking for faulty connections or damaged wires. Common signs of issues include dimming lights or a non-starting engine. Utilizing a multimeter can aid in identifying electrical faults, allowing for timely interventions that enhance reliability and performance.

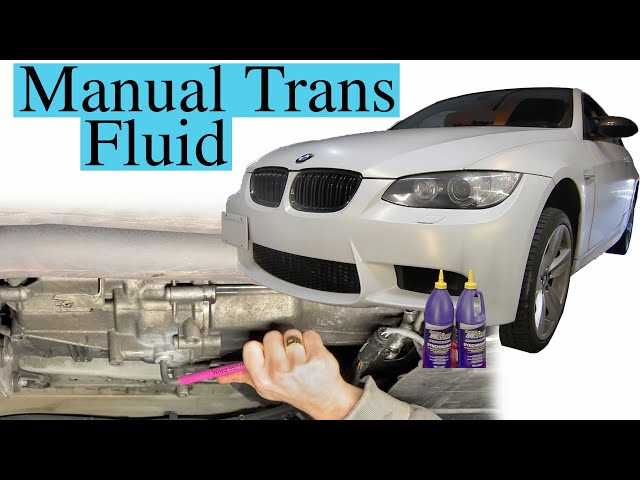

Transmission Troubleshooting Techniques

This section provides guidance on diagnosing common issues associated with gear shifting systems. Understanding the fundamental aspects of these systems can assist in identifying problems that may arise, ensuring a smoother operation and longevity of the vehicle.

Common Symptoms and Their Causes

Various signs can indicate issues within the gear shifting mechanism. Recognizing these symptoms early can prevent further damage and costly repairs. Below are some frequent problems along with their potential causes:

| Symptom | Possible Cause |

|---|---|

| Slipping Gears | Low fluid level or contaminated fluid |

| Delayed Engagement | Worn transmission bands or faulty solenoids |

| Unusual Noises | Damaged gears or bearings |

| Fluid Leaks | Worn seals or gaskets |

Diagnostic Steps

To accurately troubleshoot, a systematic approach should be taken. Begin by checking fluid levels and condition, then proceed to inspect components for wear or damage. Utilizing diagnostic tools can aid in identifying electronic issues that may affect functionality.

Brake System Inspection Guidelines

Regular examination of the braking mechanism is crucial for maintaining vehicle safety and performance. This section outlines essential practices for assessing the components involved in stopping a vehicle, ensuring that all parts function effectively and efficiently.

Visual Assessment

Start by performing a thorough visual inspection of the braking components. Look for signs of wear or damage on the brake pads, rotors, and lines. Ensure there are no leaks in the hydraulic system, as this can compromise braking ability. Also, check for any unusual noises when the brakes are applied, as this may indicate underlying issues.

Functional Testing

After the visual check, proceed with functional testing. Apply the brakes at various speeds to assess responsiveness and feel. Any delay in response or a spongy sensation may suggest air in the lines or deteriorating components. It’s essential to ensure that the braking system operates smoothly to provide maximum safety on the road.

Suspension and Steering Adjustments

The performance and handling of a vehicle significantly depend on the proper alignment and calibration of its suspension and steering systems. These components work together to ensure a smooth ride and precise control, making adjustments essential for optimal functionality.

Alignment Settings are crucial for maintaining correct wheel angles. Improper alignment can lead to uneven tire wear and affect the vehicle’s stability. Regular checks and adjustments help preserve tire life and enhance overall performance.

Suspension Components, such as springs and shock absorbers, play a vital role in absorbing road irregularities. Ensuring these parts are functioning correctly is essential for a comfortable ride. Adjustments to the stiffness and height of the suspension can also improve handling characteristics, providing a tailored driving experience.

Steering Calibration is another critical aspect that requires attention. Adjusting the steering ratio and response can enhance maneuverability, allowing for better control in various driving conditions. Regular inspections and modifications to this system help maintain a responsive and safe driving experience.

Cooling System Maintenance Tips

Regular upkeep of the cooling system is essential for optimal engine performance and longevity. Proper management prevents overheating and potential damage, ensuring the vehicle runs smoothly under various conditions.

Check Coolant Levels: Regularly inspect the coolant reservoir to maintain appropriate fluid levels. Low coolant can lead to overheating and engine issues.

Inspect Hoses and Connections: Examine hoses for signs of wear, leaks, or cracks. Ensure all connections are secure to avoid coolant loss.

Flush the System: Periodically flushing the cooling system helps remove contaminants and old fluid. This process can enhance the efficiency of the cooling mechanism.

Monitor Temperature Gauges: Keep an eye on the temperature readings while driving. Unusual spikes may indicate a malfunction within the cooling system that needs immediate attention.

Replace Thermostat: If the engine frequently runs hotter than normal, consider replacing the thermostat. A malfunctioning thermostat can disrupt the flow of coolant.

By adhering to these maintenance tips, you can significantly extend the life of the cooling system and ensure reliable vehicle operation.

Fuel System Diagnostics and Repair

Diagnosing and addressing issues within the fuel delivery system is crucial for maintaining optimal engine performance. This section outlines essential steps and considerations to effectively identify and resolve fuel-related problems, ensuring a smooth operation of the vehicle.

Common Symptoms of Fuel System Issues

Drivers may experience various indicators signaling potential fuel system malfunctions. Recognizing these symptoms early can facilitate prompt troubleshooting and minimize further complications.

| Symptom | Possible Cause |

|---|---|

| Engine misfires | Clogged fuel injectors or pump failure |

| Difficulty starting | Faulty fuel pump or low pressure |

| Reduced fuel efficiency | Leaking fuel lines or malfunctioning sensor |

| Check engine light on | Sensor failure or fuel mixture issues |

Diagnostic Procedures

Implementing systematic diagnostic procedures allows for accurate identification of issues within the fuel system. Begin by checking fuel pressure and inspecting components such as the fuel filter, pump, and injectors for blockages or wear.

Exhaust System and Emissions Control

The exhaust system plays a crucial role in managing engine byproducts while ensuring that harmful emissions are minimized. This complex network of components is designed not only to channel exhaust gases away from the engine but also to reduce pollutants that can harm the environment and affect air quality.

Key elements of this system include the exhaust manifold, catalytic converter, and muffler. The exhaust manifold collects gases from the engine cylinders and directs them into the system. Following this, the catalytic converter works to transform harmful substances into less harmful emissions before they are expelled into the atmosphere. Finally, the muffler is responsible for reducing noise produced by the escaping gases, contributing to a more pleasant driving experience.

Regular maintenance of the exhaust system is vital for optimal performance and compliance with emissions regulations. Over time, components can become worn or damaged, leading to increased emissions and decreased efficiency. It is essential to conduct periodic inspections and address any issues promptly to ensure that the system operates effectively.

Furthermore, modifications to the exhaust system may enhance performance but should be approached with caution, as they can impact emissions compliance. Always consider the balance between improved engine performance and adherence to environmental standards.