Comprehensive Repair Manual for BMW K1300S

For enthusiasts and owners of high-performance two-wheelers, understanding the intricacies of vehicle upkeep is essential. A well-maintained machine not only enhances performance but also ensures safety on the road. This guide aims to provide essential insights into the maintenance process, covering key aspects that every rider should know.

Whether you are a seasoned mechanic or a novice looking to learn, having access to detailed information can make a significant difference. This resource is designed to assist in troubleshooting, performing routine checks, and executing complex repairs. With a focus on practical steps and clear explanations, riders will find the information invaluable.

Maintaining your vehicle in optimal condition requires knowledge of various systems and components. From engine diagnostics to electrical systems, understanding how to address common issues will empower riders to take charge of their machines. By following the guidelines presented here, you’ll be better equipped to keep your vehicle running smoothly for years to come.

Essential Tools for BMW K1300S Repair

Having the right equipment is crucial for maintaining and servicing your motorcycle effectively. Each task requires specific instruments to ensure that everything is done safely and efficiently. Below is a list of essential tools that every enthusiast should have in their toolkit for working on this particular model.

- Socket Set: A comprehensive socket set is necessary for loosening and tightening various fasteners.

- Torque Wrench: To ensure proper tightening of bolts to manufacturer specifications.

- Hex Key Set: Useful for accessing hard-to-reach screws and bolts.

- Screwdriver Set: A variety of flathead and Phillips screwdrivers will cover most needs.

- Chain Tool: Essential for adjusting or replacing the drive chain.

- Oil Filter Wrench: Makes changing the oil filter a much simpler process.

In addition to these basics, consider including the following specialized tools:

- Brake Bleeder Kit: Necessary for maintaining hydraulic brake systems.

- Multimeter: Useful for diagnosing electrical issues.

- Pliers Set: Different types for various gripping and cutting tasks.

- Safety Gear: Gloves and goggles to protect yourself while working.

Investing in quality tools not only facilitates maintenance but also enhances the overall ownership experience, making every project more enjoyable and effective.

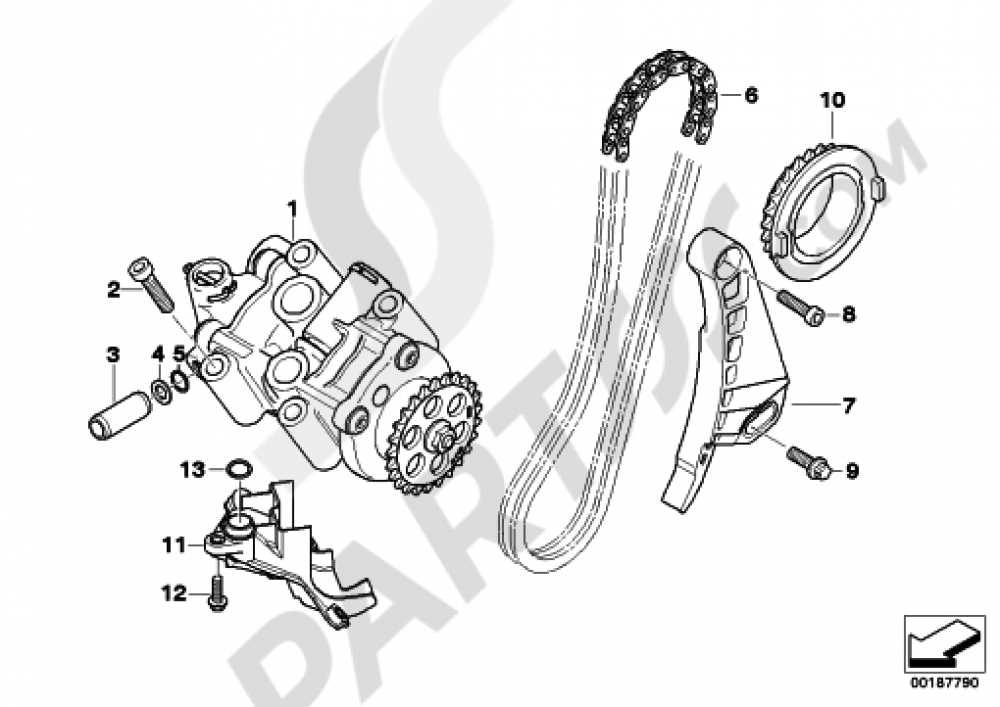

Understanding the BMW K1300S Engine

This section delves into the intricacies of a high-performance motorcycle engine, focusing on its design, functionality, and maintenance aspects. A powerful engine is the heart of any motorcycle, providing the necessary energy and responsiveness for an exhilarating riding experience. The engineering behind such an engine plays a crucial role in its overall performance, efficiency, and reliability.

Key Features of the Engine

- Displacement: The engine’s capacity is vital for determining power output and torque characteristics.

- Cylinder Configuration: The arrangement of cylinders affects balance, vibration, and performance.

- Fuel System: The type of fuel delivery system influences throttle response and efficiency.

- Cooling System: Effective cooling mechanisms are essential for maintaining optimal operating temperatures.

Maintenance Considerations

- Regular oil changes are crucial for engine longevity and performance.

- Monitoring coolant levels helps prevent overheating and potential damage.

- Inspecting the fuel system ensures efficient fuel delivery and optimal combustion.

- Keeping the air filter clean supports proper airflow and engine efficiency.

Understanding these components and their functions will help riders appreciate the engineering marvel that powers their motorcycle, ensuring a safe and thrilling ride on every journey.

Common Issues and Their Solutions

When it comes to high-performance motorcycles, various challenges can arise over time. Understanding these frequent problems and their remedies is essential for maintaining optimal functionality and ensuring a safe riding experience. Below, we explore some prevalent concerns and provide effective solutions.

Electrical System Failures

One of the most common issues involves the electrical system, which may exhibit symptoms like flickering lights or a non-responsive ignition. This can often be traced back to a weak battery or corroded connections. To resolve this, regularly check the battery’s charge and clean any corrosion from the terminals. If the problem persists, consider replacing the battery or inspecting the wiring for damage.

Suspension and Handling Problems

Riders may notice decreased stability or unusual handling characteristics, which can stem from worn suspension components or improper tire pressure. Regularly inspect the shock absorbers for leaks and ensure that tire pressure is within the recommended range. Adjusting or replacing worn parts can significantly improve ride quality and safety.

Step-by-Step Maintenance Procedures

Proper upkeep of your vehicle is essential for ensuring longevity and optimal performance. This section outlines a series of systematic tasks designed to maintain your motorcycle’s functionality and safety. Following these procedures will help you identify potential issues before they become significant problems.

Routine Inspections

Begin by performing regular visual checks of critical components. Examine the tires for wear and proper inflation. Look over the brake system for any signs of fluid leaks or pad wear. Ensure that the lights and signals are functioning correctly. A thorough inspection can prevent unexpected breakdowns and enhance your riding experience.

Fluid Changes

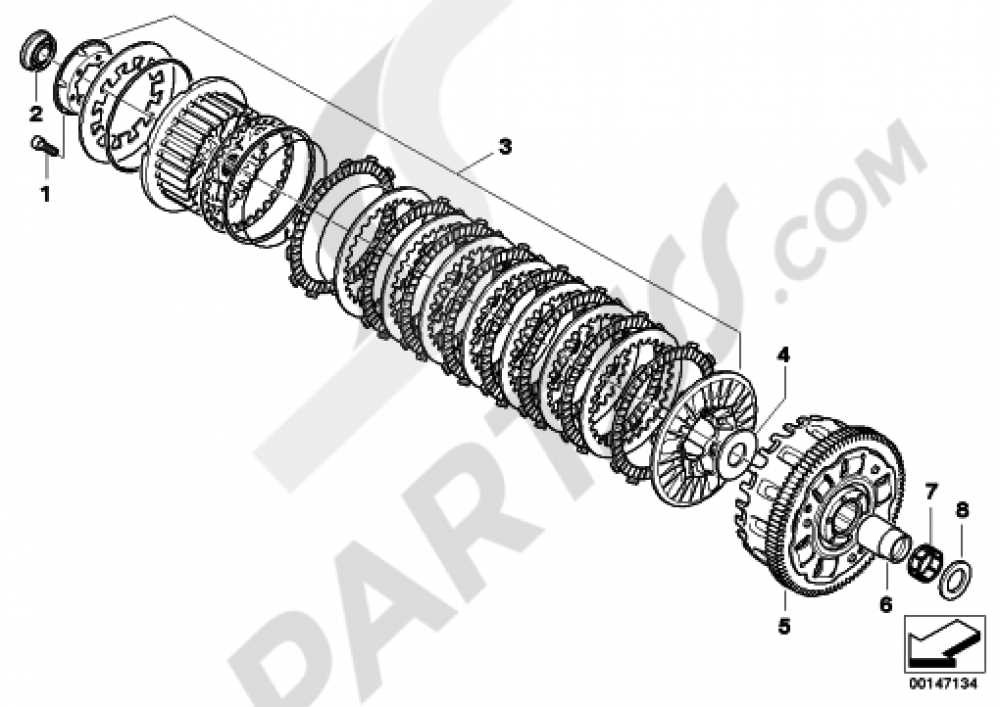

Maintaining proper fluid levels is vital. Start with the engine oil; change it according to the manufacturer’s recommendations, typically every 5,000 to 7,000 kilometers. Ensure you replace the oil filter simultaneously. Next, check the coolant and brake fluid levels, topping them up as necessary. Don’t forget to inspect the clutch fluid as well; clean, well-maintained fluids are crucial for peak performance.

Electrical System Troubleshooting Guide

This section aims to provide a comprehensive approach to diagnosing and resolving issues within the electrical components of your motorcycle. Understanding the intricacies of the electrical system is crucial for ensuring optimal performance and safety. With a methodical examination, you can identify malfunctions and implement effective solutions.

Common Symptoms and Their Causes

Many riders encounter symptoms such as flickering lights, failure to start, or erratic dashboard indicators. These issues can often stem from loose connections, corroded terminals, or faulty wiring. Conducting a visual inspection of the battery and harness can reveal obvious problems, while a multimeter can help check for continuity and voltage irregularities.

Testing and Diagnosis Techniques

To accurately diagnose electrical problems, start with the battery, ensuring it is fully charged and properly connected. Next, test the fuses and relays to confirm they are functioning as intended. For deeper issues, consider utilizing diagnostic tools to read fault codes, which can provide valuable insights into underlying electrical faults.

Replacing Brake Components Effectively

Ensuring optimal performance of your motorcycle’s braking system is crucial for safety and control. When the time comes to replace components, understanding the procedure and choosing the right parts can make all the difference. This section provides a comprehensive overview of how to efficiently execute replacements, minimizing downtime while maximizing reliability.

Before starting the process, gather all necessary tools and components. A clean workspace and the right equipment will facilitate a smoother operation. The following table outlines the essential items required for component replacement:

| Item | Description |

|---|---|

| Brake Pads | Replace worn pads to ensure effective stopping power. |

| Brake Discs | Inspect and replace if warped or damaged for consistent braking. |

| Brake Fluid | Use fresh fluid to maintain hydraulic system efficiency. |

| Tools | Wrenches, screwdrivers, and a torque wrench for proper assembly. |

| Clean Cloth | For wiping components and ensuring a clean work area. |

Start by safely elevating the motorcycle to access the brakes. Carefully remove the wheel and inspect the current components for wear. When installing new parts, follow manufacturer specifications closely, especially regarding torque settings. Bleeding the brake lines after replacing fluid ensures that the system is free of air bubbles, enhancing braking efficiency.

Finally, conduct a test ride to evaluate the effectiveness of your work. Pay attention to any unusual noises or responses during braking. Regular maintenance and timely replacements will contribute to a reliable and safe riding experience.

Upgrading Suspension for Better Performance

Enhancing the suspension system is crucial for maximizing the performance and handling characteristics of any motorcycle. An upgraded suspension not only improves ride comfort but also boosts stability during high-speed maneuvers and sharp turns. This section delves into the benefits and options available for elevating your bike’s suspension setup.

Benefits of Suspension Upgrades

Investing in a better suspension can significantly impact your riding experience. A high-quality system allows for better shock absorption, reducing the impact from uneven road surfaces. This leads to increased tire contact with the ground, enhancing traction and overall safety. Moreover, adjustable components can be fine-tuned to match your riding style, whether for daily commuting or spirited weekend rides.

Types of Upgrades

There are several paths to consider when upgrading suspension. Aftermarket shocks and forks are popular choices, offering improved performance and customization options. Additionally, components such as springs and dampers can be replaced to achieve the desired stiffness and response. It’s essential to assess the specific needs of your motorcycle and choose upgrades that align with your riding preferences.

DIY Tire Changing Techniques

Changing a tire can be a rewarding task, allowing you to save money and gain confidence in your mechanical skills. This guide will explore essential techniques and tips for successfully replacing tires, whether at home or on the road. With the right tools and a methodical approach, you can tackle this challenge with ease.

Before starting the process, it’s crucial to gather the necessary tools and materials. Below is a list of items you’ll need:

| Tool | Description |

|---|---|

| Tire Levers | Used to pry the tire off the rim. |

| Floor Jack | Elevates the vehicle for better access to the tires. |

| Torque Wrench | Ensures bolts are tightened to the correct specifications. |

| Air Compressor | Inflates the new tire to the recommended pressure. |

| Rim Protector | Prevents damage to the rim during tire removal. |

Once you have gathered your tools, follow these steps to change the tire effectively:

- Ensure the vehicle is on a flat surface and engage the parking brake.

- Loosen the lug nuts slightly while the tire is still on the ground.

- Use the floor jack to lift the vehicle until the tire is off the ground.

- Remove the lug nuts completely and take off the tire.

- Using tire levers, carefully pry off the old tire from the rim.

- Install the new tire onto the rim, ensuring proper alignment.

- Reattach the lug nuts, hand-tightening them before lowering the vehicle.

- Lower the vehicle and use the torque wrench to securely tighten the lug nuts.

- Finally, inflate the tire to the recommended pressure using an air compressor.

By mastering these techniques, you can ensure a smooth tire replacement process and maintain your vehicle’s performance effectively.

Cooling System Care and Repair

The efficiency of an engine greatly relies on its ability to manage temperature. A well-maintained cooling system is crucial for preventing overheating and ensuring optimal performance. Regular inspections and proper upkeep are essential to identify potential issues before they escalate into major problems.

Regular Inspections

Routine checks of the cooling components can help maintain the system’s integrity. Look for signs of leaks, corrosion, or wear in hoses and connections. Ensure that the coolant level is within the recommended range and inspect the condition of the coolant itself. Flushing the system periodically removes contaminants and prevents buildup, enhancing the overall efficiency.

Common Issues and Solutions

Overheating is a common concern that can stem from several factors, including a malfunctioning thermostat or a blocked radiator. If overheating occurs, it is important to address the issue promptly. Inspect the thermostat for proper function and ensure the radiator is free of obstructions. Replacing worn-out parts, such as pumps and hoses, is vital to restore functionality and maintain system reliability.

Preventative Measures for Longevity

Ensuring the long-lasting performance of any high-performance machine requires consistent care and attention. By implementing a series of proactive steps, owners can significantly enhance durability and reliability, minimizing the need for extensive repairs over time.

- Regular Maintenance Checks: Schedule routine inspections to identify wear and tear early. This includes checking fluid levels, brakes, and tire conditions.

- Proper Storage: Store the vehicle in a dry, sheltered environment to protect it from harsh weather conditions that could lead to corrosion or other damage.

- Quality Fluids: Use only high-quality oils and lubricants to ensure optimal performance of all moving parts, reducing friction and heat build-up.

- Battery Care: Maintain the battery by keeping terminals clean and ensuring it is charged adequately to prevent premature failure.

In addition to these steps, adopting a careful riding style can further prolong the lifespan of the machine:

- Avoid aggressive acceleration and braking to reduce stress on the engine and components.

- Be mindful of speed limits and road conditions, which can impact overall performance and safety.

- Warm up the engine properly before extended rides to allow fluids to circulate effectively.

By integrating these preventative measures into regular practices, owners can enjoy a more reliable and enjoyable experience, ensuring their investment stands the test of time.